Yes, all of our plastic enclosures use material that has undergone UL 94 flame rating testing! We also carry enclosures tested under the related UL 746C standard, a standard designed specifically for the control of electrical fires.These ratings can be found on the “ratings” tab of each product’s page. Questions or comments?

What is the size of a fire rated box?

Fire-rated outlet box spacing. Boxes are intended to be installed so that the surface area of individual boxes does not exceed 16 square inches, and the aggregate surface area of the boxes does not exceed 100 square inches per 100 square feet of surface area.

Is a plastic electrical box right for You?

Plastic electrical boxes, sometimes called junction boxes, have plenty of pluses, including low cost, convenience, and ease of installation. But they're not the best choice for every application. When plastic doesn't make sense, the standard alternative is a metal box.

Is an electrical box a fire hazard in a wall?

What this all means is that if the above conditions are met, then the fire integrity of the wall is not compromised simply by the presence of the electrical box. If the installation falls into one of the four conditions mentioned, then additional fire protection is required.

Are metallic and nonmetallic boxes fire resistant?

Can you help? Metallic and nonmetallic boxes are classified for fire resistance by Underwriters Laboratories Inc., and they are mentioned in the 2008 Guide Information for Electrical Equipment Directory (White Book) on pages 257–259.

Are electrical junction boxes fire rated?

Flame Resistant Junction Box A fire rated GRP junction box designed to ensure increased fire survivability for safety-critical electronic circuits. The BPGF has been tested to provide PH120 insulation integrity in accordance with BS EN 50200. The BPGF range is comprised of two sizes of fire-rated enclosures.

What is a fire rated electrical box?

Fire resistant enclosures and junction boxes are used to maintain electrical and electronic circuit integrity to emergency lighting, power and control cables in both “safe” non-hazardous and also hazardous area locations.

Can I replace metal electrical box with plastic?

Homeowners can replace their metal electrical box with plastic if non-metallic cables come in and out of the box. However, the downside of plastic electrical boxes is that they distort or crack under stress, and PVC can melt due to overheating.

Can you use plastic electrical boxes outside?

Plastic junction boxes cannot be used with metal conduit, which is required in various installations, such as outdoors or when wiring runs are exposed (not concealed inside wall or ceiling cavities).

Are fiberglass boxes fire rated?

Allied Moulded's fiberglass reinforced polyester (FRP) electrical boxes give you the freedom to make the most of your space, with an exclusive industry fire rating, backed by UL® testing, that bucks the installation limitations found in 2-HR fire resistive walls.

Can you put outlets in a fire rated wall?

fire-resistant rated assemblies All UL Listed single- and double-gang metallic outlet and switch boxes with metallic or nonmetallic cover plates may be installed in bearing and nonbearing wood stud and steel stud walls with fire rating not exceeding 2 hours.

Do plastic electrical boxes need to be grounded?

Plastic electrical boxes have their pluses and minuses. Because they are plastic, there is no need to attach a ground wire to it. Since it is made of a non-conductive material, switches and outlets cannot short out if they touch the side of the box.

Are plastic outlet boxes safe?

Though PVC can melt when overheated, it does not conduct electricity like metal does. Use plastic boxes when: There are non-metallic (NM) cables leading in or out of the box. Metal-sheathed wiring relies on bonding with the metal electric box for grounding and should not be used in plastic boxes.

Can I screw in a plastic electrical box?

It is mechanically possible to install a standard new-work box in an existing wall by: Cutting hole in drywall adjacent to a stud. Placing plastic box in the hole up against the stud. Screwing through the plastic into the stud.

What kind of box do you use for outdoor lighting?

Outdoor Electrical Box They are used for installing outdoor receptacles (outlets) and light fixtures. Outdoor boxes must have an outdoor cover or fixture rated for damp or wet locations, depending on the application.

What is the outside electrical box called?

This piece of equipment is known as the electrical panel, breaker box, fuse box, or service panel.

Do outdoor junction boxes need to be metal?

Plastic junction boxes can often offer a more cost-effective option than steel or aluminum junction boxes. For many applications, even including many outdoor ones, heavy-duty plastic such as polycarbonate offers comparable or even superior performance to metal.

Are all metal electrical boxes fire rated?

Listed metallic outlet boxes with metallic or nonmetallic cover plates may be used in fire-rated floor/ ceiling and roof/ceiling assemblies with ratings not exceeding two hours....Requirements for Recessed LED Disc Luminaires and Putty Pads on Ceiling Boxes.About UsSubscriptionMagazine ArchivesIndustry News2 more rows

How do you Fireproof an electrical box?

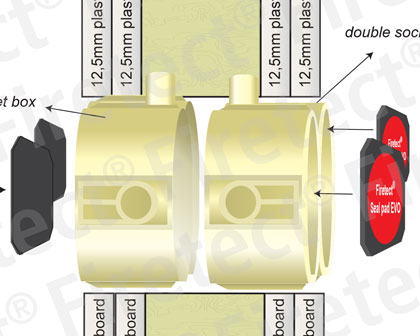

0:101:15Firestop for Electrical Outlet Boxes - YouTubeYouTubeStart of suggested clipEnd of suggested clipRequiring no tools inserts are conveniently sized the fit typical switch or outlet boxes and featureMoreRequiring no tools inserts are conveniently sized the fit typical switch or outlet boxes and feature an adhesive strip applied to the back of the pad to ensure adhesion to the back of an electrical.

Are Carlon boxes fire rated?

Fire Resistant - All Carlon boxes have a minimum two-hour fire wall rating and are UL listed.

What is ul1479?

The UL 1479 tests required by Underwriters Laboratories determine the ability of a firestop system to stop the spread of fire, smoke, and water through a fire-rated barrier in the event of a fire and for how long a period of time.

How many square feet are in an outlet box?

The individual boxes have a surface area greater than the maximum 16 square inches. The aggregate surface area of the boxes is greater than 100 square inches in 100 square feet of wall.

What is the last requirement for chase type walls?

The last requirement is specific to chase type walls where, because of the double row of studs, the stud cavity itself is not bounded by the adjacent studs. What this all means is that if the above conditions are met, then the fire integrity of the wall is not compromised simply by the presence of the electrical box.

Can you install an outlet box back to back?

Another condition for outlet boxes was alluded to earlier. That is, they should not be installed back-to-back, otherwise they will create a thermal shunt through the wall. Outlet boxes installed on opposite sides of the wall must be offset a minimum horizontal distance of 24 inches.

Is a PVC switch UL or ETL?

Our PVC Electrical Switch, Outlet and Ceiling EZ Boxes are ETL or UL listed for use as in Article 314 of the National Electrical code. CANTEX PVC Electrical Switch, Outlet and Ceiling EZ Boxes are also 2-hour fire-rated when a firing rating is applicable. At CANTEX, we know that better functionality translates into important labor cost savings for the end user. Special features on our PVC electrical boxes like enhanced, angled nails and well-engineered wiring clamps and knockouts are carefully designed for the EZ installation.

Does Cantex make EZ boxes?

CANTEX offers almost 100 styles of EZ Boxes in multiple sizes and gang applications to meet all your new and old work box needs. Our EZ Box line is backed by CANTEX’s over 60 years of experience in manufacturing and meeting the needs of contractors with unrivaled American-made PVC electrical products. Our history of quality and service, fast delivery and labor and cost savings make it easy to trust the CANTEX EZ Box line as your single-source solution for PVC electrical boxes.

What happens if you replace a metal box with a plastic box?

If you replace an old metal box with a new plastic box in this type of system, you break the ground connection.

What is a plastic junction box?

Plastic electrical boxes, sometimes called junction boxes, have plenty of pluses, including low cost, convenience, and ease of installation. But they're not the best choice for every application. When plastic doesn't make sense, the standard alternative is a metal box.

How far apart do you staple wires in a junction box?

Many do not, though, and require the wire to be stapled in place within eight inches of the box.

What is a new construction box called?

Boxes for new construction are called "new work.". There are also special boxes for remodeling work, called "old work.". These have little ears that flip out to grab the backside of the drywall when the box is screwed in place. Metal boxes also come in old work types, but they aren't always as easy to use.

Do plastic boxes need to be grounded?

Having a nonconductive box is good in most cases, but in some electrical systems it can create a problem. The nice thing about nonconductive boxes is that they don't need to be grounded.

Is plastic cheaper than metal?

Plastic is cheaper than metal. Both are pretty cheap, but plastic wins in most cases. The fact that plastic boxes usually don't need clamps also saves you a little bit more.

Do metal boxes need a separate clamp?

By contrast, many metal boxes require a separate cable clamp that is secured to the cable and then to the box. There's nothing wrong with a separate clamp ; it's just easier and a bit quicker to use the plastic tabs.

How far apart should a fire resistant box be?

Generally, the spacing between boxes cannot be less than 24 inches, but closer spacing is permitted where Wall Opening Protective Materials are installed according to the requirements of their classification. These materials are found under CLIV in the Fire Resistance Directory published by UL.

How close can you put fire rated receptacles back to back?

The electrical inspector says that I cannot install receptacles in fire-rated walls closer than 24 inches back-to-back. This is an apartment building with rooms on each side of the firewalls, and the spacing of receptacles is critical. Can you help?

What is the ampacity of a THW wire?

If Type THHW insulation is used on the 2/0 AWG copper conductors and the same procedure as is used above with 2/0 AWG copper conductors with THW insulation, the adjusted ampacity is 118.4 , a gain of about 25 amperes without changing the wire size. This is one use of 90°C insulation and is permitted by Section 110.13 (C) (1) (b), which reads in part: “Conductors with higher temperature ratings, provided the ampacity of such conductors does not exceed the 75°C (167°F) ampacity of the conductor size used, or up to their ampacity if the equip-ment is listed and identified for use with such conductors.” Other parts of this same section allow the use of 90°C ampacities for derating provided that the 75°C ampacity is not exceeded.

How many feet of cable must be secured?

Type MC cable must be secured every 6 feet unless the cable contains four or fewer conductors not larger than 10 AWG; then, the cable must be secured within 12 inches of every box, cabinet, fitting or other cable termination. Unsupported cables are permitted where fished or run between luminaires in accessible ceilings.

How many disconnects are allowed in 230.71?

Part (A) says: “Two to six disconnects as permitted in 230.71 shall be grouped. Each disconnect shall be marked to indicate the load served.”

What type of cable is used in manufactured wiring?

A manufactured wiring system uses Type MC Cable. Does this wiring method need to be secured in accordance with the requirements in Article 330, or is it exempt from these requirements because it is part of a manufactured wiring system?

How many square feet are in a box?

Boxes are intended to be installed so that the surface area of individual boxes does not exceed 16 square inches, and the aggregate surface area of the boxes does not exceed 100 square inches per 100 square feet of surface area.

What type of switch box is UL listed?

All UL Listed single- and double-gang metallic outlet and switch boxes with metallic or nonmetallic cover plates may be installed in bearing and nonbearing wood stud and steel stud walls

Do switch boxes need to be marked?

Unlike metallic boxes, all nonmetallic outlet and switch boxes intended for use in fire-resistant rated assemblies must be specifically investigated for use in such assemblies, and are required to be marked as follows:

How big is an electrical box?

of wall area, and that they are not too close to each other on opposite sides of the wall, unless protected by one of the accepted methods. However, boxes larger than 16 sq. in. are not inherently acceptable, unless additionally protected in some way to help preserve the fire resistance rating of the wall. Commonly used steel boxes measuring 4-11/16in. square would fall into this category. The IBC does permit the larger steel electrical boxes, but these boxes must all be installed in accordance with the installation instructions and listing limitations for the UL-Certified product being used to preserve the wall’s fire resistance. All steel electrical boxes larger than 16 sq. in. must be protected in some manner, regardless of the spacing to other boxes on the opposite sides of wall. The tested and UL-Certified protection methods can once again be found in UL’s CLIV category. The CLIV putty pad Certification listings will typically indicate the largest steel box that can be protected with the specific putty pad. For example, one manufacturer’s putty pad can be used to protect steel boxes 14” x 4” x2- 1/2” deep or smaller. Another product certification indicates that a certain manufacturer’s Firestop Box Insert can be installed on steel boxes up to 4-11/16” x 4-11/16” and 4-1/2” x 8-1/2”. There are product Certifications for the protection of large steel boxes recessed in fire-rated walls, such as used for circuit breaker panels. Those are not found in listing category CLIV. Rather, they are found in UL listing category XHEZ, “Through-penetration firestop systems”.

How much space between electrical box and wall membrane?

Regardless of electrical box size or material, the annular space between the wall membrane and an electrical box is never permitted to exceed 1/8 inch. This requirement appears both in the IBC and in the National Electrical Code.

How to reduce sound transmission through a wall?

through the wall due to the hole created for the box. Putty pads that fully cover the box and the gypsum cutout are an excellent way to help reduce sound transmission from room-to-room. They are often used even in non-rated walls where reduced sound transmission through the wall is a design goal. Firestop box inserts are pre-shaped thin rectangular pads of semi-rigid intumescent material, similar in composition to the intumescent wrap strips that are used to firestop plastic pipe penetrations, except thinner. They are placed inside the electrical box, at the back behind the wiring. Firestop cover plate gaskets are similar to the intumescent box inserts, pre-cut to match the shape of an electrical box cover plate, and are designed to be positioned behind the faceplate of the electrical box. Endothermic mats are rolls of semi-flexible multi-layered material, usually with one metal foil surface. The endothermic material absorbs heat from a fire via a chemical reaction, thus protecting the wrapped item. The mats are cut and applied to the exterior sides of larger recessed boxes as needed to provide the code-mandated fire resistance rating. Each of the product types are tested by the listing laboratories to the appropriate fire resistance test standards, such as ASTM E814 and UL 1479. Based on the results of the fire tests, listings and product Certifications are published by the listing laboratory, detailing the acceptable uses for each product and the fire resistance ratings obtained for each precise configuration.

How big do boxes need to be to be wallboard?

boxes and the wallboard do not exceed 1/8 in. The boxes are intended to be

What is the rating of a wood stud wall?

wood stud and steel stud walls with rating not exceeding 2 h. These walls

Can smart boxes be used with NM cables?

I've been using SmartBoxes for a good while not for old work when using NM or with low voltage cables. I'm pretty sure they're okay'ed for rated assemblies. They attach to the stud, even metal, in any event.

Do fire chiefs get UL books for free?

Threads like this remind me why I really want to get a UL orange book set. Time to visit my friendly neighborhood fire chief. Fire chiefs get the UL books for free, and are good candidates for electrician's to hit up for free old copies.

Is there a plastic box that is metallic?

Yes, very few plastic boxes are of metallic construction. But there are rated plastic boxes. I wonder where they fit in?

How many tubes can be installed in a Carlon Flex Plus?

Installation of Carlon Flex-Plus® Blue® electrical nonmetallic tubing in fire-resistive assembly described below shall comply with the applicable Electrical Code and is limited to a maximum number of six tubes in any one stud cavity.

What is fire endurance testing?

Literally hundreds of combinations of membranes and framing systems - with and without a variety of approved thermal -insulations have been fire endurance tested for applications in fire resistance rated walls and floor – ceiling assemblies. Reports on such testing can be found in the various Tables associated with fire resistive construction assemblies in the model building code chapters addressing fire resistance rated constructions.4

How many runs can be in a 6 foot wall?

Installation of the tubing and conduit in the fire-resistive assembly described below shall comply with the applicable Electrical Code and is limited to a maximum of three runs in any 6 foot (1828.8 mm) length of wall, with a maximum of two tubes or conduits in any one stud cavity.

Does thermal insulation increase fire resistance?

Since thermal insulations add to the thermal resistance of assemblies, addition of such insulations to assemblies originally tested without insulation is permissible and can be expected to increase fire resistance.