What is the best laser for cutting metal?

- Using a sheet metal laser cutter with a low power of about 500w for carbon steel below 3mm. ...

- The industrial product commonly use 8-10mm metal carbon steel sheet. ...

- In addition, the most common metal laser cutter model in the entire industrial production is the 3000w sheet metal laser cutter, and this laser cutter has the most widely use, ...

How to get started with laser cutting?

How to use a laser cutter?

- Preparation. First of all, check that your material fits inside the work area of the laser cutter and cut it to size if necessary.

- Settings. The four most important settings of a laser cutter are power, speed, frequency and for focus distance.

- Time to Cut! Finally, you should be prepared to make your first cuts. ...

How thick of metal can a laser cut?

Laser cutting of metal is a process of heating and destroying metal with a laser beam. This technology is called Laser Beam Cutting (LBC). Modern lasers are able to cut metal 0.2 mm – 40 mm thick.

Can you cut wood with a laser cutter?

Wood is a good material for laser cutting due to its strength and ease. Wood can be easily cut with a laser cutter. Wood provides many benefits such as easy storage, affordability and versatility.

What Wattage Laser Will Cut Metal?

How Thick of Metal Can a Laser Cut?

What Other Tools Can Be Used to Cut Metal?

How much does a laser engraver cost?

What is laser cutting?

What type of cutting is used to cut metal?

What materials can you use a 40 watt laser on?

See 2 more

How powerful does a laser have to be to cut metal?

A metal cutting laser has to use at least 300 W, which will run you up to at least $10,000. In addition to price, metal cutting machines additionally require gas — usually oxygen — for cutting.

What type of laser will cut metal?

YAG lasers are primarily used for cutting and scribing metals and ceramics. In addition to the power source, the type of gas flow can affect performance as well.

How thick of metal can a laser cut?

The maximum cutting thickness of different materials by 1000W fiber laser cutting machine: the maximum thickness of carbon steel is 10mm; the maximum thickness of stainless steel is 5mm; the maximum thickness of aluminum plate is 3mm; the maximum thickness of copper plate is 3mm; 3.

What Cannot laser cut?

Materials you should not process with a laser Leather and artificial leather that contains chromium (VI) Carbon fibers (Carbon) Polyvinyl chloride (PVC) Polyvinyl butyrale (PVB)

How much does a laser cutter for metal cost?

A metal laser cutter ranges from $8,000 to over $250,000! The bottom-end metal laser cutter can handle very small, low volume projects. But for more standard commercial applications, you need a metal laser cutter that will likely exceed the $20,000 mark.

How much does a metal laser cutting machine cost?

You can pay anywhere from $4,000 to $15,000 for some laser cutter models.

Can a laser cut a human?

The short answer: no consumer laser can do that. It is not legal in the United States to sell bare lasers capable of cutting to the consumer. Lasers contained inside of an apparatus that protects users and bystanders from exposure to the beam may be legal.

Can laser cut diamond?

Lasers are effective for cutting all sorts of materials but are particularly useful for cutting diamonds.

Can a 100w laser cut metal?

100w laser cutter This kind of laser cutting machine is also popular in the laser cutting industry because it can cut thick non-metal materials and thin metal materials.

Can a laser cut bone?

Background and objectives: Despite of the long history of medical application, laser ablation of bone tissue became successful only recently. Laser bone cutting is proven to have higher accuracy and to increase bone healing compared to conventional mechanical bone cutting.

What metals Cannot be laser cut?

As we all know, fiber laser cutting machines cannot cut non-metallic materials like wood, MDF, acrylic, rubber, etc. In addition, it is also not recommended for long-term cutting of rare metal materials such as aluminum, copper, and brass.

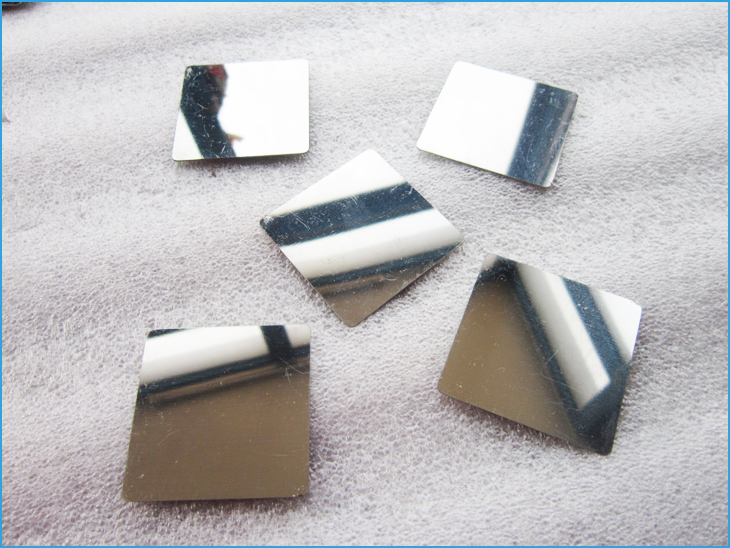

Can you cut a mirror with a laser?

It is not possible to laser cut glass with Co2 laser machines. It is best to have it supplied to us pre-cut to size by a glazier / glass cutter.

Can a 60W laser cut metal?

The 60W laser can cut through various plastics, wood types, fabrics, vinyl, and even leather. It is not designed to cut through metal.

Can a 100w CO2 laser cut metal?

CO2 Lasers In order to cut metal, these machines must have a minimum rating of 150 W and use oxygen assist.

Can a 60 watt laser cut metal?

Since this laser is a C02 laser, it will not cut ANY metal. You'd need a fiber laser for that, however it will mark on metal using thermal marking spray. It will cut cork, soft and hard wood, acrylic, cardboard, and paper. It will mark on glass, slate, stone, granite, and marble.

Can a 50W laser cut metal?

Yes, you can laser cut metals with a fiber laser, however, it would have to be an extremely potent fiber source of around 2000W. You cannot laser cut any metal with a standard fiber laser of 20W to 50W. This means that laser cutting metal is only possible for big businesses.

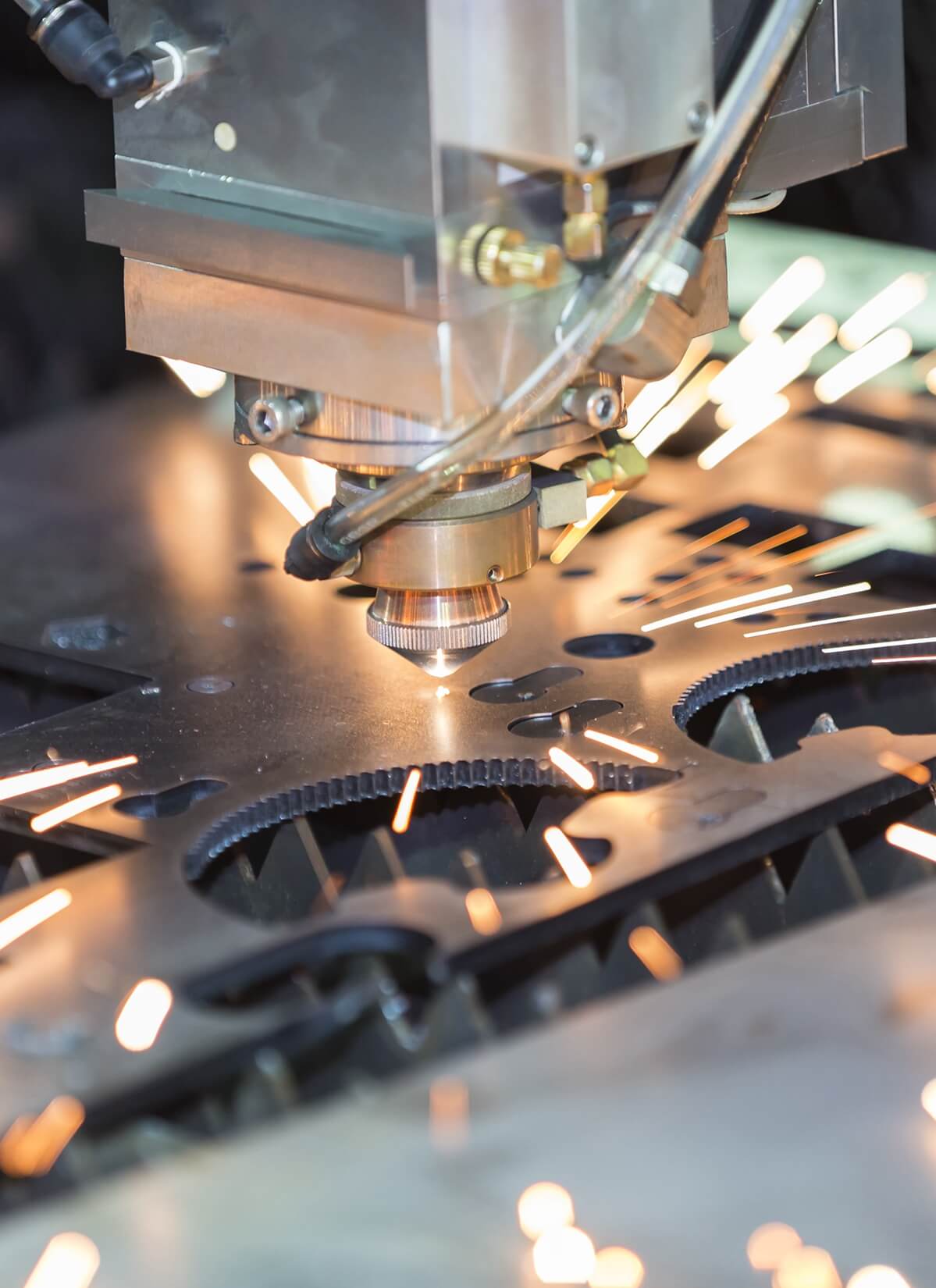

How does laser cutting work?

Laser cutting of metal is a process of heating and destroying metal with a laser beam. This technology is called Laser Beam Cutting (LBC).

How fast can a laser cut stainless steel?

For instance, the cutting speed of a 1000 W laser machine for carbon steel 0,5-8,0 mm thick will be around 0,6-15 m/min, for stainless steel 1,0-5,0 mm thick will be 0,8-18 m/min, for aluminum 1mm thick – 1,2-10 m/min, and for copper 1mm thick – 10 m/min.

Why is laser cutting needed?

Laser cutting is needed for making metal items of a complicated configuration and shape, including both flat and volumetric objects.

How many watts does a laser use?

Lasers with the power output over 500 watts are used for metal cutting . The more the power of the laser the higher is the speed, so the thicker metal they can cut.

What is laser cutter?

Laser cutters are universal tools to cut various materials. There are different types of lasers to do the task, but not all of them are powerful enough to work with metal. In this article, we’ll deal with CO2 and fiber laser cutters. These two types of laser cutters require special attention to be used properly. CO2 LASERS.

What is waterjet cutting?

Waterjet cutting is simply an accelerated erosion process within a selected material. Highly pressurised water is fired through a ruby or diamond nozzle into a mixing chamber. This pressure creates a vacuum and draws garnet sand into the stream where it is then fired at the object in place for cutting.

What is metal milling?

Metal milling is an effective way of processing aluminum mostly. Aluminum is a relatively light metal and easy for milling.

How many watts does a CO2 laser use?

Here at Kern Laser Systems, we’ve developed metal cutting technology that enables CO2 lasers of 150 to 400 watts to quickly and efficiently cut metal. This technology makes thinner gauge metal material, like stainless steel, aluminum and brass, processable via CO2 lasers.

What is the best laser for cutting?

In terms of cutting capabilities, a 400W laser outfitted with the laser cutting option can cut: 1 Mild steel up to 4.8mm thick 2 Stainless steel up to 3mm thick (with oxygen assist) 3 Stainless steel up to 2mm thick (with nitrogen assist) 4 Aluminum up to 1.5mm thick

What lasers are compatible with Kern?

The Kern lasers compatible with the metal cutting option are: OptiFlex. LaserCELL. OptiDual. MICRO. Once properly outfitted, these CO2 lasers will etch metal, providing stunning, intricate and consistent results.

What metals does Kern cut?

As you saw in the video, Kern’s metal cutting technology allows for laser processing of stainless steel, mild steel, aluminum and other light gauge metals without the high operational costs of a large, multi-kilowatt laser.

Can a 400W laser cut metal?

In terms of cutting capabilities, a 400W laser outfitted with the laser cutting option can cut: The metal cutting option is compatible with four out of the five CO2 lasers in the Kern lineup. The Kern lasers compatible with the metal cutting option are: Once properly outfitted, these CO2 lasers will etch metal, providing stunning, ...

Does Kern cut sheet metal?

In fact, the sheet metal applications that fall within Kern’s metal cutting capabilities have been known to shock customers.

Can you add videos to your watch history?

Videos you watch may be added to the TV's watch history and influence TV recommendations. To avoid this, cancel and sign in to YouTube on your computer.

METAL LASER CUTTER

Metal laser cutting machine adopts high-precision cutting head, it can cut metal and non-metal materials. It is a cost-effective various materials cutting models. Multi-function metal and non-metal mixed laser cutter has a unique metal cutting system, automatic focusing, without manual operation.

Metal Non-metal Mixed Cut

Mix cutting ,widely using on AD materials ,When the cutting machine cuts the metal, it is necessary to add oxygen as auxiliary gas. When cutting nonmetal, blow the air just like an ordinary machine.

Linear Guiding System

Linear guide, high positioning accuracy, dynamic friction is similar to static friction, Can maintain the accuracy for a long time, suitable for high-speed cutting.

What Wattage Laser Will Cut Metal?

Most metals, including stainless steel and aluminum, need at least 300 Watts to cut through them, so the higher wattage you have in your laser cutting machine, the faster your metal surface will melt. Most lasers that cut metal are pricey and can easily cost as much as $10,000. But you can still get a good one for much less. Refer to this buying guide that has great machines that go for under $5000.

How Thick of Metal Can a Laser Cut?

Depending on the wattage of the laser cutting machine, it can cut through different thickness levels of metal. The lower the wattage, the lower the inches the machine can cut through.

What Other Tools Can Be Used to Cut Metal?

Metal is a tough surface to cut through and to ensure your safety, you have to have the right tools. If you don’t want to invest in a laser cutting machine, there are other ways you can cut through metal, although you may not be able to get a detailed design.

How much does a laser engraver cost?

Laser engravers can be as expensive as $10,000 or as cheap as $200. The pricier machines are great for industrial applications but if you are looking for a simple laser engraver for making personalized gift items, or starting an engraving business in your garage, a laser engraver under $500 should suffice.

What is laser cutting?

Laser cutting is the process of using a laser cutting machine to cut into materials such as metal. Laser cutting was once used only by industrial manufacturing companies but with the advent of inexpensive laser machines, it’s now becoming commonplace. But laser machines come with different specs and wattage is one of the most important features ...

What type of cutting is used to cut metal?

Water could be mixed with grains to cut through thicker metal surfaces if need be. Plasma Cutting. This form of cutting is only used on metal surfaces, and plasma cutting can cut through any thickness of metal, unlike a laser.

What materials can you use a 40 watt laser on?

A 40 Watt laser would work best when using the following materials: Wood. Acrylic. Card stock. Rubber. Card stock. Leather.