Can engineered wood floors be used anywhere?

But engineered wood flooring technology has exploded over the last 20 years, and its products can be used just about anywhere, including in places where you’d expect to find plank floors. Before we get too far into this though, I want to make the point that the two certifications I mentioned about solid planks apply here too.

What is engineered wood and how is it used?

Engineered wood features the look of solid hardwood, with some perks: it has better moisture resistance and a cheaper cost. In the home, engineered wood can be used for a number of projects, including floors and furnishings. Whether you plan to DIY or hire a professional, here’s what you should know about engineered wood.

Can you use engineered wood for a deck?

Engineered wood is also excellent for bookshelves and even modular kitchen cabinetry. But if you’re looking to use engineered wood for your deck, you might have better luck with solid wood such as cedar or a composite, which can include wood blended with plastic for lower maintenance. Engineered Wood vs. Other Options

What is the difference between real and engineered wood?

Some engineered wood can resist warping and splitting more than dimensional lumber. Engineered wood is often less aesthetically pleasing than real wood, because of the visible wood strips (rather than the clean, natural look of solid timbers). One exception to this is architectural-grade glulam.

Why is engineered wood better than solid wood?

What is engineered wood board?

What is LVL wood?

Why is engineered wood stronger than dimensional lumber?

What is the difference between C grade and D grade plywood?

What is plywood made of?

How much gap between OSB boards?

See 2 more

Is engineered wood waterproof?

Is Engineered Hardwood Waterproof? All traditional engineered hardwood is not waterproof. A new engineered hardwood product has a vinyl core with a wooden top or outer wooden layer. It is called engineered vinyl plank or EVP.

Does engineered wood fade in sunlight?

Will Engineered floor fade or change color? Yes, it can fade in heavy sunlight. However, choose a light-color engineered hardwood that won't fade as easily as the darker woods if you insist on the engineered hardwood.

Can you put engineered wood over concrete?

Engineered hardwood can be installed on concrete using the glue-down installation method. We recommend using an acrylic or urethane wood adhesive, such as Bostik Pro-Cure or East Bay Clipper. Before installing any flooring you must follow the instructions set forth by the flooring manufacturer.

What is engineered wood exterior?

Engineered wood siding is made up of wood strands that are coated with a resin binder and compressed to create a board of superior strength, making your siding more durable when it comes to standing up to inclement weather. Moisture, Rot, and Pest-Free. Engineered wood siding is treated to prevent termites and rot.

What are the disadvantages of engineered wood?

10 Major Disadvantages of Installing Engineered Wood FlooringEngineered Hardwood Can Be Pricey. ... A Low-Quality Core. ... There's a Danger of Fading. ... You Need to Let the Wood Acclimate. ... Wooden Floors Require Specific Care. ... Engineered Hardwood Is Susceptible to Water Damage and Moisture.More items...•

How long does engineered hardwood last?

Although engineered wood flooring can't be refinished as often as solid hardwood, it can still last up to 30 years or more with proper maintenance.

Is it better to glue or float an engineered wood floor on concrete?

Many installers and manufacturers prefer the glue-down method because of its superior stability. Gluing down your floor leads to less shifting and creaking, making the engineered hardwood feel and sound more secure. You can also glue down floors on any type of subfloor, even if it's uneven.

Do you need a moisture barrier under engineered hardwood?

Do I need a moisture barrier for hardwood floors?" The answer is YES! Moisture can destroy hardwood floors. It causes cupping, warping, and even mildew if not treated. You must install a moisture barrier to protect your flooring from water wicking up from below.

Do you need underlay for engineered wood flooring on concrete?

The nature of your subfloor If concrete, an underlay with a built-in damp proof membrane – such as the Royale Professional – is necessary. This will stop moisture from seeping through and damaging your new flooring.

Is engineered wood good for house siding?

Durability: Engineered wood is a resilient product, able to resist impact better than most siding materials including vinyl, aluminum, and fiber cement siding. It is also treated to protect against termites and rot.

What is the best wood to use for exterior siding?

Pine and cedar are the two main wood species used for exterior siding. Cedar types include eastern white cedar, red cedar, and Alaskan yellow cedar; each type has a color true to its name. While pine siding can be very affordable, it can't resist rot and insects like cedar can.

Does engineered wood siding rot?

Engineered wood is just as susceptible to moisture damage as real wood, which means that in climates that see a lot of heavy rainfall and in homes that don't have a rainscreen installed, the material can begin to delaminate and rot over time. It may also have issues with mold and mildew growth.

What flooring does not fade in sunlight?

Hardwood floors, especially lighter-colored hardwood, won't be affected by UV rays. Vinyl, laminate and carpeting, on the other hand, can start to fade over time.

Does engineered hardwood darken over time?

Yes, all hardwood floors will slightly change colour over periods of time, especially if they are in contact with direct sunlight. The most noticeable colour change will happen in the first few months after being installed.

Will sunlight fade hardwood floors?

Depending on the species of hardwood flooring it will fade, bleach, or darken when exposed to the sun. Wood is photosensitive material so if there is overexposure to ultraviolet (UV) rays then there will be an effect on the color of the floors. It is said that about 40% of all interior fading happens from UV rays.

How do you fix sun damaged engineered wood floors?

0:232:12Flooring Tips : How to Fix a Faded Hardwood Floor - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd not a polyurethane water-based urethane refresher just like this you're going to take your waterMoreAnd not a polyurethane water-based urethane refresher just like this you're going to take your water-based urethane refresher squirt it on the dull area.

Why is engineered wood better than solid wood?

Engineered wood is sustainable, because it allows you to achieve (or exceed) the same density and strength of old growth timber, but with lumber made from young trees. It also reduces waste, because it uses all parts ...

What is engineered wood board?

Engineered wood boards are generally made from the same hardwoods and softwoods used to manufacture lumber, but mixed with additives like adhesives. This type of wood often utilizes waste wood from sawmills, and are treated through chemical or heat processes to produce wood that meets size requirements that are hard to find in nature.

What is LVL wood?

Made of wood veneers that are compressed together with resins and glues, LVL is a high density engineered wood product used in framing. LVL is very strong, but has only one strength axis, because its veneers are stacked with the grain running in the same direction. This means you can only load LVL in one direction.

Why is engineered wood stronger than dimensional lumber?

Engineered wood can be stronger than dimensional lumber because of its high density and layers of grain running in different directions.

What is the difference between C grade and D grade plywood?

C: C grade plywood may include knots up to 1.5 inches and knotholes under 1 inch. D: The lowest grade can have knots and knotholes up to 2.5 inches. In general, any defects have not been repaired with D grade plywood. X: An X is used to indicate exterior plywoods.

What is plywood made of?

Plywoods have several benefits to builders, since they are made by binding resin and wood fiber sheets to form a composite material whose “cross graining” property provides dimensional stability and makes the strength of the panel consistent in all directions.

How much gap between OSB boards?

However, on the tongue and groove of premium subflooring, there is a pre-manufactured stop that gives you the ⅛-inch gap in between boards.

Is engineered lumber stronger than sawn lumber?

In my experience framing houses, there’s a lot to like about engineered lumber – it’s typically stronger, stiffer, and available in larger sizes than sawn lumber, allowing for longer spans and fewer support columns underneath. In addition, manufacturers often provide warranties, which typically are not available for dimensional lumber.

Can you use LVL outside?

For example, preservative-treated LVLs are currently not offered for outdoor use, since some wood species used in LVL production don’t readily absorb the chemicals used in the preservative treatment process, and because of other factors, such as continuous glue lines between the veneers.

Is engineered wood preservative treated?

Current choices for preservative-treated engineered wood products are limited, because not all engineered wood products are suitable for preservative treatment, and not all EWP manufacturers offer preservative-treated products.

How long does engineered wood last?

An engineered wood floor will last from 20 to 100 years, depending on the thickness of of the top veneer. The best engineered wood floors available will last as long and perform as well as a plank floor, so another consideration to keep in mind is how long you want this material to last.

How thick is engineered wood?

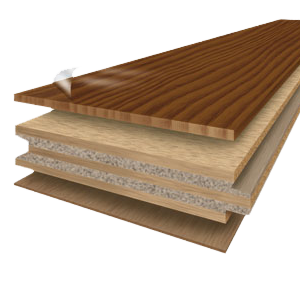

This photo shows a cross section of a high-quality, engineered wood floor. They range in thickness from 3/8” to 3/4” (that’s approximately 1 cm to 2 cm). The top layer is a veneer of the desired wood; the thicker that veneer is, the more expensive the floor will be.

When you are shopping for engineered wood floors, what should you pay attention to?

When you are shopping for an engineered wood floor, pay attention to how it’s made inside almost as much as you pay attention to how the top layer looks.

Is engineered wood flooring sustainable?

If sustainability is a priority of yours, engineered wood floors tend to be a more sustainable option. This is especially true if you're considering an exotic wood. The exotic trees that need to be harvested to make, say, a Rosewood floor go a lot further if only a 6mm-thick veneer is going on each board.

Is engineered wood flooring more expensive than plank flooring?

It’s really not so complicated. Engineered wood floors behave a little differently than plank floors do; they tend to be easier to install and they’re usually less expensive than solid planks.

Can you nail a wood floor over concrete?

Engineered wood floors were developed for use over concrete slabs, but the thicker, 3/4"-thick (2 cm) versions can be nailed down over a wood subfloor, the same way you would install a plank floor.

Can you glue down engineered wood?

Engineered wood floors thinner than 3/4” (2 cm) can be glued down, similar to how you’d glue down a vinyl or resilient floor. Gluing down an engineered wood floor is a project a do-it-yourselfer can usually take on provided he or she has a lot of time and a fair amount of experience with DIY projects.

Why is engineered wood flooring so popular?

Engineered wood flooring is growing in popularity because of its realistic wood looks and eco-friendliness. But there’s so much more to love about this floor than just its looks. Here are even more reasons why you should choose engineered hardwood.

What is the difference between engineered hardwood and hardwood?

The key difference between hardwood and engineered hardwood is the construction, installation process, and where they can be installed. While hardwood floors are wood logs cut into planks, each engineered wood plank is topped with a thin hardwood veneer to create a hardwood surface on top of an engineered core.

How thick should engineered wood be?

It’s recommended that an engineered wood wear layer is between 3mm – 5mm thick. To ever refinish your engineered hardwood flooring, the wear layer and real wood veneer should be 3mm or thicker.

How to make engineered hardwood planks?

The process of creating engineered hardwood involves adhering the layers of the plank together. The layers for planks with an HDF core consist of the real wood veneer, a single, solid layer of HDF, and the backing layer glued together creating a sturdy flooring solution. For other cores, this process is accomplished by attaching the fiberboard plies on top of each other in opposite directions under the real wood veneer.

How thick should a veneer floor be?

Therefore, it’s standard for wear layers and veneer to range from 3mm-7mm thick to ensure long-lasting flooring beauty. Remember, the thicker the wear layer and real wood veneer the better.

How long does it take for engineered wood floors to acclimate to the new environment?

Regardless of the type of engineered wood floors you choose, it must acclimate to its new environment for at least 24 hours to adjust to the temperature and humidity of the area. While engineered hardwood does not expand and contract as much as hardwood, acclimation ensures proper installation and durability.

Why do you sweep engineered wood floors?

Sweep often: Getting that excess dirt off your floors keeps your engineered wood floors looking gorgeous. Dirt, if not removed, gets ground into your floors and can cause damage over time. If you are using a vacuum, be sure it is set to the bare floor setting, because a beater bar can scratch or dent your floor.

What type of wood is used for outdoor living?

Here are some of the best most popular solid wood species used in outdoor living spaces: Yellow pine is the most common species of wood used for decking. This is mostly because of its wide availability in the U.S. However, pine requires a lot of maintenance since it’s a softwood, and it warps rather easily. Tropical hardwood species ...

What to consider when planning a wood floor for an outdoor living space?

When you’re planning to install wood flooring outside, take into account how the client plans to use the space and what the conditions are like in the area. What’s more important: Dimensional stability because of humidity fluctuations / unstable weather in their area, or hardness so that the wood can stand up to heavy foot traffic? Do your clients have pets? Kids? Do they plan to host a lot of parties outside? These are just some of the questions you want to consider when planning a floor for an outdoor living space.

What wood is good for a deck?

Tropical hardwood species including Ipe, Golden Ironwood, Red Balau, Mahogany, and Cambara are great high-grade options for decks because they are dense, durable, and naturally resistant to rot and insects.

What is the most common type of wood for decking?

Besides solid wood, here are some other types of wood available for decking and other outdoor living spaces: Pressure-treated wood is the most common type of decking material because it’s the most readily available and cheapest choice. It’s easy to cut and fasten, which makes it perfect for a DIYer.

Is composite wood a good alternative to solid wood?

You likely want to avoid installing this wood in places where the humidity levels fluctuate more than average. Composite wood is a common decking alternative to solid wood. It contains wood fiber and plastic which is either new or sourced from recycled materials.

Can you change the color of composite wood?

Composite wood won’t split, rot, or require additional coats of stain. However, the downside to this is that you can’t change the color of composite wood flooring once it’s installed. One benefit is that there are no splinters, and composite wood doesn’t attract termites and other bugs. One downside of composite is cost: about 30% more expensive ...

Is cypress wood rot resistant?

Cypress is a sturdy species that often doesn’t need a finish to maintain its long term appeal. Oils present within the cypress tree make it naturally resistant to rot and insects. One thing to keep in mind: The heartwood of a tree is more rot-resistant than sapwood. If your client’s lifestyle demands an extra durable outdoor living space, ...

What wood is used for outdoor projects?

The three most widely available and suitable exterior lumber choices, not treated with chemical preservatives, include Western red cedar, redwood, and cypress. Your geographic location will determine the availability and cost of these materials. Redwood, for example, is widely available and used in ...

How long can you air dry treated lumber?

To avoid these tendencies, you can air-dry treated lumber for two warm months, or purchase KDAT (kiln-dried-after-treatment) lumber. The downside: cost (usually double the wet stuff) and the need to special-order it from lumberyards or home centers beforehand.

What is ACQ treated wood?

Early in 2004, the old CCA (chromated copper arsenate) treatment that contained arsenic was replaced by various treatments, but the most common is ACQ (alkaline copper quat). In spite of its shortcomings, ACQ-treated wood holds up well.

Where does IPE come from?

Ipe, a relative newcomer, is imported from Central and South America, where it grows rapidly. Also called Brazilian walnut and ironwood, it is so dense that it barely floats. Strong and stable, the functional life of ipe can be as long as 40 years if left untreated. It resists movement, surface checks, warping, cracking, decomposition, and denting. Also, while it is expensive (and sometimes hard to find), ipe is comparably priced with many composite wood products.

Does ACQ wood rot?

In spite of its shortcomings, ACQ-treated wood holds up well. It might crack, warp, or shrink, but it won't rot or prove tasty to insects. ACQ is a water-based preservative forced deep into the lumber, usually Southern yellow pine. Consequently, the lumber is saturated when banded and shipped.

Is heartwood wood immune to rotting?

Although no wood is completely immune from rotting and insect damage , some resist decay better than others. Because of naturally occurring preservatives in heartwood, insects and fungi find the woods listed in the chart on the last page undesirable. Each choice has its advantages and disadvantages, so decide which wood best suits your building needs and budget.

Is mahogany a good wood?

Mahogany serves as a great project wood. It machines, sands, and finishes well, but costs more than ipe. Be sure to ask for African or Honduran mahogany, (avoiding Philippine mahogany). One nice thing: You can buy it in broad thicknesses for use in large projects.

Why is engineered wood better than solid wood?

Engineered wood is sustainable, because it allows you to achieve (or exceed) the same density and strength of old growth timber, but with lumber made from young trees. It also reduces waste, because it uses all parts ...

What is engineered wood board?

Engineered wood boards are generally made from the same hardwoods and softwoods used to manufacture lumber, but mixed with additives like adhesives. This type of wood often utilizes waste wood from sawmills, and are treated through chemical or heat processes to produce wood that meets size requirements that are hard to find in nature.

What is LVL wood?

Made of wood veneers that are compressed together with resins and glues, LVL is a high density engineered wood product used in framing. LVL is very strong, but has only one strength axis, because its veneers are stacked with the grain running in the same direction. This means you can only load LVL in one direction.

Why is engineered wood stronger than dimensional lumber?

Engineered wood can be stronger than dimensional lumber because of its high density and layers of grain running in different directions.

What is the difference between C grade and D grade plywood?

C: C grade plywood may include knots up to 1.5 inches and knotholes under 1 inch. D: The lowest grade can have knots and knotholes up to 2.5 inches. In general, any defects have not been repaired with D grade plywood. X: An X is used to indicate exterior plywoods.

What is plywood made of?

Plywoods have several benefits to builders, since they are made by binding resin and wood fiber sheets to form a composite material whose “cross graining” property provides dimensional stability and makes the strength of the panel consistent in all directions.

How much gap between OSB boards?

However, on the tongue and groove of premium subflooring, there is a pre-manufactured stop that gives you the ⅛-inch gap in between boards.