- Low moisture tolerance. While OSB boards are slow to absorb water and moisture, they’re even slower in releasing it. ...

- Heavy. Depending on the size, OSB boards can be up to 20% heavier than plywood. ...

- Cutting compromises integrity. Cut OSB boards are vulnerable to water damage, and that makes them unsuitable for concrete forms. ...

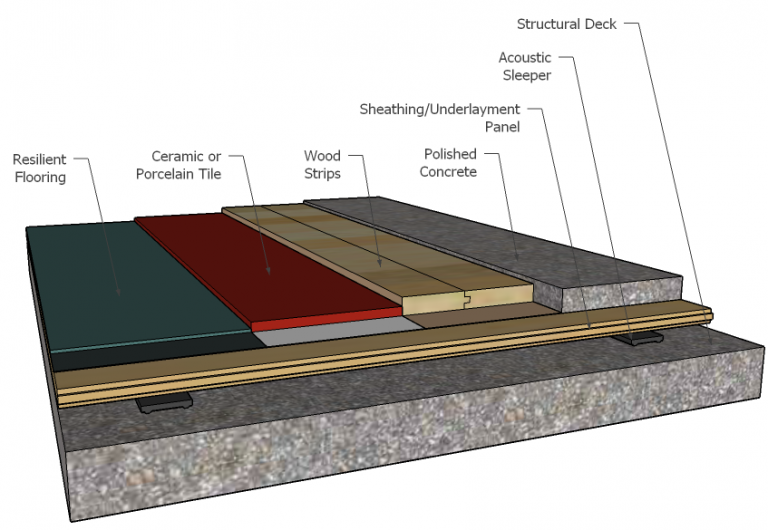

Can OSB be used as a subfloor?

OSB subfloor serves as a base under the finish floor (hardwood, engineered wood, vinyl tile, etc.) and even below the underlayment, in some cases. Plywood has long been used for subflooring. OSB was introduced in the 1970s, but mainly was used for walls.

How to use OSB on an exterior?

Instructions

- Lightly Sand the Surface. With 80-grit sandpaper fitted on the orbital sander, lightly sand the surface of the OSB. Do not sand the edges.

- Clean the Surface. Thoroughly clean the surface of the OSB. Due to the OSB's rough texture, tack cloth and cotton rags do not work well.

- Prime the OSB Multiple Times. Pour primer into a tray. ...

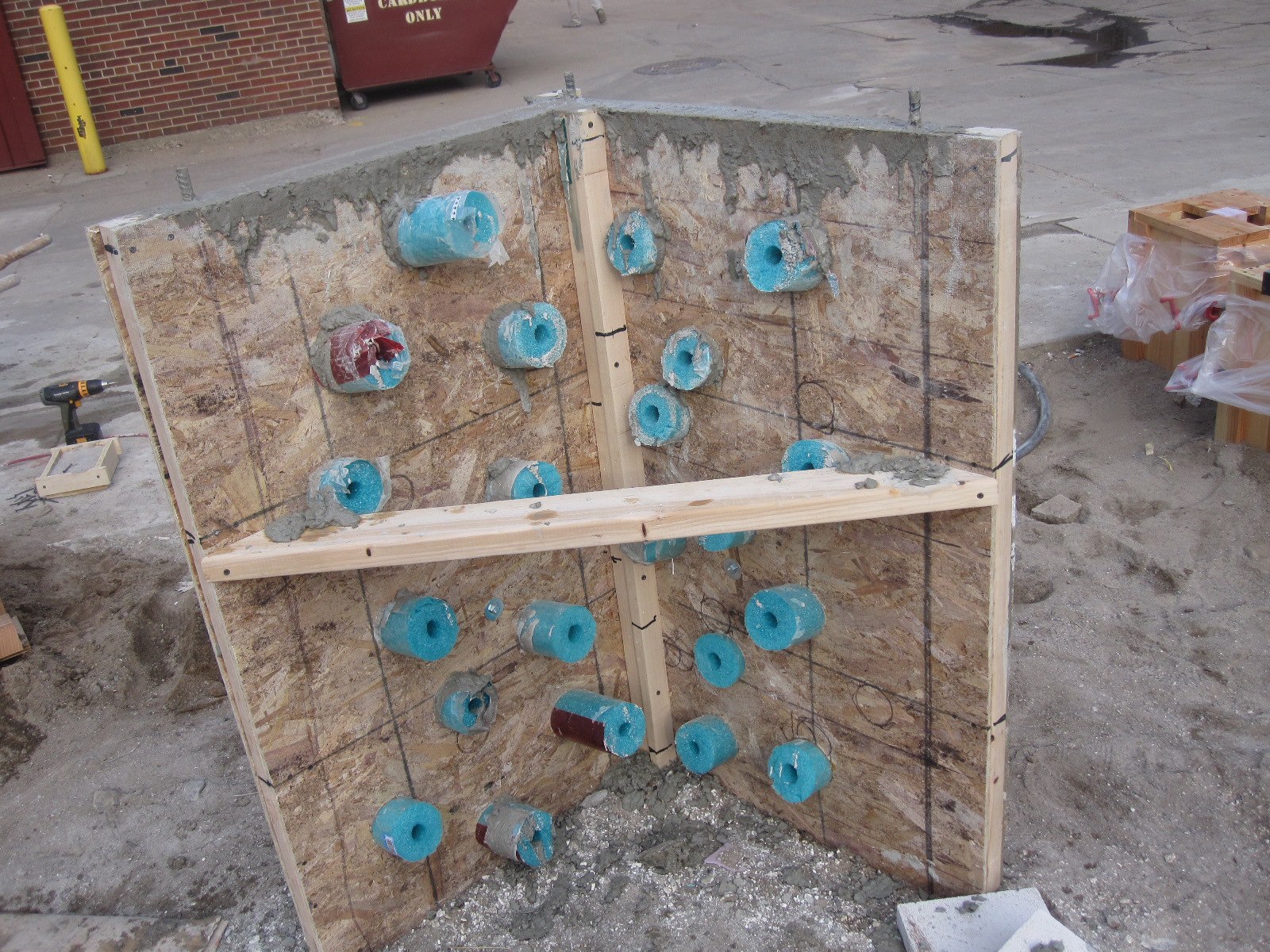

How to build a straight form for concrete?

- Check alignment of forms by eyeballing them, that is, bending down so that you can sight down the edge of the form.

- The straighter the lumber you use to form, the easier it will be to align it.

- Cut stakes long enough to get a good grip in the soil, and sharpen the ends with a long taper to a keen point to make driving them easier.

Can you put tile over an OSB subfloor?

You can put tile or sheet vinyl flooring over OSB so long as you ensure that the surface of the OSB is completely smooth without any major knicks, knots, or bulging staples. With vinyl being as thin as it is, it must have a smooth base so that the appearance of the vinyl remains very smooth.

Outlets per circuit ?

Just wondering how many outlets are allowed per 20A circuit . I've been limiting...

Kohler K3100 Repair Kit

Anyone know if there is a substitute for the no longer produced Kohler K3100...

Flying Car

Garages might have to be changed a bit to make room for this thing. It has an IC...

Cesspool pump out scam?

We recently moved to an older house with a septic system. Previous owner...

Cesspool pump out scam?

We recently moved to an older house with a septic system. Previous owner...

Cesspool pump out scam?

We recently moved to an older house with a septic system. Previous owner...

What is an MDO overlaid panel?

MDO and HDO overlaid panels have resin-impregnated cellulose fiber sheets laminated to their faces, and can have either single- or double-sided faces. With careful handling and maintenance, any double-faced forming panel, from B-B Plyform to the overlaid panels, can be poured against on both sides.

What is plywood form?

Member manufacturers of APA−The Engineered Wood Association produce a variety of plywood form panel products—Plyform—designed for most general concrete-forming applications. Usually pretreated with a release agent to facilitate stripping, these panels are available in many grades from basic B-B to products with overlays ( i.e. Medium-density Overlay [MDO]) and High-density Overlay [HDO]) that add stability, resist abrasions, and provide a smoother and more durable forming surface.

What is HDO forming?

HDO forming panels have a greater amount of resin in the overlay; their surfaces are harder and more impervious to water and impacts than MDO forming panels. A greater number of uses and smoother finish on the surface of the concrete can be expected when using HDO Plyform. Forming panels with MDO faces are often only overlaid on one side, ...

How many reuses can a B-B grade concrete forming panel withstand?

In fact, with proper care, some proprietary concrete-forming panels can achieve more than 100 reuses.

Why is it important to fasten form panels to framing?

For example, because panels absorb water, and the increase in moisture content usually causes the panels to expand and move , it is important to adequately fasten the form panels to the framing and to leave space between the panels that allows for their flatwise movement within ...

What is class I plywood?

These panels are rated as Class I, which means they are manufactured with the strongest and stiffest veneers.

What factors affect the number of pours anticipated from concrete-forming plywood?

Many factors can affect the number of pours anticipated from concrete-forming plywood, including: desired finish on the concrete; durability of the panel’s surface, including overlays; types of concrete formulation; and. which release agents are used. The most critical factor is the handling and care of the form panels.