What is the difference between copper and stainless steel?

Copper tarnishes easily. It is difficult to clean. Clearly, the advantages of a copper still far outweigh its drawbacks. 2. Stainless steel stills. Stainless steel has many desirable qualities including: It is resistant to tarnishing. It is a high-strength metal. It is cheaper than copper.

What happens when copper touches steel?

What happens when copper touches steel? Galvanic corrosion is caused by self-induced current created by electrical potential of two dissimilar metals in contact with an electrolyte. It can occur when two dissimilar metals (such as copper tube and steel pipe) are connected in the presence of an electrolyte.

Can stainless steel be connected to copper?

Yes copper and stainless steel can easily be soldered or brazed together using a filler material that usually contains tin and silver . Unlike welding were we melt the two metals together, brazing or soldering use a filler material to bond the two parts together without melting them.

Will stainless steel react with copper?

When two dissimilar metals are directly connected together, the lesser of the two metals experience galvanic corrosion. When stainless steel is directly connected to copper, copper galvanic corrosion occurs. According to Copper.org, the stainless steel plumbing pipes corrode. Click to see full answer. In this way, can you connect steel to copper?

How do you connect copper pipe to stainless steel pipe?

0:002:10Brazing Copper Tubing to Stainless Steel Tubing Using SSF-6 Silver ...YouTubeStart of suggested clipEnd of suggested clipIn this demo I'm using a propane torch to heat the stainless first as the copper is inside theMoreIn this demo I'm using a propane torch to heat the stainless first as the copper is inside the stance. Just doing a nice broad heating here both metals.

How do you join copper to stainless steel?

Yes copper and stainless steel can easily be soldered or brazed together using a filler material that usually contains tin and silver . Unlike welding were we melt the two metals together, brazing or soldering use a filler material to bond the two parts together without melting them.

Can steel be in contact with copper?

It is not necessary to isolate copper from lead, tin or stainless steel under most circumstances. The principal metals of concern in terms of direct contact are aluminum and zinc. Iron and steel are generally not a problem unless their mass is similar or smaller than that of the copper.

Can you weld copper and steel together?

Electron beam welding is the preferred welding process for welding copper to stainless steel. The main reason for this involves the fact that EBW is a great process for welding copper in general, which is the more challenging of the two metals to weld.

Does electrolysis occur between copper and stainless steel?

But what most people don't know is that electrolysis can happen not just to copper pipes, but to certified stainless steel as well. Copper is the most susceptible to electrolysis. It can be triggered just by the minor current created by touching a pipe of another metal type.

Can stainless steel and copper touch?

While stainless steel is a common plumbing material for water mains and fittings because it has an exceptionally long lifespan and is resistant to corrosion, it's not a good idea to directly connect stainless steel to copper. This is because stainless steel and copper are actually dissimilar metals.

What happens when copper touches steel?

Whenever you join copper water lines to galvanized steel pipe, you should be concerned about the corrosion caused by joining two dissimilar metals, called “galvanic corrosion.” An electrochemical reaction occurs that causes the steel pipe (in this case) to rust and clog up.

What metal is compatible with copper?

That means pairing them up will have a higher chance of leading to galvanic corrosion. On the other hand, metals like copper and stainless steel are similar. That's why steel pipes and copper tubing work well together. The same goes for copper and lead or tin.

How do you solder copper wire to stainless steel?

2:055:13How To Solder A Copper Wire Onto Stainless Steel - YouTubeYouTubeStart of suggested clipEnd of suggested clipObviously needs its way to do this is to tin both surfaces. And then salt and watch you pretend themMoreObviously needs its way to do this is to tin both surfaces. And then salt and watch you pretend them tinning the wires dead. Easy. To draw a solder it.

Can I connect brass to stainless steel?

When it comes to stainless steel (301, 304 and 310) and brass, they are only two metals apart, which means they can be safely connected together with minimal risk of galvanic corrosion.

How do you braze copper to steel?

3:024:52How to Braze Copper to Steel with Handy One® - YouTubeYouTubeStart of suggested clipEnd of suggested clipContinue heating the base materials. And apply the rod to the joint. Until you observe melting ofMoreContinue heating the base materials. And apply the rod to the joint. Until you observe melting of the alloy. Focus heat to the outside tube to draw the molten alloy into the interface of the joint.

Can copper be welded to mild steel?

A TIG welder is used when welding copper to give the weld seam the best appearance and a leak-free bond. Argon gas is used with the TIG welder and a filler material is added to the weld to create a permanent bond between the copper and the steel metals.

Why is stainless steel not soluble in copper?

Because stainless steel is not fully soluble with copper and has a substantially higher mel ting point, it will begin to solidify and form grain/crystal structures first.

What acid to use to heat copper?

You could use. Muriatic (hydrochloric) acid, phosphoric acid, fluoro-borate fluxes and zinc chloride will all work. Step 3: Place the two parts together and begin apply heat with either a propane or MAPP Gas torch to the copper. Don’t directly heat the stainless steel.

What are the advantages and disadvantages of using flux coated brazing rods?

The obvious advantage to using flux coated brazing rods is convenience. We don’t need to apply flux to the parts we are brazing because it’s already on the rod and thus we don’t need to purchase silver solder flux separately. The disadvantage with a flux coated brazing rod is that it’s difficult to control the amount of flux applied to our joint when it’s already on the rod and worse if you overheat the joint the flux can form a hard black glass like film that is incredibly hard to remove. I’ve heard arguments either way I personally like the flux coated rods better. I’d love to hear your opinion here on which method you prefer, drop me a comment at the bottom of the article.

Why is copper hot cracking?

At this point the copper is still to hot to add any structural strength to the grain structure and the weld will form large cracks, this is known as hot-cracking. Hot cracking severely compromises the weld strength of this type of weld. If you want to join copper and stainless steel brazing or soldering is your best bet.

Why braze copper?

Brazing copper will provide a stronger bond because of the high % of silver in the brazing rod. But will also cost more and requires the use of an acetylene or Mapp gas torch to melt the brazing rod. You can purchase brazing rods with varying % of silver content and either flux coated or un-coated rod.

Does CO2 work on steel?

CO2 will not work. See that o2 in CO2. That’s an oxidizer and it is exactly what you don’t want. By far on copper, your best bet is Helium. Its going to give you the strongest weld and the best looking weld. The only thing pure CO2 is used for is in steel to steel welding with a TIG. Even then its not a pretty weld. 80% argon/20% CO2 mixed gas is much better on steel and some stainless. But pure argon is hard to beat…

Can you weld copper to stainless steel?

If you want to try welding/brazing copper to stainless steel with your Tig welder Tom Spisak III has some good advice. He says ” Anyone with some Tig experience should be able to make this bond use Silicone bronze wire it’s readily available at your local welding supply shop. ” The picture above show’s a weld Tom made between a stainless steel tri-clamp ferrule and a copper pipe.

Where do electrons travel in a steel pipe?

Electrons will travel from the carbon steel anode sites (corrosion areas)way down the pipe to a non-insulated hanger, up to the steel beams and down to the stainless or copper side if they are connected to the steel, thus completing the electrical circuit.

Do you need to insulated piping?

If your piping has pipe hangers, they should be insulated too. Electrons will travel from the carbon steel anode sites (corrosion areas)way down the pipe to a non-insulated hanger, up to the steel beams and down to the stainless or copper side if they are connected to the steel, thus completing the electrical circuit.

What is the copper in an intrauterine device?

Some copper-bearing intrauterine devices (Cu-IUDs) consist of pure copper and stainless steel. Corrosion of copper in the Cu-IUD was anticipated to be affected by galvanic action due to electrical contact between these two metals.

Is stainless steel a cathode?

In most cases, when stainless steel was in the passive state and acted as the cathode, the contact accelerated copper corrosion.

Why is welding stainless steel to copper important?

An important aspect of welding stainless steel to copper is the physical design of the joint. Problems occur if the joint is designed where the weld energy comes through the copper first. Copper, being a great conductor of heat, tends to require a significant amount of welding energy before it melts. The high amount of energy causes two problems.

What is the preferred welding process for welding copper to stainless steel?

Preferred Welding Process - Electron Beam Welding. Electron beam welding is the preferred welding process for welding copper to stainless steel. The main reason for this involves the fact that EBW is a great process for welding copper in general, which is the more challenging of the two metals to weld. The electron beam has a very high energy ...

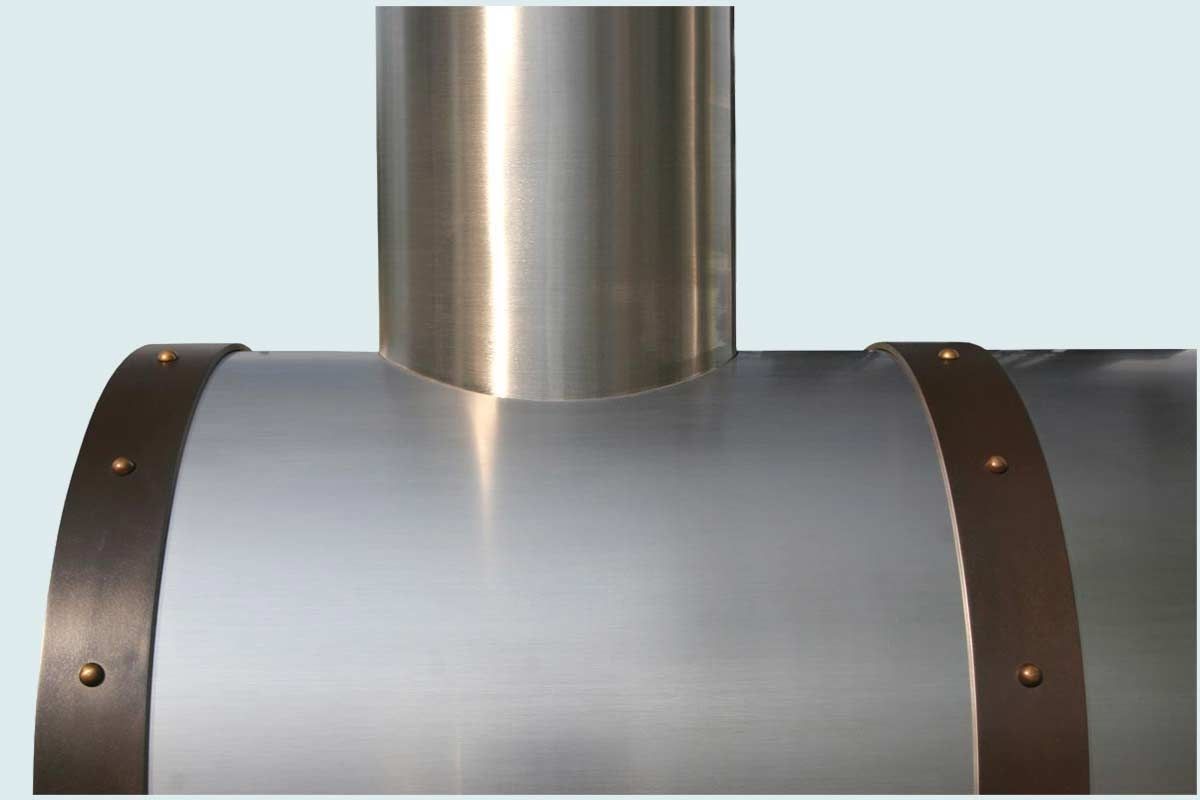

What metals can be welded together?

EB Industries is often asked how we join dissimilar metals together with precision welding. The most commonly requested combination is copper to stainless steel since both metals have unique material qualities which make them very different, yet great when combined. Copper has very high thermal and electrical conductivity, but it is fairly soft and malleable. Stainless steel has good hardness and high tensile strength, but it is not a great conductor. Also stainless steel is usually a less expensive material than copper. With the right experience and technology, these two unique metals can be cost effectively welded together for a high strength leak tight joint. The photo attached to this article shows a weld section of a 0.020” thick 316L stainless steel tube electron beam welded to an OFC copper plug. As can be seen, amazing results can be obtained with the proper design and the right welding technology.

What is the advantage of a stainless steel weld?

The advantage of this design is the right amount of heat can be applied to fuse the stainless to the copper. Any extra energy is quickly dissipated into the copper, much like a heat sink. The design gives a much more forgiving weld, and ultimately uses much less energy to fuse the parts. Diagram of joint types.

What is the purity of copper?

These alloys typically have 99.95% or better co pper purity with very low levels of oxygen and other chemical elements.

Is copper reflective to laser beams?

However, lasers have advanced in the last few years to the point where good results are regularly obtained. The primary limitation with laser beam welding stems from the fact that copper is highly reflective to laser beam light. For a CO<sub>2</sub> laser, almost 99 percent of the incident light energy is reflected away.

Does copper weld into stainless steel?

Second, as the energy comes through the copper into the stainless steel, its high energy basically disintegrates the stainless steel causing holes and blow outs. A much better design would be to have the weld energy come through the stainless first and then into the copper. The advantage of this design is the right amount ...