Can you put a fiberglass shower over a concrete floor?

A shower usually requires a 2-in. drain, with the P-trap located under the concrete slab. If you want to install a shower over a concrete floor, a fiberglass shower stall will work just fine. Ideally, you’ll already have a drain roughed in, with the pipe sticking a few inches above the floor.

Can fiber replace mesh on concrete slabs?

Getting back to the initial question of whether fiber can replace mesh, we typically say yes–with exceptions. The exceptions are as follows: 1.) Elevated cast-in-place slabs 2.) Elevated slabs on metal deck 3.) Structural slabs-on-grade (mats) 4.) Where poor subgrade conditions are expected

Should there be a gap between fiberglass roofing and concrete?

However if the fiberglass is directly against the concrete it will wick moisture out of the concrete so you do want the gap to avoid the wicking problem. Did you find the recommended reading relevant to this discussion?

Is fiber reinforcing concrete stronger on exterior slabs?

Our office, Allegheny Design Services, has examples on exterior slabs-on-grade of over 20 years old, with only fiber reinforcing that still exhibits no cracks. The use of fiber does not have a major effect on the compressive strength of the concrete.

Can you Fibreglass on top of concrete?

Lead (and concrete) can be primed with G4 Dampseal (which will prime many surfaces and facilitate adhesion when applying fibreglass). G4 should be thinly applied with a brush or roller and allowed to tack before applying the laminate.

Why do you put fiberglass in concrete?

2:197:38What is fiber reinforced concrete? - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo the fibers do not stop the crack they don't stop it from forming it will still form at the sameMoreSo the fibers do not stop the crack they don't stop it from forming it will still form at the same load. But the fibers. Keep the crack small. And if you can't see the crack is it really there and

Can fiberglass be used for waterproofing?

Fibreglass waterproofing is considered to be one of the most popular and sought-after waterproofing methods. Due to the various features and attributes of fibre glass, this product is used in various waterproofing applications like on balconies or concrete roofs.

How do you fiberglass a concrete pool?

1:125:01API Converting a Gunite Pool to a Fiberglass Pool - YouTubeYouTubeStart of suggested clipEnd of suggested clipWe applied two layers of fiberglass matting over it and then our resin. And let that harden now onceMoreWe applied two layers of fiberglass matting over it and then our resin. And let that harden now once that had completely cured. We ground the entire surface where we laid the fiberglass matting.

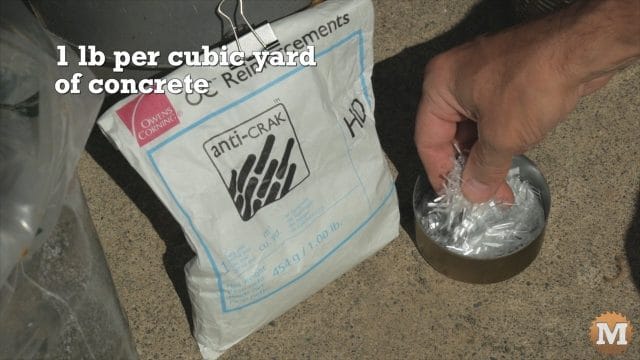

How much is it to add fiber to concrete?

In general, and depending on the type of steel fiber used, it can add between $6 to $10 per cubic yard on top of the ready-mix concrete cost. This cost is based on the assumption that you are using 1.5 pounds per cubic yard of concrete.

How do you finish concrete with fiber?

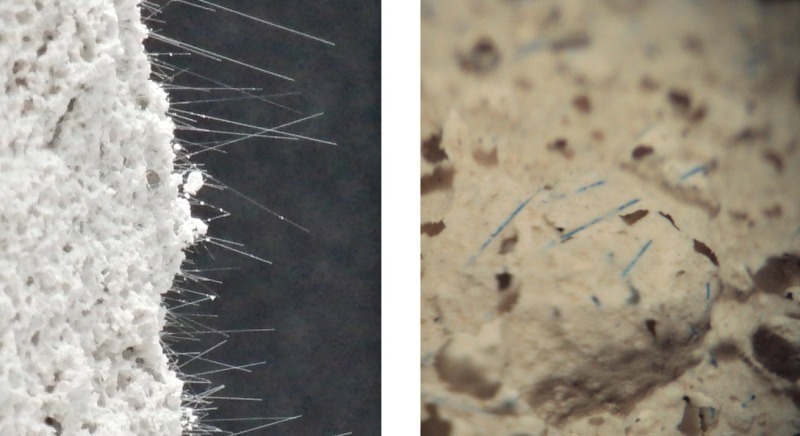

One key to finishing fiber-reinforced concrete is using external vibration. External vibration brings paste to the surface and buries fibers located at the slab surface, encapsulating them in concrete and minimizing exposed fibers.

Does fiberglass rot in water?

Actually Fiberglass Resin does rot, at least Polyester does. Not quickly (like wood), but it does. The Gel coat protects it from water intrusion. If the Gel coat is removed (digs/scratches) and the fiberglass is left exposed to water for long periods it can absorb water and eventually will "rot" and delaminate etc.

Does fiberglass deteriorate in the sun?

Fiberglass products that are continuously exposed to UV radiation may succumb to unsightly color fading. This phenomenon is not unique to fiberglass, however, and it has no bearing on the structural integrity of the part.

How do you do the poor man's fiberglass?

0:2818:12DIY: Poor Man's Fiberglass - Step-by-Step! - YouTubeYouTubeStart of suggested clipEnd of suggested clipThis is gonna be the poor man's fiberglass. And what we're using. Is just simple drop cloth got thisMoreThis is gonna be the poor man's fiberglass. And what we're using. Is just simple drop cloth got this from harbor freight tools and tight bond to glue essentially all you do to make this fiberglass.

Can a concrete pool be lined?

0:324:12Can You Put A Liner In A Concrete Pool? - YouTubeYouTubeStart of suggested clipEnd of suggested clipDifferent it's just not a good idea from a longevity perspective. If you really go hunting out thereMoreDifferent it's just not a good idea from a longevity perspective. If you really go hunting out there you'll find somebody who will give you a price to put a vinyl liner in your concrete swimming pool.

Is a fibreglass pool cheaper than concrete?

Affordable: Fibreglass pools cost around 20% less to install than a concrete pool. Ongoing costs are also lower due to less maintenance, chemicals and energy consumption.

What are the disadvantages of a fiberglass pool?

List of the Cons of Fiberglass PoolsPoor installation practices can impact the quality of your pool. ... The fiberglass can interfere with the quality of the water. ... There is still a significant cost to consider when installing a pool. ... Fiberglass pools are prefabricated. ... The fiberglass can be susceptible to warping issues.More items...•

Does fiber mesh make concrete stronger?

The purpose of fiber mesh is to reduce water loss from the concrete as well as enhance its structural integrity. This type is also used to create a higher impact resistance in the concrete, prevent thawing, and increase its strength.

Is fiber mesh better than rebar?

While there are clear benefits to both concrete fibermesh and rebar, there is one option that clearly stands out as the better option to us. This is concrete fibermesh. While rebar is outstanding, it is rather expensive, and it takes a lengthy amount of time to add this to your concrete.

Is fiberglass rebar any good?

Glass fiber reinforced polymer (GFRP) rebar has turned out to be a perfect alternative to traditional reinforcement materials such as black rebar and epoxy coated rebar. Traditional reinforcement techniques have failed to develop a corrosion-free mechanism that can keep concrete structures in good shape.

What is meant by Fibre reinforced concrete?

Fibre-reinforced concrete has more tensile strength when compared to non-reinforced concrete. It increases the concrete's durability. It reduces crack growth and increases impact strength. Fibre-reinforced concrete improves resistance against freezing and thawing.

What fibers are used to make concrete look new?

Pro: Fiberglass fibers will give the concrete a unique look when finished.

What is the problem with concrete?

One thing that is undesirable about traditional concrete is that it is a porous material, which means water can see or bleed through in certain settings and cause problems beneath the concrete. If you want concrete that is more resilient to moisture, adding fibers, especially fiberglass fibers, can help to deter that problem.

Is fiberglass reinforced concrete?

Concrete is perhaps one of the most hea vily relied upon construction materials ever, and its basic form and composition has been the same for many years. However, efforts to reinforce concrete have brought about things like fiberglass reinforcing fibers that are incorporated into the mix. Here is a look at some of the pros and cons of adding fiberglass fibers to concrete.

Is fiberglass a good additive for concrete?

However, fiberglass is one of the most affordable fiber additives when compared to something like steel or nylon. Therefore, fiberglass helps construction companies get the fibers they need for reinforcement without having to spend a lot of money to do so.

Can fiberglass be put in concrete?

Con: Incorporating fiberglass into concrete can make the project take a little longer to complete.

Is fiberglass concrete better than concrete?

The biggest advantage of having concrete that is formulated with fiberglass is the fact that the concrete will not be as brittle once the project is done and the concrete is cured. The material will be more resistant to direct impact, less prone to cracks due to breaking, and overall more resilient so that it can last for the long term. Using rebar has been the go-to for concrete reinforcement for a long time, but even rebar does not provide the same sustainability when it comes to cracks or breakage.

Plumb the drain using a special leak-proof drain assembly

Install a fiberglass shower stall over a concrete floor using a special drain assembly that eliminates leaks. You run the drain line under the concrete.

Step 1. Shower Drain Installation: Run a drainpipe under the concrete floor

A shower usually requires a 2-in. drain, with the P-trap located under the concrete slab.

Step 2. Shower Drain Installation: Mount the leakproof drain assembly

The assembly locks tightly to the pipe and clamps to the edge of the shower base to make leakproof seals.

Required Tools for this Project

Have the necessary tools for this DIY shower drain installation project lined up before you start—you’ll save time and frustration.

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time for a shower stall installation. Here’s a list.

How much air gap between cement and studs?

Usually you allow a 1-3" air gap between the stud wall & the cement to allow the water to evaporate. That said reg studs have been used & lasted for a long time. And some have not lasted long at all. All depends upon the situation.

Can fiberglass be used on concrete?

However if the fiberglass is directly against the concrete it will wick moisture out of the concrete so you do want the gap to avoid the wicking problem.

What happens if fiber is only used?

Keep in mind that if fiber is only used, the subgrade must be properly compacted and prepared in accordance with the geotechnical engineer’s recommendations. Once any differential settlement occurs, the fiber will not prevent cracks from developing and increasing in width.

What is the function of synthetic fibers and welded wire fabric?

What first must be understood is the function of synthetic fibers and welded wire fabric. When concrete is first placed, moisture will evaporate from the surface faster than within the mass of the concrete. As the surface begins to cure faster than the concrete below the surface, tensile stresses build up and shallow microscopic cracks develop in ...

What are the different types of fibers?

Several types of fiber exist. They include steel, glass, synthetic and natural fibers. Their selection depends on the usage and environment of the finished slab. Consult with the design engineer in selecting the correct type. In all cases, the fiber is considered another admixture and should be submitted with the concrete mix submittal for approval.

Is fiber reinforcement good for concrete?

Fiber reinforcing is very good in restricting the initial shrinkage cracking that occurs in the initial stages. Our office, Allegheny Design Services, has examples on exterior slabs-on-grade of over 20 years old, with only fiber reinforcing that still exhibits no cracks. The use of fiber does not have a major effect on the compressive strength of the concrete.

Can cracks grow without restraint?

If allowed to develop without restraint, these cracks can grow wider and lengthen to become major aesthetic and functional problems.

Can fiber be used to replace mesh?

FIBER MATRIX IN CURED CONCRETE. Getting back to the initial question of whether fiber can replace mesh, we typically say yes–with exceptions .

Can flexural cracks be random?

These cracks are considered structural failure cracks and are wider and predictable (not random). These cracks rarely occur in slabs-on-grade but will always occur on elevated slabs if not reinforced with rebar or welded wire fabric. If flexural cracks do develop in slabs-on-grade, there is a problem with the subgrade.

Why do you need wire mesh for concrete?

Wire Mesh. Wire mesh makes concrete more durable and increases its strength. The area in which the concrete will be laid down should be covered in mesh before pouring commences. As the concrete is poured, the wire mesh should be lifted up so that it’s positioned in the middle of the concrete in order to provide steel reinforcement.

Why seal concrete?

Regularly sealing concrete maintains its longevity and durability for decades to come. Exterior surfaces need protection from the extreme temperatures, inclement weather, heavy impacts, or harsh abrasion. Interior surfaces benefit from sealants that offer protection Read more.

What is concrete mesh?

Concrete mesh is ideal for reinforcing your slab, and it comes in two options: fiber mesh and wire mesh. Each of these types are sufficient in minimizing structural damage and cracking, but there are distinct differences between the two. Continue reading as we discuss when to use each type.

Why does concrete crack when pouring?

This is due to concrete’s lack of tensile strength, causing shrinkage to crack your slab. By understanding that these issues are going Read more

What is fiber mesh?

Fiber Mesh. Fiber mesh is made up of fibrous materials like synthetic fibers, glass fibers, natural fibers, and steel fibers. It is typically used in sidewalks, patios, and driveways. Rather than being laid down prior to the pour, this type of mesh is distributed evenly throughout the wet concrete. The purpose of fiber mesh is to reduce water loss ...

Is wire mesh better than fiber mesh?

Using wire mesh is typically a longer process than fiber mesh, because it requires time to overlap and must be laid twice. Keep in mind that the longer the project takes, the more it will cost you.

Step 1. Shower Drain Installation: Run A Drainpipe Under The Concrete Floor

Step 2. Shower Drain Installation: Mount The Leakproof Drain Assembly

- After you frame the shower walls to fit the shower bay, lay the bay on its back and install the shower drain. Use a special leakproof shower drain assembly called the No-Caulk Shower Drain. It’s available at home centers and plumbing supply houses. Although these drain baskets are available in plastic, I’d opt for the brass one. Follow these steps to attach the shower to the drain…

Required Tools For This Project

- Have the necessary tools for this DIY shower drain installation project lined up before you start—you’ll save time and frustration. 1. Hacksaw 2. Hammer 3. Slip joint pliers

Required Materials For This Project

- Avoid last-minute shopping trips by having all your materials ready ahead of time for a shower stall installation. Here’s a list. 1. Drain assembly 2. Plumber's putty