How to select the correct size of heat shrink tubing?

To choose the right tubing, you will need to know:

- Its shrink ratio. As mentioned above, a 2:1 ratio indicates that the tubing will shrink to approximately half its size when heat is applied, while a 3:1 ratio means that ...

- The thickness of the tubing walls. ...

- The ‘inside diameter’ (ID) of the tubing following shrinkage as well as its ‘expanded inside diameter’ (expanded ID) before shrinkage. ...

Can electrical tape be used instead of heat shrink tubing?

When compared to heat shrink tubing, electrical tape is easier to apply and remove. Although both are fairly simple to apply, once heat shrink tubing is shrunk to fit, it will be secure and not as easy to remove as peeling off the electrical tape. Electrical tape also offers a quick way to identify voltage by its many colors and phasing.

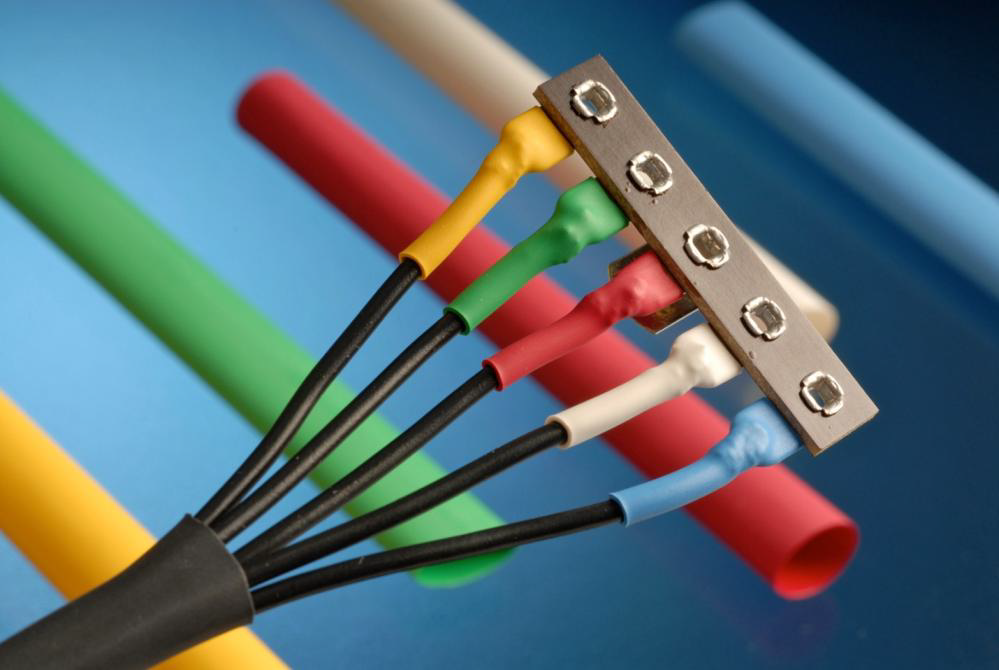

What is Heatshrink tubing used for?

Unsourced material may be challenged and removed. Heat-shrink tubing (or, commonly, heat shrink or heatshrink) is a shrinkable plastic tube used to insulate wires, providing abrasion resistance and environmental protection for stranded and solid wire conductors, connections, joints and terminals in electrical work.

Where to buy heat shrink tube?

Buy heat shrink tubing from HeatShrinkTubingDirect.com now to take advantage of our most extensive selection and best pricing options of the year!

Can you connect wires with heat shrink?

3:095:08How to Splice Electrical Wires Together & Use Heat Shrink Tubing!YouTubeStart of suggested clipEnd of suggested clipYou just want to pretty much make the the heat shrink and tubing. Pretty much shrink to completelyMoreYou just want to pretty much make the the heat shrink and tubing. Pretty much shrink to completely form on to the wire just like it. And now you've got a nice strong connection.

Can you use heat shrink instead of wire nuts?

NEVER use wire nut on any electrical connection that is exposed to the outside. The corrosion will rapidly distroy the connection. Either tightly twist the wire togetherand use heat shrink, or solder the wires together and use heat shrink. This will save you from having alot of problem in the future.

Can you use shrink tube as electrical tape?

A common misconception when determining the ideal method for wire bundling or insulation is that heat shrink tubing and electrical tape are virtually interchangeable for any application.

Is heat shrink for wires waterproof?

Is Heat Shrink Tubing Waterproof. Not all heat shrink tubings are waterproof. Although they do keep out moisture when activated, there are specifically designed marine-grade heat shrinks which you can order. These items have a layer of adhesive inside the tubing which will melt and seal the cable all around.

What can you use instead of wire connectors?

Alternative Approaches to Connecting Electrical WiresIn-line connectors. ... Wire nuts. ... Spade terminals. ... Butt-splice connectors. ... Bullet connectors. ... Wire-splice connectors. ... Butt-splice connectors with IDT.

How do you connect two wires with heat shrink?

Cut a piece of heat shrink to cover the exposed wires. Slide the heat shrink through one of the wires. Make sure to slide the heat shrink away from area where you are splicing. Face the wire terminals toward each other and touch the exposed ends together.

Is heat shrink the same as electrical tape?

Electrical tape is not as durable as, for example, heat shrink tubing. Over time it will lose its adhesive properties and eventually fall off the cable or wire. When using electrical tape, it's important to regularly monitor the condition of the tape, which is an impractical use of your time.

How strong is heat shrink tubing?

Dielectric Strength 500 V/mil (500 x Jacket Wall thickness x 1000) (for example, a typical tube thickness after shrinking will be about 0.10. Using these caculations, the rating will be about 50,000V, or 50KV) Maximum Continuous use temperature 110°C.

How long does heat shrink tubing last?

30 days to 25 yearsShelf life: FIT Heat Shrink Tubing has a shelf life that ranges from 30 days to 25 years.

How do you heat shrink electrical connections?

0:161:14How to join cables with heat shrink crimp connector (waterproof)YouTubeStart of suggested clipEnd of suggested clipThe heat shrink through connector pushing the cable in through one side of the connector. Now I'llMoreThe heat shrink through connector pushing the cable in through one side of the connector. Now I'll push it in from the other side.

How do you waterproof wire connections?

1:003:26How to Waterproof Electrical Connections - 3 Ways - YouTubeYouTubeStart of suggested clipEnd of suggested clipSimply. Use a razor to cut off a length of tape that you'll need when wrapping the connectionMoreSimply. Use a razor to cut off a length of tape that you'll need when wrapping the connection applied two-thirds. Overlap. This tape will fuse on both sides. And once cured it will remain flexible.

Is heat shrink watertight?

Is Heat Shrink Tubing Waterproof? Yes, most heat shrink tubing is watertight and will also protect against other moisture and even potentially corrosive liquids.

How strong is heat shrink tubing?

Dielectric Strength 500 V/mil (500 x Jacket Wall thickness x 1000) (for example, a typical tube thickness after shrinking will be about 0.10. Using these caculations, the rating will be about 50,000V, or 50KV) Maximum Continuous use temperature 110°C.

Is heat shrink tubing airtight?

Not only is it easy to use, but it offers a wide range of benefits as well. When heat is applied to shrink wrap, it creates a very tight seal. This plastic seal then fully protects the shrink wrapped contents. Once sealed, the items are no longer vulnerable to the damage that can be caused by dust, dirt or moisture.

What can I use instead of heatshrink?

What are Some Alternative Solutions to Heat Shrink Tubing?Tape wrapping – Wrapping bundles of wires using tape to create a wire harness.Dip coating – Dipping components into a liquid compound that will adhere and solidify creating a layer of protection on the dipped items.More items...•

How much will heat shrink tubing actually shrink?

Its shrink ratio. As mentioned above, a 2:1 ratio indicates that the tubing will shrink to approximately half its size when heat is applied, while a 3:1 ratio means that it will shrink to one third its full size. The thickness of the tubing walls. This is normally measured in millimetres or inches.

What is heat shrink tubing?

Heat shrink tubing (also called heat shrink sleeving) is a hollow, polymer tube that contracts when heated. According to cableorganizer.com, heat shrink tubing was developed in the late 1950s by Paul Cook of the Raychem Corporation.

Why is heat shrink tubing important?

Heat shrink tubing is essential in improving the protection, lifetime, and maintenance of wires in a circuit. It is great for securing connections, avoiding tangling with wires, and insulating against shocks or short-circuits.

What is the best material for heat shrinking?

Polyolefin is the most common material used for heat shrink tubing. It is flexible, fast shrinking, has excellent durability, high flame and UV resistance. It has a shrinking temperature of 120°C and withstands a high temperature of 125°C - 135°C. It is mostly used for mechanical protection, insulation and marking.

What to know before buying heat shrink tubing?

Before you purchase your own heat shrink tubing you have to understand the needs of your application first and foremost. What the heat shrink tubing will be used for will implicate the type of tubing you buy. There are a variety of different types of heat shrink tubing that vary based on material, shrink ratio, inner diameter size, length and thickness.

How much extra diameter for heat shrink?

Diameter is also another important consideration. For the best coverage, you should allow for 20-30% extra inner diameter to ensure the appropriate space for the heat shrink tubing to be able to merge along with the wiring tightly.

Why do wires wear out?

Everyday wear and tear on wires and cables is usually caused by lack of space or length thus affecting the lifespan of a wire. Heat shrink can be used to reduce the strain applied to wires by adding another layer of durability.1

Why is webbing used in wires?

It is typically used in projects that contain a complex webbing of wires or cables to ensure that the wires are insulated and protected from external forces like water damage or shocks.

What is heat shrink tubing?

Heat shrink tubing is a ubiquitous component in most electrical installations that protects cables and electronic systems from external influences including humidity, dust, and sharp objects that could otherwise damage them .

How much does heat shrink tubing shrink?

Take a piece of heat shrink tubing that is somewhat longer than the broken wire segment. Most heat shrink tubing shrinks 5-15 percent lengthwise, so make sure you have quite enough tubing to fill the open area after heating.

How to shrink polyolefin?

To shrink tubing with a hairdryer, put it to the hottest setting and press the nozzle close to the tube until it shrinks. To uniformly distribute the heat, you’ll need to rotate the wires or blow dryer.

What is the best way to start heat shrinking?

A simple lighter is another way for starting heat shrink. It works faster than a hairdryer and has a high enough temperature for any form of heat shrink. It does, however, have some restrictions.

How to get snug fit on wire?

To guarantee a snug fit, the reduced diameter should be somewhat less than the wire diameter.

Can you use a heat shrink without a heat gun?

What would you be doing if you don’t have one? You could still use heat shrink without the need for a heat gun at all. It responds to a wide range of heat sources, so there are many other tools you might want to use instead.

Can a hair dryer shrink tubing?

You may have full, moderate, or no shrinkage according to the blow dryer’s output power.

What is heat shrink tubing?

Heat shrink tubing (also known as heat shrink) is a shrinkable plastic tube with many useful applications in electronics work. It shrinks along its radius when exposed to heat, which is where its name comes from.

What is elastomeric heat shrink tubing?

Elastomeric heat shrink tubing stands out because of its flexibility, even at low temperatures down to -75°C (-103°F). It is resistant to dangerous liquids like diesel fuels, petrol fuels and hydraulic fluid. It also has good resistance to abrasion.

What size of heat shrink do you need?

But once you know what to keep in mind, choosing the correct diameter heatshrink is actually fairly straightforward.

How much does tubing shrink?

For example, tubing with a 5 mm diameter and a shrink ratio of 2:1 shrinks to 2.5 mm when sufficiently heated.

What is FEP tubing?

FEP (Fluorinated ethylene propylene) heat shrink tubing is fairly similar to PTFE in its resistance to chemicals. It shrinks at a lower temperature, however, and is a bit cheaper. Viton heat shrink tubing is a popular option for hydraulic equipment.

How to add strain relief to copper wire?

One of the easiest ways to add strain relief to cables is to add a piece of heat shrink tubing around the part of the wire that gets bent. This causes some of the forces to get transferred through the heatshrink instead of the copper wire itself. As a result, the wire will last significantly longer.

Why is heat shrink used for electrical repairs?

Because heatshrink is non-conductive, it forms a protective layer that prevents accidental short circuits. Aside from insulating electrical connections, heat shrink can also be used for repairs. For example, a wire with damaged insulation and exposed copper can be easily fixed with a section of shrink tubing.

What is heat shrink connector?

As their name implies, heat-shrink electrical connectors have insulation that shrinks when heat is applied. Most also have an adhesive inside the insulation that seals tightly against the wire to help to make the connection weather-resistant, which in turn helps prevent corrosion. An assortment of heat-shrink connectors, a good crimper, ...

What happens if you use the wrong tool to crimp and shrink heat shrink connectors?

Using the wrong tools to crimp and shrink heat-shrink connectors will result in unreliable connections that usually will fail prematurely. The most important tool you'll need to do the job right is a high-quality crimper specifically designed for use with heat-shrink connectors.

What tool to use to crimp a barrel?

Most ratchet-type crimping tools will release only when the barrel is fully crimped. Use a heat gun to shrink the insulation. This will provide both structural rigidity and a high degree of weather resistance to the crimped joint.

What is the one tool you shouldn't economize on if you want quality crimped connections?

In short, the crimper is the one tool you shouldn't economize on if you want quality crimped connections. Don't scrimp on the crimp.

Why are crimpers partially closed?

They also can be partially closed around the connector to hold it in place while you're inserting the wire, essentially becoming that third hand that you're always looking for.

Why do wire connectors fail?

The most common mistake people make when using heat-shrink wire connectors (and the most common reason why the connections fail) is not using the proper tools. Using the wrong tools to crimp and shrink heat-shrink connectors will result in unreliable connections that usually will fail prematurely.

What is heat shrinking?

As their name implies, heat-shrink electrical connectors have insulation that shrinks when heat is applied. Most also have an adhesive inside the insulation that seals tightly against the wire to help to make the connection weather-resistant, which in turn helps prevent corrosion.