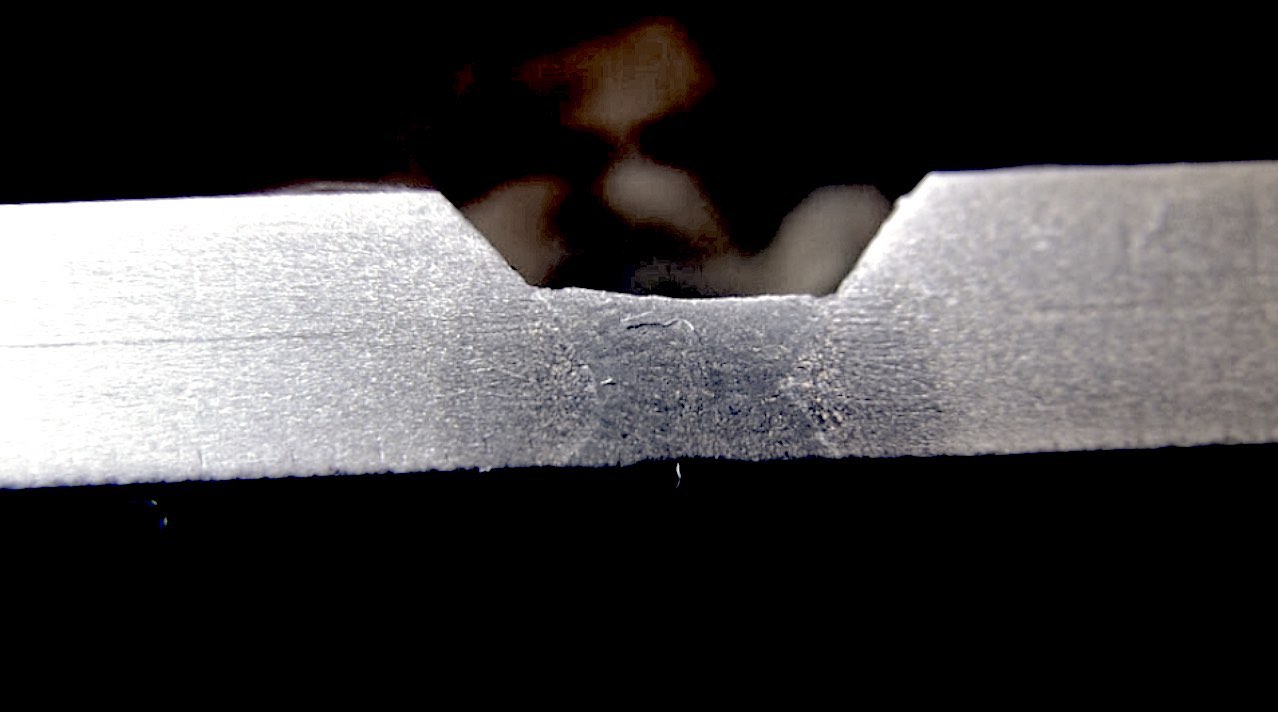

For short circuit MIG welding

Gas metal arc welding

Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) welding or metal active gas (MAG) welding, is a welding process in which an electric arc forms between a consumable wire electrode and the workpiece metal(s), which heats the workpiece …

How to use MIG welding for downhill welding?

For downhill MIG welding, you select a 15% higher amperage than the flat position. Depending on the wire diameter you use, try to use the higher half of the amperage range. This way, you melt the wire fast enough to keep up with the faster traveling speed. If the beads are concave, you can lower the voltage by steps of 0.2-0.3V to make them taller.

Should you weld thick metals uphill or downhill?

Because short-arc MIG welding has lack of fusion issues, you always weld thick metals uphill to get the best root penetration and overall fusion. Furthermore, you have improved puddle control for irregular joints and better visibility. On the other hand, welding downhill is suitable for open roots and thin metals.

What is an uphill welding position?

An uphill welding position is when you start at the bottom of the joint and work your way upward. This welding position is considered mode difficult than a downhill weld. It works really well for dealing with thicker materials; something with at least ¼ inches or more since it provides greater penetration.

How do you use a stickout on a MIG welding torch?

If you use a .045″ wire, you can set a stickout up to a 5/8″. When you weld downhill, you pull the MIG torch with a 15-20° angle below horizontal to push the puddle back. The downhill traveling speed must be fast enough to position the arc ahead of the puddle.

Should you MIG weld uphill or downhill?

By welding uphill you'll be able to penetrate deeper into the metal, stacking the weld up and giving it time to penetrate into the joint. For thin metal, such as on automotive welds, you can weld downhill and even do a stringer.

Can you weld uphill with MIG?

1:033:28Mig Welding Techniques for Uphill Welding Tested for PenetrationYouTubeStart of suggested clipEnd of suggested clipNow a lot of welding is done downhill. Yes I know but when it's very thick at all and it'sMoreNow a lot of welding is done downhill. Yes I know but when it's very thick at all and it's structural. Needs to hold you need to go uphill with short circuit MIG you're not going to burn in downhill.

Can you weld vertical with MIG?

0:297:01Mig Welding Tips for Uphill Vertical - YouTubeYouTubeStart of suggested clipEnd of suggested clipWe go. This has become my kind of like my go-to vertical uphill a technique with MIG. And it's aMoreWe go. This has become my kind of like my go-to vertical uphill a technique with MIG. And it's a series of triangles. And it looks like this on a diagram it doesn't really matter on a t joint.

Are down hill welds strong?

When welding downhill, gravity pulls the weld pool down, so it results in great speed. Vertical down welding is quite difficult at the best of times, and many welding consumables and welding parameters will not allow downhill welding.

Is it better to weld up or down?

For material thicker than sheet metal, vertical welding generally should be performed uphill. Welding thinner sheet metal can be performed downhill because less penetration is needed, and the faster travel speed produces cooler temperatures that prevent burn-through. But that's a subject for another article.

Is it easier to MIG weld up or down?

The upside down V is one of the most effective techniques for vertical mig welding of lap and tee fillet welds. Sure there are other ways of making a good looking vertical uphill weld, but for ensuring penetration as well as making a good looking uniform weld, the upside down V is a very good way to go.

What is the trick to vertical welding?

2:4612:01How to Stick Weld Vertical Joints: 4 Ways to Get the Job Done - YouTubeYouTubeStart of suggested clipEnd of suggested clipClear up to the top. And then notice here as i get to the top what i'm going to do is just roll myMoreClear up to the top. And then notice here as i get to the top what i'm going to do is just roll my weld right over the top here to finish. And so i'll finish off just like that and the slag.

What direction do you Mig Weld?

2:423:56MIG Welding: Should You Push or Lead the Puddle? - Kevin CaronYouTubeStart of suggested clipEnd of suggested clipSo you can push the funnel and the sparks are going away from you you see even out of your torch isMoreSo you can push the funnel and the sparks are going away from you you see even out of your torch is right over the top of your weld.

Can you weld flux core downhill?

Welding downhill, one must speed up the downhill progression so the flux can freeze and allow the metal to stay contained. This applies to both stainless and carbon steel flux core. It also takes greater skill to successfully weld flux core downhill.

Why do Pipeline welders weld downhill?

On thinner-wall pipe, downhill welding enables operators to run “hot and fast,” increasing productivity compared to welding uphill, which is required on thicker wall pipe to increase heat input to ensure complete penetration.

How do you weld downhill?

5:1610:38Stick Welding Techniques 6010 Downhill - YouTubeYouTubeStart of suggested clipEnd of suggested clipAs you go down so you're on your knees you're gradually moving you're trying to keep the rod angleMoreAs you go down so you're on your knees you're gradually moving you're trying to keep the rod angle right you're trying to keep the pressure on the rod. Right this is what makes pipe welding.

Why weld uphill instead of downhill?

In this instance, uphill vertical welding is the best choice as it will allow for the right level of penetration. Because the welder needs to fight the pull of gravity on the molten weld pool, they need to move more slowly and this allows them to achieve deeper penetration than they would when welding downhill.

Can you weld vertical with MIG?

You can weld vertically with MIG by using a metal-transfer mode that freezes the puddle fast enough to keep it from dripping. The popular short-circuit mode can weld vertically both up and down but has metal thickness limitations. The pulsed mode can also weld vertically, but it’s suitable for high productivity work.

Do you MIG weld uphill or downhill?

Because short-arc MIG welding has lack of fusion issues, you always weld thick metals uphill to get the best root penetration and overall fusion. Furthermore, you have improved puddle control for irregular joints and better visibility. On the other hand, welding downhill is suitable for open roots and thin metals.

Is it easier to MIG weld up or down?

It’s easier to MIG weld downhill because you don’t need to use complex techniques to fight against gravity. As gravity pulls the puddle down, you maintain a proper traveling speed and torch angle to keep the puddle behind the arc.

Vertical uphill MIG settings

Now let’s see each one of the welding parameters for the vertical-up direction.

Uphill MIG welding basics

Welding uphill is hard because gravity pulls down the puddle, and you must ensure it stays in the desired place. When you weld uphill, you create a shelf of solidified weld metal to support the molten puddle as you travel up.

Vertical downhill MIG settings

Now let’s see each one of the welding parameters for the vertical-down direction.

Downhill MIG welding basics

When you weld downhill, there is no shelf to control the puddle, so it runs downwards. To control it, you weld straight at a fast traveling speed to keep the puddle behind the arc.

Can you use iron powder flux for downhill welding?

Iron powder type fluxes are not really recommended for downhill welding. The term "All Position" Does not necessarily mean, "Anything Goes" A downhill weld made with 7018 will in many cases tend to trap slag in the weld as it builds up & flows in the direction of gravity.

Can you use heat on a downhill pass?

Also, as far as trapping slag on a downhill pass: That is why you would use a lot of heat on the second pass, (hot pass). Enough heat will burn out any slag in your wagon tracks. The bottom line on downhill welding is speed.