What is the shrink rate of EPDM?

However, the answer may vary as it depends on how much rubber formulation is changing. For example, if we are going from a 70 Shore A durometer EPDM compound to a 60 durometer EPDM compound, there typically won’t be much change in the shrink rate.

How long do EPDM roofing membranes last?

EPDM roof membranes remain stable over time and can have a life expectancy of over 50 years.** Made from synthetic rubber, EPDM roofing membranes have two primary ingredients, ethylene and propylene, which are derived from oil and natural gas. The following factors support the exceptional durability of EPDM roofing membranes.

Why do EPDM and PVC membranes fail?

More specifically, in the case of EPDM membranes [21], the effects of shrinkage were found to be the primary factor in the premature failure of these systems, whereas, in the case of PVC membranes [22], considerable research has been undertaken to determine the causes of shattering on these roofing components. ...

What are the advantages of EPDM?

EPDM Properties EPDM’s biggest advantages lie in how weatherproof it is outdoors. It can resist abrasion, UV rays, ozone, aging, and weather, and it’s the most waterproof rubber available. EPDM is also steam resistant, functioning in up to 392 degrees F (200 C) without air, and chemical resistant, including to polar fluids.

Does EPDM rubber shrink?

illustrate that EPDM gradually shrinks as the temperature increases and sees severe deformity at about 125° C, (257° F). Silicone on the other hand, showed no change when exposed to the same temperatures.

Does EPDM shrink or expand?

EPDM is a relatively sturdy rubber membrane and is often used to seal vehicles, windows, and (you guessed it) roofs. Despite its durability compared to other rubbers, EPDM naturally shrinks over time—several factors can speed up EPDM shrinkage.

What are common problems with EPDM roofs?

However, many of the common problems that are encountered with EPDM roofs are due to incorrect or improper installation....Leaking EPDM Roof Repairpunctures in, or damage to, the membrane.shrinkage.incorrectly installed or improper flashing.wrinkles extending into roof seams.

Does EPDM expand and contract?

One of the biggest advantages to EPDM being rubber is that it expands and contracts well. In the hot summer months, your roof (and other parts of your home like windows and doors) expand from the heat. During the colder months, the materials contract.

What causes EPDM to shrink?

Shrinkage is most common on EPDM or modified bitumen roofs. Its causes include aging of the material, poor installation, and UV exposure.

Which is better EPDM or silicone?

Silicone is seen as the superior elastomer to EPDM due to the added benefits it provides, as well as generally providing longer life in service meaning less replacement costs and/or downtime.

Can you walk on EPDM roof?

Yes to an extent. EPDM is designed to take LIGHT foot traffic during installation and for occasional cleaning or maintenance. If you require more use than this, i.e. for a balcony then there are additional materials that can be laid over your EPDM for a more durable solution.

What thickness of EPDM is best?

45 MilLong-Term Lifespan Rubber roofing's longevity depends on three factors: quality installation, climate, and membrane thickness. Roofing installation experts will recommend 45 Mil EPDM rubber roofing membrane in moderate climates and in situations where there's a low risk of penetrations.

How long will an EPDM roof last?

EPDM roof membranes remain stable over time and can have a life expectancy of over 50 years. ** Made from synthetic rubber, EPDM roofing membranes have two primary ingredients, ethylene and propylene, which are derived from oil and natural gas.

Which is better EPDM or PVC?

Composed of synthetic rubber, an ethylene propylene diene monomer (EPDM) roofing membrane offers superior weather resistance while remaining a cost-effective option. PVC, on the other hand, delivers exceptional seam strength; in fact, heat-welded PVC seams are stronger than the PVC roofing membrane itself.

Which is better TPO or EPDM?

EPDM roofs are the most economical choice for single ply roofing membranes. TPO roofing membranes are more expensive than EPDM. Regardless of which membrane you choose, it is better to spend more money and invest in a thicker membrane. Both EPDM and TPO roofs perform better and last longer if they are thicker.

What do you put under EPDM roofing?

If you're installing your EPDM over an existing roof, you should cover it with clean, sanded plywood or OSB board to provide a barrier to protect the membrane. If you're applying the EPDM directly to roof decking, you should consider adding a layer of insulation to prevent problems with water vapor.

Which is better EPDM or neoprene?

Neoprene has superior attributes in comparison to EPDM in applications requiring good resistance to Oils, Chemicals, Hydrocarbons and Solvents. EPDM, on the other hand, has superior attributes in comparison to Neoprene in applications requiring good resistance to UV Light, Ozone and external weathering.

What is the difference between EPDM and Viton?

Viton® rubber is a fluoro elastomer, whereas epdm rubber is ethylene-propylene-diene-monomer. The primary differences between Viton® and EPDM is in their chemical resistance and temperature ranges. Both have different properties and applications for general industrial use.

What is difference between EPDM and nitrile rubber?

EPDM rubber sheets are made with chemicals ethylene, propylene, and diene monomers that give ethylene propylene rubber its unique outdoor resistance and chemical resistance properties. Nitrile, contrastingly, is a synthetic rubber that is “derived from acrylonitrile (ACN) and butadiene” (Wikipedia.org).

How long will an EPDM roof last?

EPDM roof membranes remain stable over time and can have a life expectancy of over 50 years. ** Made from synthetic rubber, EPDM roofing membranes have two primary ingredients, ethylene and propylene, which are derived from oil and natural gas.

What is EPDM Rubber?

EPDM (ethylene propylene diene monomer) is a synthetic rubber made up of ethylene, propylene, and diene monomers. Its molecular structure has a single bond, chemically saturated backbone, which makes it extremely resistant to outdoor conditions. This is because ozone and UV rays aren’t able to break up its molecular structure in the same way as rubbers with double bonds.

How long does EPDM last?

However, if properly taken care of, EPDM products can last for decades. Roofing made from EPDM can last 30-50 years, and liners can last for 20.

What is EPDM roofing used for?

However it is also used for sealant, expansion joints, garage door seals, pool and tank liners, and waterproof coating for bitumen roofs. It’s even used on RV roofs. HVAC.

Where is EPDM found?

EPDM can be found in parts such as water system O-rings, hoses, and gaskets, as well as in electrical insulators and connectors for wire and cable. It also takes the form of accumulator bladders, diaphragms, grommets, and belts. Construction.

Is EPDM rubber used in industry?

EPDM rubber is only one of several kinds of rubber used in industry today, however. For more information on the various types of rubber, you can check out our types of rubber buying guide. If you’re more interested in sourcing EPDM rubber now, we can help with that too.

Is EPDM flame resistant?

Additionally, unlike silicone, it’s not flame resistant, and it’s also not recommended for food application. Finally, while EPDM has fair tear resistance, other rubbers such as SBR are better.

Is EPDM rubber waterproof?

It can resist abrasion, UV rays, o zone, aging, and weather, and it’s the most waterproof rubber available. EPDM is also steam resistant, functioning in up to 392 degrees F (200 C) without air, and chemical resistant, including to polar fluids.

Is EPDM Energy Efficient?

There is some debate regarding the energy efficiency, or lack thereof, of EPDM. Actually, the answer to this question depends primarily on location and membran e color.

How Is EPDM Roofing Installed?

There are three different installation methods for EPDM roofing systems:

What is the relative of EPDM?

The earlier relative of EPDM is EPR, ethylene propylene rubber, that contains no diene units and can only be crosslinked using radical methods such as peroxides. Dienes used in the manufacture of EPDM rubbers are ethylidene norbornene (ENB), dicyclopentadiene (DCPD), and vinyl norbornene (VNB). EPDM is derived from polyethylene into which 45-85 wt% ...

What is EPDM rubber?

EPDM is an M-Class rubber under ASTM standard D-1418; the M class comprises elastomers having a saturated chain of the polyethylene type (the M deriving from the more correct term polymethylene). EPDM is made from ethylene, propylene, and a diene comonomer that enables crosslinking via sulfur vulcanization. The earlier relative of EPDM is EPR, ethylene propylene rubber, that contains no diene units and can only be crosslinked using radical methods such as peroxides. Dienes used in the manufacture of EPDM rubbers are ethylidene norbornene (ENB), dicyclopentadiene (DCPD), and vinyl norbornene (VNB).

How cold can EPDM be?

As such, EPDM can be formulated to be resistant to temperatures as high as 150 °C, and, properly formulated, can be used outside for many years or decades without degradation. EPDM has good low temperature properties, with elastic properties to temperatures as low as -40 °C depending on the grade and the formulation.

What is EPDM compounded with?

As with most rubbers, EPDM is always used compounded with fillers such as carbon black and calcium carbonate, with plasticisers such as paraffinic oils, and has useful rubbery properties only when crosslinked. Crosslinking mostly takes place via vulcanisation with sulfur, but is also accomplished with peroxides (for better heat resistance) or with phenolic resins. High-energy radiation such as from electron beams is sometimes used for producing foams and wire and cable.

Why does EPDM rubber squeak?

EPDM seals can be a source of squeaking noise, due to movement of the seal against the opposing surface (and its attendant friction). The noise can be alleviated using specialty coatings that are applied at the time of manufacture of the seal. Such coatings can also improve the chemical resistance of EPDM rubber.

How many tonnes of synthetic rubber were produced in 2010?

Annual production of synthetic rubber in the 2010s has exceeded 10 million tonnes annually, and was over 15 million tonnes in both 2017 and 2018.

How much synthetic rubber is produced annually?

It is used as safety surfacing under playground play equipment (designed to help lessen fall injury). Annual production of synthetic rubber in the 2010s has exceeded 10 million tonnes annually, and was over 15 million tonnes in both 2017 and 2018.

How long does an EPDM roof last?

EPDM roof membranes remain stable over time and can have a life expectancy of over 50 years.** Made from synthetic rubber, EPDM roofing membranes have two primary ingredients, ethylene and propylene, which are derived from oil and natural gas.

What is the difference between white and black EPDM?

In southern climates, a white EPDM membrane helps save energy by reflecting heat and reducing air conditioning usage. In cold climates, a black EPDM membrane absorbs heat and helps to reduce heating costs.

When was Firestone EPDM installed?

Also, this year marks the 40th anniversary of the Firestone EPDM roofing membrane. It was installed for the first time in 1980 on the roof of Albo Manufacturing Co. in West Bend, Wisconsin.

How many options are there for EPDM?

There are three options for EPDM installation and each comes with its own performance benefits.

What is a resilient roof?

The Department of Homeland Security defines a resilient structure as one that can "adapt to changing conditions and withstand and rapidly recover from disruption due to emergencies.".

What is mechanically attached to a deck?

Mechanically Attached: The membrane is secured to the insulation and roof deck with fasteners. This is a fast and affordable installation method, particularly for wood and steel decks.

Is EPDM roofing good?

The longevity, durability, and value of an EPDM roof make it an excellent choice for almost any application. It's the definition of resilient, and can stand up to the whims of the natural world, from extreme heat to cold snaps to UV rays. Browse technical specs and product sheets for Firestone EPDM roofing membranes online. Then find a Firestone Sales Rep or licensed contractor near you to see why even after 40 years, No One Covers You Better™ than Firestone EPDM.

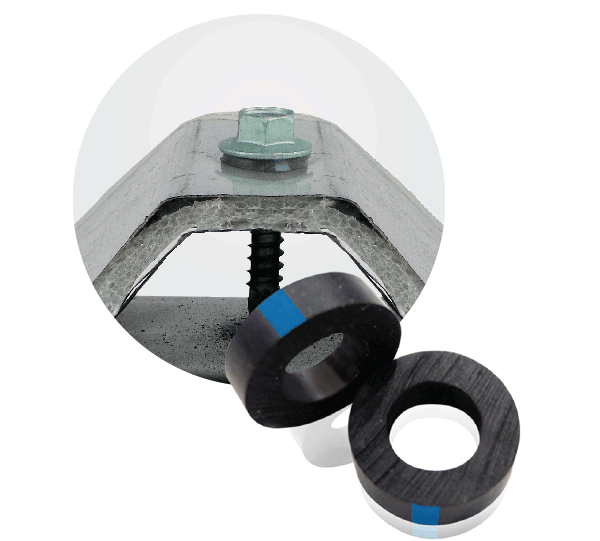

What is custom gasket?

At Custom Gasket Manufacturing, we specialize in manufacturing precision die-cut and molded EPDM rubber gaskets and seals for various industries and applications. Our commitment to outstanding quality and customer service has earned us a reputation throughout the world as an industry leader. To request a quote or learn more about EPDM gaskets, contact us today.

What temperature does EPDM rubber seal?

They can withstand harsh environmental conditions and are designed to provide reliable, long-lasting sealing capabilities over a wide range of temperatures from -60° F to 300° F.

What is EPDM rubber?

EPDM rubber gaskets are more resistant to wear from abrasion and are formulated to resist harsh chemicals such as acids and alkalis. EPDM gasket material is ideal for applications involving hydrocarbon oils and petroleum products, which typically produce swelling in many other gasket materials.

Why is EPDM unique?

EPDM is unique among elastomers because it remains flexible at very low temperatures and can be formulated to withstand extremely high temperatures. The material is also resistant to oxidation and the aging effects ...

What is the strength of EPDM?

EPDM possesses superior mechanical properties. It has a tensile strength ranging from 7 to 21 MPa, making it stronger than silicone, which has a tensile strength of 5 and 10 APa; nitrile, which is between 12 and 15 MPa; and neoprene, which is between 5 and 8 MPa.

Is EPDM good for outdoor use?

EPDM is a strong, durable, and cost-effective option that offers superior performance for use in many applications, including: Outdoor. Since EPDM gaskets are able to withstand extreme temperature fluctuations, water, and UV rays, they are ideal for use in outdoor applications. Electrical. The material’s high electrical resistance makes EPDM ...

Is EPDM gasket good for aging?

EPDM gaskets offer good electrical insulation and are highly resistant to wear, ultraviolet light, aging, wind, weather, and ozone. They are also color-stable and won’t stain mating surfaces.

What is the shrink rate of sulfur cured NBR?

A sulfur cured NBR may have a 2.4% shrink rate, while a peroxide cured might have a 3.02%. Polymer Type: Silicones and FKM compounds typically have a higher shrink rate than nitrile or EPDM compounds. Durometer: Softer durometers typically have a higher shrink rate than harder durometers.

What factors contribute to shrinkage?

Processing Factors That Contribute to Shrink Rate. Injection Pressure: Higher injection pressure can lead to a higher shrink rate. Mold Temperature: Large changes in the temperatures of incoming materials and molds may cause higher mold shrinkage. Pack Pressure: The shrink rate of plastic can be changed much more than thermoset rubber compounds.

Why should Purchasing Agents and Engineers work together?

Purchasing agents and engineers should work together to figure out what would be acceptable. Opening tolerance can prevent an increase in the cost of building new tooling and qualification for a deviation of the slight tolerance range.

Can plastic shrink more than rubber?

Pack Pressure: The shrink rate of plastic can be changed much more than thermoset rubber compounds. Higher pack pressures can still change the finished dimensions slightly. What You Need to Know About the Shrinkage of Different Rubber Polymers was last modified: June 6th, 2019 by John Tranquilli.