What is OSHA standard training?

Think Safety Always offers OSHA safety training at different levels for all their clients. The classes are available in English and Spanish to design and implement a safety program that complies with all OSHA requirements. The OSHA standard states that workers shall receive 30 hours of training before beginning work involving hazardous substances.

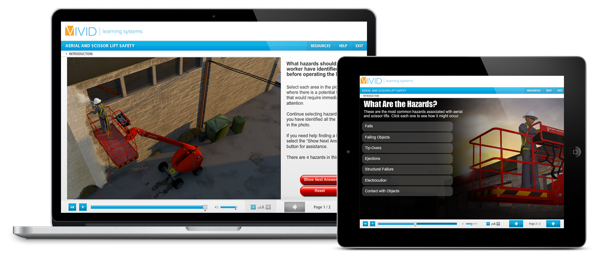

Does OSHA require aerial lift training?

Yes, aerial lift certification is required by OSHA. Your employees can’t legally operate aerial lifts, scissor lifts, aerial work platforms (AWPs), or mobile elevating work platforms (MEWPs) without training. 3) How long is aerial lift certification good for?

Who is required to have OSHA forklift training?

You cannot be certified to drive a forklift by ANY online vendor. The Occupational Safety and Health Administration (OSHA) requires forklift operators to be trained, and requires employers to “certify” that an operator has been properly trained and evaluated.

Why to use a scissor lift?

Why Use Scissor Lift Hire? A Scissor Lift is an essential piece of equipment used by many construction companies to offer a steady and level platform for worker lifting. It avoids workers from falling off or getting injured from high placed areas. In contrast with traditional ladders, this particular equipment is safer to utilize.

See more

What is the purpose of scissor lift stabilization?

To stop the scissor lift from tipping over or collapsing, en suring scissor lift stabilization is essential .

Why should a guardrail be inspected before operating a scissor lift?

The guardrail system installed should be inspected and confirmed fit for use before operating the scissor lift to ensure the safety of workers by increasing fall protection.

Is a scissor lift harness required by OSHA?

A scissor lift harness isn’t part of the OSHA scissor lift requirements for fall protection to improve worker safety, and can be considered as an additional fall protection device.

Do scissor lift operators need electrical training?

If an electrical source is unavoidable, scissor lift operators should be properly qualified to manage this and have received the required electrical training.

Is it the responsibility of the workers operating scissor lifts to ensure safe positioning?

Take note that it’s not solely the responsibility of the workers operating scissor lifts to ensure safe positioning. Traffic control measures should be implemented around the scissor lifts, as well as ground guides.

Can you be OSHA compliant without a safety harness?

You will still be OSHA compliant without safety harnesses if the guardrail is adequate, but we recommend using them when:

Is a scissor lift dangerous?

Scissor lifts (also classified as MEWPs [Mobile Elevating Work Platforms]) can be dangerous, so. only properly trained workers should be permitted to use and operate them.

What is OSHA letter?

OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations. This letter constitutes OSHA's interpretation of the requirements discussed. Note that our enforcement guidance may be affected ...

What is the ANSI/SIA standard for elevated driving?

The subject ANSI/SIA standard addresses requirements for elevated driving in Section 7.11.14, and manufacturer testing (movement of the vehicle while the scissor-lift is elevated) in Section 4.7.3. Section 7.11.14 (2) describes ideal conditions, where the driving surface is clear from obstacles, debris, drop-offs, holes, depressions, ramps and other hazards to ensure safe elevated travel. Thus, if those provisions are followed, the self-propelled elevated work platform may be driven without lowering the platform.

Does OSHA require a personal fall arrest system?

Therefore, OSHA would require the use of a personal fall arrest system (PFAS), only where the employer was not following the above-cited ANSI/SIA provisions .

Is it safe to extend a scissor lift?

This practice is not acceptable, since it is clearly unsafe and would jeopardize the safety of the employees. Extending the height by means of external devices such as platforms would render the stability test of the scissor-lift invalid. This position is consistent with Section 7.11.1 of the above cited ANSI/SIA standard which states, "Use of planks, ladders, or any other device on the aerial platform for achieving additional height or reach shall be prohibited."

Does OSHA cover scissor lifts?

OSHA addresses the fall protection to be provided to employees on self-propelled scissor-lifts through the application of the general duty clause (section 5 (a) (1)) of the OSH Act) because the OSHA standards do not cover such equipment.

What are the OSHA regulations for scissor lifts?

The OSHA regulations for scissor lifts center on three aspects: fall protection, stabilization, and positioning. Though these machines are designed to operate with ease, boasting user-friendly controls and smooth transportation for convenient access, only trained workers should be allowed to use the equipment.

What is a scissor lift?

Scissor lifts are platforms that are used in multiple industries to move workers vertically. The cross beams work in scissor-like fashion, transporting employees up and down as they complete their tasks. These lifts differ from aerial lifts, which include extendable boom platforms, aerial ladders, and vertical towers.

Why is it important to position a scissor lift?

Next, positioning the scissor lift to avoid electrocution and burns is vital. Even if a worker isn’t touching an energized pole or line, electricity can pose a danger. Power can leap from wire to the scissor lift or even directly to a worker. It’s imperative that employers monitor traffic and implement controls.

Why do scissor lifts need guardrails?

Scissor lifts must always have guardrails, and because a worker should never be leaning against or standing on the rails, they need to keep their work within easy reach . Guardrails are required to help improve working at height safety in the event of a misstep.

What happens if employers don't have OSHA?

If employers don’t have something like these handy and ready to use each day, they’re failing to be OSHA compliant. There’s no way to assure your workers are safe without a concrete method of checking equipment, limits, surroundings, protective gear, weather conditions, etc.

Is a scissor lift safe?

Scissor lifts are safe and reliable when used in compliance with the manufacturer’s instructions. If your workers aren’t trained, then a series of serious hazards may present themselves. In a single year, OSHA discovered ten preventable fatalities and over twenty injuries that were the painful and even permanent results ...

What is safety by design?

Safety by Design makes your and your workers’ safety their priority and mission. Request a consultation today and learn why we’re the leaders in the industry when it comes to assessing companies and designing business-wide efficiency with protection as our primary focus.

What is the responsibility of an employer to ensure that their scissor lift operators receive OSHA approved training and certification?

This is to ensure they understand scissor lift safety rules and procedures, including how to properly inspect and maintain the equipment, as well as understanding and following the manufacturer’s instructions. The training also needs to include the correct use of personal protective equipment (PPE).

What are the requirements for a scissor lift?

OSHA regulations 29 CFR 1926.451 (g) and 29 CFR 1910.29 (B) require scissor lifts to always be equipped with adequate guardrails that are in place under all conditions. This includes indoor and outdoor construction, water tower repairs, shipyard work – anywhere scissor lifts are used. The OSHA regulations prohibit workers from standing on, leaning against or using a scissor lift’s guardrails for stabilization, which are dangerous and serious safety violations. If guardrails aren’t available, fall protection harnesses should be worn by workers and securely fastened to the lift whenever the platform is more than10 feet above either the ground or a platform immediately below.

How Safe Are Scissor Lifts?

The report concluded that the majority of these accidents resulted from a lack of proper operator training in scissor lift stabilization, positioning, and fall protection. When operators are properly trained and certified by an OSHA approved training institution such as AerialLiftCertification.com, scissor lifts can be safe and valuable pieces of equipment . Allowing untrained and inexperienced workers to operate scissor lifts in the workplace however, can have devastating results, which is just one of the reasons why OSHA-compliant scissor lift safety training is so important.

How often should you follow OSHA safety regulations?

OSHA scissor lift safety regulations should be followed every day. Employers can provide ongoing training to help scissor lift operators comply with these regulations.

What is the foundation of scissor lift training?

The foundation of our training program is OSHA safety guidelines. Your scissor lift operators will get a proper grasp of important concepts to improve workplace safety.

How to prevent scissor lift from tipping?

To prevent scissor lifts from collapsing or tipping, both employers and operators need to ensure that all safety systems are in good working order and condition. Scissor lift operators need to be especially careful when driving the equipment to prevent colliding with other vehicles, as well as stationary overhead and ground-level obstacles. It’s also extremely important that the combined weight of workers, tools and equipment on board the platform never exceed the manufacturer’s stated load limits. Employers and workers are both responsible for following OSHA’s scissor lift safety measures to make sure the lift remains stable at all times.

How often do you need to get a scissor lift recertified?

It is mandatory for any worker that uses a scissor lift to receive proper training. OSHA requires scissor lift operators to get recertified every three years, too. If you have scissor lift operators on staff, you need OSHA-compliant training to ensure scissor lift safety.

What is an OSHA fire extinguisher?

This training is for any worker with access to a fire extinguisher, and those expected to use a fire extinguisher to extinguish small fires. OSHA defines a small fire as an "incipient stage fire", meaning, wastepaper basket-sized or smaller.

Who should have training on flammable liquids?

Employees who work directly with flammable liquids, either by moving, storing, or disposing of such liquids, should have this training.

What is Hazard Communication Training?

Hazard Communication training is for any employee who works with a hazardous substance or chemical, including some medications and vaccines, and any chemical requiring a Safety Data Sheet. The purpose of hazard communication training is for workers to understand how a chemical causes harm.

How long is a near proximity distance for OSHA?

Training is also required for any workforce where the working environment is outside the near proximity distance of an infirmary, clinic, or hospital; OSHA defines a near proximity distance of 3‐4 minutes for high-risk environments, and 15 minutes for office settings.

How often do you have to retrain for 1910.119?

For 1910.119 (Process Safety Management): new hire training and retraining every 3 years

When is retraining required?

Retraining whenever a new chemical hazard that workers have not previously received training for is introduced into work area

What is the responsibility of an employer to provide training to employees?

Employers have a responsibility to provide workforce training on appropriate response to certain types of emergencies that could affect working environments, including actions employees should take to protect themselves. Such emergencies include fires, unexpected chemical releases, natural disasters, incidents of violence, etc.

How to contact OSHA for scissor lift training?

If you have any questions about OSHA scissor lift training requirements or need to become compliant as soon as possible, please contact CMO online or call us today at (602) 277-0615. If you’re ready to master OSHA scissor lift requirements and get OSHA compliant as soon as possible, register your company with CMO now.

Why Is It Important to Comply with OSHA Scissor Lift Certification Requirements?

OSHA scissor lift certification requirements are put into place to help both employers and operators alike. It can help workers prevent accidents and protect their lives. And it can help employers protect themselves from fines and legalities.

How long does it take to get scissor lift certification?

Many companies have full scissor lift certification within a few days, depending on individual work schedules.

What are the components of a scissor lift?

Through its own research, OSHA has found that the majority of scissor lift accidents have been the result of one or more of three main components: fall protection, stabilization, and positioning. Let’s look at scissor lift safety tips associated with these components and how to prevent accidents: 1. Fall Protection.

What controls can be used to prevent contact between a scissor lift and workers or vehicles?

And, they must be aware of all overhead objects like door frames and beams that can come in contact with the lift. Traffic controls can be used to prevent contact between a scissor lift and workers or vehicles. Ground guides can be used when moving a scissor lift.

What is scissor lift?

A scissor lift is considered a type of aerial work platform (AWP) or mobile elevating work platform (MEWP), though those two terms are usually reserved for high-reaching aerial lifts.

Do all scissor lifts have the same certification?

You may believe that all scissor lift certification programs are identical. Upon close examination, you may discover you need to enroll your employees in a program that meets OSHA scissor lift certification requirements.

How to contact OSHA for scissor lift?

If you still have questions about OSHA’s scissor lift harness requirements or CMO’s other training classes, please contact us online or call us at (602) 277-0615 to speak with one of our OSHA experts who will be pleased to help you. Thank you for considering CMO.

What Are OSHA Harness Requirements for Scissor Lifts?

The regulation that requires wearing a harness in a scissor lift is OSHA standard 1926.451 (g). (1) ,which provides an overview of how and when to use fall protection and other PPE.

What Are Scissor Lift Harness Requirements?

It is an employer’s responsibility to do everything in its power to protect its scissor lift operators against falls and other workplace accidents. Scissor lift harness requirements help businesses do just that.

Does OSHA Require Workers to Wear a Harness on a Scissor Lift?

OSHA considers guardrails to be scissor lift fall protection. Assuming there’s an adequate guardrail system in place, scissor lift harnesses aren’t required by OSHA, but for all other situations, a personal fall restraint system is mandatory. At CertifyMeOnline.net, it’s our opinion that fall restraint safety systems should be used whenever possible.

Will a Harness Prevent Falls from Scissor Lifts?

Harnesses won’t stop falls from scissor lifts. They can, however, minimize their impact.

What is a scissor lift harness?

Scissor lift harness requirements define instances in which lift operators must wear a harness. Employers must provide their scissor lift operators with appropriate harnesses that work properly. They must also teach workers how and when to wear scissor lift harnesses.

Why do you need a scissor lift?

Scissor lift harness requirements are in place for a reason: to keep employees safe when they work at heights. Businesses that require workers to complete tasks at heights must learn and comply with OSHA harness requirements. That way, these businesses can protect their workers against falls from aerial lifts and other heavy-duty equipment.

Summary

Details

- The OSHA regulations for scissor lifts center on three aspects: fall protection, stabilization, and positioning. Though these machines are designed to operate with ease, boasting user-friendly controls and smooth transportation for convenient access, only trained workers should be allowed to use the equipment.

Scope

- As always, we present the following as a general list of requirements and by no means a comprehensive collection of regulations.

Safety

- Scissor lifts must always have guardrails, and because a worker should never be leaning against or standing on the rails, they need to keep their work within easy reach. Guardrails are required to help improve working at height safety in the event of a misstep. Employers must monitor and ensure that equipment is steady that no chance of tipping or even collapsing is possible. Firm, le…

Operation

- Workers should not be working directly underneath or even around the area while the lift is used. All personnel should pay attention to stationary objects near the lift, moving vehicles in the vicinity, and fixed, overhead beams, door frames, tree limbs, overhangs, etc.

Locations

- Selecting locations that do not pose the threat of overhead power lines (and within 10 feet, bear no electrical sources at all) is ideal. Workers should complete electrical training if theyre required to work in areas involving live wire, transformers, and other utilities.

Mission

- Safety by Design makes your and your workers safety their priority and mission. Request a consultation today and learn why were the leaders in the industry when it comes to assessing companies and designing business-wide efficiency with protection as our primary focus.