Does polycarbonate block the Sun?

Certain color polycarbonate sheets and panels with heat-blocking additives can absorb heat. This is done by filtering near-infrared rays, which reduce heat buildup from sun light. However, these heat blocking additives will not block visible light that can be perceived by the human eye.

Can You Heat polycarbonate sheets?

Generally, it is possible or rather appropriate to heat a pre-dried polycarbonate material up to a temperature of between 180°C to 190°C. The reason, in this case, is that at this range of temperature allows the sheet to form into complex shapes with tight curves as well as deep draw.

How does polycarbonate react to heat?

Polycarbonate does not respond to heat as well as other plastics. It tends to lose heat as it passes through the mold to the barrel and molding gun nozzle.

What material absorbs heat before transfer?

Common heat-absorbing materials include precious metals such as silver, copper and gold. Materials that conduct more heat are capable of absorbing heat before transferring it. ... The most conductive naturally occurring material is diamond, followed by other pure metals.

Does polycarbonate block heat?

While polycarbonate is versatile enough to meet a variety of design challenges, it's also extremely strong, provides effective insulation against heat, cold, and UV radiation, as well as offering unparalleled ease of installation with the added bonus of reduced costs.

What are the disadvantages of polycarbonate?

The main disadvantage of polycarbonate is that it isn't resistant to scratches. For example, if a branch should happen to fall on a patio canopy made of polycarbonate, it may be scratched. This problem can be solved by polishing the polycarbonate.

Does polycarbonate trap heat?

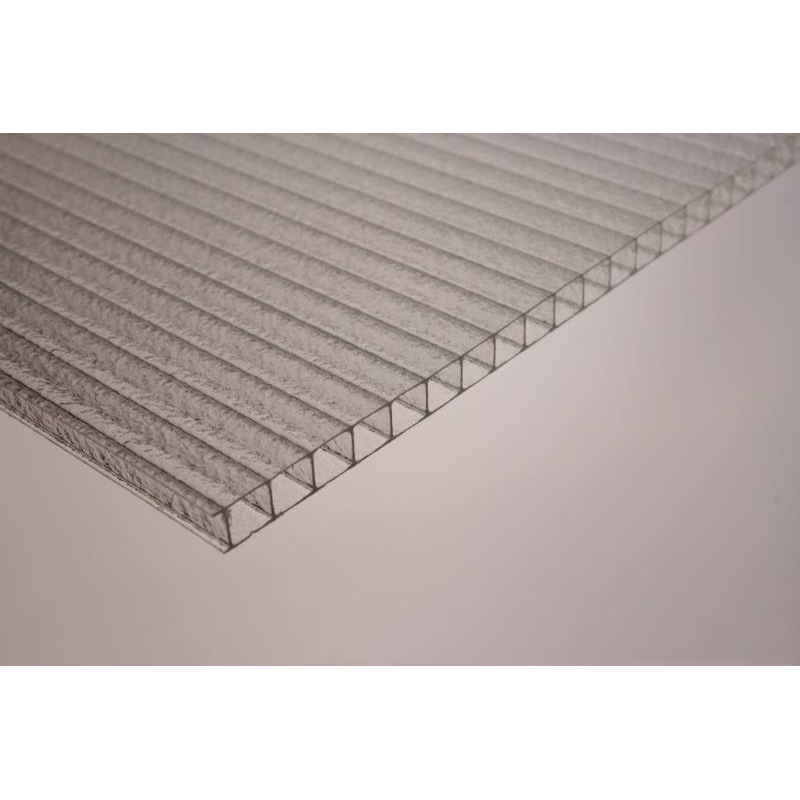

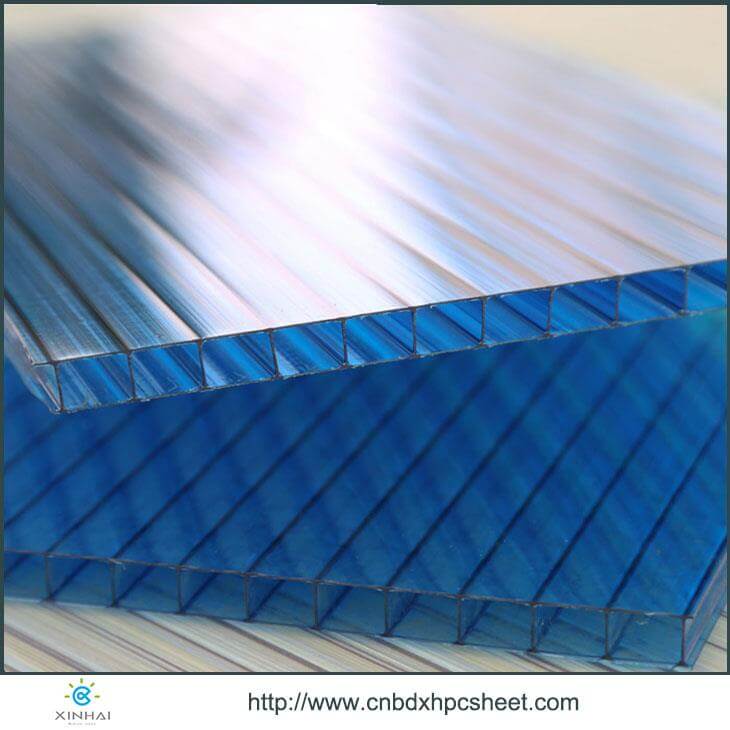

More insulation: Polycarbonate has the ability to retain heat better than glass. The twin-wall design has a double glazing effect with air pockets in between that decrease heat loss.

Is polycarbonate a better insulator than glass?

Polycarbonate sheet is also a superior insulator to glass, and installation can result in lower energy costs. Polycarbonate is practically unbreakable—especially when compared to most glass. Compared to safety glass, polycarbonate is 250 times more resistant to impact.

Is polycarbonate plastic heat resistant?

Polycarbonate also has very good heat resistance and can be combined with flame retardant materials without significant material degradation. Polycarbonate plastics are engineering plastics in that they are typically used for more capable, robust materials such as in impact resistant “glass-like” surfaces.

What is the lifespan of polycarbonate?

about 10 yearsThough polycarbonate is durable, it should be treated with UV protectant to prevent it from turning yellow or breaking down. With proper care, polycarbonate can last about 10 years, a fraction of how long glass lasts.

How do you reduce the heat under a polycarbonate roof?

Staying Cool under a Polycarbonate RoofGo high! By raising the roof height, you move any warm air further above head height. ... Invite in a cross breeze. If you keep one or both gable ends open it will allow any warm air to easily escape.Choose your roofing wisely. ... Install a fan.

Is polycarbonate good for a greenhouse?

The panels are designed to be long-lasting, so even after several hits from a ball or other knocks and scrapes, the average polycarbonate greenhouse should still be in good shape. The heat retention properties of this type of greenhouse are excellent, which is good news for any fruit and vegetables you want to grow.

Is polycarbonate fire resistant?

Polycarbonate offers a noted advantage over acrylic with respect to fire. Acrylic is considered a combustible material and performs much worse than Polycarbonate in fire tests. In comparison, Polycarbonate offers a much better combustibility grade and dripping grade.

Can you replace greenhouse glass with polycarbonate?

Acrylic and polycarbonate sheets can be used very effectively to replace glass greenhouse panels and shed windows – and these materials outperform glass in many ways.

Is 4mm polycarbonate OK for greenhouse?

4mm Twinwall polycarbonate is an ideal replacement for broken glass panels in your greenhouse. Thermally superior and 200x stronger than glass, polycarbonate is much lighter weight and easier to handle.

What is the melting point of polycarbonate?

The melting point of crystallized polycarbonate is about 230∼260℃ (Refer to Fig. 4・5・2‐2). The melting heat of the crystalline is 134J/g (32cal/g). The melting point of other resins is shown in Table 4・1・1‐1.

Is polycarbonate bad for the environment?

It never biodegrades since it is made of petroleum. The chemicals leach into the environment causing significant damage. Many of these chemicals are consumed by marine organisms and other animals resulting in a lot of damage.

Will polycarbonate yellow over time?

Unlike acrylic though, the colour clarity of polycarbonate does diminish over time and will adopt a yellow hue with prolonged exposure to the UV rays.

Is polycarbonate plastic toxic?

Exposure to BPA, used in the manufacture of polycarbonate and other plastics, has been shown to interfere with reproductive development in animals and has been linked with cardiovascular disease and diabetes in humans.

What can I use instead of polycarbonate?

Polyester. Polyester is one of the best alternatives to polycarbonate and is the closest to polycarbonates in features, according to Gerson Lehrman Group.

What temperature does polycarbonate go to?

Polycarbonate has a glass transition temperature of about 147 °C (297 °F), so it softens gradually above this point and flows above about 155 °C (311 °F). Tools must be held at high temperatures, generally above 80 °C (176 °F) to make strain-free and stress-free products.

What is the main polycarbonate?

The main polycarbonate material is produced by the reaction of bisphenol A (BPA) and phosgene CO Cl. 2. The overall reaction can be written as follows: The first step of the synthesis involves treatment of bisphenol A with sodium hydroxide, which deprotonates the hydroxyl groups of the bisphenol A.

How to make polycarbonate resin?

Main transformation techniques for polycarbonate resins: 1 extrusion into tubes, rods and other profiles including multiwall 2 extrusion with cylinders ( calenders) into sheets (0.5–20 mm (0.020–0.787 in)) and films (below 1 mm (0.039 in)), which can be used directly or manufactured into other shapes using thermoforming or secondary fabrication techniques, such as bending, drilling, or routing. Due to its chemical properties it is not conducive to laser-cutting. 3 injection molding into ready articles

Why are polycarbonate containers controversial?

The use of polycarbonate containers for the purpose of food storage is controversial. The basis of this controversy is their hydrolysis (degradation by water, often referred to as leaching) occurring at high temperature, releases bisphenol A :

How much polycarbonate is produced annually?

In this way, approximately one billion kilograms of polycarbonate is produced annually. Many other diols have been tested in place of bisphenol A, e.g. 1,1-bis (4-hydroxyphenyl)cyclohexane and dihydroxybenzophenone. The cyclohexane is used as a comonomer to suppress crystallisation tendency of the BPA-derived product.

Why are polycarbonate glasses used in pubs?

As more and more governments are restricting the use of glass in pubs and clubs due to the increased incidence of glassings, polycarbonate glasses are becoming popular for serving alcohol because of their strength, durability, and glass-like feel.

What is the structure of dicarbonate?

Structure of dicarbonate (PhOC (O)OC 6 H 4 ) 2 CMe 2 derived from bis (phenol-A) and two equivalents of phenol. This molecule reflects a subunit of a typical polycarbonate derived from bis (phenol-A).

Why is polycarbonate processed at high temperature?

Since polycarbonate is highly viscous, it is usually processed at high temperature to reduce its viscosity. In this process, the hot polymer melt is pressed through into a mold with high pressure. The mold when cools, gives the molten polymer its desired shape and characteristics.

What is Polycarbonate?

Polycarbonate is a high-performance tough, amorphous and transparent thermoplastic polymer with organic functional groups linked together by carbonate groups (–O– (C=O)–O–) and offers a unique combination of properties. PC is popularly used as an engineering plastic owing to its unique features that include:

How is polymer melt used?

The melt when cooled attains and maintains the shape acquired. This process is used to manufacture polycarbonate sheets, profiles and long pipes. Recommendations:

Why are polycarbonate blends so successful?

Polycarbonate blends are successful commercially for providing a right balance between performance and productivity.

What is polycarbonate property?

Protection from UV Radiations – Polycarbonates can be designed to block ultraviolet radiation and provide 100% protection from harmful UV rays.

What is the creep resistance of polycarbonate?

Polycarbonates’ creep resistance can be improved with the addition of glass- or carbon-fiber reinforcements. 5-40% of GF reinforcements can improve creep resistance upto 28 MPa at temperature as high as 210°F. Reinforced grades have better tensile modulus, flexural- & tensile strength as compared to standard PC grades.

When was polycarbonate first used?

Polycarbonate was first prepared in 1953 by Dr.H.Schnell of Bayer AG, Germany and by D.W. Fox of General Electric Company, USA. Main Characteristics and Properties of Polycarbonate.

What are the advantages of polycarbonate panels?

Polycarbonate panels are finding use in an increasing number of scenarios. They are virtually unbreakable and can withstand massive force. For this reason, they are used in the construction of bulletproof windows and police shields.

What is polycarbonate panel?

Polycarbonate is a thermoplastic that is exceedingly tough, resistant to ultraviolet rays, and provides an attractive look. It is available in clear and opaque forms, making it the ideal choice for construction and security-related purposes.

How long do polycarbonate panels last?

On top of that, polycarbonate factors are also resistant to sunlight, rain, and snow. This enables these panels to last in the outdoors for many years without showing signs of fading, yellowing, or discoloration.

Is polycarbonate more expensive than glass?

The high price is one of the major disadvantages of polycarbonate panels since it is much more expensive than glass and other plastics. As a result, many consumers consider opting for ABS (Acrylonitrile Butadiene Styrene), which is also considerably tough but has lower impact resistance and heat resistance.

Can polycarbonate panels be left translucent?

Depending on the needs of an organization or individual, these panels can be colored or left translucent, adding to the flexibility of use. Another favorable factor with polycarbonate panels is their high resistance to heat and cold.

Is polycarbonate abrasive?

Polycar bonate panels are not very resistant to scratching, marring, and abrasive surfaces . As a result, denting is possible on the surface if care is not taken. They are also highly sensitive to abrasive cleaners, alkaline cleaning products, and solvents.

Is polycarbonate good for greenhouses?

Combined with the excellent optical properties of polycarbonate panels for keeping out ultraviolet rays while letting in enough sunlight and heat, makes polycarbonate panels the material of choice for constructing greenhouses and plant nurseries. On top of that, polycarbonate factors are also resistant to sunlight, rain, and snow.

What is Thermoforming Polycarbonate Sheet?

This refers to the process of changing the shape and structure of a polycarbonate sheet using a wide range of methods.

Which industry uses thermoforming polycarbonate?

If you were never ware, let me tell you that the aerospace and aviation industry apparently dominates the use of thermoforming polycarbonate.

What is thermoforming equipment made of?

Most of the equipment that you see and use in various offices and other business premises are made of thermoforming polycarbonate materials.

What is the process of vacuum and pressure forming of two sheets of polycarbonate?

So it happens that you have to use a separate mold on top and bottom platens. After the plastic sheet is molded, it stays in the molds then the two molds are brought together of course under high pressure.

How many molds does polycarbonate need?

You see, thermoforming polycarbonate often needs one mold half. So in essence, you will never require a lot of tools which in most instances normally increase the cost of the process. Thermoforming polycarbonate also provides you with a wide range of options when it comes to finishing, textures, and.

Why does thermoplastic sheet cool?

So the thermoplastic sheet cools as it retains the specifications of the mold that is forming it. In other words, thermoforming a polycarbonate is primarily a process of heating polycarbonate sheet to a particular temperature, always below its melting point. This heating goes to the extent of turning glassy or soft then later on stretching ...

What is thermoforming?

Thermoforming is one of such processes which enable you to create and attain a particular part into the desired shape and size. What I know is that in many instances you’ve seen several types of unique polycarbonate materials imagining how their formation came to place.

How to dry polycarbonate?

Dry the Poly Carbonate Quickly: When moisture is in the atmosphere, pellets on the polycarbonate can absorb moisture rapidly. Molding moist polycarbonate can cause splaying, while reducing the polymer’s impact and tensile strength. A desiccant drier should be used to dry the polycarbonate products to less than 0.02% moisture.

Why is polycarbonate delaminated?

Polycarbonate does not respond to heat as well as other plastics. It tends to lose heat as it passes through the mold to the barrel and molding gun nozzle. This can result in delamination. One solution to reduce this problem is to tune the molding equipment to proper temperature control constants. This will help stabilize the process quickly, and ensure faster polymer melting and processing.

Can polycarbonate adhere to endcap?

Purging is a task that should be done regularly. If not, it is possible that two different pieces of polycarbonate may adhere together. This can result in loss of material, and unnecessary expenditure of time, effort, and money. Other errors can also take place. The valve can adhere to the endcap.

Is polycarbonate a flame retardant?

Polycarbonate is a popular polymer, which consists of unique characteristics. It provides benefits of transparency, along with immense resistance to impact and heat. It has the capability to transmit light, and can be flame retardant depending on the grade. When it comes plastic injection molding, companies are always trying to find ways ...

Can polycarbonate screw be splayed?

If the screw is not designed for polycarbonate, then there can be a tendency for the polymer to splay. However, this can be eliminated by adding heat soak. The heat soak can soften the pellets in the feed section. Due to this, the polycarbonate will be able to handle the compression transition of the screw. These are the initial four tips you can ...

How to cut polycarbonate?

There are multiple ways to cut polycarbonate sheets using a fine-tooth blade including a circular saw, saber saw, or table saw. When using a circular saw or saber saw, clamp a straight-edge to the polycarbonate sheet to guide the saw and make sure you are steadily cutting the plastic.

What is polycarbonate used for?

Polycarbonate is popularly used for bulletproofing applications, protective gear, greenhouse panels, roofing panels, lights, signals, and safety glasses.

What Types of Polycarbonate Sheets Do We Offer?

Our team of in-house professionals custom cut clear polycarbonate sheets based on the exact specifications of your material needs. Choose from a wide range of polycarbonate options, including:

What is the Best Way to Cut Polycarbonate Sheets?

When cutting polycarbonate sheets the most effective type of blade to use in all cases is a fine-tooth blade. There are multiple ways to cut polycarbonate sheets using a fine-tooth blade including a circular saw, saber saw, or table saw. When using a circular saw or saber saw, clamp a straight-edge to the polycarbonate sheet to guide the saw and make sure you are steadily cutting the plastic. When using a table saw to cut polycarbonate move the sheets through the saw as you would a piece of plywood paneling. Alternatively, you can have our knowledgeable team conveniently cut your polycarbonate sheets to size to save time, wasted material, and reduce shipping costs.

What Kind of Saw Blade is Needed to Cut Polycarbonate Plastic?

It can be cut with a variety of common handheld, and table-mounted saw equipment. Fine tooth hollow ground blades and triple chip carbide blades are the best choices for cutting polycarbonate and producing a high-quality finish.

Does Polycarbonate Absorb Heat?

Certain color polycarbonate sheets and panels with heat-blocking additives can absorb heat. This is done by filtering near-infrared rays, which reduce heat buildup from sun light. However, these heat blocking additives will not block visible light that can be perceived by the human eye. For reference, sunlight emits three main types of rays: Ultraviolet rays, visible light, and infrared rays that generate heat.

Does Polycarbonate Discolor?

Polycarbonate will slowly change color and start to yellow if it is directly exposed to UV rays for a very long time. To prevent this, some polycarbonate sheets use a special coating that inhibits the transmission of UV light, providing additional protection to the polycarbonate sheet.

What is the ability to absorb heat and then store it for a long period of time?

The ability for a material to truly absorb heat and store it is different from its ability to conduct it. Conduction is the ability to take in heat and allow it to pass into something else. Materials that can absorb heat and then store it for a long period are called phase-change materials, which store heat when changing between solid ...

How is heat conductivity measured?

Heat conductivity is measured in units of watts per meter per Kelvin or (W*m^-1*K^-1). Diamond has the most at 2,200 watts per meter per Kelvin of any natural material, and is able to go up to 41,000 when enriched by certain isotopes. Pure silver gets up to 430 watts per meter per Kelvin, copper up to 400 and gold up to 318. The isotope helium II has over 100,000 watts per meter per Kelvin, making it the most conductive.

Which material is the most conductive?

The most conductive naturally occurring material is diamond, followed by other pure metals. The most conductive material known is helium II, a superfluid isotope of helium that has over 45 times the absorption of natural diamonds.

Overview

Applications

Polycarbonate is mainly used for electronic applications that capitalize on its collective safety features. A good electrical insulator with heat-resistant and flame-retardant properties, it is used in products associated with power systems and telecommunications hardware. It can serve as a dielectric in high-stability capacitors. Commercial manufacture of polycarbonate capacitors mostly stop…

Structure

Carbonate esters have planar OC(OC)2 cores, which confers rigidity. The unique O=C bond is short (1.173 Å in the depicted example), while the C-O bonds are more ether-like (the bond distances of 1.326 Å for the example depicted). Polycarbonates received their name because they are polymers containing carbonate groups (−O−(C=O)−O−). A balance of useful features, including tem…

Production

The main polycarbonate material is produced by the reaction of bisphenol A (BPA) and phosgene COCl 2. The overall reaction can be written as follows:

The first step of the synthesis involves treatment of bisphenol A with sodium hydroxide, which deprotonates the hydroxyl groups of the bisphenol A.

(HOC6H4)2CMe2 + 2 NaOH → Na2(OC6H4)2CMe2 + 2 H2O

Properties and processing

Polycarbonate is a durable material. Although it has high impact-resistance, it has low scratch-resistance. Therefore, a hard coating is applied to polycarbonate eyewear lenses and polycarbonate exterior automotive components. The characteristics of polycarbonate compare to those of polymethyl methacrylate (PMMA, acrylic), but polycarbonate is stronger and wi…

History

Polycarbonates were first discovered in 1898 by Alfred Einhorn, a German scientist working at the University of Munich. However, after 30 years' laboratory research, this class of materials was abandoned without commercialization. Research resumed in 1953, when Hermann Schnell at Bayer in Uerdingen, Germany patented the first linear polycarbonate. The brand name "Makrolon" was registered in 1955.

Potential hazards in food contact applications

The use of polycarbonate containers for the purpose of food storage is controversial. The basis of this controversy is their hydrolysis (degradation by water, often referred to as leaching) occurring at high temperature, releases bisphenol A:

1/n [OC(OC6H4)2CMe2]n + H2O → (HOC6H4)2CMe2 + CO2

More than 100 studies have explored the bioactivity of bisphenol A derived from polycarbonates…

Environmental impact

Studies have shown that at temperatures above 70 °C, and high humidity, polycarbonate will hydrolyze to bisphenol A (BPA). After about 30 days at 85 °C/96% RH, surface crystals are formed which for 70% consisted of BPA. BPA is a compound that is currently on the list of potential environmental hazardous chemicals. It is on the watch list of many countries, such as United States and Germany.

Applications

Advantages

- Ultraviolet blockage is another great plus with polycarbonate panels. This quality makes these panels the material of choice for constructing overhead covers and awnings in commercial establishments. These panels are also very light when compared to glass, acrylic, or other plastics. This results in easy transportation, installation, and lower labor costs -- three big bonus…

Appearance

- Polycarbonate panels are available in clear glass-like shades and also opaque shades for better cover. Depending on the needs of an organization or individual, these panels can be colored or left translucent, adding to the flexibility of use.

Cost

- High price is one of the major disadvantages of polycarbonate panels since it is much more expensive than glass and other plastics. As a result, many consumers consider opting for ABS (Acrylonitrile Butadiene Styrene), which is also considerably tough but has lower impact resistance and heat resistance. ABS is much lower in price and can offer a go...

Durability

- Polycarbonate panels are not very resistant to scratching, marring, and abrasive surfaces. As a result, denting is possible on the surface if care is not taken.

Risks

- They are also highly sensitive to abrasive cleaners, alkaline cleaning products, and solvents. Therefore, you must be very careful to avoid substances containing acetone, benzene, or any other such organic solvents. The manufacturing process is not very environmentally friendly, requiring very high processing temperatures. Also, it requires phosgene, which is known for its il…