Why use wire mesh in concrete slabs?

Wire Mesh Reinforcement Wire mesh is commonly placed in concrete slabs for two primary reasons: -to resist breaking apart and deteriorating when the slab eventually does crack -to increase flexural strength of the slab.

How do you reinforce concrete with wire mesh?

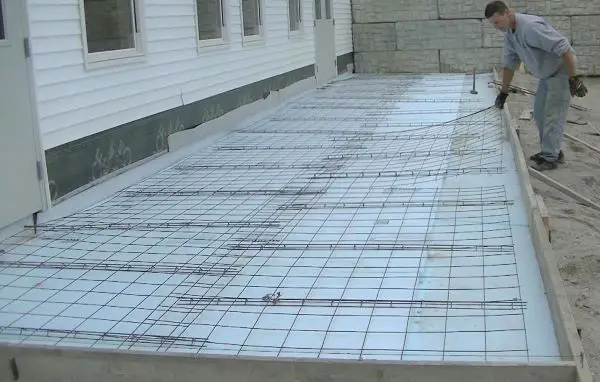

When pouring concrete for driveways, foundations, or floors, two common ways to reinforce concrete are to use wire mesh or fibers. Using wire mesh is a common method to reinforce poured concrete. The wire mesh makes a square grid pattern which is laid down before the concrete gets poured.

What type of wire mesh should I use for a concrete driveway?

We carry galvanized and welded stainless steel wire mesh suitable for concrete reinforcement. Not only that, but with our in-house measuring, laser cutting, and roll slitting services, you can get the exact size you need for your driveway.

Should I use mesh wire or steel reinforcement for my project?

If your permit or building ordinances require steel reinforcement, mesh wire is a great choice. If you’re working on residential projects or your own home, the need for support varies.

Should you use wire mesh in concrete?

When it comes to concrete, you can't avoid cracks entirely, but wire mesh reinforcement will help hold the material together when they do occur. Also, it will help evenly distribute the weight of cars on your driveway. The added strength of steel is especially crucial if your subgrade isn't up to par.

Is it better to use wire mesh or rebar in concrete?

While rebar is suitable for use in any structure poured at any angle, wire mesh is only suitable for horizontal slabs. Wire mesh is generally cheaper to use than rebar since it utilizes only thin steel bars. Rebar's cost depends on the bar's thickness and thus varies considerably.

Does wire mesh keep concrete from cracking?

Concrete Wire Mesh Helps Minimize Concrete Slab Cracking and Settling. In fact, the best way to minimize the chance of cracking and settling is to use fiber mesh and WWM in the same slab. Like any structural product, WWM won't do its job unless it's installed correctly.

Does fiber mesh in concrete work?

Fiber mesh reduces shrinkage and cracking of concrete. Similar to other reinforced concrete, it improves the tensile strength of concrete. Reduces the chance of spalling since the fiber inside melts and allows the water content in concrete to escape. It is easy to include fibers in the concrete mix design.

Do you need wire mesh for 4 inch slab?

No, they do not. Larger projects or slabs may need steel reinforcement to provide support or extra strength. Wired mesh can also help resist cracking. However, not every piece of concrete necessarily requires that extra boost.

Do you need rebar for 4 inch slab?

No, rebar is not required for a 4-inch slab of concrete on grade. A 4-inch-thick slab cast on the ground and in constant touch with it will float, with no need for rebar. For concrete that is 5–6 inches thick, rebar is suggested.

How deep should mesh be in concrete?

Although short joint spacings alleviate the need for reinforcement, wire mesh will allow for increased distance between joints if correctly placed in the upper portion of the slab, at least two inches below the surface.

How do you strengthen concrete?

One of the best ways to strengthen concrete is to start with the concrete mixture. By adding more cement to your mixture you'll end up with a stronger final product. There are many different types of concrete mixtures out there, some of which are specifically designed to create stronger concrete.

Do you need rebar for 5 inch slab?

Rebar is not necessary for every concrete project. The general rule of thumb is that if you are pouring concrete that is more than 5 inches in depth, you are probably going to want to add in some rebar to help reinforce the entire structure.

What are the disadvantages of fiber reinforced concrete?

The disadvantages of fibre-reinforced concrete include the following: Rain might expose the fibres. Fibres randomly orient in the concrete and could result in poor quality concrete, if not uniform. Reinforced concrete is about 10% to 15% costlier than non-reinforced concrete.

Is fiber better than wire mesh?

With the latest technology available in synthetic fibers, fiber reinforced concrete sometimes has greater flexural strength than wire mesh reinforced concrete. Another benefit of fiber reinforced concrete is that it requires fewer construction joints than traditional unreinforced concrete.

Should I put fiber in my concrete?

Adding fiber to a concrete mix (like our OzFlat Series) can reduce cracks, increase impact resistance, and generally increase concrete strength. With a wide array of fibers to choose from, reinforced concrete will do well in anything from residential patios & driveways to commercial parking lots.

Is Fibermesh as good as rebar?

Concrete fibermesh is incredibly effective at reinforcing concrete because the different fibers within it are designed to stop this from happening. These include steel fibers that reduce cracking by intersecting cracks and stopping them from growing, and polypropylene which protects the concrete against stress.

What can I use instead of rebar in concrete?

Alternatives to Rebar Concrete ReinforcementStainless Steel Concrete Reinforcement. Stainless steel rebar is often touted as a replacement for standard steel rebar. ... Engineered Bamboo Reinforcement. ... Glass fiber reinforced polymer (GFRP) Rebar. ... Plastic Fiber. ... Helix Micro Rebar Concrete Reinforcement. ... Many Options.

How thick should a reinforced concrete driveway be?

As for thickness, non-reinforced pavement four inches thick is standard for passenger car driveways. For heavier vehicles, a thickness of five inches is recommended. To eliminate standing water, the driveway should be sloped towards the street a minimum of one percent, or 1/8 inch per foot, for proper drainage.

Why Does Wire Mesh and Chicken Reinforced Concrete?

If wire mesh or chicken wire is used, the mesh inside the concrete absorbs the stresses that would usually hurt the concrete. While adding to some of the strength that the concrete can already handle well, giving the concrete more strength overall.

What Are The Risks Of Using Wiring Mesh Or Chicken Wire To Reinforce Concrete?

Now that we know why you should be using a mesh of something inside your concrete, we need to look at why it may be a bad idea to use wiring mesh or chicken wire. If you are going to be using these materials instead of regular rebar, there are a few dangers.

Does Wire Mesh Make Concrete Stronger?

Yes, any reinforcement laid out in a grid pattern within the concrete will strengthen it than pouring pure concrete. This is because concrete handles compressive and shear stresses but does not do well with tensile strength, which is stress when put under tension.

What kind of wire mesh is used for concrete?

We carry galvanized and welded stainless steel wire mesh suitable for concrete reinforcement. Not only that, but with our in-house measuring, laser cutting, and roll slitting services, you can get the exact size you need for your driveway.

How Do You Attach Wire Mesh to Concrete?

Whether you're hiring a contractor or are planning to tackle the project yourself, it's helpful to have a general idea of the process. Find the basic steps of reinforcing a concrete driveway below.

What is the best reinforcement for concrete?

Most often, rebar ( steel bars) are embedded into the concrete before it hardens. However, galvanized panels of welded wire mesh can be used as an alternative to rebar.

Can you use wire mesh in a driveway?

As long as a driveway or parking lot isn't regularly driven on by semi trucks and other heavy vehicles, welded wire mesh will work well. If you're like a lot of homeowners, you might be wondering if you can go without steel reinforcement altogether. While there are some exceptions, reinforcing a driveway is generally worth the investment.

When to add steel reinforcement to a subgrade?

After compacting the fill into the subgrade, it's time to add steel reinforcement.

Does wire mesh help with concrete?

When it comes to concrete, you can't avoid cracks entirely, but wire mesh reinforcement will help hold the material together when they do occur. Also, it will help evenly distribute the weight of cars on your driveway. The added strength of steel is especially crucial if your subgrade isn't up to par.

What happens when concrete is set around wire mesh?

When the concrete has set around the wire mesh the concrete will end up with a reinforcing material inside that helps to prevent cracking during temperature changes and while the concrete is setting.

What is wire mesh?

The wire mesh is usually one layer of a two-dimensional grid that runs along the length and width of the poured concrete, but not the height. During the process of pouring the concrete, the workers will raise the wire mesh that has been laid down so it runs along the middle of the concrete height. When the concrete has set around the wire mesh ...

Why does concrete crack?

Concrete also can crack due to changes in temperature or unevenly distributed weight or stress. When pouring concrete for driveways, foundations, or floors, two common ways to reinforce concrete are to use wire mesh or fibers.

Is fiber mesh more cost effective than other materials?

Fiber mesh is also more cost-effective since there is less time involved in pouring and the material is used more efficiently. There has been concern among some contractors that the fiber mesh method can create a “hairy” finish due to some of the fibers protruding from the surface.

Is concrete good for commercial construction?

Choosing concrete for a residential or commercial construction project is a great way to ensure you are using a strong, durable material. With all the uses of concrete that are possible, there are several ways to make sure your concrete has the right strength for the job. Concrete changes density when it sets, making it vulnerable to cracking.

Is fiber mesh better than wire mesh?

In addition to providing a more thorough protection for your concrete pour, fiber mesh typically takes less time than wire mesh to use. This is because the wire mesh has to be carefully measured to fit the site of the pour and needs to hold up at a certain level during the process of pouring. Conversely, fiber mesh can be added straight to the mix, removing the need for an extra step while pouring. Fiber mesh is also more cost-effective since there is less time involved in pouring and the material is used more efficiently. There has been concern among some contractors that the fiber mesh method can create a “hairy” finish due to some of the fibers protruding from the surface. However, this is only temporary since they are often laid down flat when the trowels flatten the surface of the concrete, and any fibers that still protrude are quickly worn down or burned off by the sun if outside.

Why do you need wire mesh for concrete?

Wire Mesh. Wire mesh makes concrete more durable and increases its strength. The area in which the concrete will be laid down should be covered in mesh before pouring commences. As the concrete is poured, the wire mesh should be lifted up so that it’s positioned in the middle of the concrete in order to provide steel reinforcement.

What is concrete mesh?

Concrete mesh is ideal for reinforcing your slab, and it comes in two options: fiber mesh and wire mesh. Each of these types are sufficient in minimizing structural damage and cracking, but there are distinct differences between the two. Continue reading as we discuss when to use each type.

Why does concrete crack when pouring?

This is due to concrete’s lack of tensile strength, causing shrinkage to crack your slab. By understanding that these issues are going Read more

What is fiber mesh?

Fiber Mesh. Fiber mesh is made up of fibrous materials like synthetic fibers, glass fibers, natural fibers, and steel fibers. It is typically used in sidewalks, patios, and driveways. Rather than being laid down prior to the pour, this type of mesh is distributed evenly throughout the wet concrete. The purpose of fiber mesh is to reduce water loss ...

Why seal concrete?

Regularly sealing concrete maintains its longevity and durability for decades to come. Exterior surfaces need protection from the extreme temperatures, inclement weather, heavy impacts, or harsh abrasion. Interior surfaces benefit from sealants that offer protection Read more.

Is wire mesh better than fiber mesh?

Using wire mesh is typically a longer process than fiber mesh, because it requires time to overlap and must be laid twice. Keep in mind that the longer the project takes, the more it will cost you.

Why do you put wire mesh in concrete?

Wire mesh is commonly placed in concrete slabs for two primary reasons: -to resist breaking apart and deteriorating when the slab eventually does crack. -to increase flexural strength of the slab .

Why use wire mesh in slab?

Wire mesh in a slab can offer tensile/flexural strength to the concrete, spreading loads over more area.

What happens when you put mesh in the top 1/3 of a slab?

When placed in the top 1/3 of the slab, it will have increased flexural strength in between two point loads which bend either side of the slab downward . This is why it is common for some engineers to specify mesh in the upper and lower 1/3 of the slab both.

Why do you need mesh on bolsters?

Sometimes the engineer will require the mesh be placed on bolsters or chairs to assure the mesh will rest in the correct portion of the slab section. There are many kinds of wire mesh bolsters available; There are plastic standalone supports which support the mesh at intersecting wire. More commonly there are continuous steel bolsters which are laid parallel to each other as often as is required to support the mesh and any traffic on top.

What size is road mesh?

The above mesh sizes most commonly come in 8’ x 12.5’ or 8’ x 15’ sheets. Concrete pavement road mesh comes in different sizes than the above standard sheet mesh and is typically more heavy duty.

When is wire mesh installed in the lower 1/3 of the slab?

When wire mesh is installed in the lower 1/3 of the slab, it will have increased flexural (and in turn tensile) strength when one point load bends the slab downward.

Does steel mesh keep slabs from cracking?

A common thought process is that steel wire mesh keeps the slab from cracking. The accuracy of this theory depends on where the wire mesh is placed and how well the subgrade is designed and compacted:

Does sidewalk matter if it's concrete?

TOM: In a sidewalk it doesn’t matter as much as if it was a concrete patio or driveway. However, having said that, I will tell you that it’s a better job if you use it.

Is concrete strong in compression?

See, concrete by itself is only strong in compression. It’s not strong in tensile strength. And what that means is it can easily crack. But if you have reinforcing steel bars that go through it or the wire mesh, that makes it a lot stronger. Now in a sidewalk, typically they don’t put metal mesh in; they don’t put the mesh in there.

Do you put mesh in a sidewalk?

Now in a sidewalk , typically they don’t put metal mesh in; they don’t put the mesh in there. But if it was like a driveway or a patio, they would. And with a sidewalk, you usually pour it in more narrow pieces and you put expansion joints about every six feet or so or eight feet or so; so that if the slabs of concrete want to start to move, ...

What gauge wire should I use for concrete?

A: I advise welded wire fabric (6x6x10x10 mesh – 6″x6″ pattern with #10 gauge wire both directions), low slump concrete which means poured pretty dry (not a lot of water mixed in), 3,000 psi concrete, air entrained (little air bubbles in the cured concrete allowing water freeze expansion to fill the air bubbles instead of expanding inside the concrete causing stress), and soft cuttings (meaning weakening the concrete with tools in a straight line inviting the concrete to crack in a predetermined, usually straight, line when it cracks.

What type of concrete should I use for a 12x12 slab?

Remember … all concrete cracks …. soft cuts define where they crack. For a 12×12 exterior slab …I advise 4″ of compacted stone sub-grade, wire mesh, no fiber, low slump concrete, air entrained, 3,000 psi mix, and soft cuts creating a four-square pattern. The slab will definitely crack on the four-square lines but you will have done all you could. The rest is up to mother nature. Good luck. I wish you many wonderful times enjoying your new concrete space.

Where to put rebar on a driveway?

also put the rebar in the other heavy load areas like down the driveway for extra support. The fiber mesh strengthens the concrete and the steel rebar reinforces the extra load areas.

Can you put crushed stone under a concrete slab?

I suggest you invest in a 4″ crushed stone, compacted base under the slab. This is the true strength of any pavement. If the sub-grade or rock under the slab is done correctly … then the concrete behaves solidly. Many homeowners worry about the concrete, which is the skin, and miss the opportunity to make the crushed stone base (structure) the solid structure beneath the slab (skin).

Is 12x12 mesh good for concrete?

Fiber mesh can adversely affect the finish depending on whether you want a swirl finish, boom finish or exposed aggregate stone finish. The fiber mesh is good stuff but can stick up above the concrete surface and look fuzzy.

Can you use fiber mesh on a 12x12 slab?

All concrete cracks. All concrete shrinks. Soft cuts allow the installer to plan the event rather than have some random, angled crack which looks like a mistake. You can add the fiber mesh too for added insurance and it will strengthen the slab. I would rather you use the wire mesh, low slump concrete, and soft cuts. Your 12×12 is pretty small for more than this.

How thick is steel mesh?

The wires form a square, grid-like pattern. Like the rebars, mesh comes in varying sizes and thicknesses. The most common size is 1/8″ thick (4 mm) and 6″ long by 6″ wide (150 mm x 150 mm).

Is concrete needed for a construction project?

In almost any modern construction project, a certain amount of concrete is necessary to get the job done. It’s firm, sturdy, and reliable when you know how to use it. Sometimes, the bigger the construction project, the stronger you need your concrete to be.

Do steel slabs need reinforcement?

The main slabs that require the steel reinforcing mesh will be those that expect a heavy workload. Anything from a lot of foot traffic, walls, or other foundational pieces will need that extra strength.

Is mesh wire good for steel?

If your permit or building ordinances require steel reinforcement, mesh wire is a great choice . If you’re working on residential projects or your own home, the need for support varies. Take note of the project, the ground underneath, and the purpose of the concrete. All of these factors will help you decide if and how much reinforcement you need.

Do you need steel mesh for driveway?

If you’re working on something residential like a pathway or a shed floor, you likely don’t need the reinforcement. Even some driveways don’t need the steel mesh, but most recommend it since vehicles weigh quite a lot.

Do you need steel reinforcement for concrete?

No, they do not. Larger projects or slabs may need steel reinforcement to provide support or extra strength. Wired mesh can also help resist cracking. However, not every piece of concrete necessarily requires that extra boost.

Why use fiber reinforced concrete instead of wire mesh?

Using fiber-reinforced concrete instead of wire mesh concrete decreases the costs on-site, specifically in the amount of labor needed and the time taken to pour the concrete. Fiber-reinforced concrete does not require the time-consuming task of measuring, cutting, and placing wire mesh and is thus much faster and cleaner to pour.

How to Use Fiber Mesh in Concrete?

Fiber mesh concrete is easy to work with and doesn’t require specialized site personnel in the same way that wire mesh reinforced concrete does. It does not require a specialized concrete mix design – the fibers are added to the standard mix design. As long as the concrete is sufficiently cohesive to prevent segregation, the fibers will disperse through the mix design and remain in place.

Why does concrete have a ridged profile?

As the concrete sets, the resulting crystalline structure forms around the macro fibers, gripping on to them in the process. In areas where the concrete experiences large tensile forces, cracks would start forming. Without macro fibers present in the mix design, these cracks would travel through the structure’s profile, usually leading to failure. When macro fibers are included in the mix design, they halt these cracks’ progress by holding the two sides of the crack together. That’s the reason for the ridged or stepped profile – it allows for better grip on the concrete.

What is wire mesh?

Wire mesh is the traditional method of improving concrete’s flexural strength in flooring applications. Here, a large sheet of wire mesh is placed in the area where the slab will be constructed and kept in place with spacers and wire ties. Once the wire mesh is in place, fresh concrete is poured onto and around the mesh. It is consolidated and compacted, usually with poker vibrators.

Is fiber mesh concrete cheaper than wire mesh?

Fiber mesh concrete is often cheaper than wire mesh concrete. The maintenance cost involved in warehousing decreases since the need for construction joints decreases or is eliminated. Compared to wire mesh concrete, it requires less space on-site and fewer deliveries, freeing up precious space and decreasing traffic.

Is fiber reinforced concrete stronger than unreinforced concrete?

Fiber-reinforced concrete is stronger than unreinforced concrete. Compared to wire mesh reinforced concrete, it usually has the same flexural and compressive strength. With the latest technology available in synthetic fibers, fiber reinforced concrete sometimes has greater flexural strength than wire mesh reinforced concrete.

Does fiber reinforcement increase flexural strength?

The addition of macro fiber reinforcement to concrete increases flexural in the same manner that wire mesh reinforcement does. This is ideally suited to flooring applications, where the floor slabs are not suspended but at ground level. While strong in compression, concrete is weak in tension and thus prone to cracking in areas where flexural strength is needed. Adding fiber reinforcement to the concrete formulation improves flexural strength and reduces the need for construction joints.