The ½-inch impact wrench is the best size for changing car tires. A 3/4-inch or even a 1-inch impact wrench could be an option, but unless you are working on a big truck, construction site or in a commercial setting, it’s a bit overkill. I definitely recommend sticking with either the 3/8-inch or 1/2-inch option.

Full Answer

What type of impact wrench should I buy?

The ½-inch impact wrench is the best size for changing car tires. A 3/4-inch or even a 1-inch impact wrench could be an option, but unless you are working on a big truck, construction site or in a commercial setting, it’s a bit overkill. I definitely recommend sticking with either the 3/8-inch or 1/2-inch option.

How many lbs torque impact wrench is good?

You must fall in trouble unexpectedly as long as you do not know about the proper size of impact wrench for removing lug nuts and tightening lug nuts. I suggest using 3/8 or 1/2 inch impact wrench because these two sizes will fulfill your maximal requirement.

How do I know what size Allen Wrench I Need?

Aug 16, 2021 · For easy understanding, we have grouped the sizes of impact wrenches below into how often people use them. Most Commonly used impact wrench sizes: ½-inch, 3/8-inch, and ¼-inch. Least commonly used impact wrench sizes: ¾-inch and 1 inch. Now we will move into a detailed explanation on these wrenches and their uses.

How to lubricate an impact wrench?

Mar 09, 2020 · In this regard, what size impact wrench do I need? Impact wrenches that are ½ inch in size are a standard tool found in auto shops. This size wrench is the correct size for auto repairs, such as suspension and tire jobs. For construction sites, the ½ inch impact wrench is the perfect size for small to medium assemblies and disassemblies.

What size impact do I need to remove lug nuts?

What size impact wrench do you need to change a tire?

How strong of an impact wrench do I need to remove lug nuts?

What is the most common size impact wrench?

Is 450 ft-lbs enough to remove lug nuts?

Will a 1/4 inch impact driver remove lug nuts?

How many pounds should you torque lug nuts?

| Hardware Bolt or Stud Size | Typical Torque Range in Ft/Lbs | Minimum Number of Turns of Hardware Engagement |

|---|---|---|

| 12 x 1.25 mm | 70 - 80 | 8 |

| 14 x 1.5 mm | 85 - 90 | 7.5 |

| 14 x 1.25 mm | 85 - 90 | 9 |

| 7/16 in. | 70 - 80 | 9 |

How much torque do you need in an impact wrench?

Can I use my impact driver to remove lug nuts?

Whats bigger 3/8 or 1/2 impact wrench?

How much torque does a 1/2 impact have?

What is good torque for an impact driver?

What is a 3/8 inch impact wrench?

3/8 inch impact wrench is a much smaller impact wrench and able to work even in tight spaces. It is a light-weighted and compact tool. It’s the second most popular impact wrench among the users. Before using it, you have to think more about the connection between the bolt and maximum torque, which it can generate with the size. For M10 bolt, the wrench should produce 66.38 ft-Ibs maximum torque, and the bolt size is M14, the wrench should offer 191.77 maximum torque. We got two types of styles: pistol grip and inline grip styles.

What size impact wrench should I use for lug nuts?

I suggest using 3/8 or 1/2 inch impact wrench because these two sizes will fulfill your maximal requirement.

What is impact wrench?

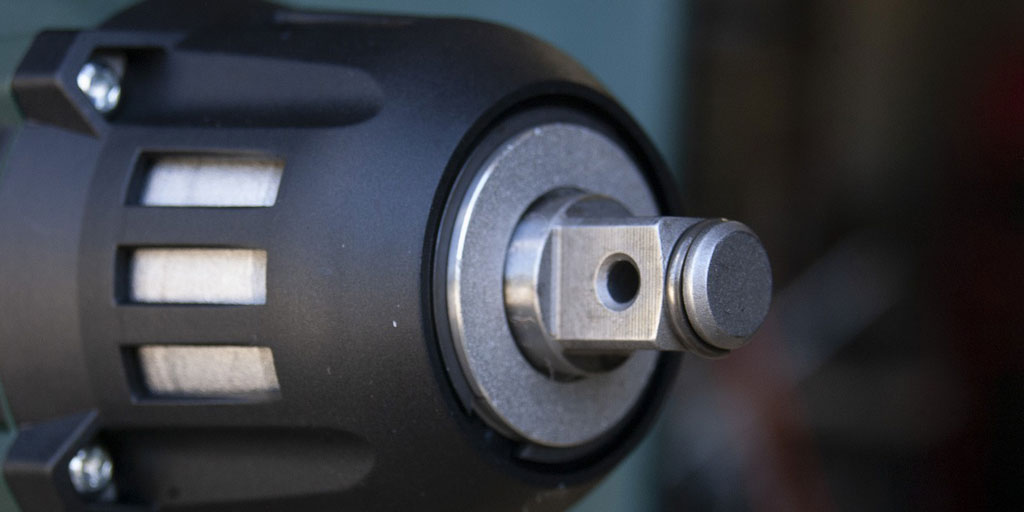

Impact wrenches are useful tools that can help break loose stubborn bolts or nuts or tighten bolts and nuts. Beginning users may have a hard time determining what size wrench to use for what type of project. These few tips on selecting the appropriate sized wrench can help ensure a successful and easier job.

Why use a larger wrench?

Using a wrench of a larger size in order to gain more torque than what is required is not beneficial, but actually detrimental to your tools and task. When using a larger wrench that offers more torque than you need, you can over tighten a nut or bolt that can lead to cross-threading, cracking or breaking. Stick with the correct size of wrench and socket for your task to ensure you are not doing more harm that good. Also, using a socket in your wrench that is not the correct size for the wrench can be detrimental as well. Even though a socket may seem that it fits the impact wrench, it may not be properly fitted or aligned into the wrench. Using an incorrect socket can be unsafe and can wear or break internal parts of the impact wrench.

How much does an impact wrench weigh?

Plus, this class of impact wrenches is small and light. Most weigh less than 3 lbs with a battery inserted. This makes these tools particularly helpful when you need to work overhead for any length of time. Lower pricing on most sub-compact tools also makes them a great choice.

Do impact wrenches have torque?

Since impact wrenches come in all shapes and sizes and offer a wide range of torque output, it can be tough to settle on just one. Around the shop, you might have (or need to have) a variety of impact wrenches. Different applications simply call for more or less torque. We look at each major category of impact wrench to help figure out which types ...

Do impact wrenches use pneumatic power?

A lot of Pros, if not most of them, still use pneumatic power to drive their impact wrenches —and for good reason. Pneumatic impact wrenches weigh less, cost less, and typically offer more torque. While cordless models have recently increased their torque output, it comes with a steep price. On the downside, pneumatic impact wrenches are still tethered to hoses and require large (and often loud) compressors.

What is an impact wrench?

The solution: an impact wrench. This is a tool that uses mechanized torque to effortlessly remove (and tighten) nuts and bolts. Specifically, a motor inside of the impact wrench speeds up the mass, and when you push that against whatever you’re trying to fasten or loosen, the job is done quickly. It sounds great, but the truth is, many impact ...

Is an electric impact wrench good?

Electric impact wrenches are the weakest of the three, but that doesn’t mean that they don’t pack a powerful punch. They’re good enough for the vast majority of home workshops – unless you’re dealing with heavy machinery, an electric one will suffice.

What is hydraulic impact wrench?

Hydraulic impact wrenches use hydraulic oil to produce exorbitant amounts of torque. Even for mechanics, this amount of torque will be overkill. The only places that need the power of hydraulic impact wrenches are industrial sites, and sometimes construction sites. The wrench is hooked up to a hydraulic system, so usually, ...

What to do if you don't have a high torque impact wrench?

If you are not doing projects that require high-torque impact wrenches, you might want to consider the amount of storage space you have. In this case, if you have limited space, you might want to go with something smaller like a pancake air compressor.

What are the factors that determine if an air compressor is a good fit for you?

These include horsepower, CFM, and PSI. So it is important that you keep these things in mind while shopping around for an air compressor.

How to determine air compressor power?

For that reason, it is difficult to determine an air compressor’s power just by looking at its size. However, you can still judge if a compressor is powerful enough by looking at these four things: 1 Power rating in Horsepower (HP) 2 CFM – Amount of airflow from the air compressor 3 Pounds per Square Inch (PSI) – Pressure of airflow 4 Tank size in liters

Tip 1 – Use The Correct Size

- Using a wrench of a larger size in order to gain more torque than what is required is not beneficial, but actually detrimental to your tools and task. When using a larger wrench that offers more torque than you need, you can over tighten a nut or bolt that can lead to cross-threading, cracking or breaking. Stick with the correct size of wrench and socket for your task to ensure you are not …

Tip 2 – Size Determines Design

- It is helpful to know that the size of an impact wrench also determines its design, handle location and features. The smaller wrenches, such as the ½ inch size, are going to have a pistol grip handle that resembles a drill grip. The larger impact wrenches, such as the ¾ inch wrench, will have a D or T handle, which allow the user to get a firmer grip to power against the increased torque of the …

Tip 3 – When to Use ½ Inch Wrenches

- Impact wrenches that are ½ inch in size are a standard tool found in auto shops. This size wrench is the correct size for auto repairs, such as suspension and tire jobs. For construction sites, the ½ inch impact wrench is the perfect size for small to medium assemblies and disassemblies. The average torque for a ½ inch impact wrench is 300 ft/lbs w...

Tip 4 – When to Use ¾ Inch Wrenches

- Impact wrenches that are 3/4 inch in size are suitable for heavier equipment. Most commonly, this size wrench is found in shops that work on large equipment and work trucks. For construction sites, the 3/4 inch impact wrench is the preferred size for large or major assemblies and disassemblies. The average torque for a 3/4 inch impact wrench is 1200 ft/lbs, which is more th…