Why is it called a Jersey barrier?

Concrete barriers were used on some roadways in California in the 1940s, but the term “Jersey barrier” stuck because of the structure’s widespread introduction on the highways of New Jersey, beginning in 1955. By the end of the decade the size and shape of the barriers were refined.

What is the size of a Jersey barrier?

Jersey barriers are generally 32 inches high, and two-feet wide at the bottom. Then the unit will curve to a width of approximately 6 inches at the top. At low-angle impacts, the barrier’s shape is designed to minimize sheet metal damage by allowing a vehicle’s tires to ride up the barrier’s lower slope.

How do crash-protective Jersey barriers work?

Crash-protective Jersey barriers are designed to redirect sideswipe energy. If a line of post-like bollards was used as a highway median, a shallow-angle crash might shred the vehicle and create extra flying debris.

What is the difference between Jersey barriers and bollards?

Jersey barriers are short traffic guiding “walls” of roughly the same height as bollards, often used on highways. Though related by function, they have different strengths as perimeter protection. Bollards are often chosen because they don’t impede foot traffic.

What are jersey barriers called that?

The Jersey Barrier — also known as a Jersey Curb, K-rail, or Jersey Wall — refers to the barricades you see along the center and sides of highways, at construction sites, in parking lots, and pretty much anywhere traffic is being directed.

Who invented jersey barriers?

Stevens Institute of TechnologyJersey barrier / InventorDevelopment and use. The Jersey barrier, also called New Jersey wall, was developed at the Stevens Institute of Technology in 1950s (introduced in current form in 1959), New Jersey, United States, under the direction of the New Jersey State Highway Department to divide multiple lanes on a highway.

How is a Jersey barrier made?

A typical Jersey barrier is made of steel-reinforced poured concrete. The embedded steel reinforcements protrude from each end, allowing the barriers to be linked together with additional concrete that can be poured on site. In this way, the barriers can be made permanent.

How does a Jersey barrier work?

Jersey barriers are generally 32 inches high, and two-feet wide at the bottom. Then the unit will curve to a width of approximately 6 inches at the top. At low-angle impacts, the barrier's shape is designed to minimize sheet metal damage by allowing a vehicle's tires to ride up the barrier's lower slope.

How heavy is a Jersey barrier?

The most common concrete jersey barricade size used is: 10 ft Long x 24 in Wide x 32 in High and weigh approximately 4,000 lbs.

What are the green things on highway dividers?

CLEVELAND — You've probably seen the green plastic-looking things on top of concrete barriers on the highway. They're called plastic glare shields -- and some of us here have noticed, they're looking a little rough lately. If you've seen more of these broken on the side of the road this winter…

How are jersey barriers moved?

A barrier transfer machine, also known as zipper machine or road zipper, is a heavy vehicle used to transfer concrete lane dividers, such as jersey barriers, which are used to relieve traffic congestion during rush hours.

How big is a Jersey barrier?

Dimensions: 12ft long x 24in wide at base x 34in tall. 12ft 6in long x 24in wide at base x 32in tall. weigh approximately 5,200 – 5,500lbs.

What is an Alaska barrier?

Similarly, the largest barriers, which stand around 20-foot-tall (6.1 m), are called Alaska barriers. Unlike the Jersey barrier, which has sloped sides at the base, some Texas and Alaska barriers have a rectangular ledge base, usable as a bench for sitting or resting and approximately knee-high for a typical adult.

Where are jersey barriers used?

Jersey barriers are the sloped steel-reinforced concrete barriers often used as highway medians or roadside barricades. They are also sometimes used to demark lanes, provide perimeter protection around work zones, or to channel pedestrians.

What is the most common barrier used?

The strong-post W-beam is the most common barrier system in use today. It consists of wood posts and wood blockouts or steel posts that support a W-beam rail element blocked out from the posts with routed timber or composite blockouts.

What is the most common barrier used drivers ed?

Barricades, vertical signs, concrete barriers, drums and cones are the most common devices used to guide drivers safely through work zones.

What is the most common barrier used in Texas?

Jersey Barrier This is the most common kind of PCTB (Precast Concrete Traffic Barrier).

What is a krail?

What Does K-Rail Mean? A K-rail is a modular concrete or plastic traffic barrier used to separate lanes of traffic. They are commonly used to reroute vehicular traffic during roadworks and delineate the construction zone.

What is the most common barrier used safety shape barrier shape freeway cone concrete shape?

Concrete safety shape barriers or concrete median barriers (CMB) are one of the most commonly used types of median barriers on highways of United States. These barriers are designed to minimize the crossover of vehicles into on-coming traffic on divided highways.

How much do bin blocks cost?

Customers frequently call to buy highway barriers, but after speaking with a representative about intended use, typically decide to use bin blocks instead. Highway, or Jersey, barriers sell from between $500 to $700, whereas large concrete blocks are available under $150.

Why are Jersey barriers used?

The basic reason why people choose Jersey barriers is that the New Jersey profile redirects a vehicle that hits it. This makes the vehicle’s wheels and sheet metal on the impacting side ride upward to prevent vehicle rollover. The ability of these barriers to absorb proportional impacts and the ease of taking up desired designs and shapes, they are commonly accepted by the public. Hence, they are named Jersey barriers and are still acceptable, because they adequately pass crash tests administered by the National Highway Traffic Safety Administration.

When were concrete barriers first used?

In fact, these barriers made their first appearance on a treacherous stretch of California mountain highway in 1946. These barriers are used to minimize the need for maintenance on a very narrow median and to help trucks stay out of oncoming traffic. In 1949, Jersey first introduced their barriers which were 18 inches tall and looked like a short wall with curbs on both sides. These barriers made in Jersey met with some success reducing head-on collisions and the injuries on highways fell by 75%. It is also reported that these concrete barriers reduced the overall accident rate and fatal highway accidents by 20%

How high are road barriers?

These original barriers measured 19 inches high and 30 inches wide, with 2 inches buried in the road to provide stability. Each was anchored to the roadbed by steel dowels and consisted of a 2-inch thick outer layer of white concrete to make it more visible at night. Though the initial barriers were somewhat successful in reducing the impact of collisions, New Jersey state highway engineers continued to tinker with the design, creating progressively larger prototypes based on amounts of observed accidents (as opposed to performing controlled crash testing). Eventually, in 1959, they settled on a standard barrier height of 32 full inches above the pavement with a 24-inch-wide base. The base is 3 inches high and is followed by a 13-inch side slope before the barrier becomes vertical. These barriers would be implemented in various states, but would bear the name of the state in which they were developed.

What is a Jersey barrier?

Jersey Barriers are designed to redirect a crash, using the car’s momentum to absorb the impact and slide the vehicle up parallel along the side of the barrier to prevent a rollover. In high-speed crashes with small cars along Jersey Barriers, however, there is a greater likelihood that the car will roll over, so an alternate barrier was created. According to the Federal Highway Administration, the F-Shape barrier has the same 3-inch-high base, but features a side that slopes 10 inches above the pavement— three inches less than the side slope of the Jersey Barrier—and is thus able to better absorb proportional impacts from smaller chassis to prevent a rollover. Though the F-Shape is generally preferred, the use of Jersey Barriers—as well as other barrier designs, including constant slope, single slope, and vertical—are still acceptable, because they adequately pass crash tests administered by the National Highway Traffic Safety Administration.

When were concrete barriers first used?

Concrete road barriers were first used in California in 1946; they replaced the standard (but weak) wood beam guardrails on the treacherous Grapevine section of the state’s Ridge Route highway —the home of the original “Dead Man’s Curve”—where the roads had a 6 percent downgrade that led to many head-on collisions.

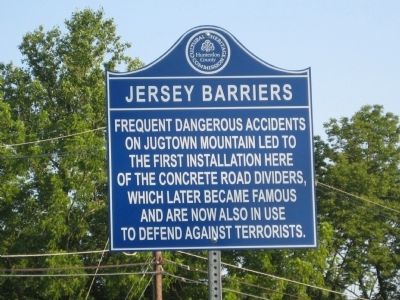

When did New Jersey adopt concrete barriers?

Then, in 1949 , the state of New Jersey adopted comparable concrete structures and installed preventative parabolic median barriers on the Jugtown Mountain section of US Route 22 in Hunterdon County, which had a similarly hazardous downgrade to the Ridge Route highway.

Is the Jersey barrier a F shape?

Though the F-Shape is generally preferred, the use of Jersey Barriers— as well as other barrier designs, including constant slope, single slope, and vertical—are still acceptable, because they adequately pass crash tests administered by the National Highway Traffic Safety Administration.

What is the Ohio Department of Transportation's mandate for precast concrete barrier walls?

The Ohio Department of Transportation (ODOT) mandates specific design requirements for their precast concrete barrier walls. ODOT has marked all compliant precast concrete barrier walls with "350", indicating that they adhere to the requirements laid out in the National Cooperative Highway Research Program's Report 350.

What is the purpose of the Jersey barrier?

The design of the Jersey barrier was specifically intended to minimize damage in incidental accidents and reduce the likelihood of a car crossing into oncoming lanes in the event of a collision. In common shallow-angle hits, sheet-metal damage is minimized by allowing the vehicle tires to ride up on the lower sloped face. Head-on vehicle collisions are minimized by gradually lifting the vehicle and pivoting it away from oncoming vehicles and back into traffic heading in its original direction.

What is hollow polyethylene?

Hollow polyethylene barriers have been developed for short-term applications where portability is important. These plastic barriers are normally filled with water after placement on-site to provide a moderate level of crash protection, then emptied prior to removal. They are not designed to deflect vehicles, so vehicles may penetrate the barriers. These barriers can also be filled with sand at the cost of reduced portability.

Why are Jersey barriers important?

It is designed to minimize vehicle damage in cases of incidental contact while still preventing vehicle crossovers resulting in a likely head-on collision. Jersey barriers are also used to reroute traffic and protect pedestrians and workers during highway construction.

What are the two rectangular notches on a forklift?

Designs with two rectangular notches at the bottom (through the short axis) allow for forklift-style lifting by front-end loaders. Barriers meant for short-term placement, especially in military and security barrier uses, might include steel rebar loops embedded in the top surface for rapid hook-and-cable system lifting.

What is the F shape of a barrier?

The F-shape is generally similar to the Jersey barrier in appearance, but is taller, with somewhat different angles. The UK equivalent is the concrete step barrier. First tested in 1968 by the then Department of Highways in Ontario, Canada, the Ontario Tall Wall is a variant of the Jersey barrier. Standing at 42 inches (107 cm), it is 10 inches (25 ...

Why was the Qaddafi fence called Qaddafi Blocks?

The fence used the barrier as sturdy base to prevent protesters from toppling the fence around the security zone at the Metro Toronto Convention Centre. The U.S. military nicknamed the devices "Qaddafi Blocks" after truck bomb attacks in Beirut in 1983 resulted in more widespread use in military installations.

Jersey Barriers: What They Do

As many of you know, a Jersey barrier is a safety and traffic control barricade that one finds in the center of highways, in parking lots, along the sides of roadways, and in other areas. And while the Jersey name stuck, they were being produced in other states, as well, most notably California.

In the Pacific Northwest

No doubt, commuters in our region of the country have seen Washington State Department of Transportation (WSDOT) and Oregon Department of Transportation (ODOT) traffic barriers. These are simple but effective precast concrete barriers. They help keep our community’s drivers safe while also keeping traffic flowing smoothly and efficiently.

How wide is a Jersey barrier?

Jersey barriers are generally 32 inches high, and two-feet wide at the bottom. Then the unit will curve to a width of approximately 6 inches at the top. At low-angle impacts, the barrier’s shape is designed to minimize sheet metal damage by allowing a vehicle’s tires to ride up the barrier’s lower slope. It is essentially designed to prevent the vehicle from rolling over, careening over the barrier, or being bounced back into traffic.

Why are Jersey barriers important?

Jersey barriers have helped to increase and maintain safety on numerous roadways since the 1950s. Set up as walls which separate lanes of traffic, they are specifically designed to minimize damage and reduce the likelihood of a car crossing into oncoming lanes.

What are plastic barriers used for?

Plastic barriers are now frequently used not only for road work, construction zones, and water and sewer projects, but also at airports and garages (for access denial). They have also been used immediately following floods or other natural disasters and they have been used by the National Guard and the Army Corps of Engineers as a portable retaining wall.

What is the purpose of Jersey Barriers?

And they have moved beyond their traditional purpose of preventing auto accidents. These barriers are now also used for public safety purposes in many other situations, including construction projects, emergencies, and in defense against potential terrorism threats.

How fast can a tractor trailer hit a Jersey barrier?

Test results have shown that a tractor trailer, impacting a Jersey barrier at a 15 degree angle at 60 miles per hour will be successfully redirected. There are a number of variations of the Jersey barrier, some with slightly different dimensions and angles, but all adhere to the same goals and principles.

What happens when a vehicle's front bumper hits a barrier?

At higher impact angles, the vehicle’s front bumper will impact the barrier’s upper sloped face and slide upwards. When the vehicle’s wheels contact the lower sloped face, the lift reduces the friction between the tires and the paved surface; this helps to bank and redirect the vehicle.

When were concrete barriers first used?

Concrete barriers were used on some roadways in California in the 1940s, but the term “Jersey barrier” stuck because of the structure’s widespread introduction on the highways of New Jersey, beginning in 1955. By the end of the decade the size and shape of the barriers were refined. Engineers at the state highway department analyzed accident results to alter the barriers’ dimension to increase their effectiveness.

How much do Jersey barriers weigh?

Concrete and steel Jersey barriers weigh 390 to 440 lbs per foot , depending on materials and manufacturing processes. A good, easy to remember rule of thumb is that a 10-foot barrier will weigh about 4000 lbs. Although 10 feet is standard, barriers come in many different lengths.

What is the difference between a bollard and a jersey barrier?

Bollards are short traffic guidance posts often used on sidewalks and around buildings. Jersey barriers are short traffic guiding “walls” of roughly the same height as bollards, often used on highways. Though related by function, they have different strengths as perimeter protection.

What are the colors of Jersey barrier?

The most popular tend to be high-visibility options like red and white stripes, or orange. Crash-protective Jersey barriers are designed to redirect sideswipe energy. If a line of post-like bollards was used as a highway median, a shallow-angle crash might shred the vehicle and create extra flying debris.

Why are Bollards used?

Though related by function, they have different strengths as perimeter protection. Bollards are often chosen because they don’t impede foot traffic. Bollards around a perimeter don’t create pedestrian bottlenecks, whereas Jersey barriers might. Bollards are often used as perimeter protection around entrances to stadiums or other large buildings ...

Why are Jersey barriers carved through the bottom?

Jersey barriers often have channels carved through the bottom to allow water to pass through. Steel connectors protruding from either end to allow the barriers to be linked together.

Why are barriers needed?

Barriers are a final measure added to contain the explosive force of traffic accident should other safety measures fail. What type of barricade is needed depends on several factors: Engineers consider the type of accident or event likely to occur, the needed permeability through the barrier, and the aesthetics of a landscape.

How many head on collisions were there in 1955?

Gathering accident data made it clear barriers made a huge difference; in 1955 before barriers were installed, one region saw 15 serious head-on collisions in one year. After barriers like California’s were installed, there was only one such collision over the next 3-1/2 years.