How do I organize my workbench?

- Start with a Clean Slate. The first thing you should do when you begin to organize your workshop is to wipe your slate clean.

- Build Your Shelves.

- Open Shelving.

- Budget Conscious Shelving.

- Get Creative with Gutters.

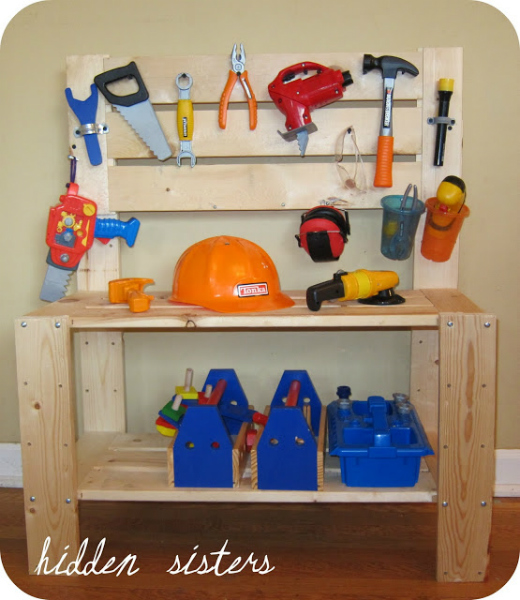

- Pegboard.

- Organizing Cords.

- Copper Tubing.

How do you organize a kitchen workbench?

Nov 10, 2021 · Use drawers or jars for extra storage — If your workbench has no built-in drawers, you can use metal or plastic drawers so you can easily organize accessories and favorite power tools. Another idea is to use tin cans or Mason jars to hold small objects such as nails, bolts, and nuts. What does every work bench need?

How do you organize a pegboard Workbench?

How do I organize my work bench? Start with a Clean Slate. Build Your Shelves. Open Shelving. Budget Conscious Shelving. Get Creative with Gutters. …

How can I make my workbench more useful?

5 Best Workbench Pegboard Ideas These pegboard organization ideas make it simple to keep your workbench ship-shape. Put the tools you use most often at eye-level where they're easiest to grab. Place your next most-used tools toward the bottom of …

How do you organize a PVC pipe Workbench?

Here are some tips on how to get your workshop organized to let you work on your projects without clutter. Start with a Clean Slate. Build Your Shelves. Open Shelving. Budget Conscious Shelving. Get Creative with Gutters. Pegboard. Organizing Cords. Copper Tubing. Subsequently, question is, how do you organize a small woodshop? Organize your work areas

How do I organize my garage work bench?

0:442:59How To Set Up a Workbench | Tips for Planning a Garage WorkshopYouTubeStart of suggested clipEnd of suggested clipUse an open storage system like a pegboard and hooks to keep the tools you use most often withinMoreUse an open storage system like a pegboard and hooks to keep the tools you use most often within reach adding bins to the pegboard is a great way to keep up with loose screws or nails.

What do you put on top of a work bench?

Almost any lumber or sheet good can be used to top a workbench. The main factors in choosing a bench top material are the function of the bench and the desired effect.

What do you put in a workbench drawer?

0:1411:13Simple Way to Add Drawers to Any Workbench | How To - YouTubeYouTubeStart of suggested clipEnd of suggested clipNo matter what type of workbench you have the first thing you're gonna want to do is take stock ofMoreNo matter what type of workbench you have the first thing you're gonna want to do is take stock of what you're working with I remove the lower shelf of the table. And I took some measurements.

How do I organize my mobile work bench?

1:443:00Mobile Workbench with Tool Organizer | House One - YouTubeYouTubeStart of suggested clipEnd of suggested clipOnce in position i screwed the shelves into the walls of the cabinet with pocket hole. Screws next iMoreOnce in position i screwed the shelves into the walls of the cabinet with pocket hole. Screws next i added the lower shelf and dividers using glue and pocket hole screws.

Is MDF good for a workbench top?

The best type of wood to use for a workbench top depends on how you intend to use it. MDF, Plywood, and hardboard are all good options. MDF is smoother which is good for moving heavy objects around easier. Also doesn't splinter like plywood.Sep 17, 2020

What do you cover a work bench with?

Leftover scraps of laminate flooring make a great workbench surface. Laminate is tough and easy to clean—dried glue or paint scrapes right off. If you fasten the laminate with small nails, you can easily pry it off and replace it every few years.Feb 25, 2022

How do you build a workbench with drawers?

0:1315:03Building a workbench with lots of drawers - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd it will fit an existing drawer. That's this thing here the frame for this workbench is it'sMoreAnd it will fit an existing drawer. That's this thing here the frame for this workbench is it's going to be made out of regular two by fours.

How do you make a drawer on a work table?

1:1012:52165308 views - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt's gonna be a cabinet that spans all the way across the table and has a set of four drawers onMoreIt's gonna be a cabinet that spans all the way across the table and has a set of four drawers on each side. So that's gonna be a pretty simple cabinet that'll just slide into the frame. For the right

How do I keep my workbench from sliding?

0:531:46How to Stabilize the Bench Balancing a Workbench - YouTubeYouTubeStart of suggested clipEnd of suggested clipAround. So what i ended up doing was getting these silicone trivets they're just silicone that youMoreAround. So what i ended up doing was getting these silicone trivets they're just silicone that you get your kitchen. Store. And i cut them down to shape to be a little larger in the bottom leg.

How do you clean a work bench?

Cleaning ProceduresAlways use the appropriate protective gear. At a minimum, wear latex gloves and goggles. ... Remove loose items from the laboratory work station. ... To meet the minimum, 10 percent bleach, mix one-part bleach with nine parts water. ... Dip a paper towel in the mixture and wipe the workbench surface thoroughly.Aug 16, 2019

Where do you put a workbench?

Try to place your bench against a wall and under a window, especially if you use hand tools. The wall braces the workbench as you are planing cross-grain and sawing. The light from the window points out the flaws in the work that your hand tools are trying to remove.Aug 3, 2020

How do I organize my toolbox?

How to Organize a Tool BoxStep 1: Sort All of Your Tools. In order to keep your tool box organized, you have to first gather all of the tools in one location. ... Step 2: Make Some Decisions. ... Step 3: Decide on a Storage Location. ... Step 4: Choose Your Tool Box or Storage Container.Dec 17, 2019

How long does it take to organize a workshop?

Setups vary wildly depending on one’s specialty, while organization and workflow are often an organic process that can take months or years to fine-tune. Advertisement.

Who is Michael Colombo?

Michael Colombo an interaction designer, inventor, and musician. Projects of note are the TapeScape audio robot, which was made almost entirely of a dual cassette deck, a method of casting plastic lumber from shopping bags, and the Magnetotron, an audio tape-based musical instrument. He is currently a Master’s candidate at NYU's Interactive ...

Is a pegboard good for a workshop?

If you're planning to go vertical in your workshop, pegboard can be your best friend. It's inexpensive, and there are so many add-ons you can buy that provide near-infinite organizational possibilities.

Step 1: It Is Working!

A little more sanding and some wipe-on poly. The screw holes were plugged with contrasting wood plugs. This isn't cabinet quality, but I wanted it to look good. The mahogany and maple make a nice contrast, even if the sanding is a pain. And my desk looks organized!

Step 3: Start Gluing and Fastening

I screwed the mahogany feet onto the maple legs so I don't have to worry about loosening. Wood sces will be covered with mahogany plugs. A technique I learned from my grandfather.

Step 3: Deconstruction

This was fairly straightforward I was going to try and reuse as much wood from my old workbenches as I could to keep cost down and to stay green. Keep in mind you may have to work around things such as vents,dust collection, etc. My cats use a vent we cut out to go in and out of the house so I have to keep that in mind.

Step 4: Hanging the Ledgers

First step here is deciding your overall height you want your new workbench to be I wanted mine to be around 40" so I hung my ledgers at 39 1/2" yours may differ. Next you need to find and mark your studs, they should be every 16" on center but if you have bump outs in the wall like I did they maybe be a little different around the bump . You do not have to put shelves in like I did but space them according to your needs I made mine just a tad under half the height of the whole workbench I drove a lag screw into every stud for both the top and bottom ledgers,unfortunately I forgot to take pictures during this step but you can still see the ledgers in these photos..

Step 5: Legs and Shelf Support

I decided to use 4x4's for my legs because I had enough of them left over from my old workbench and the extra strength couldn't hurt but you could easily get by with using 2x4's. After having all the ledgers hung its time to brace the legs I used 2x4's for this. I wanted my overall width to be 2ft so I measured accordingly and secured all the braces to the legs using 3" screws which was plenty strong.

Step 6: Bracing the Top

Bracing the underside of your workbench will make it more strong and will help it from warping/bowing over time. After I lucked out and found a 2x4 in my backyard that could span the length of my workbench I secured it with more 3" screws and was then ready for bracing the center. For bracing I used 2x4's cut at 45 degrees as well as a straight piece for the center. To secure them I screwed from the front and toe nailed the back braces making sure they stayed level with the top. Where the two sheets of plywood where going to meet i added in a scrap 4x4 to give me ample room to screw them down to so the seam wouldn't be two noticeable..

Step 7: Laying Down the Bench Top

At this step your workbench is almost complete but its missing one vital part, the bench top.

Step 8: Adding "extras"

Three things I wanted on my new workbench was a coat of polyurethane, pegboard, and a long shelf. First we will start with polyurethane, this step is totally up to you and its certainly not needed however after a couple years of abuse my old workbench was starting to flake apart.

Step 9: Organize Your Workspace

The Last step is to find a place for all your tools,parts,etc After cleaning out my tool box of unneeded things its much more organized and dosent take up much bench space. Having the pegboard to hang things from made staying organized a easy task.