What is the purpose of a spring washer?

Spring Washers General Description. To maintain fastener tension or “tightness.” To compensate for expansion and contraction or cold flow of material. To absorb intermittent shock loads and function as working springs capable of providing controlled reaction under dynamic loads.

Do helical spring washers help prevent bolts from loosening?

Don't take my word for it, here is NASA concluding they do not help prevent loosening and they have known about this for decades! “The typical helical spring washer … serves as a spring while the bolt is being tightened. However, the washer is normally flat by the time the bolt is fully torqued.

Can a helical spring washer lock a lock?

“The typical helical spring washer … serves as a spring while the bolt is being tightened. However, the washer is normally flat by the time the bolt is fully torqued. At this time it is equivalent to a solid flat washer, and its locking ability is nonexistent.In summary, a lockwasher of this type is useless for locking.”

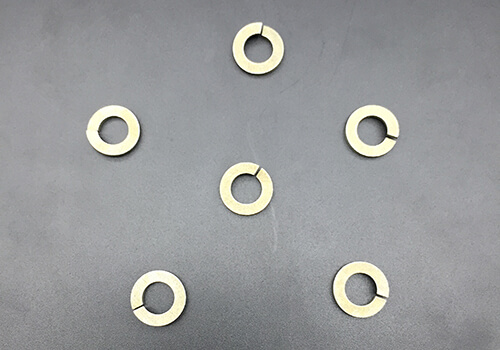

What is a split in a spring washer?

A spring washer has a split in the washer section that when tightened each side of the split bites into the nut and the mounting surface. This “bite” prevents any anti-clockwise rotation from occurring under vibration. There are two types of spring washer, square and rectangular section. This refers to the shape of the split end section.

What is scalloped periphery washer?

Washers with scalloped peripheries provide added, and sometimes controlled, spring reaction or deflection with some loss in load bearing capability. Like solid periphery washers, divided periphery washer will take an initial set when loaded to flat.

What is a square cone washer?

Square Cone (Square Dome) Washers enhance both load and deflection. Two distinct conical configurations are combined in the washer to provide: 1) live spring action under full design loads; 2) greater control as a result of a longer deflection period; 3) controlled tension; 4) improved load distribution. Load is delivered toward the outer periphery of the washer, making it ideal for clamping fragile materials and for spanning large clearance holes.

What are the characteristics of a spring washer?

Load and deflection are the key characteristics of a spring washer. How much will the washer deflect under a given load and at what point will it flatten.

What is a spring washer?

Spring washers are specifically designed to provide a compensating spring force and sustain a load or absorb a shock. Many design variations have evolved to best serve one or the other of these two basic functions or to optimize both functions in a single part within specific I.D./O.D. limits.

What are the environmental factors that affect the performance of a spring washer?

The environment in which a spring washer operates can effect the anticipated performance of the washer in terms of load bearing and reactive characteristics. Temperature and exposure to corrosive agents are the most important environmental considerations and washer material specifications must be made with these factors in mind.

What is the first criteria that must be determined as the design engineer evaluates available options?

Although listed last, the degree of precision and sophistication required by the application is the first criteria that must be determined as the design engineer evaluates available options.

What is spring tension in automated assembly?

Automated assembly requires some “play” or tolerance in the “fit” of components. Spring tension is needed to compensate for these tolerances.

How long have helical spring washers been around?

Helical spring lock washers have been in use for well over 100 years. They are still used on many applications in the belief that they will will "lock" the nut/bolt to the joint and prevent loosening.

What did Junker show about washers?

Junker originally showed in his work published in 1969 that these washers are ineffective in preventing loosening. Joints containing these washers have come loose resulting in structural failure leading to both material and human loss.

What is a locking washer?

The Basics of Locking Washers. A locking washer is a type of washer that’s designed specifically to prevent the bolt with which it’s used from loosening. Like other washers, they’ll distribute the load of the fastened object or objects more evenly. Locking washers go one step further, though, by “locking” the bolts in place.

How do locking washers work?

How Locking Washers Work. Locking washers work by exerting downward tension. When inspecting a locking washer, you may notice that it doesn’t have a complete circular shape. While most traditional washers are circular, locking washers have a slightly different shape. They consist of a semi-raised piece of circular metal.

What are the different types of washers?

Some of the most common types of locking washers include the following: 1 Split washers 2 Spring washers 3 Wedge washers

What is a washer in place?

With a washer in place, the load of the fastened object or objects is distributed more evenly. There are different types of washers, however, including locking washers.

Can a locking washer loosen?

Bolts can loosen over time. If installed in a machine or piece of equipment, a bolt may gradually loosen. Eventually, the bolt may work its way out of the threading hole where it was originally installed.

Why are washers important?

Washers are important. They ensure that a nut is installed properly and prevent softer materials from damage by distributing the pressure over a greater surface area.

Why do you need a washer on a bolt?

Washers are used on a bolt, between the installation material and the nut to provide a smooth even surface area for the nut to tighten against . They also help distribute pressure over a wider area.

What is lock washer?

A lock washer is a washer that adds extra tension to an assembly to make it less likely to loosen by accident or vibration.

How are washers sized?

Washers are sized by their inner diameter.

How to determine washer size?

A washers size is determined by the inner diameter of the washer.

When do you need a lock washer?

Lock washers are needed when the fastener assembly is subject to vibration or wherever back off is considered an issue.

Where is a washer used?

Typically, a washer is only used on the nut side of a bolt and nut assembly but more can be used depending on the application.