How does a thread insert work? Threaded inserts are cylindrical metal and plastic shapes placed in existing holes to provide a threaded track for bolts, screws and other fasteners. The outer shell of a threaded insert allows it to lock in place once put in the hole, and its inner cavity is threaded to allow for the insertion of fasteners.

What are threaded inserts?

Threaded inserts are a clever little invention with a coarse wood screw thread on the outside an a fine machine screw thread on the inside. It effectively allows you to use machine screws in wood and are invaluable for any item where you might want to remove the screw at a later date.

How do you put a thread in a door insert?

Use thread-in inserts in softer woods and plywood where their coarse outside threads cut easily into the surrounding wood. Simply drill a hole sized for the body of the insert, and screw it into place. In very hard woods, such as white oak and maple, or when the insert is close to the edge...

What is the use of TIME SERT insert?

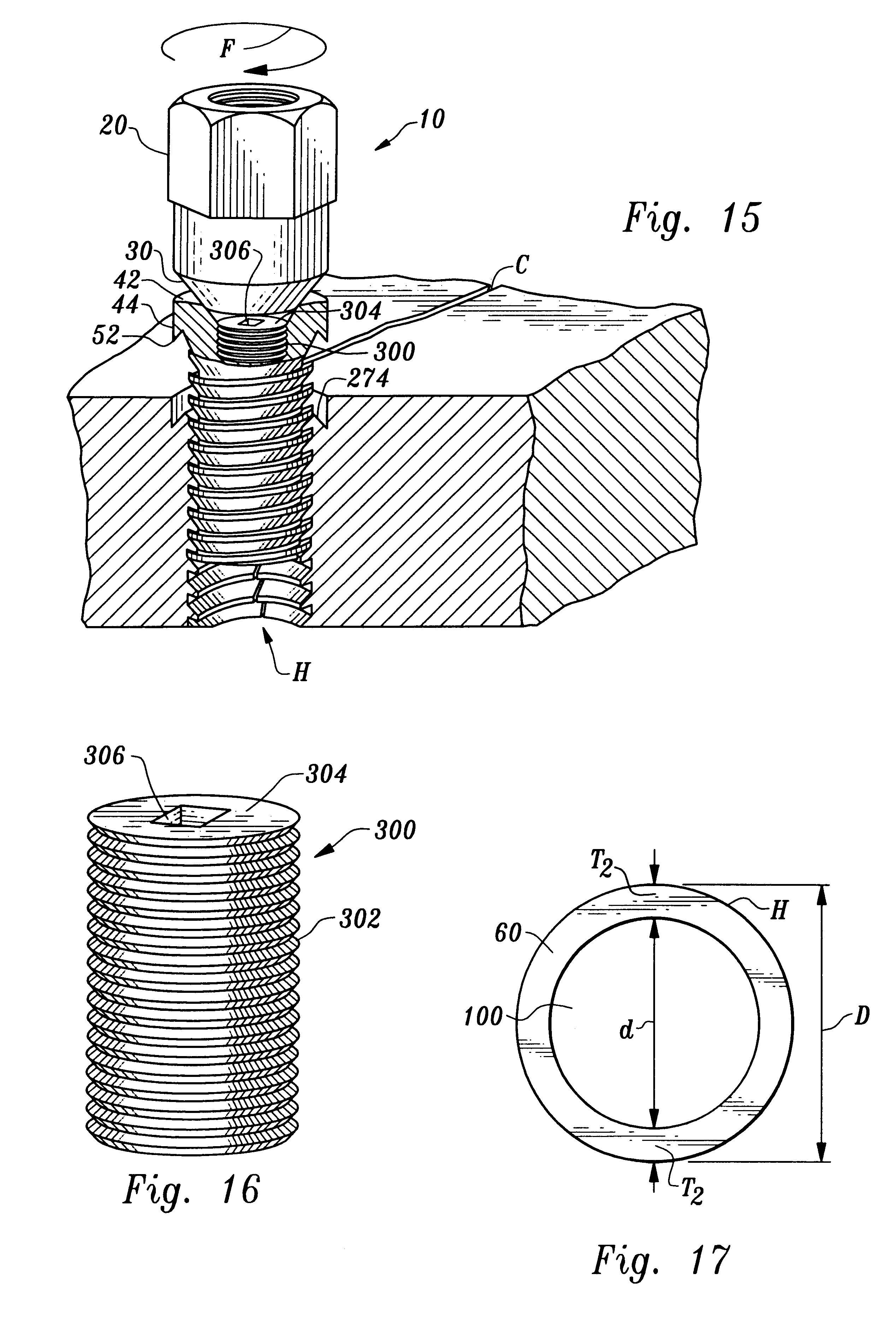

TIME-SERT insert. A threaded insert, also known as a threaded bushing, is a fastener element that is inserted into an object to add a threaded hole.

When should you use a threaded insert on an old motorcycle?

When working on old motorcycles, you’ll eventually find yourself dealing with damaged threads at one point or another, and a threaded insert is a great way to repair them. The most common reasons for damaged threads are:

How do threaded inserts work metal?

1:5314:40How to Use Threaded Inserts for Wood, Metal, and 3D Prints!YouTubeStart of suggested clipEnd of suggested clipAnd then they have a uh a hex key opening on one end that you then use to drive into the wood. SoMoreAnd then they have a uh a hex key opening on one end that you then use to drive into the wood. So the it has these coarse blades on the outside that really bite into the wood and cut well.

How do you attach threaded inserts?

2:2710:06Foolproof Threaded Insert Installation - YouTubeYouTubeStart of suggested clipEnd of suggested clipThese one simple ways is simply take either a section of a bolt or some threaded stock of what theMoreThese one simple ways is simply take either a section of a bolt or some threaded stock of what the internal threads are this is quarter 24 thread and simply put a couple of nuts jam them.

Are threaded inserts better than screws?

They offer a stronger alternative to weld nuts and tapped holes, and they provide a stronger bond than self-tapping screws. In fact, threaded inserts are usually the strongest and least time-consuming fasteners used in any manufacturing setting, especially because they were designed for automation.

Do threaded inserts need glue?

There is a speciality glue called 'thread-locking adhesive', which is for securing all threaded items. This can be applied to the external surface of threaded inserts to secure their position when installed. Thread-locking adhesive works anaerobically, which means without oxygen.

How do you tighten a threaded insert?

1:544:21How do you use Threaded Inserts / Insert Nuts In Wood? Woodworking ...YouTubeStart of suggested clipEnd of suggested clipIn this case it's an m6 pop it in about half way ish. And put a lock nut. Against it like that. AndMoreIn this case it's an m6 pop it in about half way ish. And put a lock nut. Against it like that. And just finger tighten it for the minute we'll come back to that.

How do you get threaded inserts straight?

0:312:46Woodworking Tip: Threaded Insert Installation Jig - YouTubeYouTubeStart of suggested clipEnd of suggested clipIn a wood block that does the work of keeping the insert square to your surface. The spring on theMoreIn a wood block that does the work of keeping the insert square to your surface. The spring on the bottom provides. Just enough downward pressure to make it easy to start the insert that.

Do threaded inserts allow wood movement?

Advantages of Using Threaded Inserts Allows for slight wood movement while maintaining stability.

Can you use threaded inserts in plywood?

“Pressed-In” Threaded Metal Inserts Pressed-In inserts are ideal for hard woods, soft woods, and plywood. These threads only require a drilled hole the size of the body of the insert, making installation quick and easy.

How does an insert nut work?

Insert nuts work in a similar way as wall anchors by creating a support system for a separate fastener, such as a bolt. Rather than driving a bolt directly into an object, an insert nut is inserted into the object. The bolt is then driven into the insert nut.

What size hole do you drill for a 1/4 threaded insert?

Brass Wood Insert (1/4"-20 Thread x 5/16" Drill Size)

Can you thread a bolt into wood?

Embedding a threaded insert, a prong T-nut, or gluing-in a common nut is surely an option, but a cheaper and faster to install technique is at hand. Just thread a pre-drilled hole in the wood to accept the machine thread of the tightening fastener, and reinforced the wooden threads with super glue.

Can you put a nut on a wood screw?

Wood screws and sheet metal screws make their own threads in the hole, so they are not used with a nut. Machine screws and cap screws, for instance, thread into threaded holes or are used with a nut. In either case, though, you tighten or loosen the screw by turning its head.

How do you install threaded plastic inserts?

1:043:02Install Brass Heat Set Threaded Insert for Plastics and 3D Printed PartsYouTubeStart of suggested clipEnd of suggested clipSo basically you heat the iron. Up. And insert it into the insert push down do not breathe thatMoreSo basically you heat the iron. Up. And insert it into the insert push down do not breathe that that's nasty in fact you should have a fan going on there are I'm in a well-ventilated.

How are threaded inserts installed automotive?

Installing Threaded InsertsDrill out old threads using tap drill specified in table (Important: Correct tap drill is slightly larger than standard for that thread size).Countersink to diameter shown in table.Tap new threads, using standard tap.Screw in insert until body is slightly (.More items...

How do you install insert nuts in metal?

1:092:12How To Easily Install Threaded Rivet Nut Inserts - YouTubeYouTubeStart of suggested clipEnd of suggested clipSimply screw the rivet nut onto the hampire. Tool until it stops push the rivet nut into the holeMoreSimply screw the rivet nut onto the hampire. Tool until it stops push the rivet nut into the hole until it stops continue to press the rivet nut into the hole. While you gently squeeze the handles.

How do you use a threaded rivet insert tool?

0:221:12How to Use Threaded Nut Rivets / Rivnuts / Blind Nutserts - YouTubeYouTubeStart of suggested clipEnd of suggested clipJust big enough to suit the threaded nut rivet's diameter. Then simply screw the threaded nut rivetMoreJust big enough to suit the threaded nut rivet's diameter. Then simply screw the threaded nut rivet onto the tool's mandrel. And pass the rivet through the workpiece.

Understanding Threaded Inserts

If you aren’t familiar with threaded inserts, they are a type of fastener that is set into the workpiece to provide a solid fastener that can accept bolts or other types of threaded fasteners. Threaded inserts are sometimes referred to as rivet nuts and are designed to create a threaded hole for a durable fastener.

Types of Threaded Insert Tools

Because there are so many different types of threaded inserts, there are many different types of threaded insert tools as well. The different types of tools use different types of installation techniques to accommodate each threaded insert. Here are some of the most common:

Getting Started with Threaded Insert Tools

Threaded nut inserts are useful for a wide range of fastener applications, but whatever insert you choose for the task, you need to choose the right threaded nut insert tool as well. There are specialty tools that are best suited for different applications, whether it’s on the assembly line or in the field.

What is threaded insert?

A threaded insert, also known as a threaded bushing, is a fastener element that is inserted into an object to add a threaded hole. They may be used to repair a stripped threaded hole, provide a durable threaded hole in a soft material, place a thread on a material too thin to accept it, mold or cast threads into a work piece thereby eliminating ...

Why use threaded inserts on sheet metal?

People who use sheet metal or sandwich panel or honeycomb sandwich-structured composite often install threaded inserts to spread shear, tension, and torque loads over a larger area of the material.

What is an externally threaded insert?

Externally-threaded inserts. A self-tapping insert. Externally threaded inserts have threads on the outside and inside of the insert. The insert is threaded into a pre-tapped hole, or some inserts tap their own threads in a drilled or molded hole. It is then anchored by various means, such as a nylon locking element.

What is press fit insert?

Press fit inserts are internally threaded and have a knurled outer diameter. They are pressed into a plain hole with an arbor press.

What is a hexagonal insert?

For softer more pliable plastics, hexagonal or square inserts with deep and wide grooves allow the plastic to flow and adhere. The process allows large product manufacture i.e. fuel tanks, boats etc., so the torque inserts may be of large thread sizes.

What is a mold in insert?

Mold-in inserts are internally threaded and have a specially shaped outer diameter to anchor the insert in plastic. The insert is placed in the mold of an injection molded part beforehand. The mold is then closed and filled with the plastic filling in around the insert. These inserts can also be heated and pressed into pre-made thermoplastics.

What is the key strength factor in case of inserts?

Resistance is the key strength factor in case of inserts, pull-out & torque-out are the two parameters to judge inserts. Pull-out: the force required to pull the insert out of the parent material. Torque-out: the amount of torque required to turn the fastener without inducing any clamp load on the fastener.

What is a press in insert?

Press-in inserts, with their barbed exteriors, work well in hard woods, soft woods, and plywood. Drill a hole sized for the body of the insert, and press it into place with a clamp or tap it in with a hammer and a block of wood.

How to protect wood inserts from epoxy?

In very hard woods, such as white oak and maple, or when the insert is close to the edge of a part and screwing it in may split the wood, drill a hole slightly larger than the outside thread diameter, and epoxy the insert in place. To protect the internal threads from epoxy, cover the end of the insert, as shown below.

What is a Threaded Insert?

A threaded insert kind of looks like a small spring or more specifically, it’s a small metal cylinder with threads on the inner and outer surfaces. The internal threads have the exact same size of the thread that you are trying to repair.

Where should the tang end on a threaded insert?

Once you’ve fully screwed in the threaded insert, the tang should end up at the bottom of the part. The final step is to break off the metal tang.

What size threads fit a 10mm bolt?

For example, an M10 x 1.5 threaded insert will fit a 10mm bolt with a 1.5mm pitch.The threads on the outer surface of the threaded insert are the same size as the tap that’s included in the kit, and will be a little bit larger than the original thread.

What happens when you over tighten a bolt?

Overtightening bolts – when too much force is used to tighten down a bolt the excess pressure will cause the threads to become deformed.

How to keep a threaded tap straight?

During the threading process, you’ll want to keep the tap as straight as possible and work slowly to avoid any mistakes. Turn the tap clockwise then back it out a bit to break off the chip, otherwise known as swarf or shavings, after the first few turns.

What causes threads to become weaker and breaks it down much quicker?

Corrosion – rust and corrosion causes threads to become weaker and breaks it down much quicker.

What is cross threading?

Cross threading – inserting a bolt at the wrong angle then tightening it down causes a lot of damage to the thread.

Overview

A threaded insert, also known as a threaded bushing, is a fastener element that is inserted into an object to add a threaded hole. They may be used to repair a stripped threaded hole, provide a durable threaded hole in a soft material, place a thread on a material too thin to accept it, mold or cast threads into a work piece thereby eliminating a machining operation, or simplify changeover from unified to metric threads or vice versa.

Types

Thread inserts come in many varieties, depending on the application. Threaded inserts for plastics are used in plastic materials and applied with thermal insertion or ultrasonic welding machines.

Manufacturers of ready-to-assemble furniture often ship the parts with threaded inserts and other kinds of knock-down fasteners pre-installed.

Strength factor for threaded inserts

Resistance is the key strength factor in case of inserts, pull-out & torque-out are the two parameters to judge inserts.

• Pull-out: the force required to pull the insert out of the parent material.

• Torque-out: the amount of torque required to turn the fastener without inducing any clamp load on the fastener.

Knurling

Knurling is the metalworking which is done on the outer side of the component. In case of Brass Insert, knurling plays an important role in increasing pull-out & torque-out resistance. Types of knurling and its benefit are as follows:

• Straight knurls: Greatest torque resistance

• Diagonal or helical knurls: Balance resistance in both direction

Installation methods

For industrial purposes, following installation methods are the standards:

• Thermal insertion

• Injection molding

• Manual pressing

See also

• Insert nut

• Nut

• Rivet nut

• Screw

• Screw thread