10 Steps for Proper Pump-Pipe Alignment

- Step 1. Note: This step is only for cases in which NO thermal growth is experienced—otherwise skip to Step 2.

- Step 2. When the location of the equipment is set, the baseplate can be put in place, leveled and rough-aligned, with...

- Step 3. Once rough alignment has been completed, remove the equipment (pump, motor gearbox) from the...

What is the alignment of a pump?

Alignment is mainly based on accurately measuring the position of the pump and driver motor shafts at two or more points. Different equipment such as laser alignment tools, dial indicators, vernier calipers, and feeler gauges can be used to measure alignment. The pump shaft installs in three-dimensional space.

How do you align a pump coupler?

A proper alignment will include aligning the pump shaft to the motor shaft in both the horizontal and vertical planes. Always follow the manufacturer’s instruction manual on how to properly align the pump as it can vary from one coupler type to another.

What are the benefits of precision alignment of the pump shaft?

Proper alignment of the pump shaft with the driver can reduce vibration and significantly improve reliability. For appropriate applications, the time, expertise and instruments needed to achieve precision alignment (tolerances of less than 0.005 in) will prevent seal leakage and extend bearing life.

What size alignment do I need for my water pump?

For a large 1,200 rpm pump with an elastomer-in-shear coupling, alignment with a straight edge and feeler gauge to precision of 0.005 in would suffice. A medium-size 3,600 rpm hot water circulation pump with a jaw coupling, however, would require precision alignment with dial indicators or a laser system.

How pump alignment is done?

For angular misalignments, a simple approach is as follows:With the motor and pump shaft flanges close to each other, but disconnected, mark a spot on each shaft, then measure the separation between them with a feeler or taper gauge.Rotate both shafts by about 90 degrees, keeping the marks close to each other.More items...

How do you perform a shaft alignment?

Shaft Alignment Procedures ( Rim and Face Alignment Method )Rotate the dial indicators to 12:00.Set the face dial indicator to zero.Record the setting of both dials at 12:00.Rotate the dial indicators to 3:00.Determine and record the reading on both dials.Rotate the dial indicators to 6:00.More items...•

How do you fix a misalignment in a pump?

A common way to rectify pump misalignment is by using a close coupling. In close coupling, the pump and motor are joined directly by mounting the motor onto the pump. When done correctly, close coupling offers a precise alignment and secure hold.

What are the method of pump and motor alignment?

Methods of Shaft Alignment Straight Edge Alignment. Rim-Face Dial Indicator Alignment. Reverse Dial Indicator Alignment. Laser Alignment.

What is the methods of alignment?

The three primary methods of producing pairwise alignments are dot-matrix methods, dynamic programming, and word methods; however, multiple sequence alignment techniques can also align pairs of sequences.

How do you check a shaft misalignment?

Diagnosis via laser shaft alignment system Checking for shaft misalignment is often the first course of action when a machine starts having a problem. A laser shaft alignment system determines misalignment at the coupling and calculates the appropriate machine movement to be performed at its base.

What causes pump misalignment?

High temperatures in a pump system can cause pipe-work to expand, the expansion being equal to the coefficient of thermal expansion of the piping material used. This thermal growth can force joints of piping apart, leading to both misalignment and increased nozzle loading.

What causes shaft misalignment?

Shaft misalignment is considered the second most prevalent source of vibration after imbalance, it occurs due to poor alignment between corresponding components, such as coupling halves, clutches, shafts, pulleys, etc.

Why alignment is important for pumps?

Proper alignment of the pump shaft with the driver can reduce vibration and significantly improve reliability. For appropriate applications, the time, expertise and instruments needed to achieve precision alignment (tolerances of less than 0.005 in) will prevent seal leakage and extend bearing life.

How many types of pump alignment are there?

Correct Alignment Basically, there are two types of misalignment: parallel (or offset) misalignment and angular misalignment. With parallel misalignment, the center lines of both shafts run parallel to one another, but they are offset. With angular misalignment, the shafts run at an angle to one other.

How many types of shaft alignment are there?

There are two types of misalignment: offset or parallel misalignment and angular, gap, or face misalignment. With offset misalignment, the center lines of both shafts are parallel but they are offset. With angular misalignment, the shafts are at an angle to each other.

How do you line up a centrifugal pump?

Centrifugal pump start up procedureOpen the suction valve.Open any recirculation or cooling lines.Fully close or partially open the discharge valve, depending on system conditions.Start the driver.Slowly open the discharge valve until the pump reaches the desired flow.More items...

Which method is used to check alignment of shaft?

Method 1: 9-12-3 The clock method, or 9-12-3 as it is also known, is the origin of all shaft alignment. Anyone who knows how to use analogue dial indicators will recognize this method.

How do you perform a laser alignment?

1:172:44How to perform shaft alignment in 5 steps - YouTubeYouTubeStart of suggested clipEnd of suggested clipSystem. Set up your laser alignment. System. Take two sets of measurements to ensure repeatability.MoreSystem. Set up your laser alignment. System. Take two sets of measurements to ensure repeatability. Ensure the misalignment is less than 0.5 millimeter at the coupling.

What is the purpose of shaft alignment?

While misalignment has no measurable effect on motor efficiency, correct shaft alignment ensures the smooth, efficient transmission of power from the motor to the driven equipment. Incorrect alignment occurs when the centerlines of the motor and the driven equipment shafts are not in line with each other.

How do you check a shaft and coupling alignment?

The necessary tools used for checking the alignment of a flexible coupling are a straightedge and a taper gauge or a set of feeler gauges, or by use of dial indicators. A rough check for angular alignment is made by inserting the taper gauge or feelers between the coupling faces at 90 degree intervals (see Image 2).

What is proper alignment?

A proper alignment will include aligning the pump shaft to the motor shaft in both the horizontal and vertical planes.

When to have pump aligned?

Remember to always have your pump aligned when replacing or moving the motor after maintenance has been performed on your pump. This will give your equipment the best possibility of minimizing issues and achieving its maximum life.

Can you have two misalignments at the same time?

There are two types of misalignment and you can have both types in the same pump at the same time. These can occur both in the vertical and horizontal positions.

How to measure misalignment?

Measurement: Alignment tolerances and misalignment are measured at the coupling, where the power is transmitted . The simplest way to measure these parameters is with a straightedge and feeler gauges. A taper gauge or caliper can also be used to measure angularity between the coupling faces. These methods can achieve accuracy of about 0.005 in, which is acceptable for many pumps that operate at 1,200 rpm or less.

How accurate is pump alignment?

Alignment tolerances for pumps range from the "rough alignment" that a conscientious technician can accomplish with visual indicators (accuracy of about 0.02 in) to precision alignment (accuracy of 0.0005 in or greater). The latter requires an experienced technician and accurate instruments (e.g., dial indicators or a laser alignment system). Accuracy of about 0.005 in can be accomplished with a simple straightedge and feeler gauge.

What is shaft alignment?

The purpose of shaft alignment is to minimize the vibration resulting from forces transmitted across the coupling. The goal is to have both shafts rotating on a common axis, referred to as collinear. All misalignment of shaft centerlines (i.e., deviation from the collinear condition) can be described in terms of offset and angularity.

Why is it important to document pre alignment?

Documentation: It is essential to record pre-alignment data, target values, tolerances and final aligned condition. This information can help maintenance personnel determine when to perform maintenance tasks and spot developing problems that may otherwise result in unexpected, costly failures and downtime. The documentation features included with many alignment calculators and laser systems may not be adequate for recording data about foundations, machine feet, shims, coupling components and observations. If so, a paper or an electronic work order system should be used to capture this information (see an example data form below).

What is offset tolerance?

Offset tolerances are measured in thousandths of an inch (or mils), centerline-to-centerline at the coupling. Angularity tolerances are expressed as pitch or slope (mils/inch).

How does alignment of pump shaft help?

Proper alignment of the pump shaft with the driver can reduce vibration and significantly improve reliability. For appropriate applications, the time, expertise and instruments needed to achieve precision alignment (tolerances of less than 0.005 in) will prevent seal leakage and extend bearing life.

What is the process of pump alignment?

Successful pump alignment requires careful planning and execution, beginning with evaluation of tolerances and target values based on pump speed, thermal characteristics, coupling type and spacing. The technician must also be adequately trained and systematically document the entire procedure, including the original misalignment, the final alignment condition, and any observations related to machine reliability. The expense or sophistication of the alignment tools-whether laser, dial indicator or manual-will not produce the desired results if these essentials are ignored.

How much damage does misalignment do to a pump?

Up to 50% of damage to rotating machinery is directly related to misalignment. Machine vibration, bearing damage, premature seal wear, and coupling damage are all examples of issues pumps experience if improperly aligned at installation. Misaligned pumps can also draw up to 15% more energy than aligned pumps.

What was wrong with Crane Engineering?

A wastewater treatment operator called Crane Engineering with a problem . He was replacing bearings on the same centrifugal pump in his lift station again and again. When the operator's account manager visited in person, it was obvious something was wrong. Even before he saw the pump, he could hear the sound of grinding bearings from outside the lift station.

What is the best way to align a pump?

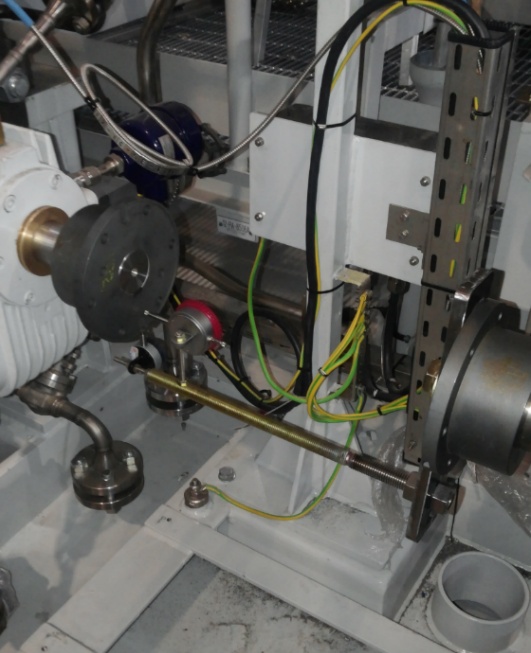

There are 3 common tools and methods used to align pumps. Here are the pros and cons of each: Straight Edge - This method requires placing a straight edge on the pump and motor coupling, then making a visual check to see if the components are aligned. Pros. Quick and easy to perform. Cons.

What is reverse dial indicator?

Reverse Dial Indicator - This method uses two indicators that check for radial run-out and angularity. The readings are then plugged into mathematical formulas to calculate shim requirements for proper alignment.

What is laser alignment?

Laser Alignment - This method uses lasers to determine the relative shaft positions. The computer then makes recommendations for adjustments.

How is an alignment done ?

The alignment of misaligned shaft are done by using different types of shaft alignment methods which are mention below :

What is rim and face alignment?

Rim and Face alignment method are oldest method used for shaft alignment of misaligned equipment/shaft. In this method two dial indicator ( rim and face dial ) are used to determine the relative position of movable shaft with respect to stationary shaft. The rim dial indicator is used to measure offset in one plane along the shaft length and face dial indicator is used to measure angularity or slope between the shaft.

How to use an indicator in a pump?

Place an indicator in the horizontal and vertical planes, using the motor and pump coupling. Uncouple the pump and motor, while watching the indicators for movement. Start unbolting the flanges, and continue watching for movement in the indicators.

What is rough alignment?

The rough alignment step, mentioned above, is critical to minimize the changes that will be required to appropriately fit the piping to the pump. At the last stage, when the final spools are installed, the final alignment will be achieved with small adjustments. This will minimize the adjustments required on the motor feet/bolts. Unfortunately, motor hold-down bolts are often too tight and allow for only small adjustments to the motor before becoming bolt bound.

How to level a motor gearbox?

Level the baseplate to a maximum out of level of 0.025 inch (0.06 millimeter) from end to end in two planes. Use machined pads as the base for the leveling instruments. Inspect the foundation for cleanliness, and if not clean, use a solvent to remove grease and oil.

Can anchors be used for pump piping?

Occasionally, anchors (only if NO thermal growth, which is rare) can be used for the pump piping. The delivery of the equipment can either be early or it can be late in arriving at the site. When the equipment is late it is critical to have certified elevation prints of the equipment.

Does sliding support keep piping from sliding up?

A. Correct configuration—Sliding support does not keep the piping from sliding up/away.

Can a hot water pump cause piping expansion?

If, in addition to that, the pumped product is hot, the piping expansion could be worse. However, even the daily fluctuations of ambient temperature alone could cause problems, as shown in the calculation above.

Effects of Misalignment

- A common misconception about pump shaft/driver misalignment is that it increases bearing load, causing bearings to fail prematurely. In fact, except in cases of extreme misalignment, the resulting vibration is what damages bearings and seals. Since some vibration is normal for pumps, it is best to have an experienced vibration technician determine if the vibration is due to …

Alignment Basics

- The purpose of shaft alignment is to minimize the vibration resulting from forces transmitted across the coupling. The goal is to have both shafts rotating on a common axis, referred to as collinear. All misalignment of shaft centerlines (i.e., deviation from the collinear condition) can be described in terms of offset and angularity. Theoretically, two perfectly aligned shafts would rot…

Tolerances

- Alignment tolerances specify how close the pump and driver shaft centerlines should be to collinear at running conditions. Offset tolerances are measured in thousandths of an inch (or mils), centerline-to-centerline at the coupling. Angularity tolerances are expressed as pitch or slope (mils/inch). Alignment tolerances for pumps range from the "rou...

Alignment Procedures

- Rough Alignment:When installing the pump and driver, experienced technicians will perform a "rough alignment" based on visual indicators. They also will ensure that all machine feet are in good foot-plane and have 0.025 in to 0.050 in shims under them. Good foot-plane must be established and maintained throughout the alignment procedure to avoid stressing the machine …

Conclusion

- Successful pump alignment requires careful planning and execution, beginning with evaluation of tolerances and target values based on pump speed, thermal characteristics, coupling type and spacing. The technician must also be adequately trained and systematically document the entire procedure, including the original misalignment, the final alignment condition, and any observatio…