What are the steps in installing and trimming PVC edge banding?

- STEP 1: Measure the length of the PVC edge banding depending on needed surface to be covered. Provide enough allowance for adjustment later on.

- STEP 2: Apply contact cement to both plywood and PVC edge banding. ...

- STEP 3: After about 15 minutes or when the contact cement is dry to touch, bond the plywood and PVC edge banding together. ...

- STEP 4: ...

- STEP 5: ...

How do you apply edge banding?

We apply the glue to the edge while it’s still hot and then apply the banding, pressing it to the side. Ambient temperature plays an important role in the edge banding process. We need to regulate the temperature of both the building and our materials.

What is the best wood edge banding for HPL tops?

As we alluded to above, internal solid wood edge banding with HPL tops are probably our strongest and most durable solution. We choose to use a hot melt glue for our adhesive solution because it’s user friendly and provides a great seal. We apply the glue to the edge while it’s still hot and then apply the banding, pressing it to the side.

What is the best material for edge banding?

3. Wood Veneer is the most common edge banding material for plywood cabinet sides, drawer fronts, and MDF wardrobe doors. It’s made from thin slices of wood—typically oak, maple, ash, walnut, birch, and mahogany—that are joined together in a roll using finger jointing.

What is edge banding machine?

And edge banders are the industrial grade machines that apply the edging tape to the raw edges of the wood panels with a hot-melt adhesive or glue. What’s the purpose of edge banding? Edge banding serves both functional and aesthetic purposes. Functionally, edge bands perform some key duties for your furniture.

How do you do PVC edge bands?

What is edge banding?Step 1: Measure and cut the PVC edge banding as per the requirement.Step 2: Apply the contact cement to PVC edge banding and the material with a brush or spray contact cement . ... Step 3: Let the contact cement dry to touch.More items...•

How do you attach edge banding?

0:011:14How to Apply Edge Banding - YouTubeYouTubeStart of suggested clipEnd of suggested clipRub a wood block across the banding that makes sure that it stays flat while the glue hardens grab aMoreRub a wood block across the banding that makes sure that it stays flat while the glue hardens grab a sharp utility knife and trim off the ends. A quick pass of the edge trimmer take care of the edges.

How do you use pre glued PVC edging?

Preglued PVC Edgebanding is coated on the back with Hot Melt Adhesive. Typically applied with a low temperature Hand Held Hot Air Edgebander and then rolled for best adhesion. This Product cannot be ironed on, PVC will melt before the glue.

How do you cut a 2mm PVC edge band?

1:226:27Edge Banding Trimmer - YouTubeYouTubeStart of suggested clipEnd of suggested clipBit as the work is pushed. Through the flush trimming bit trims it off flush with the base of theMoreBit as the work is pushed. Through the flush trimming bit trims it off flush with the base of the plywood. That works with the saw wood. And it works for the veneer as.

What glue do you use for edge banding?

Hot Melt GluesHot Melt Glues… Most edge banding is applied with hot melt glue. The two main choices for hot melt glues are EVA (Ethylene Vinyl Acetate) and PUR (Polyurethane). Each has its advantages and disadvantages depending on your project and the material you are working with.

Can I use a heat gun to apply edge banding?

Tooling up to apply edge banding is easy. You need something to activate the adhesive; a heat gun or household iron works great. You'll also need a scrap of wood you can use to press the heated veneer tape in place. A great way to trim the oversized tape is by using a card scraper.

How do you paste edge banding tape?

1:364:41Easily Apply Edging Tape - YouTubeYouTubeStart of suggested clipEnd of suggested clipBut just know that you want to keep it on there long enough for the glue to melt. But not for theMoreBut just know that you want to keep it on there long enough for the glue to melt. But not for the veneer to burn. Now follow the iron with your piece of wood to make sure it's pressed all the way.

Can I use a regular iron for edge banding?

0:235:25Woodworking Tip: How to Use Iron on Edge Banding - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou can also get the iron-on edge banding in different widths including inch.MoreYou can also get the iron-on edge banding in different widths including inch.

How do you iron on pre glued edge banding?

0:002:55How To Edge Band Plywood - Iron On Veneer Edge Banding - YouTubeYouTubeStart of suggested clipEnd of suggested clipThere are a couple of different tools that you can use to heat up the edge banding. So it'll stick.MoreThere are a couple of different tools that you can use to heat up the edge banding. So it'll stick. And the first is a heat gun. And the second is a regular clothes iron.

What is the best way to trim edge banding?

0:582:54Quick Tip on Trimming Edge Banding - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo what I like to do is use a sanding block and then sand along the edge kind of bending the edgeMoreSo what I like to do is use a sanding block and then sand along the edge kind of bending the edge banding in you don't want to pull the sander because you can pull the edge banding away.

Can you trim edge banding with a router?

0:117:01Routers - Trimming Edge Banding on the Routing Table - YouTubeYouTubeStart of suggested clipEnd of suggested clipEvery piece in the carcass. So that the edge band is perfectly flush let me show you a greatMoreEvery piece in the carcass. So that the edge band is perfectly flush let me show you a great technique for taking care of that on the router.

What is the difference between PVC and ABS edging?

PVC is more resistant to solvent and UV lights. It is possible to use the strongest form of solvent. ABS can be damaged if a strong solvent is used. ABS is less resistant to lights.

How do you install veneer edge banding?

4:096:15How to Apply Real Wood Edgebanding for beginners (Iron on)YouTubeStart of suggested clipEnd of suggested clipFirst you're gonna lay your piece over the edge. So that way you're not putting it directly flat onMoreFirst you're gonna lay your piece over the edge. So that way you're not putting it directly flat on the table.

How do you put an edge band on a circle?

3:345:03How To: Cutting Circles and Applying Edgebanding - YouTubeYouTubeStart of suggested clipEnd of suggested clipMake sure that you apply consistent pressure using the iron. And either your hand or a blockMoreMake sure that you apply consistent pressure using the iron. And either your hand or a block afterwards to get a good seal on the adhesive. As it melts.

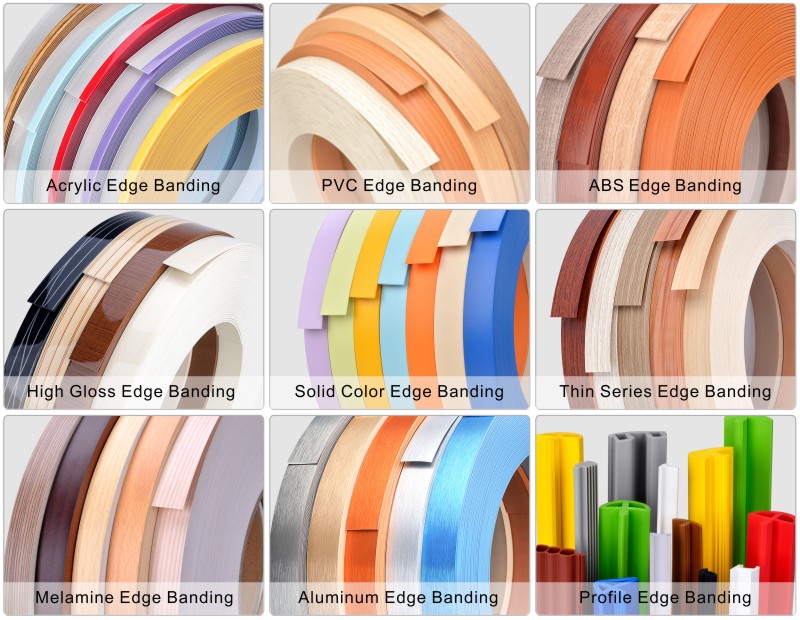

What are the different types of edge banding?

Edge Banding is available in variety of materials, but there are two categories that are most commonly used : PVC and Veneer. EDGE BANDING material used to seal the exposed and raw edges of the plywood. PVC edge banding is most popular when using Pressure Laminated and Melamine Cabinets.

How do you attach melamine edging?

1:317:08How to apply iron on edge melamine Dave Stanton easy woodworkingYouTubeStart of suggested clipEnd of suggested clipThe iron has been set to wool. That's the temperature that they recommend. Now what i do i put theMoreThe iron has been set to wool. That's the temperature that they recommend. Now what i do i put the edge strip on. And i go across it slowly. Making sure that the iron is dead flat once i've done that.

How to Apply Edge Banding to Plywood?

I already mentioned various types of plywood edge banding. Now I describe one by one how to apply them. But I will only talk about manual process of edge banding. There are some edge bander available at the market those will automatically complete the edge banding process without man power.

How long does it take to apply edge banding?

While it may seem like a daunting task, most people find that they can do it in approximately five minutes. However, the advantage of this type is that you can add as much adhesive to it as needed and remove or reposition if necessary before they fully cool down.

What is Edge Banding?

Before we start talking about how to apply edge banding, we must establish what exactly edge banding is. Edge bands are usually made out of laminated paper or plastic, or thin wood, and they come in a variety of colors. They can also be found with wood grains, metallic finishes, or even designs like stone tiles. The main function of edge bands is to protect your plywood edge from moisture damage and also to look nice on your wood project.

How long does it take for edge banding to cool down?

When your iron is hot enough, pass over the edge banding until its adhesive melts and sticks onto plywood properly. When you are using the iron, hold the edge banding tightly so it does not move until the adhesive cools down. It takes only about 30 seconds for this type of edge banding to cool down.

How does edge banding work?

It works by heating up a roller on your iron that melts the adhesive within the strip as you pass over it with a hot iron. Once the adhesive cools down, it holds all of your wood together, and you are ready to go!

What glue is used for hot iron?

Usually, the glue used for the hot iron method is an adhesive with a low-temperature melting point.

How to melt glue in a cloth?

This process is as simple as ironing cloth. You just have to pass over it with a hot iron, and the glue will melt immediately.

Why are edgebanders so expensive?

There is a reason these banders are so expensive. Because the do a much better job than we can do by hand . Again, try it and see if you are satisfied. From contributor A:

How to buff 3mm?

By far the easiest way to do this is to sub this out to someone with an edgebander. To do 3mm on a machine you need a scraper and a buffer. The scraper will remove the knife marks left by the trimmers, and the buffer will polish out the edge. If you are doing a dark color, you would benefit from a re-generator - a heater at the end that will bring the color back. While Harold recommends a 3/16" r, 1/8" (3mm) is most common. I have tried to buff with a buffer, but again, mixed results.

How to do radiuses with contact cement?

As far as doing radiuses go, be sure you have full coverage of contact cement and, for doing radiuses, use a heat gun to get the 3mm really hot, then use a palm roller and apply pressure the entire length of the radius. (A caution is in order here. If you get the 3mm too hot, it will start to bubble.)

Can you apply PVC edgebanding by hand?

PVC edgebanding can be applied by hand, but it's tricky and difficult. Here is a handful of tips and advice. November 20, 2005

Does Seamfil dissolve pvc?

It has to be Seamfil solvent, others, like Wilsonart 110, will not polish the edges. I am not a chemist, but Seamfil solvent will actually dissolve pvc whereas the other solvents I have tried do not. I would think that if you used steel wool or something similar, it would eave a dull finish.

Can you use 3mm PVC edgebanders?

Can 3mm PVC be applied by hand, yes. But the results will not compare to an edgebander. PVC is very stiff (unless you get the kind for contour edgebanding - another story). It has been coiled up, and retains its memory. You will have to fight this. I tried to warm this up on a Texas parking lot, and it still was fighting me. An edgebander has a pressure roller (s) that apply an incredible amount of pressure to the edge, which is difficult to reproduce by hand.

How to prevent overspray on PVC board?

Otherwise, acceptable method would be to use spray-on contact adhesive on both board edges and rear of PVC edge. Mask face of board with masking tape and use scrap board cuttings to prevent overspray.

Can you use mineral turps on PVC?

Do not use thinners, under any circumstance, to remove any surplus adhesive. Use mineral turps, as this will not damage the PVC.

Does solvent damage PVC?

Also, solvent (acetone) does not damage PVC. How else would you get the glue off edgebanded parts? Lacquer thinner works fine, too.

How to Apply Edge Banding to Plywood?from thetoolsmag.com

I already mentioned various types of plywood edge banding. Now I describe one by one how to apply them. But I will only talk about manual process of edge banding. There are some edge bander available at the market those will automatically complete the edge banding process without man power.

How long does it take to apply edge banding?from thetoolsmag.com

While it may seem like a daunting task, most people find that they can do it in approximately five minutes. However, the advantage of this type is that you can add as much adhesive to it as needed and remove or reposition if necessary before they fully cool down.

What is Edge Banding?from thetoolsmag.com

Before we start talking about how to apply edge banding, we must establish what exactly edge banding is. Edge bands are usually made out of laminated paper or plastic, or thin wood, and they come in a variety of colors. They can also be found with wood grains, metallic finishes, or even designs like stone tiles. The main function of edge bands is to protect your plywood edge from moisture damage and also to look nice on your wood project.

How to glue plywood to edge?from thetoolsmag.com

When you are applying glue, make sure that all the area near the edge of your plywood is covered with glue, and do not leave any dry area. Use glue on both edge and edge banding to ensure a good result.

How long does it take for edge banding to cool down?from thetoolsmag.com

When your iron is hot enough, pass over the edge banding until its adhesive melts and sticks onto plywood properly. When you are using the iron, hold the edge banding tightly so it does not move until the adhesive cools down. It takes only about 30 seconds for this type of edge banding to cool down.

What glue is used for hot iron?from thetoolsmag.com

Usually, the glue used for the hot iron method is an adhesive with a low-temperature melting point.

How to melt glue in a cloth?from thetoolsmag.com

This process is as simple as ironing cloth. You just have to pass over it with a hot iron, and the glue will melt immediately.

How is edge banding applied?

According to RA Learning Center, there are at least four methods of applying edge banding. There are a lot of things to say about each of these but for now, here’s a simple list of application methods and mediums.

What material is used for edge banding?

1. PVC is the most popular material for edge banding on case good tops. Pros: It’s inexpensive, durable, and boasts a long life. It doesn’t require any finishing process. It’s also easy, albeit tedious, to repair. Cons: You can’t recycle it. It doesn’t biodegrade. Once it’s blemished, you can’t refinish it. (NB: ABS—Acrylonitrile Butadiene Styrene—is an eco-friendly alternative to PVC because it’s both recyclable and safe to incinerate.)

Where won’t you find edge banding?

DCI doesn’t use edge banding on cabinet backs or drawer bottoms because they are already embedded (sealed) in dato grooves. Likewise we don’t edge band internal plywood drawer parts because it doesn’t add value.

Why does my edge banding peel?

When that happens, the edge banding will start to peel away from the edge. Peeling can also happen because of rough use . For example, .5mm edging doesn’t provide much resistance to impacts.

What is the best material for edge banding?

Pros: It’s inexpensive, durable, and boasts a long life. It doesn’t require any finishing process. It’s also easy, albeit tedious, to repair. Cons: You can’t recycle it. It doesn’t biodegrade. Once it’s blemished, you can’t refinish it. (NB: ABS—Acrylonitrile Butadiene Styrene—is an eco friendly alternative to PVC because it’s both recyclable and safe to incinerate.)

Why use edge banding on furniture?

Second, edge banding improves durability and resilience by providing impact resistance. If you’re using solid wood edging, it can also add to the overall strength of the furniture.

Why thicker edging?

The thicker edging is used in high traffic and commercial environments because it provides greater resilience and impact resistance. For example, the military requires a thicker ⅜” solid wood edge banding for maximum impact resistance.