To use sand or salt to bend the pipe:

- Straighten out the copper pipe or tubing. ...

- Tape off the bottom of the copper pipe with duct tape or electrical tape.

- Fill the copper pipe with sand or salt, using a funnel.

- Tape up the other end of the pipe.

- Bend the pipe to the desired curve.

- Remove the tape and let the sand or salt flow out.

- Straighten out the copper pipe or tubing. ...

- Tape off the bottom of the copper pipe with duct tape or electrical tape.

- Fill the copper pipe with sand or salt, using a funnel.

- Tape up the other end of the pipe.

- Bend the pipe to the desired curve.

What is the method of bending a pipe?

In this method, the pipe is held down at 2 external points and the ram pushes on the pipe at its central axis to bend it. Bends tend to deform into an oval shape at both the inside and outside of the bend. Rotary draw bending is used to bend pipe for use as handrails or ornamental iron,...

How do you bend aluminum conduit with a pipe bender?

Steps Use a manual pipe bender or a hydraulic bender if you have one. You can bend 1 1/4" aluminum conduit by hand, but a manual pipe bender will make it easier. Fill the pipe with sand or other material, and secure three layers of window screening, with double hose clamps on the ends.

How do I fix a bent pipe?

Plan ahead - the end closest to the bend will likely have to be cut off and discarded. The first thing to do is to plug one end of the pipe. I used a small carriage bolt that fit snugly in the end. The next step is to fill the pipe with sand. I used beach sand. The sand should be nice and compact to stop the pipe from buckling.

How do you bend a frozen copper pipe?

Coil up the copper pipe so that the two open ends point upward. With a funnel, fill the copper pipe with water. Put the pipe in the freezer and let it freeze completely. Remove the pipe from the freezer and bend it. If you have sand or salt on hand, those will be easier for you to work with than this method.

What is rotary draw bending?

How does induction bending work?

How long is a pipe bend?

How to find where a bend in a pipe starts?

How to calculate how long a piece of pipe is needed?

How to check the angle of a pipe?

Why won't my pipe grow?

See 4 more

About this website

How do you bend an AC refrigerant line?

0:1015:29How to Bend, Prep, and BRAZE Copper to Copper on an HVAC ...YouTubeStart of suggested clipEnd of suggested clipPut one about right here. And that way it's just a straight shot. I'm going to bend a 90 there i'mMorePut one about right here. And that way it's just a straight shot. I'm going to bend a 90 there i'm going to bend a 90 coming up and then bend to 90 going into the air handler.

How do you bend aircon piping?

8:0910:16How to bend copper tubing for refrigeration and air conditioningYouTubeStart of suggested clipEnd of suggested clipYou're going to want to look at it visually. All right make sure it lines up I mean every time youMoreYou're going to want to look at it visually. All right make sure it lines up I mean every time you make a mistake you're going to have to throw away another piece of copper.

How do you bend hard copper pipe?

1:152:43How to bend copper pipe - YouTubeYouTubeStart of suggested clipEnd of suggested clipIf you want to bend further down the pipe. You should tie a piece of swing to that end a piece ofMoreIf you want to bend further down the pipe. You should tie a piece of swing to that end a piece of really tough sling and then you can pull it back out again afterwards.

How do you bend tubing without kinking it?

1:033:20Bending Tube and Pipe without kinking it... Tubing Bender ...YouTubeStart of suggested clipEnd of suggested clipTime to band the vice grip is just holding it from wrapping around the sands going to keep it from.MoreTime to band the vice grip is just holding it from wrapping around the sands going to keep it from. Kinking. You can hear the sand is crunching.

Can hard copper pipe be bent?

Both annealed tube and hard drawn tube can be bent with the appropriate hand benders. The proper size of bender for each size tube must be used.

How do you bend a line set?

0:000:29Mini Split Install Tricks and Tips - Bending Line Set Correctly!YouTubeStart of suggested clipEnd of suggested clipAs you start bending it you can slowly pull your fingers out don't be afraid to crush your fingersMoreAs you start bending it you can slowly pull your fingers out don't be afraid to crush your fingers cuz. It's better than crushing the line set.

Can we bend AC copper pipe?

While copper is soft, it's not soft enough to bend smoothly and perfectly on its own. Bending copper pipe without special methods or tools usually results in pipe collapse.

How do you bend a pipe without a bender?

Use a blow torch (for harder materials) or a hair dryer (for softer materials) and heat the area where you want to bend the pipe. Once the material gets extremely hot, put on heat-resistant gloves and bend the pipe by hand.

Does bending copper pipe weaken it?

If a copper pipe is just forced to bend, the walls of the tubing will collapse and possibly rupture, it is therefore essential to use the correct tools to avoid this happening.

What is the difference between a pipe bender and a tube bender?

The difference between a pipe and tube bender is pretty simple, there is none. If a machine can bend a tube, it can bend a pipe. The only exceptions to this would be for either very large or very small tubes and piping.

How do you bend tubing accurately?

1:436:11How to Use a Hand Tube Bender | Tech Tips | Swagelok [2020]YouTubeStart of suggested clipEnd of suggested clipCarefully lower the short handle until the rolled eyes rest gently on the tube. While keeping theMoreCarefully lower the short handle until the rolled eyes rest gently on the tube. While keeping the link straight and parallel to the long handle.

Why does my pipe bender kink the pipe?

One of the main reasons a tube may be kinking or buckling during the bend has to do with the hardness of the material. When a material is too hard, it may not compress on the inside radius of the bend. This lack of compression forces the material to push toward the tube's center line.

How do you bend copper pipe 90 degrees?

1:423:38HOW TO BEND COPPER PIPE - 90 DEGREE ELBOW - Plumbing TipsYouTubeStart of suggested clipEnd of suggested clipGo slightly over the band because when you let go the pipe springs back a little bit. So there we goMoreGo slightly over the band because when you let go the pipe springs back a little bit. So there we go you're on streamate your arms that's half why pull your former out. If.

How do you bend a pair coil?

1:083:45How to bend copper pipe with a bending spring. A cheap ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipTo do it like that use your disaster. Pull it round now if you lay on the floor. And just bend itMoreTo do it like that use your disaster. Pull it round now if you lay on the floor. And just bend it back a little piece like that just because I've showed you it's decided to bend it quite properly.

How do you bend copper tubing 180 degrees?

0:082:10P B Plumber how to pull a 180 bend #Shorts - YouTubeYouTubeStart of suggested clipEnd of suggested clipHold it there and with our off cut line that up you can see that we've created our 180 i'm going toMoreHold it there and with our off cut line that up you can see that we've created our 180 i'm going to mark that on the pipe. And then just go lengthways as well to make it into a cross.

How do you bend copper wire?

1:456:27How to Bend Wire for Jewelry Making DIY Tutorial - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo you just hold the wire like that and then what I'd like to do is just kind of bend it like holdMoreSo you just hold the wire like that and then what I'd like to do is just kind of bend it like hold my hand fixed here and then just push this with that side so you're holding with the pliers.

How to Bend Pipe Without a Pipe Bender - Instructables

How to Bend Pipe Without a Pipe Bender: Ahoy! So you have some pipe that needs to be bent but you don't have a pipe bender. Well no problem! This instructable will show you how to do it using sand and some creativity. The pipe shown here is 4130 steel - 3/4" in diameter with a…

What is rotary draw bending?

Rotary draw bending is used to bend pipe for use as handrails or ornamental iron, as well as car chassis, roll cages, and trailer frames, as well as heavier conduit. Rotary draw bending uses 2 dies: a stationary counter-bending die and a fixed radius die to form the bend.

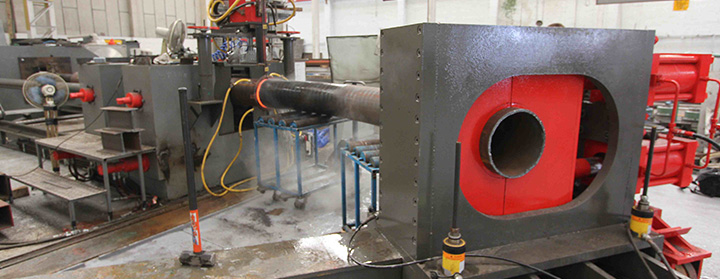

How does induction bending work?

Induction bending heats the area to be bent with an electric coil, and then the pipe or tube is bent with dies similar to those used in rotary draw bending. The metal is immediately cooled with water to temper it. It produces tighter bends than straight rotary draw bending.

How long is a pipe bend?

If the markings on each end of the pipe bend touch the square at 6 inches (15 cm) from the inside corner of the square, the total length of the bent section of the pipe is 12 inches (30 cm).

How to find where a bend in a pipe starts?

Find the place where the bend in the pipe starts. You should see or feel a small flat spot or distortion at the place where the bend starts and where it ends.

How to calculate how long a piece of pipe is needed?

Once you know how much pipe is needed to form the bend, you can calculate how long a piece of pipe you need by adding this figure (called the bend deduction) to the vertical and horizontal lengths of the pipe .

How to check the angle of a pipe?

To check the angle of your pipe, lay it against a carpenter's square with the outer bend facing the corner of the square. Both ends of the pipe should just touch the square's sides and run parallel to them.

Why won't my pipe grow?

The pipe will not grow in length if you bend it properly so that it does not collapse across its diameter.

How to braze copper pipes?

When you are doing more than a single braze it is advised that you purge the pipe work with oxygen free nitrogen during the brazing. The build up of oxidisation inside the pipework will cause issues with the refrigerant oil and cause compressor failure. Once the pipe has been run you will then need to insulate it with lagging. Once all the pipe is lagged, run in your interconnecting comms and power cables. Secure all interconnecting services with the correct type of supports dependant on the installation. Be sure to to follow the manufacturer electrical installation guidelines and consider using a screened comms cable to prevent interference from other cables.

What type of coils are used for AC?

Soft copper coils are the preferred type for most residential air conditioning installations due to the flexibility and ease of handling. It is easy to kink your pipe work and in some cases over braze and block capillary connections. You will find issues like refrigerant starvation to your home AC indoor unit and in turn critical oil starvation ...

How does over sizing an AC unit affect the room temperature?

In turn, over sizing an air conditioning system will cause swings in the room temperature during operation. Draft problems from the air outlet being too powerful will also cause comfort cooling issues. There is a lot to consider prior to installation and may be a better choice to use an air conditioning installation contractor.

Is AC installation the same as commercial installation?

The installation processes for your home AC and commercial air conditioning are the same and require the same tools and knowledge. If you don’t have the tools or manual labour experience it is best to seek advice first. Guide performed by individuals training or with trade experience.

Can you mount an air conditioner on the floor?

A wall bracket is another option to use when direct floor mounting is not possible . Wall brackets come in different weight capacities so be sure to select the right type for the condensing unit.

Can drafts cause cooling issues?

Draft problems from the air outlet being too powerful will also cause comfort cooling issues. There is a lot to consider prior to installation and may be a better choice to use an air conditioning installation contractor.

Tube and Pipe Bending Terms

Rigid metal pipe and tubing tend to be made of copper, steel, stainless steel or aluminum, but are not the same thing.

Types of Bending

There are multiple methods of bending to meet the requirements of pipe and tubing of different sizes and materials.

How to Make a Reference for a 90-Degree Bend

When bending tube or pipe, the interior wall of the bend becomes more compressed and thicker, while the exterior wall becomes stretched and thinner. To determine how long a piece of tubing you need and to make sure it achieves the correct shape, use this method to create a 90-degree reference bend.

Preparing to Use a Manual Bender

Many heavy-duty benders require a power source, but manual pipe and tube benders can be operated by hand. Learning how to use manual tubing benders can be the simplest and most cost-effective route.

Manually Bending the Tube or Pipe

Grip the roll support arm and bring it down until the tube reaches the desired degree mark on the bending die.

Step 1: Pack Your Pipe

The first thing to do is to plug one end of the pipe. I used a small carriage bolt that fit snugly in the end. The next step is to fill the pipe with sand. I used beach sand. The sand should be nice and compact to stop the pipe from buckling.

Step 2: Bend!

Clamp one end to a form. Here I used a wine barrel planter and then added a rounded block (that just happened to be in my workshop) to get a tighter radius. You will likely need a lot of leverage to bend the pipe. This piece was 4 feet long and it took some muscle to get the bend.

Step 3: Finish It Up

Cut the deformed end off. Clean out the sand. I used a piece of string with a rag on the end to get all the sand out. The picture below shows the slight dimple in the center of the bend.

How to bend 1 1/4" conduit?

1. Use a manual pipe bender or a hydraulic bender if you have one. You can bend 1 1/4" aluminum conduit by hand, but a manual pipe bender will make it easier. It doesn't matter what you use to bend the pipe, the main thing is how you keep it from collapsing.

How to bend aluminum conduit?

Steps. Use a manual pipe bender or a hydraulic bender if you have one. You can bend 1 1/4" aluminum conduit by hand, but a manual pipe bender will make it easier. It doesn't matter what you use to bend the pipe, the main thing is how you keep it from collapsing. Fill the pipe with sand or other material, and secure three layers of window screening, ...

What is wikihow wiki?

X. wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 20 people, some anonymous, worked to edit and improve it over time.

How many people edit wikihow?

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 20 people, some anonymous, worked to edit and improve it over time. This article has been viewed 111,384 times.

What is the radius to wall ratio for pipe?

A loose rule of thumb is a maximum 3 1/2" radius to 1" diameter ratio.

Is aluminum pipe easier to bend than aluminum tubing?

Learn more... Aluminum pipe is much easier to bend than aluminum tubing, due to the greater wall thickness, since it is less likely to collapse or deform when you bend it. The thicker material will also require more muscle or the use of a power bender.

Can you bend a pipe with a die?

Consider building dies to bend your pipe if you have the equipment, you can machine your own bending dies for bending the pipe, or you can rent a manual or hydraulic bender for this purpose.

How to bend copper pipe with a spring?

To bend a copper pipe with a tube spring: Use an indelible marker to mark the spot on the copper tube where you want to make the bend. The mark should be at the outermost point of the bend's radius. Clean off any burrs on the end of the copper pipe from cutting. Choose the correct size of spring for the pipe.

What is the best way to bend copper pipe?

Use Sand or Salt to Bend the Pipe. Dense materials packed inside the copper pipe produce an effect much like pipe bending springs. They prevent any single area from receiving all of the bending force. Instead, the force is distributed along the entire length of the curve. Fine sand and salt can be used.

What is tube bending?

Tube-bending springs fit in the copper pipe and act as support to better distribute the force. Bends as extreme as 180 degrees are possible with tube springs. Tube springs come in kits of various sizes that fit copper pipes ranging from 1/4-inch to 5/8-inch diameter.

What is a pipe bender?

A pipe bender is a small, inexpensive, dedicated tool that does only one thing but does it very well. It bends various sizes of copper and other soft metal pipes to a set radius, usually about 2 or 3 inches.

How to straighten copper pipe?

It doesn't have to be perfectly straight; only straight enough to allow the material to flow. Tape off the bottom of the copper pipe with duct tape or electrical tape. Fill the copper pipe with sand or salt, using a funnel. Tape up the other end of the pipe.

How to retrieve a spring from a copper pipe?

If the spring is longer than the pipe, you can easily retrieve the spring after bending the pipe. If the spring is shorter , attach a wire to the end of the spring. After padding the copper pipe with a soft cloth, bend it over your knee.

What is copper pipe used for?

Durable and easy to work with, copper pipe is frequently used in homes as a water supply pipe. Since copper is a beautiful metal, whether polished and shiny or left to age to a green patina, copper pipe is often used as a crafting material for its own decorative qualities.

What is rotary draw bending?

Rotary draw bending is used to bend pipe for use as handrails or ornamental iron, as well as car chassis, roll cages, and trailer frames, as well as heavier conduit. Rotary draw bending uses 2 dies: a stationary counter-bending die and a fixed radius die to form the bend.

How does induction bending work?

Induction bending heats the area to be bent with an electric coil, and then the pipe or tube is bent with dies similar to those used in rotary draw bending. The metal is immediately cooled with water to temper it. It produces tighter bends than straight rotary draw bending.

How long is a pipe bend?

If the markings on each end of the pipe bend touch the square at 6 inches (15 cm) from the inside corner of the square, the total length of the bent section of the pipe is 12 inches (30 cm).

How to find where a bend in a pipe starts?

Find the place where the bend in the pipe starts. You should see or feel a small flat spot or distortion at the place where the bend starts and where it ends.

How to calculate how long a piece of pipe is needed?

Once you know how much pipe is needed to form the bend, you can calculate how long a piece of pipe you need by adding this figure (called the bend deduction) to the vertical and horizontal lengths of the pipe .

How to check the angle of a pipe?

To check the angle of your pipe, lay it against a carpenter's square with the outer bend facing the corner of the square. Both ends of the pipe should just touch the square's sides and run parallel to them.

Why won't my pipe grow?

The pipe will not grow in length if you bend it properly so that it does not collapse across its diameter.