Bending the Offset

- Insert the conduit into the bender with the 38" mark positioned at the arrow normally used to bend a 90. (You can use any mark on the bender, as long you use it for both bends. ...

- The bender handle is likely to kick out when bending in this manner. ...

- Slowly bend the conduit, keeping pressure as close to the bender as possible. ...

How to bend PVC pipe the easy way?

Method 2 Method 2 of 2: Using a Hairdryer or Heat Gun

- Fill the pipe with enough sand to cover two to three inches above the planned bend. ...

- Apply the heat evenly around your planned bend. The sand inside will make this take longer, but it also ensures that the pipe holds its form and doesn't cave ...

- Slowly bend the pipe, applying more heat as necessary. ...

- Remove the sand and let the pipe cool. ...

What is the maximum degree of one bend in Conduit?

No section of conduit shall contain more than two 90-degree bends, or equivalent between pull points. For conduits with an internal diameter of 2 inches or less, the inside radius of a bend in conduit shall be at least 6 times the internal diameter.

How do you bend a concentric bend in Conduit?

- Back to back bends. Two 90° stub up bends on opposite sides of the conduit, with both stubs moving in the same direction.

- Offset bends. Almost a sidewinder pattern, this bend incorporates two 45° angles in order to shift the conduit beside an obstacle but still run in parallel with the old line.

- Three- and four-point saddle bends. ...

How to bend EMT metal conduit?

Part 2 of 3: Making a Basic Bend Download Article PRO

- Work with a bender. A bender is an essential for any conduit bending project. ...

- Slide the conduit into the bender. Be sure to leave the appropriate amount past the arrow on the bending shoe.

- Pull the bender handle toward you to create the bend. ...

- Bend until your bender reaches the 90° mark or other desired corner angle. ...

How to bend conduit?

What is the degree of bend between conduits?

What Is an Offset Bend?

What happens if you bend an offset bend?

How to bend a 90?

How to bend a pipe that is not straight up and down?

What is the most important thing to consider when bending conduit?

See 2 more

How do you bend a 30 degree offset?

2:343:31Conduit Bending Offsets - YouTubeYouTubeStart of suggested clipEnd of suggested clipWe're going to bend it down to the 30 degree mark. One thing you want to remember always keep theMoreWe're going to bend it down to the 30 degree mark. One thing you want to remember always keep the bend in front of you.

How do you bend a conduit offset without a bender?

1:3813:20HOME MADE CONDUIT BENDER - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd the whole when you drill that you're going to want to use a drill a little bit bigger than yourMoreAnd the whole when you drill that you're going to want to use a drill a little bit bigger than your conduit this is half inch conduit I've got a 3/4 inch drill. So it's almost exact.

What is the multiplier for bending 30 degree offsets?

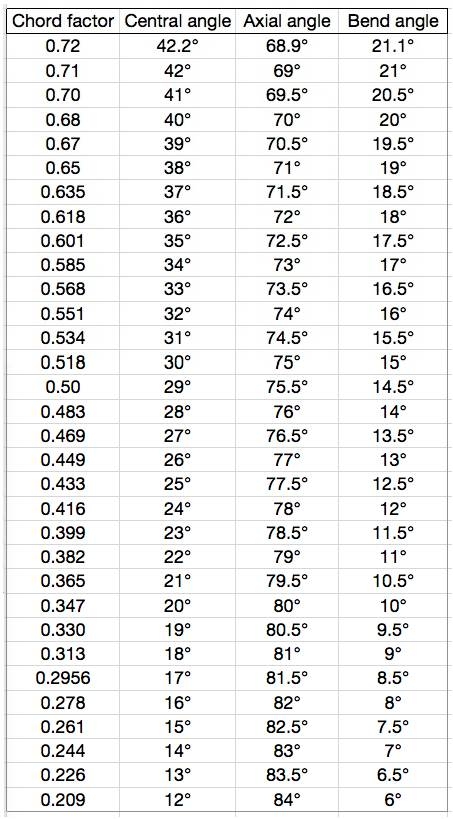

2 1/4Mathematics of the Offset BendDegree of Bend in Degrees (Angle)MultiplierShrinkage Multiplier in inches153.91/822.52.63/163021/4451.43/82 more rows•Jan 26, 2006

How do you bend an offset pipe?

0:594:25Offset bend - YouTubeYouTubeStart of suggested clipEnd of suggested clipI lay it on top. I lock the arm back down and as you can see currently that cross is too far away soMoreI lay it on top. I lock the arm back down and as you can see currently that cross is too far away so I'm going to slowly move the pipe into position I wanted to go through the top of the cross.

How do you bend a conduit 90 degrees without a bender?

How to Bend Pipe Without a Pipe BenderStep 1: Pack Your Pipe. The first thing to do is to plug one end of the pipe. I used a small carriage bolt that fit snugly in the end. ... Step 2: Bend! Clamp one end to a form. ... Step 3: Finish It Up. Cut the deformed end off.

What 5 degrees can be used to make an offset bend?

Using the Multiplier When Bending an Offset You should memorize this number for the common bends of 10, 22, 30, and 45 degrees.

How do you calculate bending offset?

0:052:48Measuring method for Offset Bends - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe first step in bending an offset rise is measuring the offset rise needed this measurementMoreThe first step in bending an offset rise is measuring the offset rise needed this measurement represents the distance from the bottom of the conduit to its supporting surface.

How do you bend a perfect offset?

3:495:07How To Make A Box Offset Bend - YouTubeYouTubeStart of suggested clipEnd of suggested clipNow step three is to slide the conduit down to the second mark okay and again line up the secondMoreNow step three is to slide the conduit down to the second mark okay and again line up the second mark with the arrow on the side of the bender head and then you're going to rotate the conduit 180

How do you calculate a 22 1 2 offset?

2:014:48Calculating a 22 1/2 degree offset piping system - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo it's the same kind of thing. All right so what we'll do here is we'll do a couple examples toMoreSo it's the same kind of thing. All right so what we'll do here is we'll do a couple examples to show you how to calculate this stuff. So first one find the length of the tri if the offset is 12.

How is conduit offset calculated?

(Offset Distance) X (Constant Multiplier) = Second Mark Distance (Distance between Marks). Example: 6” X 1.4 = 8.4” between 1st & 2nd mark. This calculated value is how far apart to make your marks from each other on the conduit and where to make your 45° bends. 4.

What is the formula for bending conduit?

Answer: There is no real formula, but it can be calculated with a fair degree of precision. Multiply the radius of the bend you want to make by 6.28, then by degrees, bend and divide by 360. Divide once more by two, measure from the center of the pipe that far then set that mark at the front edge of the bending shoe.

How many inches do you deduct for a 90 degree bend?

The most common deducts are 5" for ½" conduit, 6" for ¾" conduit and 8" for a 1" bender. It is a function of the curvature radius of the bender and cannot be changed. The deduct for your bender should be stamped on the bender.

How do you bend a pipe without a pipe bender?

Use a blow torch (for harder materials) or a hair dryer (for softer materials) and heat the area where you want to bend the pipe. Once the material gets extremely hot, put on heat-resistant gloves and bend the pipe by hand.

How do you bend a rolling offset EMT?

1:329:36How To Bend A Rolling Offset On Conduit - YouTubeYouTubeStart of suggested clipEnd of suggested clipPeople just offset more and then roll it in there and then bend it in like push. It.MorePeople just offset more and then roll it in there and then bend it in like push. It.

How do you bend a 60 degree offset?

1:014:27Electrical Conduit Bending Tutorial: 60 Degree Offset - YouTubeYouTubeStart of suggested clipEnd of suggested clipOn the bender to put your mark right here on the edge of the pipe. Put my four and a half inch markMoreOn the bender to put your mark right here on the edge of the pipe. Put my four and a half inch mark right there and then I'm I've been down to sixty degrees.

What is the multiplier for a 15 degree offset?

The calculator tells us that the inverse tangent of . 2666 = 15º. At the same time, we can find the multiplier of a 15º bend by dividing one by the sine of 15º; the answer comes back that the multiplier for 15º is 3.86.

How to get rid of burrs in conduit?

Cut the conduit to the size you need, removing burrs from the end. Use a conduit reamer or knife to scrape the edges to get rid of any fragments, or burrs. Ensure that all burrs are removed before you install the conduit. Otherwise, this may cause a short or ground fault after the wire has been installed.

How to bend conduit?

Then, cut the conduit, scrape off any rough edges, and slide it into the bender so that the place you want the conduit bent lines up with the arrow.

What is conduit bender?

A bender is an essential for any conduit bending project. The tool should fit the correct sized conduit tube that you need to use. Before you start the bending process, locate any instructions on the conduit bender that may describe how much conduit should remain past the bend to the end of the bending shoe.

How to measure conduit length?

1. Measure the length of conduit you’ll need. Start from a corner or other orienting point, then measure from the corner to where the conduit will end (usually a converter box). Place a pencil mark on the conduit at the measurement where the corner should be.

What is a back to back bend?

Back to back bends. Two 90° stub up bends on opposite sides of the conduit, with both stubs moving in the same direction.

What is a dog leg on conduit?

Be careful about creating a dog leg when you shape conduit. A dog leg is where multiple bends on a line don't line up in the same plane. Examine the alignment in all directions before bending off.

How many bends are there in electrical work?

Experiment with different kinds of bends. A typical electrical job will require more than simply a 90° stub-up bend. In fact, there are dozens of different combinations of bends you can use. It's helpful to experiment with bending a couple of them. Remember that practice makes perfect!

Where to place a bender on a conduit?

Place the bender on the conduit facing the free end that is opposite the original bend you made in step 2. Line up the mark from step 3 with the start point symbol on the bender.

What to do if your conduit is not at the correct angle?

If the curve in your pipe is not at the correct angle, just place it back in the bender and adjust the bend. When your measurements are all correct, the conduit will fit securely in the space in which it is to be installed. As always, wear protective gear to prevent injury.

How to bend a bender with arrows?

Line up the start point symbol on the bender (often an arrow) with the line you made in step 3. Apply pressure to the heel end of the bender with your foot, using the handle as a lever, until you reach the 90 degree position. Remove the conduit from the bender and check the angle. Overbending may be necessary if you get a slight spring-back ...

How to balance conduit in air?

Place the bender on the conduit and line up the start point symbol with the first mark on the conduit. Keep the conduit flat, using foot pressure to roll up the conduit to the 45 degree angle mark on the bender. Flip the bender and conduit (keep them together) until the bender’s handle is on the floor and the conduit is balanced in the air.

How to calculate stub height?

Calculate the stub height by using the free end height and subtract the stub adjustment (from Bender Take Up Table below)

How to line up a bender?

Rotate the conduit 180 degrees in the bender cradle and slide the conduit to line up the bender’s start point symbol with your second mark.

What do the symbols on a bender mean?

Symbols on the bender are used to indicate the beginning and back of the bend. Depending on the type of bend you are completing, you need to align the curve with the correct symbol and match the top of the pipe with the correct degree marker. A bender uses your foot pressure to make the bend.

How to bend conduit?

1. A proper bend is made by rolling the conduit about the bender in the conduit’s cradle using all foot pressure. 2. Use the correct size bender for the conduit size being bent. 3. Some over bending may be required to allow for spring back of the conduit. The resting condition of the conduit is to be at the final angle desired. 4. Measure and properly mark your conduit using the tables and information provided. 5. Floor bending: Make sure conduit is secure so it does not slide prior to bending. Apply ample foot pressure to the benders heel while minimizing the use of the handle as a lever but more of a guide. 6. Air Bending: Make sure handle’s hilt is secure on ground and is reinforced by your foot so it does not slide out. Make sure you are balanced and apply force close to the tool and your body controlling the tubing as you bend it around the bender’s cradle making sure the conduit does not slide in the bender head. 7. To prevent injury, always wear protective gear and do not over exert.

What happens if you bend conduit?

When the bend is done properly the conduit will lay flat and will fit inside the two surfaces measured.

What is offset bend?

An offset bend is a style of bend that is built independently of the 90° stub and the Back to Back bend and is an important bend to know when running conduit. It is common to shift the conduit a certain distance while continuing to run parallel in the same direction as the pre-shift portion of the conduit. There are many situations that call for an offset bend. The most common uses of this bend are: staggered joists, running tight on a wall and offset into an electrical box and changes in elevation.

How to make a stub bend?

The stub bend is made by bending a piece of conduit into an L shape or 90° bend by placing the free end (short end) of the tube to a predetermined length as indicated in the diagram below. This is the most common bend and is a building block for other bends. Common uses for this bend are: Running conduit into electrical boxes, running conduit up or down walls, running conduit into walls through floors and ceilings and making inner and outer corner turns.

What is back to back bend?

The back to back bend is the next style of bend that is needed while running electrical conduit. In reality the concept is formulated by the need to know the distance from the backedge of a 90° bend to a fixed point down the conduit to mark for other bend operations to meet the installation requirement. As you will see it builds on the 90° stub bend and when done the most common use of this bend will look like an elongated U.

What is a saddle bend?

The three point saddle bend is a variant of the offset bend since it is an offset bend that returns to the original in-line run after clearing an obstacle. This bend is intended to bridge over obstacles such as existing conduit or plumbing running perpendicular to the intended conduit installation.

What are the different types of conduits?

Conduit come in two types, EMT and Rigid conduits and can be found in various sizes. Klein Tools provides conduit benders for EMT in ½”, ¾”, 1” and 1-¼” conduit and ½”, ¾”, and 1” Rigid conduit.

How to bend conduit?

To bend a “kick” place your bender facing your 90, or facing away from the direction your pipe run is coming from. Once your conduit is laying in the bending shoe, push down with your foot slightly (with a tape measure held in front of your bend to measure the height of the kick) until the kick yields the desired clearance/height. That is seriously all you do.

What is offset in conduit?

A standard offset is something you will use the heck out of when you have different heights or obstacles in your runs of conduit. Sometimes, rarely…but sometimes, you will work in the ceiling of a building that doesn’t require any offsets. Everything is perfectly straight and can be achieved by straight runs and 90s. But again, this is rare. More often than not you’ll need to bend an offset or two on every job you do, so let’s look at how it’s done.

What is the easiest offset to bend?

The easiest offset to bend is the 30 degree offset , and it is the one I choose most often because of speed and accuracy. The first reason I choose 30 degrees is that both of your bends are easy to gauge. When bending the offset, each bend results in the handle of the bender pointing straight up to the sky when you hit your 30 degrees. If the handle is level and perfectly perpendicular to the floor, you should look down at the 30 degree mark on the shoe of the bender and notice it lines up exactly with your pipe. Reason 2 for choosing a 30 degree offset is that the math is easy. Every offset angle has a specific mathematical multiplier that you use to achieve your result. You must stick to this multiplier when marking the distance between bends, if you want your offset to land exactly where it needs to. See below for a list of multipliers:

How to offset a pipe?

To execute a box offset, place the shoe of the bender at the end of the pipe, as you would a stub 90. Slightly press down on the shoe of the bender until the conduit is between the 10 and 22.5 degree marks on the bender. Once this is set, scoot the pipe back about a 1/2” to 3/4” of an inch behind the first bend and twist/spin the conduit 180 degrees to prepare for the next bend. Next you’ll do the exact same thing, bending the second bend between the 10 and 22.5 degree mark to match the first bend. Now your pipe should make a slight “Z” shape at the end. You should be able to put your tape measure down on the ground and measure roughly a 1/2” space below the end of the pipe and the ground. If it’s too much you may have to use the bender to take out a tiny bit of bend from both bends. If the measurement is too little, you may have to go back and bend each of the bends a tad more.

How to bend a 30 degree angle?

To bend a 30 degree angle with a conduit bender, you bend the pipe up from the ground until the 30 degree line on the bender is parallel to the pipe and floor. You would flip the bender over and repeat this step if you were trying to bend a 30 degree offset to overcome an obstacle.

How to know what conduit bender to use?

To start off, every bender has stamped in it what type of conduit the bender is designed to be used for. A 1/2” bender will say “1/2” EMT Only” or something similar – usually located where the shoe meets the threaded end of the handle. If you flip the bender around 180 degrees, in the same spot there will be a stamp for what size takeoff you’ll need to use to achieve the proper bend with this bender.

How to measure a 90 degree bend?

A forward 90 is a 90 degree bend made by measuring from the front side of a pipe (front being the side you’re looking at if you’re kneeling at the half way point of the pipe. The part of the pipe behind you is called the “back side” of the pipe. With a forward 90 you take a measurement from the end of the pipe and mark that measurement. If you need to bend a 90 to hit a wall or some arbitrary line, you’ll use this exact measurement to mark your pipe. From this measurement you’ll subtract whatever amount you need (depending on the size of the pipe) towards the end of the pipe you just measured from. So from your original mark you measure, AWAY FROM YOU, 6 inches with 3/4” EMT (electrical metallic tubing) and mark the pipe again. This mark is now your only important mark. The first mark no longer matters to us.

Calculations & Formulas

Using just a few mathematical formulas allows you to properly calculate a bend of nearly any angle.

Elements of a Bend

It is important to understand the different elements of a bend in order to make accurate calculations.

How to bend conduit?

Bend the conduit. Place the length of conduit you measured flat on the floor. Apply firm pressure on the foot pedal until the conduit bends to a 90º angle. Checking this angle with a level is highly recommended, since it's important that the two bends of the U are parallel.

What angle to bend conduit?

As a general rule, the shorter the offset distance, the smaller the angle. An offset of a few inches can use a 10º or 22.5º angle, but an offset of several feet may call for 30º or 45º. Smaller angles will "use up" less of your conduit, but may be more difficult to bend precisely.

How to measure a stub up bend?

A stub up bend is a 90º bend near the end of the conduit. Measure the distance on the wall from the end of the conduit to the position of the bend.

How to measure conduit length?

Measure from this wall along your conduit, to the desired length. Mark the conduit at this length using a permanent marker or pencil.

How to bend conduit without pulling?

Without pulling, use one hand to steady the handle on your bender, and the other to steady the conduit end once it rises within reach. Apply firm, constant foot pressure, as a pause could create a kink in your conduit. Bend until the end of the conduit is vertical, or very slightly past vertical.

What is the center bend on a saddle?

Bend the center. Most benders have a teardrop mark used for the center of a 22.5º–45º–22.5º saddle. Others may have three notches or marks along the rim, next to a "center bend" mark that looks like a semicircle with an arrow at the center. These three notches correspond to 30º, 45º, and 60º angles.

How to use offset bends?

1. Use offset bends to shift the position of the conduit. An offset bend requires you to bend the conduit in two places at opposite angles, usually between 10 and 45 degrees. Use this to shift the conduit to avoid an obstacle or change elevation, the continue in its original direction.

How to bend conduit?

Slowly bend the conduit, keeping pressure as close to the bender as possible. Although more leverage makes it easier, be careful! If pressure is applied several feet back from the bender, it will result in an unsatisfactory bend.

What is the degree of bend between conduits?

While bending conduit, one of the more important things to consider is the total number of degrees of bend between pull boxes. The NEC (national electric code) limits this number to 360º and some job specifications limit it even further. Fewer degrees of bend also result in an easier pull when it comes time to pull wire into the conduit—always a good thing. While bending an offset may be inevitable and necessary, the degree of the bend is variable depending on circumstances and the electrician doing the work.

What Is an Offset Bend?

One of the more common bends made in electrical conduits is the offset bend: a technique used to move a run of conduit a set distance to one side, up or down. It is very rare that conduit can be placed in a straight line along the entire distance needed. There will usually be small projections in the way, other equipment to navigate around, or other reasons to move the conduit over some distance.

What happens if you bend an offset bend?

If bent in this position, the completed offset bend will have a dogleg in it. Make sure the conduit is straight in the bender

How to bend a 90?

Insert the conduit into the bender with the 38" mark positioned at the arrow normally used to bend a 90 . (You can use any mark on the bender, as long you use it for both bends. The very toe of the bender is often more convenient for offsets intended to begin close to the end of the conduit).

How to bend a pipe that is not straight up and down?

Answer: Simply bend the offset and then turn the pipe so that it is not straight up and down, but rolls to one side. The bending process is exactly the same as if there were no roll - any roll you need is accomplished during the installation of the pipe.

What is the most important thing to consider when bending conduit?

While bending conduit, one of the more important things to consider is the total number of degrees of bend between pull boxes.