How do you calculate speed and feed? Speed (RPM) = (Surface Feet per Minute x 3.82) / Diameter of the Tool Feed Rate = RPM x Chip Load x Number of Teeth

- Speed (RPM) = (SFM x 3.82) / D.

- Feed (IPM) = RPM x FPT x Z.

- SFM (Surface Feet per Minute) = (RPM x D) / 3.82.

- IPT (Inches per Tooth) = (IPM / RPM) / Z.

- MRR (Cubic Inches per Minute) = IPM * WOC * DOC.

- AFPT (@ less than 1/2 dia. WOC) = IPM x sqroot of (D / WOC)

- HP (Horsepower Consumption) = MRR x mf.

What is the equation for RPM?

rpm = (mph x Rear End Ratio x 336) / Tire Diameter I knew my rear axle ratio was 4.10:1 and measured my tire height (on blacktop) and came up with an average of about 31 inches. I headed out to the highway and got my truck up to 65 mph in overdrive and set the cruise.

How to figure out rpm?

Calculate RPM from horsepower and torque. The formula to calculate Rev. Per Min (RPM) is: RPM = Horsepower * 5252 / torque; With our online Horsepower, Torque & RPM Calculator. Power can be measured in. Horsepower (HP), Watts (W) or. Kilowatts (kW). Torque can be measured in.

How do you calculate the instantaneous speed?

- First, we must measure the initial velocity. We will say for this example that this is a car moving along the street. ...

- Next, we must determine the acceleration of the car. ...

- Now, the total time that has passed needs to be determined. ...

- Finally, enter the information into the formula above. ...

- Analyze the results and apply them to future problems.

How to improve calculation speed?

- You can find speed tests online or in your local school supply store. Typically, there will be 50 problems on a single sheet that you will work through.

- Work as fast as you can to finish and then go back to check your work. ...

- Aim for accuracy above time, but eventually you will only to have to focus on how fast you can get the right answer out.

What is feed rate?

Feed rate is the velocity at which the cutter is fed, or the rate advanced against the workpiece, often expressed in units of distance per revolution for turning, that typically is inches per revolution (IPR) or millimeters per revolution (MPR). Turning feed rate is determined by the type of cutting tools, surface finish desired for milling parts, power available at the spindle, rigidity of the machine and tool setup, characteristics of the material to be cut, workpiece strength, cut width, etc.

How to determine spindle speed?

The preferred speed is determined by working backward from the desired cutting speed (SFM or m/min), which may be defined as the rate at the workpiece surface, and incorporating the diameter of cutter or workpiece. CNC turning is a computer-controlled manufacturing process in which bars of material are held in a chuck and rotated while a cutting tool is fed to the workpiece to remove excess material to create designed CNC turned parts. In turning operation, the cut diameter is used.

What is SFM in machining?

Cutting speed (SFM): the rate at the workpiece surface, measured in surface feet per minute, irrespective of the machining operation used.

What is RPM in a lathe?

The RPM calculated in the Turning (Lathe) Speed and Feed Calculator refers to the spindle speed in turning process, and the IPM refers to feed rate.

What is feed speed?

What are Feeds and Speeds? Feed refers to the rate of movement of the axes of your machine, it is programmed in inches per minute (IPM) or millimeters per minute for metric. Speed refers to the RPM of the machine spindle, i.e. the rotational speed of the tool on a mill or workpiece for a lathe.

How fast is a SFM?

A typical SFM for aluminum on an industrial machine can be as fast as 1200. This would be way too much for a small benchtop cnc machine. Hobby machines are too limited in their spindle speeds and movement.

What is the RPM range of a router?

To get around this we will need to make adjustments. For example a router usually has a very high RPM, 12,000 and up, so to enable a higher RPM you can use a smaller dia cutter.

Why does my spindle pulley have more torque?

This will be caused by a lack of power in your spindle motor. Slow down both spindle and feed. On machines with a pulley system to control RPM, a slower spindle pulley will generate more torque.

What SFM should I use for aluminum?

For aluminum I would use 130 SFM and keep the feedrate at .002” per rev, at least initially.

Where is the navigation pane on the speed and feed calculator?

On the top of the Speeds and Feeds Calculator, you will find the “Navigation Pane”.

How many configurations does the milling calculator support?

In total, the Milling Speeds and Feeds Calculator support 11 configurations!

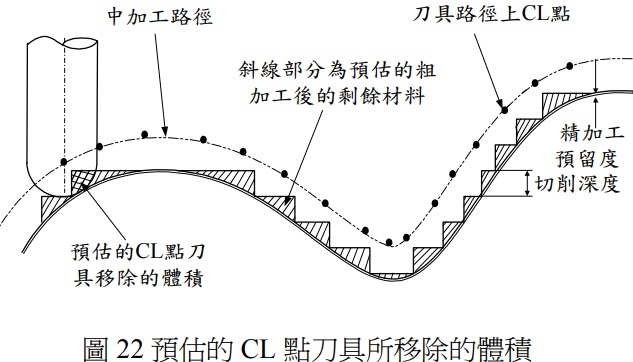

What is chip load?

The Chip Load (Maximum chip thickness), is the largest chip that a cutting edge can handle without breaking and still maintain decent tool-life. In the case of 90° cutters taking a radial depth of more than 50% of the cutter’s diameter, the chip load is exactly the Feed per Tooth. However, when the radial depth gets smaller, and the cutter is not a 90° shape, you can dramatically increase the feed without getting above the allowed Chip Load. The Milling Speed and Feed Calculator automatically calculated the right feed to keep the desired chip load. The calculator works in two stages:

How many milling cutters does the calculator handle?

In total, the calculator handles 11 different Milling Cutter configurations!

What is the maximum RPM for a lathe?

For all applications, you can set the Machine’s maximum RPM and Power limits. By default, the maximum RPM for lathe machines is 6000 and for milling machines 15,000. Power is not limited unless you set a value.

Can you set a maximum speed on a carbide?

Limit maximum speed – You can set an upper limit that the system will not exceed (even if, according to the algorithm, a higher speed can be used), and the carbide grade recommendations will be altered accordingly. Force Speed Manually – If you know you will use a specific speed, you can type it in.

What is feed rate?

Feed rate is the velocity at which the cutter is fed, or the rate advanced against the workpiece, often expressed in units of distance per time for milling, that typically is inches per minute (IPM) or millimeters per minute (MPM). Milling feed rate is determined by the type of cutting tools, surface finish desired for milling parts, power available at the spindle, the rigidity of the machine and tool setup, characteristics of the material to be cut, workpiece strength, cut width, etc. To work out the feed rate, the cutting feed is required, which is the product of feed per tooth (IPT) and the number of teeth.

What is spindle speed?

The spindle speed is the rotational frequency of the spindle of the machine, such as milling machine, lathes, drills, and routers, measured in revolutions per minute (RPM).

What is RPM in milling?

The RPM calculated in the Mill Speeds and Feeds Calculator refers to the spindle speed in milling process, and IPM refers to feed rate.

What does SFM mean in machining?

Cutting speed (SFM): the rate at the workpiece surface, irrespective of the machining operation used.

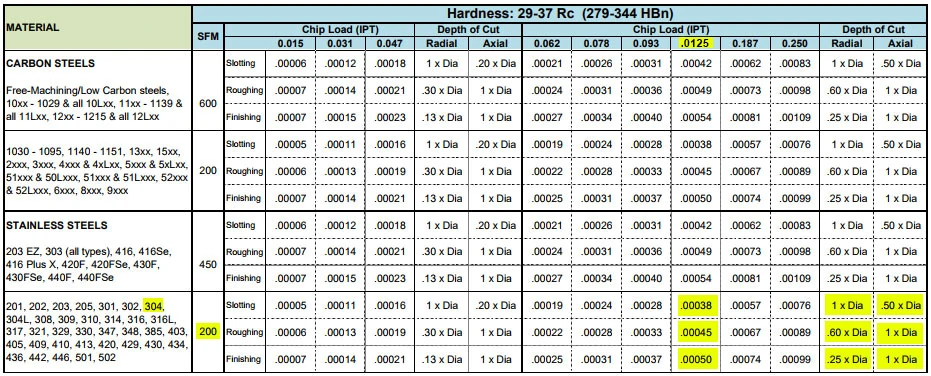

Can you cut stainless steel at a wide range of spindle speeds?

Some materials can be cut at a wide range of spindle speeds, while cutting speed is critical to some materials like stainless steel, it’s easy to harden under cold working, then resist the tool’s cutting action. When determining which feed rate to use, the calculation for milling is a little more complicated, because the operation on milling ...

Why are tapping feeds and speeds easy to calculate?

Tapping Feeds and Speeds are pretty easy to calculate because they’re constrained by the thread that is being tapped. Everything starts from Tapping Speeds

What is tapping feed rate?

Given the spindle rpm’s the Tapping Feed Rate is just how fast we have to feed to move one full thread per spindle revolution. It’s our spindle rpm divided by our threads per inch (TPI).