How to Dress a Grinding Wheel in 6 Steps

- Always put safety first. Wear a pair of glasses or a visor to protect your eyes/face from sparkles and dust. ...

- Align the grinder’s tool rest properly. If you’ve been using your bench grinder for quite some time, the wheel probably has worn down a lot. ...

- Now, you need to get a dressing tool. There are several different tools on the market, and we are going to talk about them in a minute.

- Turn on the bench grinder, and wait until it gets to full speed.

- Now to the core of the dressing process: rest the tool on the guard and move in back and forth across the spinning wheel, until you get a flat surface ...

- After dressing the wheel, re-adjust the guard so it is positioned 1/16 of an inch (or a couple mm) from the wheel.

Why does grinding wheel need to dress?

Dressing. When the sharpness of grinding wheel becomes dull because of glazing and loading, dulled grains and chips are removed (crushed or fallen) with a proper dressing tool to make sharp cutting edges and simultaneously, make recesses for chips by properly extruding to grain cutting edges. Thus, these operations are for the dressing. Trueing.

Why do grinding wheels need washed after dressing?

For your information, a grinding wheel is made of abrasive grains clogged together with a bonded material. After some use, those grains can crack down and become smoother; also, bits of metal can be stuck between them. Therefore, dressing the wheel is a way of cleaning the wheel from worn-out abrasive grains and bits of metal.

How do you replace a grinding wheel?

How to change bench grinder wheel?

- Your safety. Before you even start on your work, it is essential first to confirm that your power or source of energy is switched off at all times.

- Familiarize yourself with your tools. There is no need for you having tools that you have no idea how to use appropriately. ...

- Eliminate any hindrance. ...

- Detach your wheel. ...

- Fix a new grinding wheel. ...

- Machine test. ...

How to dress and balance a surface grinder wheel?

- Always put safety first. ...

- Align the grinder’s tool rest properly. ...

- Now, you need to get a dressing tool. ...

- Turn on the bench grinder, and wait until it gets to full speed.

- Now to the core of the dressing process: rest the tool on the guard and move in back and forth across the spinning wheel, until you get a flat surface ...

How do you clean and dress a grinding wheel?

0:332:17How to Clean and Maintain a Bench Grinder Wheel - YouTubeYouTubeStart of suggested clipEnd of suggested clipWe can just use a dressing stone a dressing stone is just a carbon stone that you can take when theMoreWe can just use a dressing stone a dressing stone is just a carbon stone that you can take when the grinder is running you can go slowly. And well without too much force.

Can you dress the side of a grinding wheel?

0:083:04How to dress a grinding wheel - YouTubeYouTubeStart of suggested clipEnd of suggested clipWe can scrape all that away. So all you need is a dressing tool and I'll show you what to do. Next.MoreWe can scrape all that away. So all you need is a dressing tool and I'll show you what to do. Next. So here's a look at my grinding wheel and as you can see it's a little bit matted.

What tool is used to dress a grinding wheel?

A grinding dresser or wheel dresser is a tool to dress (slightly trim) the surface of a grinding wheel.

When should a grinding wheel be dressed?

If you do not know, a good “rule of thumb” is to discard the wheel when you are 1” away from the recess. Portable cup wheels must be discarded when the machine's guard prevents proper grinding. In this case a proper guard will determine discard size by preventing additional grinding on the wheel's rim.

What is glazing of grinding wheel?

Glazing- when the cutting edge of a grinding wheel takes a glass like appearance due to wear of abrasive grains then it is called glazing of the grinding wheel. It decreases the rate of grinding.

What is the difference between wheel dressing and wheel truing?

Truing creates a smooth surface on the wheel periphery, and with no exposed grit the wheel won't cut. Dressing sharpens the wheel by removing bond material and fracturing the superabrasive grit to expose fresh edges, so dressing always follows truing.

How do you resurface a grinder wheel?

0:433:50Resurfacing a grinding wheel fast and easy. - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd you're just gonna get that in there just you'll see these wheels start spinning. And you want toMoreAnd you're just gonna get that in there just you'll see these wheels start spinning. And you want to hold this nice and parallel to just move it back and forth. Real. Easy.

How do you dress an aluminum oxide grinding wheel?

Dressing Stones and Sticks Dressing stones are used for profiling, dressing, and sharpening grinding wheels. These stones are typically made of aluminum oxide or silicon carbide which is why they're abrasive and suitable for this application. Aluminum oxide dressing sticks are another great option as well.

What is a dressing stick made of?

3M™ Dressing Stick is commonly used to dress Phenolic Resin, Polyimide Resin, and Hybrid bond superabrasive wheels. The dressing stick comes in two minerals: aluminum oxide and silicon carbide.

Can you grind on the side of a grinding wheel?

Do grind on the wheel's face (outer diameter) only. Side grinding is NOT allowed. Do keep your grinding wheel face open and free of metal build-up. Dress wheel to remove foreign metals and to open the wheel face with new sharp abrasive grains.

How do you dress a cutting wheel?

2:466:17Dressing Wheels The Proper Way - YouTubeYouTubeStart of suggested clipEnd of suggested clipKeep the handle parallel to the floor. Push. The dresser into the spinning wheel for about 10MoreKeep the handle parallel to the floor. Push. The dresser into the spinning wheel for about 10 seconds. Hear that sound. That is the sound made when a wheel is dressed correctly.

How do you dress valves with grinding stones?

1:472:14How to dress a grinding stone - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt literally is as simple as that light pressure just slightly side to side. And just wear it downMoreIt literally is as simple as that light pressure just slightly side to side. And just wear it down flat.

How do you shape a grinding stone?

0:497:43How to shape a grind rock - YouTubeYouTubeStart of suggested clipEnd of suggested clipWhat I'd like to do is to shape this if you notice we're at this angle. So I would like to shapeMoreWhat I'd like to do is to shape this if you notice we're at this angle. So I would like to shape that at that same angle. And. So as I shape that as that angle I'm slowly.

How to clean and dress a bench grinder wheel?

How to Clean and Dress a Bench Grinder Wheel: The simple way to clean and dress a grinding wheel is to purchase a special grinding wheel dresser. These tools make short work of the issue and have your grinding wheel ready for action. They also help protect you from any contaminants that may put you at risk of injury.

What is a grinding wheel dresser made of?

Made from cast iron , this grinding wheel dresser is a little bit heavy but it will handle the pressure you put on it as you dress your grinding wheels. The 6 little wheels have teeth on them. These teeth remove the grit and grime from your grinding wheel.

How to keep diamond chips covered?

You need to have coolant on hand to make sure the wheel and the dresser do not overheat. You should start the flow of coolant prior to dressing and the flow should be great enough to keep the diamond chips covered.

What does dressing the wheel do?

What dressing the wheel does is remove the clogged layer of the wheel exposing a fresh layer of grit underneath. This action reduces the wheel size, so it is best to only dress the wheel when it is really needed. Too much dressing and you shorten the lifespan of the wheel.

How to get a grinding wheel back in shape?

To get the grinding wheel back in shape and safe to use, here are a few steps to follow: Rest your grinding wheel dresser on the wheel. Press the on button and then turn the bench grinder off quickly. As the grinding wheel slows, use a little pressure to press the dresser against the wheel.

What is the good news about bench grinder wheel dressers?

The good news about bench grinder wheel dressers is that you are not restricted to just one design. You have cleaning tool options and each one does their job quite well.

Why are my grinding wheels clogged up?

The pores get clogged up with metal and other materials very easily when the wrong materials are used. This is a very big problem when you use soft metals on the wrong grinding wheels. When this happens the wheels get clogged up and become dangerous to use. They also lose their grinding edge and do not do a good job.

How to use a grinding wheel on a dresser?

Depending on the dresser you are using, you might start by placing the dresser’s leg behind the rest. Then you should apply pressure on the surface of the grinding wheel and then run the machine back and forth.

What should you do when dressing a grinding wheel?

One of the vital things you should consider when dressing a grinding wheel is avoiding long sleeve clothes. This will help you prevent accidents from occurring. This applies to long hair as well; you should consider pulling it towards the back to prevent them from getting caught by the grinding wheel.

How to dress a bench grinder?

Dressing and truing are carried by holding the dresser against the surface of the rotating grinding wheel and moving it across the face of the wheel back and forth.

How long does it take to dress a grinding wheel?

The entire process of dressing a grinding wheel is not complicated, and it will take you approximately five minutes to complete the whole process. You should consider truing and dress your grinding wheels enough to create new sharp abrasive diamond grains or establish concentricity to your workpiece.

How to carry truing and dressing?

Dressing and truing are carried by holding the dresser against the surface of the rotating grinding wheel and moving it across the face of the wheel back and forth. You should then switch on the grinder to attain maximum RPM. Commence by positioning your dresser from the center to one end of the grinding wheel.

What is a wheel dresser?

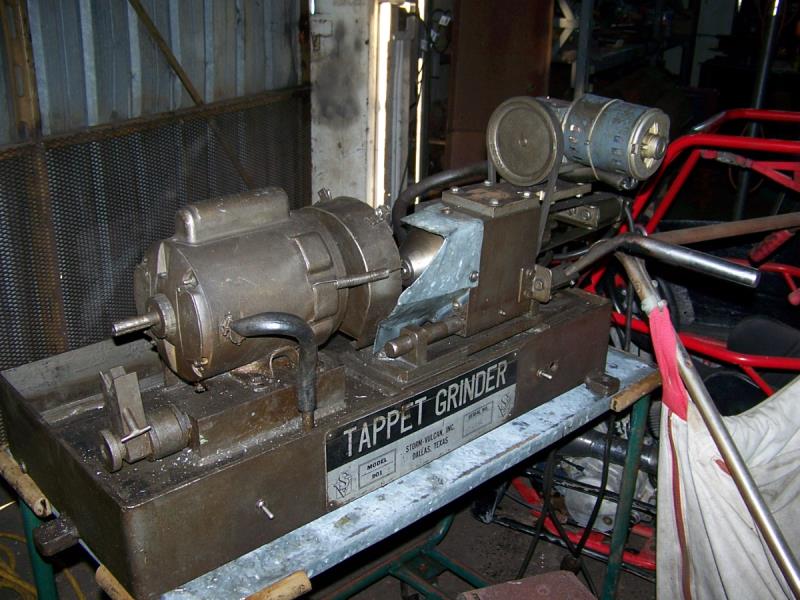

Wheel dresser, also known as a gridding dresser, is a tool used in dressing grinding wheel surface. Grinding dresser is used in returning a wheel to the original circular shape. A bench grinder is a cutting edge tool, and some of them feature single points, whereas other features multiple points.

How to keep sparks from coming into contact with grinding wheel?

Most grinding wheels feature spark-guard, which helps in keeping the spark from coming into contact with your face or workpiece by following the wheel spin. You should adjust the spark guard and ensure that it is closer to the wheel by 1/6 inch.

Why do grinding wheels need dressing?

Using dressing throughout the grinding process is important to consistently produce parts with the required size and surface finish.

Why do we use dressing in grinding?

Using dressing throughout the grinding process is important to consistently produce parts with the required size and surface finish. Instead of replacing the entire grinding wheel, a process called “dressing” is used to restore the wheel. Dressing returns the grinding wheel to its original sharpness by removing old grains to reveal ...

What is truing dressing?

There are two main types of dressing: truing and standard dressing. Truing is a type of dressing that is performed after installing a new grinding wheel. Truing can be performed to straighten the grinding wheel/removing runout or it can be done to form the grinding wheel into a desired form (shape). Standard dressing occurs at varying intervals ...

What is standard dressing?

Standard dressing occurs at varying intervals during the grinding process. The frequency of standard dressing depends on many factors such as amount of material being removed, surface finish requirements, and accuracy of forms required on the grinding wheel.

How to properly dress a grinding wheel?

Here are the steps to take to effectively and properly dress a grinding wheel. Step 1. Determine the proper dressing tool for the wheel. Make sure the grit of the dressing tool is finer by one or two sizes than the abrasive surface of the grinding wheel. Also make sure you choose the appropriate shape of dressing tool to coincide ...

How to use dressing tool on a wheel?

Using light to medium pressure, apply the dressing tool to your wheel's abrasive section; continue applying pressure just until the wheel stops rotating.

What is diamond dressing?

Diamond dressing tools are among those essential assisting tools that keep grinding wheels true and free from buildup of particles. This dressing procedure keeps grinding tools, drill bits, chisels, and other tools with points or edges honed to their required sharpness.

What is the function of diamond dressers?

Using the appropriate diamond dressers or other diamond products on these abrasive wheels performs three important functions: (1) trues or re-balances the wheel to a concentric shape; (2) dislodges buildup of abrasive particles and bits of metal, exposing new abrasive surfaces of the wheel for more accurate grinding; and (3) cleans the wheel, renewing its edge and revealing sharper abrasive and fresh grains.

What is metal bonded grinding wheel?

Metal bonded grinding wheels are superhard wheels made of CBN or diamond power mixed with metal bonded by sintering or electroplating.

What laser is used to dress a diamond wheel?

Japanese scholar Kunidea used frequency multiplier Nd: YAG laser on cast iron-based diamond grinding wheels to do dressing experiment. Hosokawa of Kanazawa University in Japan used the YAG pulse laser to dress the bronze bond diamond wheel, which can effectively and reliably remove the diamond wheel.

How to overcome the poor strength of the bond agent of electroplated wheel and falling off the abrasive grains?

In order to overcome the poor strength of the bond agent of electroplated wheel and falling off the abrasive grains , try to increase the holding force of the metal bond on the abrasive grains and improve the bonding strength of the grinding wheel. In the early 1990s, scholars at home and abroad began to study the monolayer high temperature brazed ...

How does laser dressing work?

The laser dressing method utilizes the optical system to focus the laser beam into the very small spot to act on the surface of the grinding wheel, and the metal bond material on the surface is removed by evaporation vaporization and melting sputtering in the very short time.

What is the RA of 600# diamond wheels?

XieJin from South China University of Technology and Tamaki from Kitami Institute of Technology in Japan used contact discharge dressing to dress 600# diamond wheels. Ra is 0.12 μm after grinding the optical glass (BK10). It is shown that the electrolyte largely determines the performance of the electro-contact discharge dressing by the study of electrolytes.

What is a sintered wheel?

A sintered metal bond wheel is mostly made of metal such as bronze and cast iron by high-temperature sintering method. It has high bonding strength, good formability, high-temperature resistance, good thermal conductivity, wear resistance, long service life and can withstand the big load.

What technology did Miller use to trim the metal bond diamond grinding wheel?

Miller used EDM technology to trim the metal bond diamond grinding wheel to obtain the good diamond abrasive grain edge height. Japanese scholars did EDM on the diamond wheels and did the grinding experiment of BK7 glass to obtain the surface roughness of Rz=7 μm. Mr. Gao from Tianjin University used deionized water as the discharge medium to dress the cast iron-based precision diamond wheel with electron discharge machining technology. The roundness of the grinding wheel was 0.75μm and the taper error was less than 0.5μm.