How to Repair a Bulkhead.

- Step 1: Drill the Rotten Part. The first step to repair a damaged bulkhead is to drill the rotten part of the wood. Use a drill to gently drill the ...

- Step 2: Clean the Holes.

- Step 3: Fill the Hole with a Waterproof Sealant.

- Step 4: Insert Pressure Treated Planks.

- Step 5: Screw the Planks.

How do you repair a bulkhead washout?

Repairing Bulkhead Washouts. Estimate enough bulkhead cloth (can be purchased from Shoreline Companies on FM 830) to create a sack large enough to fill the resulting hole. Weight the sack down to the bottom of the hole with a brick or equivalent. Fill the sack with Scott’s Lawn Turf Builder.

Why do bulkheads need to be replaced?

Over time, soil and water erode the bulkheads and cause small or large holes to form. If these holes are not addressed right away, they become larger, eventually requiring bulkhead replacement.

How can I extend the life of my bulkhead?

If you fill the holes and stabilize the bulkhead, you will not have to replace the bulkhead as quickly and can extend the life of the bulkhead by several years. Drill out any rotted wood around the holes with a drill.

How do you fill in a large hole in the ground?

Estimate enough bulkhead cloth (can be purchased from Shoreline Companies on FM 830) to create a sack large enough to fill the resulting hole. Weight the sack down to the bottom of the hole with a brick or equivalent. Fill the sack with Scott’s Lawn Turf Builder.

How do you repair a hole in a bulkhead?

Drill out any rotted wood around the holes with a drill. ... Clean out the holes with acetone. ... Fill the holes with waterproof epoxy sealant.Place 2-inch pressure treated planks horizontally over the holes. ... Screw the planks in place with 6-inch screws every 24 inches along the plank.More items...

What is a bulkhead repair?

Seawall Repair & Bulkhead Repair Services in Southern CA The process is similar to the technique used to repair foundation walls and landlocked retaining walls. Helical anchors, also called tiebacks or earth screws, provide the lateral support to firmly secure the wall to the shore.

How much does it cost to repair a bulkhead?

Depending on the local construction market and bulkhead design requirements, repairs may cost $100-$400 per linear foot of wall. Bulkhead replacement may cost $500-$1,000 per linear foot.

How do you plug in a bulkhead hole?

Option 1: Simply leave the bulkheads in and put threaded plugs in them. Doing this, you can go back and use them easily in the future. Option 2: Remove the bulkheads and "patch" the holes using pieces of Acrylic that are the same thickness as the panes with the holes in them.

How do you seal a leaking bulkhead?

A waterproof sealant is applied both inside and outside the bulkhead door to seal the joints. The sealant should bond with both concrete and metal around the edges of the bulkhead door. Let it dry for several days before testing it with outside water.

How often should a bulkhead be replaced?

If your bulkhead requires additional repairs or modifications and is more than 15 years old, it is recommended to replace the bulkhead with a new unit.

How long does a wood bulkhead last?

15-20 yearsTypical wooden bulkheads only last 15-20 years, bulkheads with vinyl sheeting, it can reach 25 years in some cases. With both vinyl and wooden sheet systems, you still have a wooden structure which is vulnerable to rot.

Why do bulkheads fail?

FACTORS LEADING TO FAILURES OF BULKHEADS AND BRACING SYSTEMS ARE ANALYZED UNDER THE FOLLOWING CLASSIFICATIONS: (1) EXCESSIVE EARTH PRESSURE, (2) INADEQUATE SUPPORT, (3) INADEQUATE CONSIDERATION OF OR ALLOWANCE FOR DEFLECTION, (4) POOR DESIGN DETAILS, (5) CORROSION OR DETERIORATION OF THE STRUCTURAL COMPONENTS, AND (6) ...

How long does it take to build a bulkhead?

You can build a bulkhead in 30 minutes to an hour, depending on the size and scope of the project. Measure the width of the footer that will receive the bulkhead. Add an extra 6 inches to the final width. Measure the widest -- rather than the narrowest -- part of the footer at the step down.

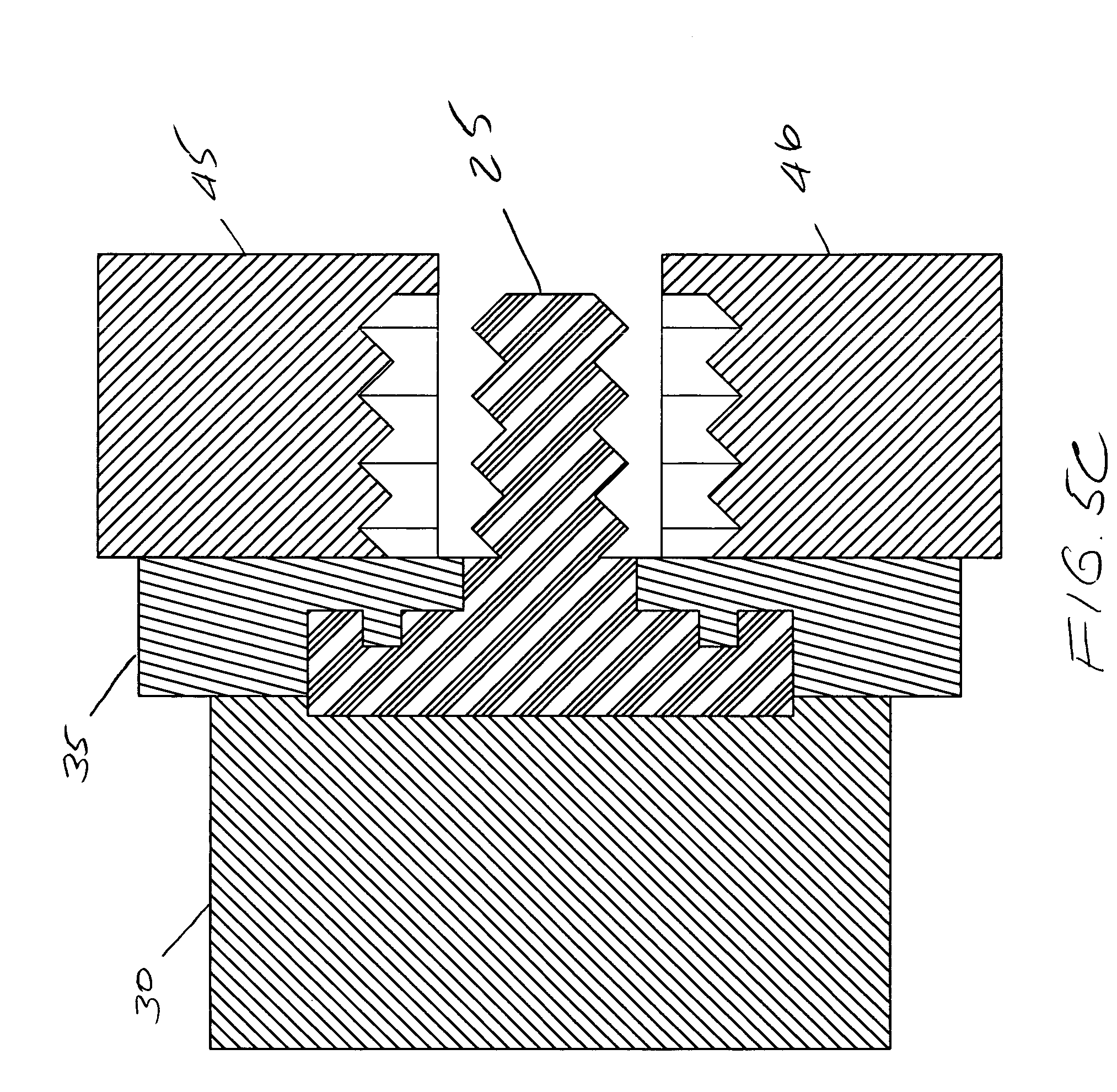

How do you seal bulkhead fittings?

Fitting, the bulkhead fittings seal by drilling a single hole into the sidewall of the tank. The installer places a ring gasket onto the bulkhead fitting, and it goes from the inside of the tank to the outside through the hole. A compression nut then threads onto the bulkhead fitting, is tightened up and is sealed.

How does a bulkhead fitting work?

A bulkhead fitting allows piping connections to be made to a tank. A hole is cut in the tank into which the fitting body is inserted. A locknut threads onto the body to hold it in place. The locknut puts pressure on the gasket(s) that allows it to make a liquid tight seal.

What is a bulkhead tank fitting?

Bulkhead tank fittings permit the free flow of liquids for tank or drum drainage or filling. They can be used as an inlet or outlet for faucets, pipes, and spigots.

What is a bulkhead construction?

A bulkhead is a box-like housing installed onto a ceiling to provide extra space for wiring, piping, and ductwork. They are common in kitchens, bathrooms, and basements. They can run around the perimeter of the room or form a central box. Bulkheads can also refer to external basement or cellar doors.

What is the difference between a bulkhead and a seawall?

Seawall: structure that provides shoreline protection from waves but also retains soil. Bulkhead: vertical shoreline stabilization structure that primarily retains soil, and pro- vides minimal protection from waves.

Why do bulkheads fail?

FACTORS LEADING TO FAILURES OF BULKHEADS AND BRACING SYSTEMS ARE ANALYZED UNDER THE FOLLOWING CLASSIFICATIONS: (1) EXCESSIVE EARTH PRESSURE, (2) INADEQUATE SUPPORT, (3) INADEQUATE CONSIDERATION OF OR ALLOWANCE FOR DEFLECTION, (4) POOR DESIGN DETAILS, (5) CORROSION OR DETERIORATION OF THE STRUCTURAL COMPONENTS, AND (6) ...

How long does a wood bulkhead last?

15-20 yearsTypical wooden bulkheads only last 15-20 years, bulkheads with vinyl sheeting, it can reach 25 years in some cases. With both vinyl and wooden sheet systems, you still have a wooden structure which is vulnerable to rot.

Step 2

Clean out the holes with acetone. Allow the acetone to dry for one to two hours.

Step 4

Place 2-inch pressure treated planks horizontally over the holes. If you have several holes in a row, cover all of the holes with the same plank piece.

Step 5

Screw the planks in place with 6-inch screws every 24 inches along the plank. Place a washer on the back of each screw to prevent it from working its way inside the wood.

Step 6

Place 2-by-4 boards horizontally on top of the 2-inch planks. Screw the 2-by-4 boards in place using the same screws and washers that you used to secure the smaller planks in place.

Use Olshan's Cost-Effective Seawall & Bulkhead Repair System to Seal Cracks & Control Erosion

Is the ground around your seawall caving in? Are cracks starting to form? Are joints failing? If you notice voids and sinkholes beginning to appear near your property, it may be time to repair the seawall.

Excellent

We had our bulkhead on Lake Conroe repaired and was extremely happy with the job. The men we super friendly, answering my many questions, very happy with the cleanup after the job and would recommend them for your bulkhead repairs.

Olshan's Cost-Effective Bulkhead Repair System

Well, our foundation was repaired this week. It is AMAZING!!!!! Once they "jacked" it up you could immediately tell the difference! So cool! When you walk to that side of the house, you don't go downhill. Oh my goodness - what a HUGE difference. Thank you, Thank you, Thank you!

Sinkholes

One of the most common problems I run across is losing land behind the bulkhead. Basically, your bulkhead is “Leaking” dirt. If the sheeting is wood, most of the time you have either a gap in the sheets or a hole has rotted out. In both cases, some steps can be taken to mitigate the leak or to repair it.

Bulkhead leaning out

Another major problem that I see with all types of bulkheads is, leaning out. This can happen to concrete, wood, and vinyl bulkheads and is an indication that some or all the tie-back rods have rotted out. If the piles, walers, and sheeting all look fine, but the bulkhead is leaning out, your rods are gone.

Licensure & Insurance Coverage

Lamulle Construction is the region's only licensed heavy construction contractor to carry truly comprehensive insurance coverage for building on the water. Our 4 types of million-dollar coverage protect not just our team and equipment, but your people, property, and investments. To reduce your risk exposure, we go the extra mile.