Spray any exposed portion of the bolt, screw, or nut that you can get to. Let it sit for 5 to 10 minutes and then gently tap on the head of the bolt or screw and housing that it is threaded into. Tapping helps the rust remover get into the threads of the bolt and the assembly.

- Drill thread. First you drill the damaged thread with a twist drill. ...

- Cut thread. Now you can cut the new thread with the single-cut tap. ...

- Insert thread insert. Put the thread insert on the fitting-tool or directly into the hole (see second picture below). ...

- Break pin.

How to remove stripped screws with a screw extractor?

Tips for Using a Screw Extractor

- To use a screw extractor, begin by drilling a hole into the head of the damaged screw. Apply thread cutting oil to the drill bit prior to drilling. ...

- Before attempting to remove the damaged screw with the extractor, apply penetrating oil to the screw’s threads. ...

- If using a power drill to remove the screw, use a slow speed. ...

How to remove stripped screws and stripped nuts fast?

Some other things that might cause your bolt to get jammed are:

- Using the wrench or impact gun at an angle with the bolt

- Using the wrong sized socket set

- Using old and rusty tools

- Not keeping the bolt, screw or nut dry at all times

What causes a screw to be stripped?

Some things that will cause a screw to become stripped include:

- Using poor quality tools

- Working too fast and without enough care

- Turning screws with screwdrivers (or a drill) at an angle to the screw

- Using the incorrect sized screwdriver (particularly one that is too small)

- Using the incorrect sized drill bit with a power drill

- Using an old and worn drill bit

- Over-tightening a screw

How do I fix stripped sheet metal screw holes?

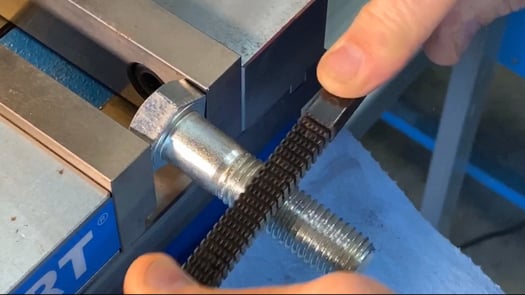

Third Step: Use the Tap Set to Create New Threads

- With your tap set, you must tap a hole to get it ready for the helicoil insert.

- You must make sure you have the right size. In case you have not noticed, size does matter.

- Using your drill, you must insert the tap to give the helicoil insert something to grab onto.

How do you fix a stripped screw?

0:446:22How to Fix Stripped Screw Holes - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd get some toothpicks for this hole right here three ought to do it just place them in the hole.MoreAnd get some toothpicks for this hole right here three ought to do it just place them in the hole. Like that break off the excess.

How do you Rethread a screw?

0:302:51Fix Stripped Nut/Bolt (Tap & Die Set) // Supercheap Auto - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd even pressure with a quarter turn clockwise followed. By a quarter turn anti-clockwise. To clearMoreAnd even pressure with a quarter turn clockwise followed. By a quarter turn anti-clockwise. To clear the metal shavings from the thread.

How do you fix a screw threaded metal?

0:009:51FIX stripped bolt hole threads the POOR MANS WAY - YouTubeYouTubeStart of suggested clipEnd of suggested clipToday we're gonna see if we can repair strip threads with j-b weld. Let's find it out keep watching.MoreToday we're gonna see if we can repair strip threads with j-b weld. Let's find it out keep watching. So here we got a piece of cast aluminum that I have intentionally stripped out some threads.

How do you get a screw to stay in a stripped threads?

The complete repair for stripped threads is to use a coil-type thread insert. These inserts will give the bolt hole completely new threads which accept the size of the original bolt. In order to use inserts, you must drill the damaged holes slightly larger so that it can take the thread insert.

Can you Retap a threaded hole?

Use a rethreading tap to restore threads on nuts or threaded engine component holes. Don't try to rethread the entire bolt, hole or nut in one operation. Insert the rethreading tap or die and rotate a few turns, then back it off a full turn. That will dislodge the debris from the teeth.

What happens if a screw gets stripped?

A stripped screw is a screw with a head that has become so damaged and bored out, that the screw bit on your screwdriver/drill can no longer get a good grip and thus extract it.

What is a Rethreading tool?

Taps and dies are metal threading tools used to cut and restore internal and external threads precisely.

How do you rethread a bolt without a tap?

0:352:11Easily repair a cross threaded hole without a tap! - YouTubeYouTubeStart of suggested clipEnd of suggested clipSlide to the bolt will make our act as a cutter when it gives it a relief for the material to getMoreSlide to the bolt will make our act as a cutter when it gives it a relief for the material to get into the slide. Once you run that through the thread your bolts for reading with its.

How do you cut and rethread a bolt?

0:403:14How to Cut a Bolt & Save The Threads - YouTubeYouTubeStart of suggested clipEnd of suggested clipStraight across the slight angle. So you'll be cutting across through the threads. And just workMoreStraight across the slight angle. So you'll be cutting across through the threads. And just work this across back and forth until you get the top off which we can lapse there for about 15 seconds.

Hard Times

Forty years ago, the world was a harder place. Your grandparents weren’t lying to you. Cast-iron alloys and steels were the basic building blocks for just about anything. On the automotive side, grey cast iron was the “go-to” material for engine blocks, cylinder heads, manifolds, housings and heavy brackets.

Going Soft

Today, it’s not just “emo” millennials that are softer. We live in a softer world. The materials that have replaced grey cast iron and steel are relatively so . The world has moved from the Steel Age to the Aluminum Age. Pure aluminum will only hit 15 on the HB scale, whereas aluminum alloys can range in hardness from 20-to-150.

Hard Bolt Meets Soft Threads

While the materials where threads live have become softer, the materials used for fasteners have in many cases become harder. In fact, some of the super-alloys used in high-performance head studs and rod bolts have hardness levels approaching that of tap (every try to drill out a broken tap?).

The Solution

If every single aluminum component in the world could be manufactured from 7075-T6 aluminum alloy (which has equal hardness to typical grey cast iron alloys), the number of strippers in the world could be brought back down to the Steel Age numbers. Due to the high-cost of this material and the need to cast certain parts, this will never happen.

Insert Tech 101

Thread-repair inserts come in a variety of materials and in a myriad of designs from domestic and overseas manufacturers. Timed thread body inserts, wire coil inserts and keyed inserted make up the three major families of thread inserts you’ll likely encounter.

HeliCoil Helical Coiled Wire Inserts

Band-Aid is a brand synonymous with bandages, while Heli-Coil is a brand synonymous with thread repair inserts. Encounter a stripper and the solution is often touted as ,”just HeliCoil it.” HeliCoil and the similar designs inspired by this design are available from a number of other companies.

TIME-SERT Timed Solid Body Insert

While not as well known to the mainstream, TIME-SERT and the family of solid body inserts are many mechanics number one choice for thread repairs in high-preload fastener applications.

The thread repair

First you drill the damaged thread with a twist drill. The twist drill must match the size of the thread diameter.

Insert thread insert

Put the thread insert on the fitting-tool or directly into the hole (see second picture below). The pin (the transverse part in the middle of the thread insert) must sit down in the groove opening.

Break pin

Crack the pin of the thread insert with the pin-breaker at the bottom of the thread.

Thread repair tools

We have a thread repair set in our range of products. So you have all the tools you need to easily and quickly make repairs to damaged and worn threads.

Choosing the Right Method to Fix a Metal Screw Hole

Fortunately, there are several options available, it’s just a matter of finding the right method that works for you. Choosing the best method for you will depend on your level of experience and tools needed for the project. So, let’s dive in!

How to Fix a Stripped Screw Hole in a Metal Door

To fix a stripped screw hole in a metal door, we first recommend trying a larger screw. If this is not possible, you can try an epoxy in the hole to help grab the screw. Lastly, using an anchor may be an option, either plastic or a soft metal like lead that will conform to the hole.

How to Fix a Stripped Screw Hole in Sheet Metal

Because sheet metal is so thin, we recommend trying a hammer and dolly to try to smash the hole into a smaller diameter. This method is often used for auto body repair, but would be a great first option for a stripped screw hole in sheet metal.

How to Fix a Stripped Screw Hole in Aluminum

In addition to some of the methods mentioned above, such as drilling and tapping, Helicoil inserts, JB Weld, and using a larger screw, we offer another suggestion for Aluminum. Using copper wire strands, which is usually softer than most aluminum, to compress into the old threads seems to be a preferred method by many.

How to Fix a Stripped Bolt Hole in Metal

To fix a stripped bolt hole, we recommend using the Helicoil method mentioned above in Method #3.

How to Measure the Hole Depth

The easiest way to measure the depth of a screw hole is to simply find something with a smaller diameter, such as a wooden skewer stick. You’ll then place the stick into the screw hole and mark the stick at the surface with a pencil. This will allow you to measure from the tip of the stick to your pencil mark, thus giving you the depth of the hole.

How to Measure the Hole Diameter

The old-school way of measuring a screw hole diameter is by using an inside caliper and then measuring that distance with a micrometer. This method is a little dated and there are now easier ways to get the measurement. If that’s all you have on hand, it’ll work.

Repair or Replace?

The following procedures will guide you through the basics of how to repair damaged threads. As with any repair, be careful of what you fix versus replace. If it is a high-load or critical part (steering, suspension, drivetrain), consider replacing the item over repair.

Going Forward With A Repair

Choosing to repair damaged threads requires knowing exactly what thread you are working with, whether it is fine or coarse, and what size the threads are. Please see our article on fasteners for more information on thread sizes. There are several tools you can use to determine the thread sizing.

Using A Tap

With the correct size of the threads, you can select the tap. There several types of taps; taper, plug, and bottoming. The taper tap is the most common tap design. This is the style used for creating new threaded holes. The first 8 to 10 cutting flutes of the tap are not full, they gradually build up to the full thread size.

Using A Die

Fixing threads on a threaded shaft follows much of the same path; however there are few minor differences. Dies come in cutting and rethreading types. A cutting die cuts new threads, whereas a rethreading die is like a thread chaser to fix slightly damaged or dirty threads.

Use a Larger Screw

The first fix you can try is to replace the stripped-out screw with one that is slightly longer or that has a slightly larger diameter. Or better yet, use a screw that is both larger (with a higher gauge number) and longer.

Screw Repair Kit

Several manufacturers offer screw repair kits, which are sold by online retailers and in woodworking outlets. Most of these kits consist of simple plastic anchors and glue. When the anchors are glued inside the screw hole, they provide a surface for the screw threads to grip when you re-drive the screw.

Fill the Hole and Redrive the Screw

If driving a larger screw is not practical, the next-best fix is to fill the screw hole with small strips of the same type of wood, then re-drive the screw.

Hardwood Plug

There are some instances where the stick-fill fixes aren't effective. Particleboard and MDF (medium-density fiberboard) are particularly susceptible to stripped screw holes, due to how they are engineered.

Tips

If you can access the rear side of the object, see if the screw shaft is protruding through it. If it is, grip the end with pliers or a hex wrench and rotate out from below.

Warnings

Metal burrs caused by stripped screws can cause injury or mechanical malfunctions. Use a file to smooth them out.

About This Article

This article was co-authored by Gino Colucci. Gino Colucci is a Home Improvement Specialist and the Owner of Crackerjacks Handyman Services (not a licensed contractor) in Chandler, Arizona.