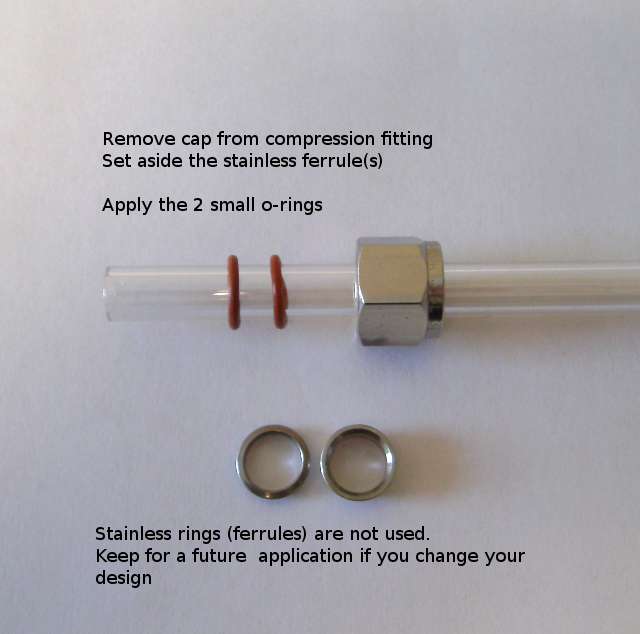

Remove the compression nut and compression olive, then put the nut on the tube, followed by the olive. Insert the tube end up to the fitting's tube stop. Slide the olive and the nut down to the fitting body. Tighten the nut using your fingers to secure the fitting in place.

How to install a compression fitting gate valve?

- If installing a solder-type valve, place the valve onto the pipe to ensure a tight fit. ...

- If installing a push-to-connect type valve, press it squarely and evenly onto the pipe until it bottoms out. ...

- If installing a compression-style valve, thread the valve into the compression. ...

How to connect a compression fitting to CPVC?

- Every connection must have one male fitting and one female fitting in order for the two fittings to attach. ...

- The sizes of the threaded ends must match in order for the PEX fitting to twist onto the copper pipe fitting.

- You can connect pipes of different sizes as long as the threaded ends are the same size. ...

How to install F type compression connectors?

- Check your already stripped cable has no loose metal shards bridging the white plastic dielectric to touch the centre conductor. ...

- Line up your hex F connector, so that the bare conductor and shield of the coax cable will go through inner barrel.

- Slide the connector down the end of the cable until resistance is felt.

How to install compression fittings for PEX pipes?

Installing PEX Tubing

- Plan: Figure out what type of project it is, how much pipe, how many fitting you need, and anything else you may require. ...

- Collect all materials: It helps to draw out a diagram of how the pipe will run and where fittings will be necessary. ...

- Run the PEX tubing: PEX needs to be supported a minimum of every 32 inches when running horizontally. ...

How do you install a compression fitting on a gas line?

0:031:37How to Install CSST Fittings - YouTubeYouTubeStart of suggested clipEnd of suggested clipSee SST flexible gas pipe uses compression fittings to make transitions. Here's how they work firstMoreSee SST flexible gas pipe uses compression fittings to make transitions. Here's how they work first cut the flex pipe to length along a valley in the corrugation. Using a steel tubing cutter.

Do you use tape on gas compression fittings?

If you are connecting gas lines and their fittings to an outdoor grill or inside stove, you should make sure to use the right Teflon tape. There is Teflon tape made to seal the threads on gas fittings and to prevent leaks in those connections.

How tight should a gas compression fitting be?

Compression fittings should be tight enough to create a watertight seal but not so tight that the pipe warps or the thread is damaged as this could encourage leaks and make the fittings much harder to remove later.

Do you need PTFE on gas compression fittings?

Use none,there is no need at all for PTFE on compression fittings,it is for going on threads. If you want, use a bit of boss blue/white on the fitting depending what it is being used for.

Is it OK to use Teflon tape on gasoline fittings?

Backyard mechanics will tell you they've used regular old gas resistant teflon tape (yellow stuff) with success. This is not recommended because it risks breaking free. Liquid or paste type thread sealants are kinder to sensitive components down stream.

Do you need sealant on compression fitting?

Compression joints are designed to be used without any sealant. The nut compresses the olive driving it into the cone shaped profile at the end of the fitting body, causing deformation of both the metal surfaces of the olive and the pipe, zeroing the gap and creating a watertight seal.

Can I over tighten a compression fitting?

Hold the compression fitting body tightly with a pair of grips and tighten the nut with a spanner. Its often said in the trade to not over tighten a compression fitting, leaving you more thread in the case of a leak and not distorting the olive or fitting. Generally a nut will need one whole turn after hand tightening.

How do I stop my compression fitting from leaking?

Tighten compression fittings firmly with two wrenches to crimp the ferrule onto the pipe (Photo 3). Also make sure the pipe or tube goes straight into the fitting. Misalignment will cause a leak. If the fitting leaks after you turn on the water, try tightening the nut an additional one-quarter turn.

Can you tighten a compression fitting too much?

Though valve breakage is a rare occurrence, never underestimate a poorly trained installer with a big wrench. This is a threaded needle valve that was severely over-tightened. Unfortunately, if a compression valve or fitting has sustained this kind of damage from over-tightening, you should replace it.

Can you use blue PTFE tape on gas fittings?

The cheap Teflon tape that comes in the blue package is for water pipes. You can't use it on gas.

Do gas flare fittings need tape?

Do not use Teflon ® tape or pipe sealant on any flare ends because you will not obtain a leak-free seal. Keep flare end of fitting free of grease, oil and thread sealant. Use a wrench only on the hex surfaces of the fittings. tighten more if a leak is detected.

How do you seal compression fittings?

1:256:15How To Fix a Leaking Compression Fitting | Stop Plumbing LeakYouTubeStart of suggested clipEnd of suggested clipOkay like so all neat. And if you notice i did that in a clockwise. Motion. That's just a good habitMoreOkay like so all neat. And if you notice i did that in a clockwise. Motion. That's just a good habit to get into because if you're doing it on threaded fittings. It stops it from peeling.

How to tell compression fittings?

Compression fittings differ from threaded fittings in that, you can easily tell their seal by how well the nut grips the fitting without overcompressing the soft copper olive. Despite their versatility, their longevity remains dependent upon their current application, even though most technicians consider them to be more reliable.

How Do I Know If My Compression Fitting is Tight Enough?

When you follow the thread of the coupling nut closely, you can tell if the ring is tight, but only when you do not cross-thread; it is obvious when you can spot the last fraction of the thread on the fittings.

How to tighten a copper olive ring?

Next, tighten the compression nut using another wrench for not more than a half-turn; the maximum is three-quarter turns. Also, remember that overtightening the nut can cause damage to the soft copper olive ring.

Why should gas fittings not be used?

So generally unless assessed and approved by relative authorities, gas compressed fittings should not be used because of the complexity that comes with their installations. The nuts, the bulky weights in the joints as well as their need for minimal pressure could trigger disaster anytime.

What materials are used for compression fittings?

Brass, plastic, cast iron, and copper are among the useful materials in the making of compression fittings. However, their applications vary depending on the materials and contents in transit. For example, copper compressed fittings are the best choice for gas pipes.

What is a hand tight fitting?

A hand-tight fit is perfect for any gas compression fitting. This results from the soft copper olive rings in the fitting that make it easier to hand tighten, sealing the joint. Gas leaks are nonetheless susceptible in these joints due to over-tightening the nuts, squeezing the copper olives.

Why do gas pipes explode?

Gas pipes sometimes contain flammable gases, so they would explode if heat or torches were used to repair them. The compressed fittings are therefore useful.

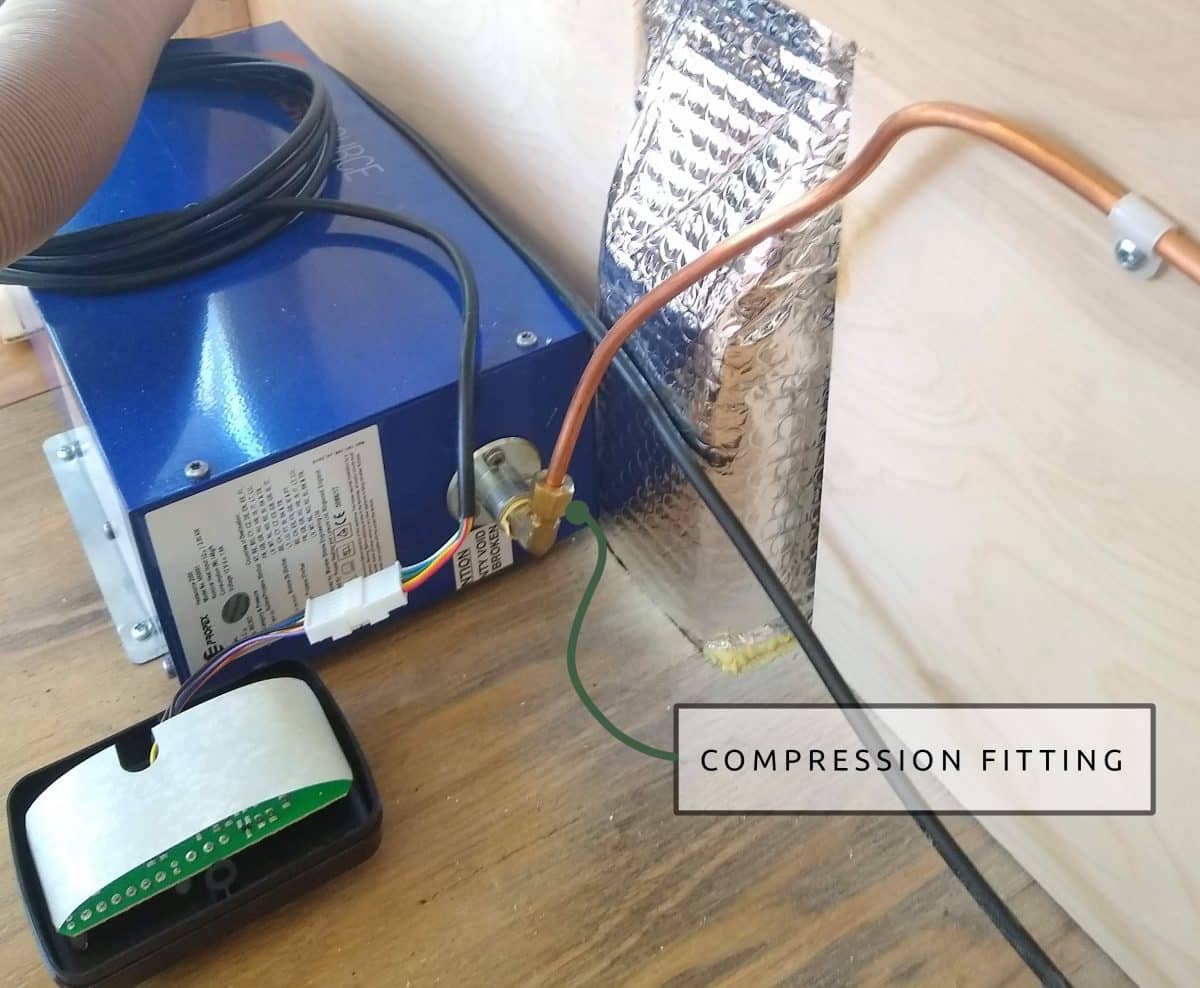

What is a compression fitting?

Compression fittings are the old-school version of the quick-connect fitting. While these fittings may require more work upon installation, they still provide strong, tight, and reliable seals for any of your water treatment configurations. John, our Master Water Specialist, offers his knowledge on compression fittings

How to tell if compression fitting is leaking?

If a compression fitting is leaking, you should determine where the leak is coming from. Usually, if you have a sound connection, you've put the fitting together properly, and you've wrenched down to where it's good and tight, the fitting is not likely to leak.

What material is used for compression fittings?

The most common material for a compression fitting is brass, but you must make sure to buy lead-free brass fittings because it's illegal to use any fitting with lead content in the U.S. They are also commonly made from plastic and stainless steel.

How to make a watertight seal on a tubing?

To create this seal, you must: Slide the nut onto your tubing. Slide the sleeve up to the nut on its threaded side. Put the tubing into the connector on the fitting body, and pull the nut, and then the sleeve, down so that the threads on the nut meet the threads on the fitting body.

How to stop a leak with a fitting?

The best way to stop a leak with this type of fitting is to turn the water off.

Why does plastic tubing leak?

Plastic fittings might be more prone to start leaking once they've been installed, but again, usually that's because something has happened externally to alter or stress the component.

What are compression fittings?

Plumbing compression fittings are designed to connect two pipes; a fixture and a pipe or a fixture and a valve together.

Can you recycle compression fittings?

When using compression fittings, please ensure that you won’t recycle its parts. For instance,yYou just can’t use the old ring and the old seat and then afterwards just replace the nut. That’s a big no-no. If you need to replace the fitting, you must ensure that all the components of the replacement are new.

Do you have to be a master plumber to install compression fittings?

Compression fittings are pretty easy to install. You don’t have to be a master plumb er to be able to create connections with the help of these plumbing parts. However, there are some things that you should remember. 1. These fittings are designed to keep the pipes, fixtures and valves in place.

Can compression fittings be used to lengthen pipes?

Another thing that you have to take note of is that compression fittings are not meant to lengthen pipes. That’s definitely not their job. If you’ll use a double compression type, you’ll have to anticipate that it won’t last very long. Every rotational movement or impact on the fitting will result to its wear and tear.

What is compression fitting?

Compression fittings are one of the most common and versatile methods of connecting metal or hard plastic tubing. Particularly useful for their extreme temperature and pressure capabilities, and their compatibility with aggressive fluids, compression fittings can be seen in systems varying from gas lines in refineries, ...

What are the factors that determine the success of compression fittings?

Chief among these are fitting and ferrule design, tubing selection, and installation procedure.

What is the importance of the shape of the ferrule and the mating angle of the fitting body?

The shape of both the ferrule and the mating angle of the fitting body are critical factors in the reliability of a compression seal. Both components must be tapered in a manner that allows the ferrule to compress properly as the nut is tightened, while maintaining axial alignment with the tubing.

How does metal tubing affect compression?

The way in which metal tubing is produced can have a significant effect on its performance with compression fittings. Tubing should be smooth and free of roughness or extrusion lines that can create a leak path past the ferrule. Furthermore, tubing that has been stored in coils can often have an asymetrical diameter, preventing even compression. While an elastomeric seal can deform to match these slight variations, the metal-to-metal seal of a compression fitting is less forgiving. It is also important that the end of each section be squarely cut, to allow the tubing to sit symmetrically in the fitting body.

Why use softer tubing?

The use of softer tubing (such as polyurethane or vinyl) is not normally recommended with compression style fittings because the tubing wall is likely to collapse, or move away from the ferrule. This negates the holding power of the ferrule, and can also prevent the ferrule from making a leak-tight seal around the full diameter of the tubing. If there is a particular design issue (for example, a tight bend radius) that necessitates softer tubing, it is important to reinforce the tubing wall. Some manufacturers offer tubing inserts for this purpose. The tubing insert, usually made of metal, is pressed into the soft tubing, and supports the tubing wall so that it will not collapse as the ferrule is compressed.

What is the radial compression of a ferrule?

It is this radial compression that creates the leak tight seal between the fitting, ferrule, and tubing, and gives the compression fitting its name. ...

Why is PTFE tubing used?

PTFE tubing is a popular material choice for tubing because it is resistant to most chemicals, handles relatively high pressure, is low out-gassing, and is more flexible than metallic tubing. One key design factor when using this kind of tubing is its tendency to “cold flow”, or deform away from a compressive load. This can cause leaks to develop over time, as the tubing wall begins to creep (cold flow) away from the ferrule. The cold flow issue is exacerbated when the tubing is exposed to high temperatures, and can occur even when fittings are properly installed and initially leak free.