The Best Way to Install a Solid Rivet

- Line Up Pieces. Pick up a rivet hammer kit on Amazon. ...

- Mark Rivet Holes. When you install rivets into metal, they are slid through a hole that is already there, so you have to make these holes yourself.

- Drill Rivet Holes. ...

- Insert Rivets into Hole. ...

- Use Air Hammer. ...

- Repeat Process. ...

- Check Fit. ...

How to set tubular rivets?

Installing a Tubular Rivet with a Gun

- Hold Rivet Gun Against the Rivet. There are many ways to install a tubular rivet. ...

- Use the Bucking Bar Against the Tail. Hold a bucking bar against the tail. ...

- Use Rivet Gun to Install Rivet. The rivet gun will then create a series of high-impulse vibration or force that will put the rivet in place.

- Inspect the Rivet. ...

How to install rivet nuts, nutserts, rivnuts?

Part 2 Part 2 of 3: Fitting the Rivet Nut onto the Mandrel Download Article

- Connect a mandrel and nosepiece that fits your rivet nut to the tool. ...

- Open the handle of the rivet nut tool. The handle of the tool needs to be loaded up so you can drive the rivet nut into the hole and ...

- Screw the rivet nut onto the nosepiece of the mandrel. ...

- Pull the end of the mandrel back and wind the adjuster. ...

How to install a tubular rivet?

How to Set a Tubular Rivet

- Line Up Two Pieces. Before you get to the installation of the tubular rivets you will need to line up the two pieces that you are going to ...

- Mark Each Rivet Hole. When you install rivets into a workpiece they are slid through a hole that has been pre-drilled. ...

- Drill Each of the Rivet Holes. ...

- Insert Rivets into Hole. ...

- Use Small Hammer. ...

- Repeat the Process. ...

How to remove rivets with a drill bit?

Top Tips for Removing Rivets

- Use Hand Tools. If you don’t have a power drill, a chisel, a hammer and a punch will do. ...

- Use a Grinder. You could also use a grinder to slice the head off the rivet and repeat the same procedure with the hammer and punch.

- Hand-Turn the Bit. ...

- File the Rivet Head. ...

- Remove Paint. ...

How to make a rivet nut fit?

Increase the size of the drill bit to widen the hole until the rivet nut fits. Swap out the drill bit for one with a larger diameter and place the end of it into the hole you made with the smaller bit. Bring the drill up to speed slowly and apply pressure to it. Drive the drill bit through the hole to create a wider opening. Try sliding the rivet nut into the hole whenever you change bits to see if it fits. Whenever it slides into place, stop increasing the size of the hole .

How to remove a rivet nut?

Start by drilling a hole that will fit the rivet nut. Then, attach the rivet nut onto the rod known as a mandrel of a handheld rivet nut tool. Insert the rivet nut into the hole, squeeze the handles of the tool, and remove the tool from the nut by unscrewing the mandrel. Steps.

What is a mandrel on a rivet nut?

On a rivet nut tool, the mandrel is a rod that holds the rivet nut in place when you’re securing it to the metal and the nosepiece holds the rivet nut on the tool when you’re installing it. Slide it into the tool and screw on the nosepiece that secures it and allows you to thread your rivet nut onto the tool.

What to do if rivet nut won't slide?

If the rivet nut won’t slide into the opening, expand your pilot hole by using a slightly bigger drill bit.

How to make a hole wider?

Drive the drill bit through the hole to create a wider opening. Try sliding the rivet nut into the hole whenever you change bits to see if it fits. Whenever it slides into place, stop increasing the size of the hole. Try to fit the rivet nut into the hole before you widen it further.

What is rivet nut?

Learn more... A rivet nut is a threaded fastener that can be installed in many different types of material including steel, plastic, fiberglass, and composite materials. They’re also really easy to install. Start by drilling a hole that will fit the rivet nut.

How to use a drill bit on a power drill?

Insert a small drill bit into the end of your power drill, hold the chuck again, and squeeze the trigger to close the jaws and hold the bit in place. Make sure the drill bit is held securely by tugging at it. Use a 1⁄8 inch (0.32 cm) drill bit or smaller to start. ...

How to remove a rivet from a sleeve?

To remove a defective rivet, follow these steps: 1 Drill a hole (same size as the original) into the head of the rivet, using the rivet dimple to help locate the center. Drill only through the head (either universal or flush). 2 Insert a pin punch into the hole and pry off the head. 3 Support the material on the back side, and using the pin punch drive the remaining rivet shank out. 4 Replace the rivet with the same size and type of the original rivet, provided that the hole has not been enlarged.

How long does it take to drive rivets?

Rivets of the AD category should be driven within two to three seconds. As these rivets are driven, the material hardens. If rivet cracks are visible, the strength of the joint is compromised.

How does a rivet squeezer work?

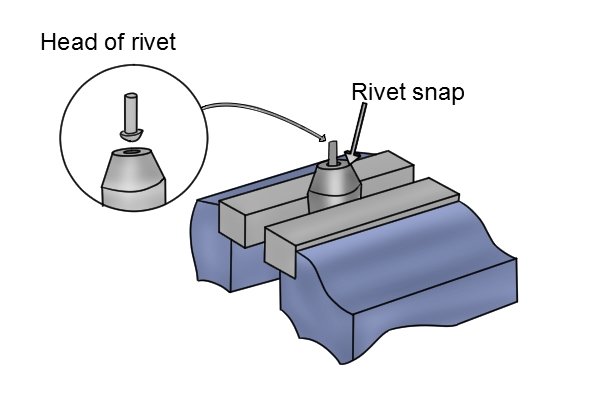

The material pieces are firmly clamped together and also firmly clamped to a workbench or jig, and the squeezer is operated smoothly and axially to the rivet to set or deform the shop head. It is very important to begin the squeezing operation with the rivet factory head as tight to the material as possible, allowing the setting to take place at the shop head of the rivet (Figure 2).

Why do you need to clamp the rivets together?

Next, the individual material pieces need to be firmly clamped together during this setting process so that no intermediate space allows the rivet to swell between the materials.

What happens when a rivet is dumped?

Rivet “dumped.” If the rivet length protruding through the material of the joint is more than 1.5 times its diameter, and especially if the setting forces are not perfectly axial, the rivet shank will tend to bend over rather than deform concentrically.

What is rivet squeezer?

Two riveting procedures have evolved. The rivet squeezer is a compression type of tool that applies a continuous axial force to the rivet, deforming the shop head. The rivet gun is an impact type of a tool that provides repeated axial impact forces (think hammer) to deform and set the rivet.

What causes a rivet to be defective?

Defective rivets will result from: Improper diameter and/or length of the rivet. Remember that material distortion is likely if the rivet diameter is more than 5.5 times the thinnest material of the joint. The length of the rivet is very important. The rivet length protruding through the joint should be 1.5 times the rivet diameter.