Building your solar Cell Step 1. Cut a piece sheet copper into the size and shape you wish for your cell. Although.025 inch thick copper was used for the cells described here, just about any thickness will do. Copper is a soft metal and can be cut with tin snips or even with an old pair of scissors. Copyright 2011 www.completefreeenergy.com

How do you make a solar cell out of copper sheets?

Assembling the Solar Cell Place the 2 copper sheets into your container. You will need to bend both pieces to match the curvature of the plastic bottle. Connect alligator clips to each sheet. Use the alligator clips to attach both pieces to opposite sides of the plastic bottle. Make a saltwater solution.

How do you make a solar cell out of glass?

To make a solar cell, you’ll need 2 glass plates, transparent tape, and a titanium dioxide solution. First, you’ll need to clean both plates with alcohol. Then, bake a titanium dioxide coating onto 1 of the plates before soaking it in a red dye. The other plate should be coated with carbon.

How do you attach solar cells to a soldering iron?

Make sure you put the nails in places that when you are soldering that they do not get in the way of your solder iron. Make sure that the solar cells can easily slide in and out of your nails, solar cells are very brittle and break easily. The board i am using is large enough to put 4 solar cells in a row on it.

How do you heat up a copper sheet?

Place 1 copper sheet on a hot plate. Once you have placed a sheet on the hot plate, turn the hot plate on. This will heat the copper and provide the energy needed for the copper to react quickly with the oxygen in the air.

How much copper is in a solar panel?

Solar power systems can contain approximately 5.5 tons of copper per MW.

How do you make a sheet of copper?

4:0915:57Artificer Made ep. 03 - Lets Make Copper Sheet Metal! - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt up and spin it around. And every couple of turns around you tighten it a little bit more until.MoreIt up and spin it around. And every couple of turns around you tighten it a little bit more until. And cameras moving until you get a piece of pipe the length you want.

Can you cut a solar cell?

Using the nanosecond laser Metsolar is able to cut the polycrystalline and monocrystalline solar cells into any desired shape and size. Cutting of solar cells are usually required to achieve desired solar module voltage options.

How do you make graphene out of solar cells?

0:177:11Graphene Use In Solar Cells - YouTubeYouTubeStart of suggested clipEnd of suggested clipInto solar cells a typical thin film solar cell consists of a transparent conductive layer an anti-MoreInto solar cells a typical thin film solar cell consists of a transparent conductive layer an anti-reflective coating beneath that and n-type semiconductor a p-type semiconductor.

How do you make copper plate at home?

2:217:02Easiest Copper Plating Method Revealed - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo just for a first test object one of the easiest things to do is just an iron nail copper loves toMoreSo just for a first test object one of the easiest things to do is just an iron nail copper loves to play to iron as a matter fact it'll play to it a bit even without a current.

How do you bend a sheet of copper by hand?

2:546:04How To Bend Sheet Metal Without A Brake - YouTubeYouTubeStart of suggested clipEnd of suggested clipNumber two with a hammer with everything clamped I give a good push by hand like the first methodMoreNumber two with a hammer with everything clamped I give a good push by hand like the first method then on the bend. I give it a soft hammer slowly refining the edge moving.

How do you split solar panels?

Solar cells are not damaged by cutting them in half. As long as you retain the full tabs on the front and back of the cell, the divided cells with still produce the full voltage. This means that a solar cell can only be divided along lines parallel to the tab lines and can only be divided by the number of tabs.

Can cells be cut in half?

There are two additional steps needed when making half-cut cells: a cell cutting step and a stringing step. Cell cutting is done with a laser and involves splitting standard solar cells into two halves. Solar cells can be very fragile, and laser cutting allows for precise lines to be cut into solar cells.

What is the difference between half-cell and full cell solar panels?

Traditional full cell panels ( 60 cells) are made with 60 or 72 cells on the entire panel. A half-Cell module doubles the number of cells into 120 or 144 cells per panel. The panel is the same size as a full cell panel but with double the cells.

Can graphene replace silver in solar panels?

As well as taking advantage of the transparency and stability of graphene in the interlayers of the solar cell, a highly conductive graphene-based paste will be used in the back contact and metal front grid, replacing expensive and finite metals such as silver.

Can graphene replace silicon in solar panels?

Graphene certainly has the potential to replace silicon in electronics, but it will be dependent on several different factors, including the willingness of end-users to adopt graphene over the status quo (and, in turn, change all their manufacturing methods).

What is the voltage of solar cell?

approximately 0.5 volts to 0.6 voltsIndividual solar cell devices are often the electrical building blocks of photovoltaic modules, known colloquially as solar panels. The common single junction silicon solar cell can produce a maximum open-circuit voltage of approximately 0.5 volts to 0.6 volts.

Why are copper based CIGS important?

Copper-based CIGS modules offer more efficient , lower-cost manufacturing, which should eventually lead to a resumption of the historic (downward) price trend. This is where CIGS offers an important advantage. Its manufacturing process, while certainly complex, is relatively energy-efficient compared with that for silicon.

Is Global Solar a consumer appliance?

But consumer appliances are only a part of Global Solar's plans. The company has completed development of a series of rigid, panel-mounted modules that will be suitable for a solar farm like Springerville, and can be used, as well, for those increasingly familiar rooftop installations.

How to make solar panels out of copper?

To make a solar panel out of a copper sheet, start by putting on gloves, then cutting your sheet into two 6-inch squares. After cleaning off a sheet, place it on a hot plate, heat until it’s covered in a black coating, then continue cooking it for 30 minutes.

How to make a solar cell conductive?

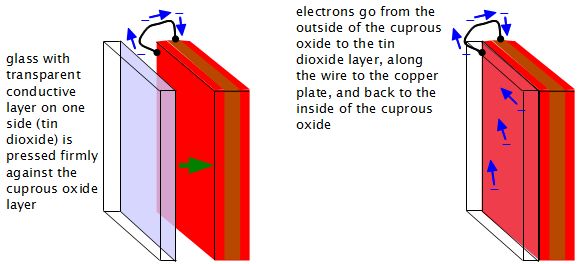

1. Place the solar cell in the sun. When the sun hits the cuprous oxide layer, it causes electrons to be released. The cuprous oxide is not conductive, but the electrons are able to move through the salt water to the conductive copper plate. This plate transfers the electrons to the wires.

How to make a copper bottle?

1. Place the 2 copper sheets into your container. You will need to bend both pieces to match the curvature of the plastic bottle. Both pieces need to be able to fit in the bottle without touching each other. Be sure not to damage the red cuprous oxide layer when bending the cooked sheet.

How long does it take copper to cool?

Leave the copper on the burner to cool. This allows the copper to cool very slowly to room temperature, which should take about 20 minutes. During the cooling process the copper and the cuprous oxide layer shrink at different rates.

How to make a hot plate with copper sheets?

1. Cut 2 copper sheets. You can use sheet metal shears to do this easily. Make the sheets the same size. You want 1 sheet to fit on your burner or hot plate, and both to fit in the 2-liter bottle. Making them both 6 in (15 cm) squares should work well. ...

How long to cook copper sheet?

This covering is cuprous oxide. Once the whole sheet is covered in cuprous oxide, allow it to cook at least 30 more minutes. Cooking the extra 30 minutes makes the cuprous oxide layer thick and brittle. This allows it to break away from the copper.

What color does copper turn?

As the copper heats up you will see varying shades of red, pink, purple, and possibly other colors. This is a sign that oxidation is taking place. Finally, you will notice that these colors are all being replaced by a black covering. This covering is cuprous oxide.