Making Dovetail Joints Using a Table Saw

- Mark the shoulder line. Use a marking gauge to scribe the shoulder line onto your tail board. ...

- Cut the tails. Cut through the base of the jig first, and then raise the blade gradually with each pass. Stop when the blade barely touches the shoulder line.

- Remove the tail waste. There are two ways to remove the waste from your tail board. ...

- Adjust your mitre gauge. While all your pin cuts will be made at the same angle, half of them slope in one direction and the other half slope in another.

How do you cut dovetails on a table saw?

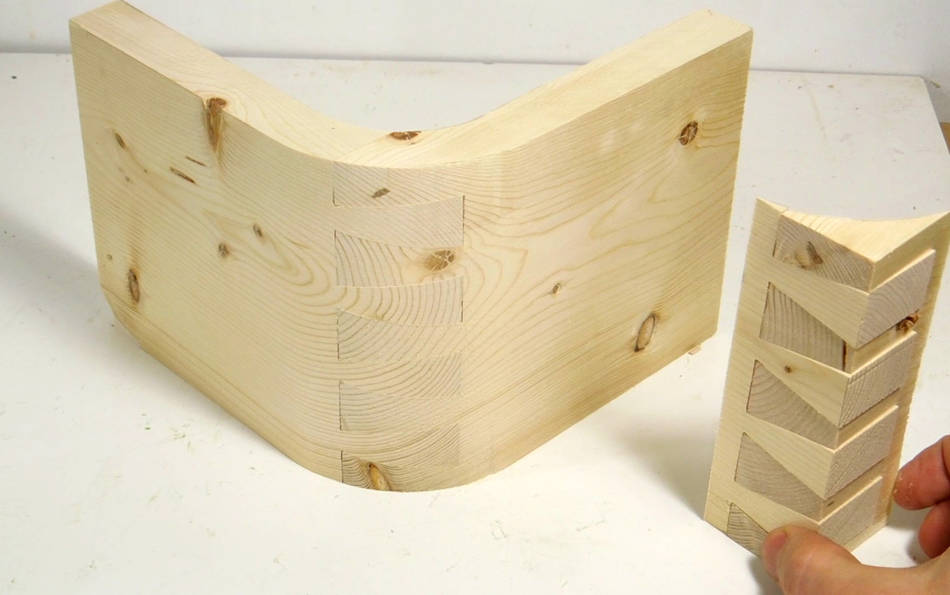

The jig for cutting dovetails on the table saw. The jig is simple and is attached to the miter gauge of your saw blade. The angle for the tails is achieved by tilting the blade and the angle for the pins by adjusting the miter gauge. The stop block ensures perfect repeatability of the cuts on multiple boards.

How to cut pinholes in a dovetail?

A fast method with a hand-cut dovetail look 1 sliding bevel 2 narrow chisel 3 to get into the pinholes 4 marking knife 5 flat-top grind table saw blade 6 (optional) 7 dovetail marker (optional, you can use the sliding bevel) More ...

Is hand-cutting dovetails a good idea?

But when you have to cut a lot of dovetails the same size, like multiple drawers, hand-cutting gets tedious, time consuming and repetitive.

How do you use a jig saw jig?

The jig is simple and is attached to the miter gauge of your saw blade. The angle for the tails is achieved by tilting the blade and the angle for the pins by adjusting the miter gauge. The stop block ensures perfect repeatability of the cuts on multiple boards.

Can you use a table saw to make dovetail joints?

0:006:37How to Cut Dovetails on a Tablesaw - YouTubeYouTubeStart of suggested clipEnd of suggested clipHand cut look wide tails narrow pins so to make machine cut dovetails with a handsaw and look FrenchMoreHand cut look wide tails narrow pins so to make machine cut dovetails with a handsaw and look French our maker Greg Paolini turns to the table. Saw.

How do you make a sliding dovetail joint on a table saw?

1:559:13This will make you look like a woodworking master! (Sliding ...YouTubeStart of suggested clipEnd of suggested clipTo cut the dovetail shaped sockets in the face of your panel. Such as on the side of a bookcase orMoreTo cut the dovetail shaped sockets in the face of your panel. Such as on the side of a bookcase or cabinet where you do a lot in a row. So this task falls to the handheld router. And an edge guide.

How do you make a dovetail jig table saw?

0:1622:44Dovetail Jig for the Table Saw // Woodworking Joinery - YouTubeYouTubeStart of suggested clipEnd of suggested clipBefore but I kept seeing this jig for the table saw that looked really cool and I really wanted toMoreBefore but I kept seeing this jig for the table saw that looked really cool and I really wanted to try it. So I could not find any videos on anybody making it I just saw a bunch of pictures. I saw

How do you make a simple dovetail joint?

7:2318:11How to Cut a DOVETAIL JOINT with Hand Tools | 8 Simple StepsYouTubeStart of suggested clipEnd of suggested clipI bring the saw blade about halfway down the joint. And then i start sawing in the curve. As i'mMoreI bring the saw blade about halfway down the joint. And then i start sawing in the curve. As i'm sawing i slowly turn the saw inward toward the waist. I saw down close to the baseline.

What are the disadvantages of a dovetail joint?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.

How do you make a sliding dovetail jig?

0:477:57How to make a diy SLIDING DOVETAIL JOINT with a routerYouTubeStart of suggested clipEnd of suggested clipFirst we sort the two pieces into male the dovetail. And female the socket. And mark with a markingMoreFirst we sort the two pieces into male the dovetail. And female the socket. And mark with a marking gauge align that 10 millimeters from the edge on both sides of the wooden.

Can I make my own dovetail jig?

0:2010:00Make this Dovetail Jig & Cut Perfect Dovetails [EVERY SINGLE TIME!]YouTubeStart of suggested clipEnd of suggested clipBelow this jig is a little bit different in that it attaches to my already existing crosscut sledMoreBelow this jig is a little bit different in that it attaches to my already existing crosscut sled and i use a combination of the table saw and the band saw to cut the dovetails.

How do you make a wood joint with a table saw?

2:084:41How to Make Finger Joints on the Table Saw // Box Joint ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd you place it next to the pin on the jig clamp. It down or use your fingers. However you feelMoreAnd you place it next to the pin on the jig clamp. It down or use your fingers. However you feel comfortable. And run it along the saw. Now that you've made that first cut.

How do you make a dovetail joint template?

Method one:Set the router plane blade to ¼” (5mm)Run the router plane down the sides of your dovetail template.Run the router plane on the end grain of your dovetail template.The sharp edge of the router blade makes a definitive mark.Use the vise for safety.

How do you make a dovetail joint without a router?

0:2819:22Make Dovetail Joints Without a Jig - WOOD magazine WWW15 - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo what we did was we actually figured out how to cut the pins with a table saw and we did the tailsMoreSo what we did was we actually figured out how to cut the pins with a table saw and we did the tails with a bandsaw. So the pins on this are on the front and on the back.

What tool makes dovetail joints?

Dovetail joints can be cut by hand as they have been for thousands of years, but power tools such as a table saw or a router and jig make the job much faster and accessible for total beginners.

How do you mark and cut a dovetail joint?

1:495:06How to Mark out and Cut a Simple Dovetail Joint - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd probably the most accurate way to mark out the dovetail pin the waste wood should be shaded withMoreAnd probably the most accurate way to mark out the dovetail pin the waste wood should be shaded with a pencil. This will help you avoid cutting away the wrong part of the joint.

What are the Tools Needed to Make Dovetail Joints?

An easy way to spot a quality piece of furniture is by observing its joinery. When it comes to dovetail joints, you need perfect execution to make sure you can reap all the advantages of these finger-like fittings.

How are Dovetail Joints Made?

Once you have all your tools ready, it’s time to get down to business. Here’s a simple step-by-step guide to answering the question: “how are dovetail joints made?”

What are the Different Types of Dovetail Joints?

There are different types of dovetail joints that you can make depending on the project’s function and design.