How to Install a Cut-Off Wheel on an Angle Grinder in 3 Easy Steps

- Inspect the Wheel I always like to make sure that there is no cracking in the wheel, or chipping off the sides. ...

- Remove the Nut, Inspect Grinder To get your angle grinder ready, we need to remove any wheel which is already on. ...

- Put the Cut-Off Wheel In Place Make sure that the wheel fits well into the grinder. ...

- Tighten the Nut ...

- Conclusion and Warnings! ...

How to put the disc on the grinder correctly?

What to do if the disc is jammed (bitten) on the grinder?

What are the two surfaces of a cutting disc?

Why is the metal ring on a cut off wheel important?

Do cut off wheels have a rotation?

Can you sharpen a tool with a grinder?

See 1 more

Which way does a cutting wheel go on a grinder?

Every right-angle grinder is marked with a directional arrow on the head of the grinder that indicates the direction the wheel is rotating when in use. For optimal performance, it's important to orient the cutting wheel so it rotates into and pulls itself into the workpiece rather than rotating away from the workpiece.

How do you put a wheel on a grinder?

A grinder wheel you want to install....Here's the easiest way to change an angle grinder wheel:Hold the wheel lock button down and turn the wheel until it locks.Turn the Kwik Lock flange counterclockwise by hand until it loosens. ... Hand thread the flange off.Swap the wheel and reverse the process.

How do I insert a cutting disc?

4:227:28Install angle grinder disc | Angle grinder safety - YouTubeYouTubeStart of suggested clipEnd of suggested clipIf you're mounting a flap disk or a cutting disk be it storm or metal. You put the disc on thereMoreIf you're mounting a flap disk or a cutting disk be it storm or metal. You put the disc on there that way and you put the flange nuts on sort of the flat. Surface. Top cheese the disc.

How do you put a wire wheel on an angle grinder?

0:523:10Angle Grinder Safety Chapter 2: Mounting Wheels - YouTubeYouTubeStart of suggested clipEnd of suggested clipMake sure the threads of the wheel hub matched the grinder spindle thread and that the wheel isMoreMake sure the threads of the wheel hub matched the grinder spindle thread and that the wheel is tightened snugly onto the spindle. The mounting hardware is not reusable.

How do you put a cutting wheel on a Dewalt grinder?

3:064:49DEWALT Product Guide - Grinder Guard & Wheel Installation - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo again we're going to take this dcg 418 grinder. We're going to press the guard lever we'llMoreSo again we're going to take this dcg 418 grinder. We're going to press the guard lever we'll install the guard. And again this is our type 27 guard just lock it into place.

How do you change a grinder wheel without a tool?

0:123:09Remove a grinder disc without the wrench - very dangerous - YouTubeYouTubeStart of suggested clipEnd of suggested clipDirection in some instances you do need to get some momentum by striking it with the palm of yourMoreDirection in some instances you do need to get some momentum by striking it with the palm of your hand like. So punches on that it will then loosen. You can then remove the disc.

Can you put a cutting blade on a grinder?

The exposed blade can cause significant injuries as the uncontrollable tool flies backwards and strikes the operator. For these reasons, angle grinders must never be fitted with circular saw blades.

How do you attach a rotary tool cutting disc?

1:514:20Rotary Tool How to - Mandrels and Attachments - YouTubeYouTubeStart of suggested clipEnd of suggested clipHere. You can start it by hand and get it most of the ways by. Hand. You take your screw driver. AndMoreHere. You can start it by hand and get it most of the ways by. Hand. You take your screw driver. And finish tightening it. Okay and then again once we've got a tight. No need to over tighten. It.

What is the difference between a grinding wheel and a cut off wheel?

Cut-off wheels cut small material workpieces at 90-degree angles, whereas grinding wheels grind large material workpieces from a low angle. As a result, cut-off wheels are quite thinner than grinding wheels. Cut-off wheel thinness provides more clean, and accurate cuts.

Can you use a wire wheel on a grinder?

2:5217:28Why Wire Wheels? - Metal Working Tools You Need! - YouTubeYouTubeStart of suggested clipEnd of suggested clipWith something like this now one of the most common types of wire wheels you're going to come acrossMoreWith something like this now one of the most common types of wire wheels you're going to come across in a shop. Environment is one that's on a bench grinder. Now this is a six inch bench grinder.

How do you put the cutting wheel on a Milwaukee grinder?

2:4911:22Milwaukee M18 Angle Grinder (Paddle Switch Version) - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe wheel guard there's a guard lock lever right here you want to press that in and as you keep itMoreThe wheel guard there's a guard lock lever right here you want to press that in and as you keep it pressed in you can move the wheel guard.

What wheel type do I need to cut metal on an angle grinder?

. 045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “Kerf”) than grinding wheels (1/4”) and pipeline wheels (1/8”). This is because grinding and pipeline wheels are mainly designed for grinding metal as opposed to cutting.

How do you put a flap disc in a grinder?

1:413:34How to set up and remove a flap disc - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe lower adapting nut flush. And level install the flap disc with the Arbor hole centered over theMoreThe lower adapting nut flush. And level install the flap disc with the Arbor hole centered over the raised flange. And the abrasive flaps facing away from the grinder.

How do you put a grinding wheel on a bench grinder?

0:272:09Surface Grinder Basics - How to Install a Grinding Wheel - YouTubeYouTubeStart of suggested clipEnd of suggested clipJust be real careful and slide it on. There. Then left-handed thread okay you put the nut on itsMoreJust be real careful and slide it on. There. Then left-handed thread okay you put the nut on its left threads use the adjustable spanner wrench tighten it up. And after you have the wheel tight.

How do you set up a grinder?

0:079:43Angle Grinder Set up - YouTubeYouTubeStart of suggested clipEnd of suggested clipBut once it's on there should allow you to spin. Around. And you'll notice that that little lever.MoreBut once it's on there should allow you to spin. Around. And you'll notice that that little lever. Allows this shroud to lock in in different positions.

How do you use a grinder step by step?

1:553:56How To Use An Angle Grinder - Ace Hardware - YouTubeYouTubeStart of suggested clipEnd of suggested clipHold the tool at about a twenty to thirty degree angle. Keep it moving back and forth to preventMoreHold the tool at about a twenty to thirty degree angle. Keep it moving back and forth to prevent gouges edge grinding or cutting should be done straight on without bending the wheel.

How to change a disk if it is jammed?

What to do if the wheel on the “angle grinder” is stuck? This can happen, for example, when, as a result of work, pieces of the workpiece being cut sharply clamp the rotating disc. This often leads to its destruction.

What to use to install the disc?

However, in order to do such work, it is necessary to take into account certain rules and use certain tools.

What is the nut on a label washer?

On the side on which the label is glued, a wide pressure washer is placed, and the movable nut acts on it when tightening (installing the disc). The nut slides on the polished surface of the washer, without it it will become more difficult to tighten or unscrew, since the abrasive will firmly hold the nut and more effort will be required. This is especially important if a quick replacement of the disc is required or if it breaks down (jamming).

What thread do you use for angle grinder wheels?

They are attached to the spindle of the angle grinder using a clamping flange (nut) with an M14 thread. To unscrew it, a special open-end wrench with pins on one side must be included with the angle grinder.

Why is the ring on an angle grinder disc mounted?

Also, the ring is mounted on an angle grinder disc to significantly increase the bearing surface area. In addition, the washer is designed so that the abrasive does not “stick” to the nut, which simplifies the removal process.

How to stop a clamping nut from jamming?

Some owners of an angle grinder, in a situation where the clamping nut is jammed, install a “chisel” or “jackhammer” nozzle into the hammer drill, insert it into the hole of the flange at an angle and turn on the hammer mode without rotation. Accordingly, the stop button must be pressed.

Why do you need a washer on a stopper?

A washer or simply a metal ring is necessary to protect the abrasive from excessive tightening, since many users tend to tighten the stopper tighter, fearing that the circle will fly off while working with the tool.

How to put the disc on the angle grinder?

To correctly place the disk on the angle grinder, it is first worth noting that the disk is mounted on the spindle of the angle grinder using a special clamping flange with M14 thread. Let’s take a closer look at how to remove a disc from an angle grinder. In order to unscrew the disk from the angle grinder, you first need to dismantle the flange. Especially for such purposes, manufacturers complete the angle grinder with a special open-end wrench. It has a specific shape. The pins located on the horns of this key are inserted into specially provided holes on the flange.

What to do if the angle grinder has jammed (bitten) a disk?

Everyone who has experience working intensively with an angle grinder must have come across such a situation at least once.

How to put the disc on the grinder correctly?

To put the disc on the grinder correctly, it should first be noted that the disc is installed on the grinder spindle using a special clamping flange with M14 thread. Let’s take a closer look at how to remove a disc from a grinder. In order to unscrew the disc from the grinder, you first need to dismantle the flange. Especially for such purposes, manufacturers complete the grinders with a special open-end wrench. It has a specific shape. The pins located on the arms of this key are inserted into specially provided holes on the flange.

What to do if the disc is jammed (bitten) on the grinder?

Everyone who has experience of intensive work with a grinder has probably at least once encountered such a situation.

What are the two surfaces of a cutting disc?

On any cutting disc, two surfaces are clearly visible. One of them (back) is plain, formed by abrasive material. The second (front) has a label containing basic information about the characteristics of the disc. But the main distinguishing feature of the two surfaces is the presence of a metal ring on the front side.

Why is the metal ring on a cut off wheel important?

The metal ring increases the footprint. Therefore, when the disc is mounted on the shaft and starts to tighten with the nut, the pressure is evenly distributed. This ensures a smooth fit of the cut-off wheel and reduces the possibility of damage due to skewing.

Do cut off wheels have a rotation?

The cut-off wheels do not have a programmed direction of rotation. Therefore, it does not matter which side will carry out their installation. But as mentioned above, installing the circle with its front side outward makes it easier to replace it (it is much more difficult to unscrew the nut on the abrasive side). In addition, this arrangement provides several other advantages.

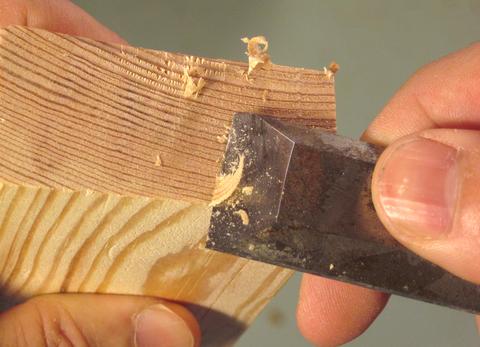

Can you sharpen a tool with a grinder?

To sharpen the tool, grinding machines (sharpeners) are usually used. But if you do not have the latter, but have a grinder, then you can purchase a sharpening (grinding) wheel for it, with which you can easily sharpen almost any cutting tool.