Removing Penetrant

- When sufficient penetration time has been allowed, wipe the surface clean with a clean towel or cloth.

- Repeat if necessary. Some surfaces will require only wiping.

- In general, however, remove excess surface penetrant with clean cloths premoistened with Cleaner/Remover.

- DO NOT flush surface with Cleaner/Remover because this will impair sensitivity. ...

- When sufficient penetration time has been allowed, wipe the surface clean with a clean towel or cloth.

- Repeat if necessary. ...

- In general, however, remove excess surface penetrant with clean cloths premoistened with Cleaner/Remover.

What is the best way to clean a dye penetrant?

Cleaning processes inspectors commonly follow could include less invasive methods, like vapor degreasing, the use of solvents, or just wiping it with a wet rag, or more invasive methods, like grinding or wire brushing. 2. Apply the dye penetrant

What are the essentials of the method of dye penetration?

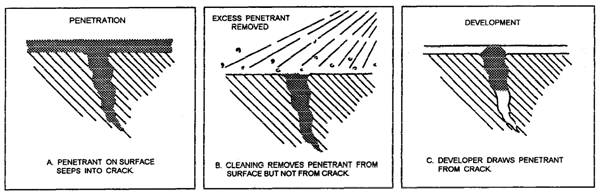

The essentials of the method are: penetration of the defect by the Dye Penetrant - removal of the excess Penetrant from the surface - development of the indication - inspection. A deep red indication will mark the defect. Surfaces should be free of foreign materials and paint.

What is dye penetrant testing?

What Is Dye Penetrant Testing? Dye penetrant is a dye used by inspectors in dye penetrant inspections, an inspection method in which inspectors apply a dye or liquid to a surface to identify defects in it. Dye penetrant is also commonly called liquid penetrant or liquid dye penetrant.

How to remove the extra penetrant from the paint?

3. Remove extra penetrant and apply remover Remove any excess penetrant with a dry rag. After cleaning off extra penetrant, apply a remover to the surface and rub it dry with a fresh clean, dry rag. 4. Apply developer After cleaning and removing the dye penetrant, apply a white developer to the surface.

How long does penetrant stay on a part?

What is visible dye penetrant?

What should surface be free of?

Why not flush with cleaner?

What to do if playback doesn't begin?

Does Magnaflux offer penecert?

How long does it take for a crack to show up?

See 2 more

What is the proper technique for removal of excess penetrant?

Water washable penetrants are removed by manual or automated water spray, manual wipe or air agitated immersion wash. If a manual spray is used the water pressure should not exceed 40 psi; the temperature should be between 50–100°F / 10–38°C using a coarse spray at a minimum distance of 12 in / 30 cm from the part.

What should be applied after a part is cleaned of excess dye penetrant?

After cleaning and removing the dye penetrant, apply a white developer to the surface. The developer will draw the penetrant from the flaws or cracks on the surface of the material and make them visible.

How long do you leave dye penetrant on?

Apply the penetrant to the test area. Allow the penetrant to dwell for 10-30 minutes. Then, remove the excess penetrant by wiping the part down using a clean dry cloth.

What is solvent removable penetrant?

It is a solvent removable Penetrant used in a process Of LPI/DPI (Liquid / Dye penetrant inspection for identification and detection of hairline cracks, porosity and discontinuities on the surface of a nonporous material.

What is the difference between liquid penetrant and dye penetrant?

Dyes Vs. With dye penetrant, the liquid penetrant itself is the indicating material. The subject material in magnetic testing must be magnetized, whereas liquid penetrant techniques may be used on a wider variety of materials.

What is the most common source of penetrant bath contamination?

Q.What is the most common source of penetrant bath contamination?B.WaterC.DeveloperD.SolventAnswer» b. Water1 more row

What is the disadvantages of the liquid penetrant test?

Disadvantages of LPI Extensive, time-taking pre-cleaning critical—surface contaminants can mask defects. Sensitive to surface-breaking defects only. Direct connection to the surface under test necessary. Works on relatively non-porous surface materials only.

What is difference between DPT and LPT?

Dye Penetrant Test (DPT) is one of the most inexpensive non-destructive test (NDT) methods, used to check the surface irregularities of any component. This test method is popular by many names, which are as follows; Liquid Penetrant Inspection (LPI) Liquid Penetrant testing or Liquid Penetrant test (LPT)

What are the 4 methods of penetrant systems?

The four methods are listed below:Method A - Water Washable.Method B - Post-Emulsifiable, Lipophilic.Method C - Solvent Removable.Method D - Post-Emulsifiable, Hydrophilic.

What are the two types of penetrant?

Penetrant materials come in two basic types: Type 1 - Fluorescent Penetrants: they contain a dye or several dyes that fluoresce when exposed to ultraviolet radiation. Type 2 - Visible Penetrants: they contain a red dye that provides high contrast against the white developer background.

How many types of penetrant are there?

three basic types of penetrant: Colour contrast. Fluorescent. Dual purpose (fluorescent / colour contrast)

Which type of developer should not be used with a visible dye penetrant process?

Water soluble developers may not be used with Type 2 visible dye penetrants because, like dry powder developers, water soluble developers do not produce an adequate white contrasting background that is necessary for visible dye penetrant inspection.

Which of the following is a reason to post clean a part after a liquid penetrant test?

When using a post emulsifiable penetrant process, it is important to drain as much excess penetrant as possible from the surface of a test piece which has been immersed in the penetrant because: When performing a post emulsifiable penetrant test, the test piece does not rinse acceptable clean during normal processing.

Which of the following parts could not be tested by the liquid penetrant method?

a. Penetrant testing cannot be used on ferromagnetic material. 2.

How long does penetrant stay on a part?

If penetrant pulls back in droplets, stop and clean part again. Allow penetrant to remain on the part from 10-30 minutes.

What is visible dye penetrant?

How to Use a Visible Dye Penetrant. The dye penetrant method of inspection is a nondestructive test for defects open to the surface. It may be used on such materials as aluminum, magnesium, brass, copper, cast iron, steel, stainless steel, carbides, stellite, certain plastics and ceramics. The essentials of the method are: penetration ...

What should surface be free of?

Surfaces should be free of foreign materials and paint. Grease, oils, etc., prevent penetration and should be removed by precleaning with. Cleaner/Remover or by solvent degreasing. Scale, sand, dirt, etc. trap penetrant and hinder removal, therefore wire brushing or similar. precleaning is necessary.

Why not flush with cleaner?

DO NOT flush surface with Cleaner/Remover because this will impair sensitivity. Repeat this procedure with additional wiping until residual surface penetrant has been removed.

What to do if playback doesn't begin?

If playback doesn't begin shortly, try restarting your device.

Does Magnaflux offer penecert?

Magnaflux offers PeneCert Testing Service for in-process penetrant materials. Contact Magnaflux Customer Service for details at [email protected].

How long does it take for a crack to show up?

Watch for large cracks to show up immediately. Smaller cracks may take a few minutes to develop the best indication.

What are the two types of penetrants in a dye penetrator?

Depending on the physical characteristics and performance of the penetrant materials, they are of two basic types: Type 1-Fluorescent Penetrants containing dyes that fluoresce under ultraviolet radiation and. Type 2-Visible Penetrants containing red color dye.

How to remove excess penetrant from a sample?

The excess penetrant needs to be removed from the sample surface. Depending on the dye penetrant type, The removal method is selected from water-washable, solvent-removable, lipophilic post-emulsifiable, or hydrophilic post-emulsifiable, etc. Emulsifiers are used for the highest sensitivity level, and it chemically reacts with the oily penetrant, thus making it easier to remove using water spray. The excess penetrant has to be removed thoroughly otherwise, on the application of the developer, it may leave a background in the developed area that can mask indications or defects. Also, while using solvent remover and lint-free cloth, care must be exercised not to spray the solvent on the test surface directly, because this can remove the penetrant from the flaws.

How many types of dye penetrant are there?

Again, depending on the detectability of defect indication, five types of dye penetrant is available:

What is a dye penetration test kit?

Dye penetration test kit contains all the required elements for performing dye penetration test. These kits are easily available in the market and contains the Penetrant, Cleaner and Developer as shown in Fig. 2 below.

What is a DPT test?

Dye Penetration Test (DPT) is one of the simplest and oldest Non-Destructive Inspection methods. Also, known as the Liquid penetration test, the Dye penetrant test is widely used to detect surface discontinuities like cracks, fractures, porosity, grinding defects, incomplete fusion, and flaws in joints. This test or inspection method is serving as an aid to finding irregularities in aluminum, cast iron, brass, steel and stainless steel, copper, magnesium, carbides, stellite, ceramics, and even certain plastic materials. So, the dye penetration test is suitable for both ferrous and non-ferrous materials and highly economic as compared to the other non-destructive inspection methods.

What is the purpose of a developer?

The main function of the developer is to draw the penetrant out of the flaw making an invisible indication, visible to the inspector. Depending on the type of dye used, the dye penetration inspection is performed under white or ultraviolet light.

How long does it take for a liquid penetrant to penetrate a flaw?

Next, The liquid penetrant is applied on the specimen surface and allowed to soak into any flaws for its dwell time (generally 10 to 60 minutes). The dwell time varies depending on the used penetrant (viscosity: longer duration for high viscosity), test material, and the defect sizes (smaller flaw sizes require longer penetration time). Dwell time is normally provided by the penetrant manufacturers and depends on the following:

What temperature should a fluorescent water washable penetrant be?

The temperature of the penetrant materials and the surface of the part should be between 50°F and 100°F for fluorescent water washable penetrants and between 60°F and 125°F for visible penetrants.

How to remove penetrant from specimen?

After the elapse of penetrant dwell time, the excess penetrant is removed by water spray. Water at 60°F to 110°F and a pressure not exceeding 30 psi (210 KPa) is applied with droplet type sprayer specifically designed for penetrant removal. The nozzle of sprayer is held so that water strikes the surface of the specimen at an angle of approximately 45 degrees. Care is to be taken to avoid over-washing, which causes washout of penetrant from discontinuities. Other methods of referenced codes or specifications could also be used if applicable for the test surface conditions.

How long does a penetrant stay on the test surface?

c) Penetrant shall remain on the test surface for the entire dwell time period.

Why not follow a visible penetrant examination?

Note: Caution - Fluorescent penetrant examination shall not follow a visible penetrant examination because visible dyes may cause deterioration or quenching of fluorescent dyes.

What is the minimum light intensity required for a penetrant?

Adequate illumination is required to ensure no loss in the sensitivity of the examination. A minimum light intensity at the examination site of 100 fc (1000 Lx) is recommended.

What temperature should an aerosol can be kept out of?

10.4 Aerosol cans of penetrant materials should be kept out of direct sunlight or areas in excess of 130 °F. Excessive heat may cause aerosol cans to explode. 10.5 Avoid looking directly into black light source, since the eyeball contains a fluid that fluoresces if black light shines directly into the eye. 11.

How much of the base material on both sides of a weld is covered?

When welds are tested, at least one inch of the base material on both sides of the weld is to be covered.

What is a white developer?

After excess penetrant has been removed, a white developer is applied to the sample. Several developer types are available, including: non-aqueous wet developer, dry powder, water-suspendable, and water-soluble. Choice of developer is governed by penetrant compatibility (one can't use water-soluble or -suspendable developer with water-washable penetrant), and by inspection conditions. When using non-aqueous wet developer (NAWD) or dry powder, the sample must be dried prior to application, while soluble and suspendable developers are applied with the part still wet from the previous step. NAWD is commercially available in aerosol spray cans, and may employ acetone, isopropyl alcohol, or a propellant that is a combination of the two. Developer should form a semi-transparent, even coating on the surface.

What is a DP inspection?

Dye penetrant inspection ( DP ), also called liquid penetrate inspection ( LPI) or penetrant testing ( PT ), is a widely applied and low-cost inspection method used to check surface-breaking defects in all non-porous materials (metals, plastics, or ceramics). The penetrant may be applied to all non-ferrous materials and ferrous materials, although for ferrous components magnetic-particle inspection is often used instead for its subsurface detection capability. LPI is used to detect casting, forging and welding surface defects such as hairline cracks, surface porosity, leaks in new products, and fatigue cracks on in-service components.

How to apply DPI?

The penetrant may be applied to the test component by dipping, spraying, or brushing. After adequate penetration time has been allowed, the excess penetrant is removed and a developer is applied. The developer helps to draw penetrant out of the flaw so that an invisible indication becomes visible to the inspector. Inspection is performed under ultraviolet or white light, depending on the type of dye used - fluorescent or nonfluorescent (visible).

How long does it take to test for fluorescent dye?

Inspection of the test surface should take place after 10- to 30-minute development time, and is dependent on the penetrant and developer used. This time delay allows the blotting action to occur. The inspector may observe the sample for indication formation when using visible dye. It is also good practice to observe indications as they form because the characteristics of the bleed out are a significant part of interpretation characterization of flaws.

What are the steps of liquid penetrant inspection?

Below are the main steps of Liquid Penetrant Inspection: 1. Pre-cleaning: The test surface is cleaned to remove any dirt, paint, oil, grease or any loose scale that could either keep penetrant out of a defect or cause irrelevant or false indications.

How long does it take for a penetrant to soak into a flaw?

The penetrant is allowed "dwell time" to soak into any flaws (generally 5 to 30 minutes). The dwell time mainly depends upon the penetrant being used, the material being tested and the size of flaws sought. As expected, smaller flaws require a longer penetration time. Due to their incompatible nature, one must be careful not to apply solvent-based penetrant to a surface which is to be inspected with a water-washable developer.

What does it mean when a developer is bleed out?

Any areas that bleed out can indicate the location, orientation and possible types of defects on the surface.

What is Penetrant Testing or DPT?

Liquid penetrant testing (LPT) or also known as Dye penetrant test (DPT) is one of the most popular Nondestructive Testing (NDT) methods. It is cheap, handy, and requires minimum training when compared to other NDT methods. Like other nondestructive test methods, DPI allows inspectors to test materials without cutting, boring, or otherwise disturbing the surface. Dye penetrant inspection helps to reveal surface cracks or other defects that may not be visible to the naked eye. One of the biggest limitations to dye penetrant inspection testing is that it can only be used on non-porous surfaces. Porous materials like concrete or stone simply soak up the dye, making it easy to miss problem areas. This test method may also be ineffective on objects with a roughly textured surface. Dye penetrant tests generally work best on relatively smooth surfaces, where the dye will penetrate only into cracks and other defects.

What is LPT in ASME?

The American Society for Nondestructive Testing (ASNT) uses the name liquid penetrant testing (LPT). The American Society of Mechanical Engineers Boiler and Pressure Vessel Code (ASME B & PVC) and the National Board Inspection Code (NBIC) use the name liquid penetrant examination (LPE) but the term is same as PT in both ASNT and ASME.

Why is dye penetrant solvent removable method so popular?

The dye penetrant solvent removable method is most popular because it is low cost and very versatile. It typically comes in three aerosol cans –

Why is precleaning important?

The importance of precleaning cannot be overstated because adverse surface conditions, including paint, oils, and surface soils, or corrosion products, chemically active residues, and moisture, can interfere with the following: wetting of the test surface by the liquid penetrant, entry of the liquid penetrant into discontinuities, and the subsequent bleed out of liquid penetrant to form discontinuity indications.

What is the purpose of magnetic particle examination?

In the ASME B & PV Codes of Construction, magnetic particle examination or liquid penetrant examination is called out many times to detect the possibility of surface defects. If material is nonmagnetic the only choice is PT.

How long does it take for penetrant to dry?

A dwell (soak) time needs to be observed to allow for the penetrant to permeate into cracks and voids. This is typically 5 to 20 minutes but should never be long enough for the penetrant to dry.

How many steps are there in penetrant testing?

The penetrant testing process consists of six basic steps regardless of the type of penetrant and removal method:

How long does penetrant stay on a part?

If penetrant pulls back in droplets, stop and clean part again. Allow penetrant to remain on the part from 10-30 minutes.

What is visible dye penetrant?

How to Use a Visible Dye Penetrant. The dye penetrant method of inspection is a nondestructive test for defects open to the surface. It may be used on such materials as aluminum, magnesium, brass, copper, cast iron, steel, stainless steel, carbides, stellite, certain plastics and ceramics. The essentials of the method are: penetration ...

What should surface be free of?

Surfaces should be free of foreign materials and paint. Grease, oils, etc., prevent penetration and should be removed by precleaning with. Cleaner/Remover or by solvent degreasing. Scale, sand, dirt, etc. trap penetrant and hinder removal, therefore wire brushing or similar. precleaning is necessary.

Why not flush with cleaner?

DO NOT flush surface with Cleaner/Remover because this will impair sensitivity. Repeat this procedure with additional wiping until residual surface penetrant has been removed.

What to do if playback doesn't begin?

If playback doesn't begin shortly, try restarting your device.

Does Magnaflux offer penecert?

Magnaflux offers PeneCert Testing Service for in-process penetrant materials. Contact Magnaflux Customer Service for details at [email protected].

How long does it take for a crack to show up?

Watch for large cracks to show up immediately. Smaller cracks may take a few minutes to develop the best indication.