How do you sharpen a split bit drill bit?

- MATERIALS AND TOOLS Available on Amazon.

- Examine your dull bits.

- Don your goggles and turn on the bench grinder.

- Hold the bit at this angle against the wheel for no more than four to five seconds.

- Pause after four to five seconds of grinding and dip the drill bit into the ice water to cool the metal.

How do you sharpen a drill bit?

How do you sharpen a split bit drill bit? MATERIALS AND TOOLS Available on Amazon. Examine your dull bits. Don your goggles and turn on the bench grinder. Hold the bit at this angle against the wheel for no more than four to five seconds. Pause …

How do you fix a broken drill bit?

Carefully lower the separating disk to lightly touch the targeted surface. Without changing the angle, rotate the bit in the holding device and repeat on the opposite relief area plane. Once this is complete, you will have a newly sharpened bit. This may take a bit of practice, but it’s a valuable technique that can save time on the job.

How to use a drill bit?

Use a "C" clamp to hold the bit in place. Put some oil on a small handstone, like those used for sharpening fishhooks. Stroke along the angled surface of the block so the bit is being sharpened at the same time. When the stone is no longer cutting on …

How do you cut a block with a drill bit?

How to Sharpen Used and Dull Drill Bits (By Hand!!) Step 1: Know Your Drill Bit. There are many features on a drill bit that can be defined. For speed sake, were only... Step 2: Uderstand Why Drills Chip and Dull. In order for you to know how to better sharpen your bit, …

How do you sharpen a broken drill bit?

Is it worth sharpening drill bits?

How do I sharpen a drill bit by hand?

What are split point drill bits used for?

What angle is used to sharpen drill bits?

They are at an angle of around 118 degrees to each other (point angle).Feb 6, 2018

Can concrete drill bits be sharpened?

How do you sharpen a drill bit at home?

How do you sharpen a drill bit without a sharpener?

One of the fastest ways to sharpen a drill bit is using a bench grinder. If you are like most DIYers, you probably own one already. All you need to do is strap on some protective clothing and start sharpening.May 4, 2022

How do you sharpen a wood drill bit?

Can you sharpen split point drill bits?

What does a split drill bit look like?

What is the difference between 118 degree and 135 degree drill bits?

How to sharpen a drill bit?

STEP 1 — Check Your dull bit. Sharpening a drill bit involves removing just enough metal to get a sharp edge. Removing too little metal will not sharpen it while removing too much metal will make it wear out faster. That’s why you need to examine your drill bit to decide how much metal you need to remove.

How to keep drill bits sharp?

Top Tips for Keeping Your Drill Bits Sharp For Long 1 The sharpening process is tiresome, that’s why you need to strive to keep your drill bits sharp for a long. Here are some useful tips for keeping the drill bits sharp longer. 2 Clear the chips off as you drill. 3 When drilling hardwood, have a cup of water nearby to cool the bit. 4 Start holes using a like-new or new drill bits. You can switch to a re-sharpened bit once the hole is started. 5 Avoid overheating. 6 Use the Stop-and-cool technique when grinding. 7 Keep two sets of drill bits.

What is a bench grinder?

Bench grinders come with two grinding wheels, one fine, and the other coarse wheel. The coarse wheel removes bigger pieces of metal, and it’s the one you need to start with when dealing with highly ravaged drill bits. After you are through with the coarse wheel, you can switch to the fine wheel for a smooth finish.

What angle should a drill be sharpened?

The drill sharpening angle should be 60 degrees for not more than five seconds. Should remain in contact with the wheel, the aim is to grind away the dull surface, so if you let it stay longer, it may get worn out.

How often should you grind a metal bit?

You should be grinding and pausing after every five seconds or less. This is necessary to give the metal some time to cool down; otherwise, it can become too hot for you to hold. When the bit is too hot, it may wear out faster, thereby shortening its effective lifespan.

How to test a drill bit?

Hold its tip perpendicularly against a piece of wood, then twist it by hand. Just use a little pressure and see if it can drill a hole.

How to get rid of chips in wood?

Clear the chips off as you drill. When drilling hardwood, have a cup of water nearby to cool the bit. Start holes using a like-new or new drill bits. You can switch to a re-sharpened bit once the hole is started. Avoid overheating. Use the Stop-and-cool technique when grinding.

Step 1: A Dull Bit and a Sharp Bit

The bit on the left is a little dull. Notice the glint of light on the cutting edge between the two flutes. Compare that with the crisp edge on the freshly sharpened bit on the right.

Step 2: My Favorite Sharpening Tool

People who know what they are doing can sharpen bits by hand. In theory, hold the bit with the shank angled off to the left at about 59 degrees. As the bit contacts the grinding wheel, simultaneously move the shank farther left and downward while twisting it clockwise.

Step 3: Set to 59 Degrees

This sharpening guide can accept drill bits with several different profiles. My bits have a 59 degree profile on the cutting edge. Set the tool to 59 degrees and tighten the thumbnut.

Step 4: Catch the Edge

The tool has a small tip and the edges of the bit's flutes rest against it. You may have to raise or lower the tip so it fits against the flute edges properly.

Step 5: How Much Overhang

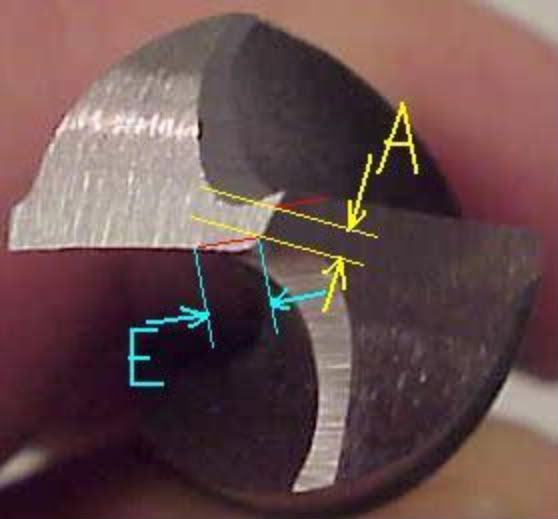

As a starting point make the overhang (space between the yellow lines) equal to the radius of the bit (space between the green lines). See the next step for why it matters.

Step 6: Width and Angle of the Cutting Edge

Notice the angle of the red line. If there is too much overhang in the previous step, the red line will approximate the cutting edge at the tip of the bit. It is too wide and the bit profile will be too flat. The bit will skate on a metal surface and the hole will be hard to start. You can reduce the bit's overhang quite a bit, but be careful.

Step 7: Ideal Cutting Edge Angle

The ideal is to have the shortest cutting edge possible. This would be a cutting edge that runs between the low points in the valleys of the fluting. See the yellow line. This bit is close to ideal and will cut steel very well.

How to sharpen a belt sander?

Start in a comfortable position with your hand against the machine support and take the drill bit into both hands. Hold the bit at a 60 degree angle to the face of the belt sander. Place the end of the landing so that it is directly against the belt. Use steps 5-7 to move the bit across the belt into the finish position. Notice in these two pictures how little difference there is between the start and finish sharpening positions. Steps 5-7 are simultaneous steps to get you to that finish position but notice how the only hand that moves is the left hand. The right hand stays stationary, with only the fingers guiding the drill bit.

What are the features of a drill bit?

There are many features on a drill bit that can be defined. For speed sake, were only worried about 3 basic features on the bit: the lip, land, and chisel. The "lip" is what does the actual cutting. The two lips on the twist drill should be symmetric if an equal cutting is to be done while drilling.

What is step 5-7?

Steps 5-7 are simultaneous steps to get you to that finish position but notice how the only hand that moves is the left hand. The right hand stays stationary, with only the fingers guiding the drill bit. Ask Question.

How to sharpen a drill bit?

Start with the first bit and look at the tip, this is the area in which you will sharpen. The shank is the long stem that is at the top and the portion with spiral grooves is the body that connects the bit to the drill. Unless something has attached itself to the shank, you should never have to use the grinder on that part of the bit.#N#Hold the bit so you can clearly see the tip and rotate it to view all of it. Change the angle so you can see the tip fully and note any dullness, flaws, or other imperfections. These are the areas that you will sharpen. Now you are ready to sharpen the bits.

Can you use a drill sharpener on a drill bit?

Drill sharpeners such as Drill Doctor are not only convenient but are also a safe way to sharpen drill bits. You can use a drill sharpener on a masonry bit or concrete drill bit, provided it has a diamond grinding wheel.

What is a bench grinder?

Bench Grinder. A bench grinder or a pedestal grinder is the standard machine tool for sharpening masonry bits. It has grinding wheels on both ends that rotate at high speeds and can sharpen most bits rather quickly. But you need the right type and grade grindstone.

What is a drill sharpener?

Drill Sharpener. While the bench grinder is a general-purpose tool, the drill grinder is a tool that is specifically designed for grinding drill bits. A drill sharpener usually has a diamond wheel and you can precisely set the cutting tip angle to grind.

What is the point angle of a masonry bit?

The point angle of a masonry bit tip is 135 degrees. This is the included angle of the tungsten carbide tip. It may vary according to the manufacturer and the material that you are drilling holes into. I have seen drill bits with angles ranging from 118° to 135°.

How to get a bit out of a grinder?

Turn on the grinder and ensure that it is running smoothly. Place the bit in your hand so the tip is exposed as this will contact the grinding wheel. Place your forefinger on the grinder tool stop, this will help you guide the bit while keeping your fingers far enough away to be safe.

How to keep a grinding wheel sharp?

Be sure to hold the tip of the bit close to the grinding wheel and get set before pushing it in. Gently press the bit into the wheel and do so in pulses. This means pressing in for a few seconds and then pulling away slightly for a few seconds. This will help keep the bit from overheating in your hand. The goal is to sharpen the bit while keeping the temperature down, so you can hold it.