A tank’s size is determined by:

- Dimensions of the system

- The output of the compressor

- Cycles of air demand

What is a good tank size of an air compressor?

There is a great discrepancy in the sizes between each type of air compressor. For air compressors that are supposed to have greater mobility or are portable, this can range from 1 to 6 gallons. If you are still looking for something a little lighter but require it for more heavy-duty jobs, there are also 20 – 30 gallon tanks available.

What size of air compressor do I Need?

Medium-duty 30 to 45 CFM compressors can efficiently run multiple tools and pieces of equipment. At the high end is a diesel powered 16,000 to 18,000 CFM compressor built onto a towable trailer. The airflow of the compressor will vary based on the PSI setting. CFM Requirements for Common Air Tools

How big is a compressed air tank?

The compressed air tank is much lighter than an air compressor with a similarly sized tank, and it's much bigger than the tanks on highly portable compressors, such as pancake compressors. Compressed air tanks come in different sizes, with capacities measured in gallons of compressed air. Common sizes include five, seven, nine, 10, and 11 gallons.

Can we use air compressor instead of refrigerant compressor?

Originally Answered: can we use air compressor instead of refrigerant compressor? you can’t use an air compressor as your refrigerant compressor due to following reasons, Air compressor has a breather pipe that communicated directly with the atmosphere but in refrigerant compressor, its crank case if filled up with refrigerant so it will leak out to the atmosphere entirely.

How do I know what size compressor tank I need?

An air receiver tank should be sized between 6–10 times the flow rate of the system. For example, compressors with a rating of 25 scfm at 100 psi should have a tank that is size at a minimum of 150 cubic feet.

How are air compressor tanks measured?

In addition to capacity, compressed air tanks have a maximum pressure rating measured in pounds-per-square-inch or psi. Common ratings range from 125 psi to over 150 psi. This rating indicates the maximum amount of air pressure the tank can safely handle.

Does tank size matter on air compressor?

The size of the compressor's tank will help to determine the amount of time that your air tools can run before the air compressor shuts off and has to be turned on again. If you only require intermittent use of air-powered tools, you won't need a compressor with a large tank size.

Why is a bigger tank better in an air compressor?

A larger tank holds more air and will allow you to use more air before the pressure drops and the motor kicks on to refill the tank. That might let you avoid stopping work while the compressor refills the tank.

What does the gallon size mean for air compressor?

GALLONS: This is a measure of tank size, which can be a factor when using tools that require a continuous flow of air, such as spray guns or sanders. The larger the tank, the longer a job can be done at the air tool's required pressure before work must pause in order to rebuild pressure in the tank.

Will adding a tank increase CFM?

Use an Auxiliary Storage Tank Another method to help produce more airflow through your air compressor expands upon the idea in our first method, reducing the pressure on your regulator. As we explained in the previous examples, reducing the outlet pressure allows you to produce more airflow for a longer period of time.

What size air compressor is needed for spray painting?

While some air spray guns have a rating of lower than 10 CFM, we'd recommend your compressor CFM for spray painting is at least 12 CFM. For professionals, this figure may need to be higher – the important thing is you've checked your spray gun's CFM requirements and chosen a compressor that exceeds that figure.

What is a good CFM for air compressor?

0 to 5 cubic feet per minuteAir tools made for general use with portable air compressors typically require 0 to 5 cubic feet per minute (cfm) at 70 to 90 pounds per square inch (psi), whereas with larger tools connected to stationary systems, the requirements usually exceed 10 cfm at 100 to 120 psi.

DOES CFM increase as PSI decreases?

The CFM rating is always given at a specific PSI and even if it's just a compress with a hose (effectively a small storage tank) you will get more CFM at a lower pressure than at a higher one.

What is a good size air compressor for home use?

For your home garage, a compressor size in the 2.6-gallon to 20-gallon range should do nicely.

How big of an air compressor do I need for a nail gun?

If a nailer will be used almost continuously throughout the day, look for a big tank and plenty of horsepower. A 6 gallon tank pancake-style compressor will be about the minimum, and you may be better off with a large twin stack or possibly even a wheelbarrow-style unit.

Is a 60 gallon air compressor big enough?

A 60-gallon compressor is powerful enough to power up even the most demanding power tools. In fact, it can power up multiple tools at once.

How much air is in a compressed air tank?

It means that 80 cubic-feet of air at sea-level air pressure are contained in the tank. Air pressure at sea level is approximately 14.7 psi. Now, follow this. If you compress 80 cubic-feet of air to 3,000 psi, that's compressing it 204.08 TIMES.

How many gallons does an air compressor hold?

Air compressor sizes range from 2 gallons to more than 80 gallons. The larger the tank, the greater the capacity of the pump, so it can fill up the tank and recover quickly when the air runs low.

What does scfm mean on an air compressor?

Standard Cubic Feet per MinuteStandard Cubic Feet per Minute (SCFM) is the rate of flow of a gas or air through a compressor at standard temperature and pressure conditions.

How many gallon air tank do I need?

A good rule of thumb for most applications is to have three to five gallons of air storage capacity per air compressor cfm output. So if your air compressor is rated for 100 cfm, you would want 300 to 500 gallons of compressed air storage.

How big is an air compressor tank?

There is a great discrepancy in the sizes between each type of air compressor. For air compressors that are supposed to have greater mobility or are portable, this can range from 1 to 6 gallons. If you are still looking for something a little lighter but require it for more heavy-duty jobs, there are also 20 – 30 gallon tanks available. If you are looking for ones that are stationary and cannot be handled easily, then there are tanks that are as large as 60 to 80 gallons.

What does it mean when an air compressor tank is bigger?

As you can imagine, the bigger the air compressor tank, the more compressed air that can be stored . What does this mean for the functioning of the air compressor, however? How long an air compressor can run for without turning on, is dependent on the size of the tank. The larger the tank, the less frequently the air compressor has to turn on. This means that the air compressor has more time to cool down between each time that it is used.

How to measure air compressor capacity?

First it is important to know how the capacity of an air compressor is measured. 1. Volume of Compressed Air Flow upon a particular given time. This means how much volume of compressed air can be generated by an air compressor when it has run for a particular amount of time. This unit is exactly measured as volume of air upon time. Eg: CFM (Cubic Feet per Minute) – Cubic Feet is a unit of volume and minutes is a unit of time. 1 cubic foot is = 28.317 Liters. Therefore 1 CFM = 28.31 (LPM) Liters Per Minute. Similarly Liters per Second (L/sec) or Cubic Meter per hour are units of flow of air.

How much compressed air is needed for 2 pneumatic machines?

Eg: There are 2 pneumatic machines / equipments of the same kind and each requires an air consumption of 20 CFM @ 6 Bar(g). Then your total Compressed air consumption will be 20 x 2 = 40 CFM @ 6 Bar(g). Note that the Pressure does not need to be multiplied with the number of pneumatic machines.

How many CFM does a 5HP compressor have?

A 5HP reciprocating piston compressor shows 15 CFM but below it says that this CFM is measured at 7 Bar. Therefore when this pressure is increased to 10 Bar the flow will not remain 15 CFM and will drop down. Therefore this 5HP machine will not be sufficient and a 7.5HP will have to be looked into.

How does altitude affect air compressor performance?

c. Because of the above the altitude of your factory / site affects the air compressor performance. At a higher altitude compared to sea level there is less atmospheric pressure which is why the compressors suction capacity will reduce therefore the same machine will give much less air. Eg. Places like Shimla, Mussorie etc. In these cases a much bigger machine is required to deliver less amount of air. Similarly temperature of air and humidity in air also affect the performance of the air compressor but their impact on compressor is less.

What does CFM mean on air compressors?

Please note that air compressors are rated and measured as CFM at a particular pressure. Most brands have an asterisk (# or *) at the bottom of the compressor technical specifications which states that the compressor CFM rating is measured at X pressure but the maximum pressure of the machine is Y. This is important because CFM (Flow of Air) and the pressure are inversely proportional which means when one goes up the other has to come down.

How much bigger should a machine be than the required air?

10. Consider a machine 10 to 15% bigger than the required air because in future you may want to add some equipment, your piping may have some leaks, your filters may get clogged etc. Having a little spare amount of air is always better.

Does compressed air remove moisture?

But moisture present in compressed air is harmful for the pneumatic cylinders as they could rust over time. Here you will need a refrigerated air dryer to remove the moisture down to +3 Deg C PDP(Pressure Dew Point) – {usually all dryer manufacturers are giving this rating} and a general purpose filter of around 5 or 1 micron rating to stop dust particles and liquid water entering the dryer. There will be people who will recommend a glass type moisture separator but this does not remove moisture in form of water vapour which is removed by the dryer.

How many gallons are in an air receiver tank?

Air receiver tanks are sized in terms of volume (measured in gallons). They are available in sizes ranging from 5-gallon capacities to several thousand gallon capacities. It is important to choose the size based on the needs of the application. Key considerations to keep in mind include:

Why Are Receiver Tanks Important in Compressed Air Systems?

First, they serve as reservoirs that supplement compressed air supply during peak demand. Second, they remove water that might be present in a compressor system by cooling the air. Third, they decrease the amount of pulsations experienced by the system.

What is an air receiver tank?

Air receiver tanks—also referred to as compressed air tanks—are engineered to temporarily store compressed air before it enters equipment or a piping system. They help connected compressed air systems operate efficiently during operations by acting as a buffer between the compressor and fluctuating buffer. Additionally, they can be used to supply additional air to the system to accommodate surges in demand and/or run the system even when the compressor is not running.

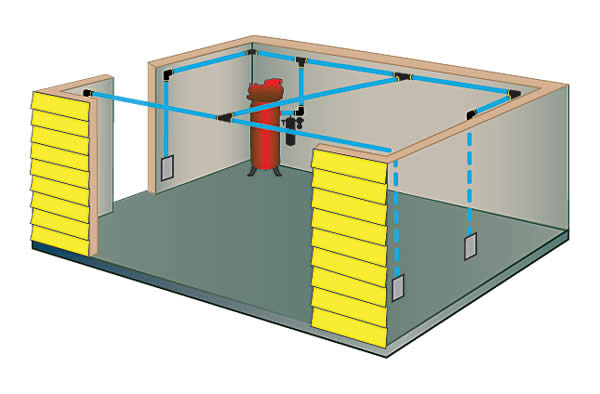

What are the two types of air receiver tanks?

Compressed air systems use two types of air receiver tanks: primary and secondary. Primary tanks are located close to the air compressor system and act as air storage devices. Secondary tanks are located further from the compressor system while still being accessible to any device that requires air.

What happens if a compressor is set to 100 PSIG?

If the consumption process requires 100 PSIG and the compressor is set to deliver 100 PSIG, there is no storage and no buffer. Any increase in demand will result in a tank pressure drop below 100 PSIG until the compressor responds by increasing the air volume compressed to refill the tank and restore the 100 PSIG.

How many gallons of air is in an air receiver tank?

Air receiver tanks are sized in gallons and range from small 5- and 10-gallon tanks to massive tanks that hold thousands of gallons of air. The ideal size of an air receiver tank will depend on the type of air compressor and the application.

Why use an air receiver tank?

However, smart operators may choose to use an air receiver tank to give their compressor a little boost for higher CFM tools. For example, if an operator routinely uses a 1” impact wrench that requires 40 CFM but only has a 30 CFM air compressor, he may choose to add a 12-gallon air receiver tank to compensate for the difference. By the time the air receiver tank is empty, the task will be complete. Operators can sometimes save money or “make do” with a smaller system using this savvy strategy.

How much air does a torque wrench consume?

Initially, the tool will consume the full rated 20 CFM as it tightens the nut against almost no resistance, but as the torque rises on the nut, the tool consumes less air until the final torque is achieved. The tool also won’t consume air when it isn’t used in between nuts.

What is the formula for maximum air consumption?

In the t = V (p1 – p2) / C pa formula, maximum air consumption is measured in SCFM and represented by “C.”

Can you use an air receiver tank with a reciprocating air compressor?

Properly sizing the air receiver tank that’s used with a reciprocating air compressor can help reduce interruptions and time wasted waiting for the tank to refill. A simple and straightforward rule ...

Is air consumption uniform throughout the process of torquing the nut?

The tool’s air consumption under load is not uniform throughout the process of torquing the nut, and the interval between applying the tool between individual nuts varies. This difference in CFM load and time interval becomes the utilization factor.

How Many PSI Do I Need?

PSI or pounds per square inch is the metric that measures force or pressure. If an air compressor is rated at 150 PSI, it simply means that it’s able to produce up to 150 pounds per square inch of pressure. It doesn’t mean that it provides this amount to your tools at all times, but only that it can if you need it to.

How Many CFM Do I Need?

CFM stands for cubic feet per minute. While PSI measures the force or pressure of the air being supplied, CFM measures its volume. Like PSI, if a given air compressors CFM rating doesn’t match or exceed the CFM requirements of your air tools, it’s not going to work.

Other Considerations You Should Make

Aside from PSI and CFM, there are a few other considerations you should make. The first is tank size.

Air Tool Consumption Chart

If you’re anything like me, you don’t feel like looking through the owner’s manual of all your air tools looking for CFM requirements. I get it. That’s why I put together this handy chart.

What is a Good CFM for an Air Compressor?

An air compressor’s “good CFM” entirely depends on the tool you will be using, taking assistance from the air compressor.

Air Compressor Tank Size vs. CFM – What is the Calculation

Before finalizing an air compressor model, you need to learn how to calculate air compressor tank size and CFM rating. Thus, making a decision will be much easier.

What Factors Play a Vital Role When Sizing an Air Compressor?

3 factors are crucial when sizing an air compressor – size, power, and discharge pressure. Let’s look at a more in-depth discussion from below.

Is it Possible to Increase CFM Rating on an Air Compressor?

After using an air compressor for many days, you may need to increase the CFM rating of your air compressor. So, you might be thinking, is it really possible?

Final Words

Pneumatic tools are dependent on an air compressor for efficient performance. And the performance of air compressors incredibly relies on the CFM rating and tank size.

How much pressure can a compressed air tank hold?from mcmaster.com

Able to withstand pressures up to 600 psi, these tanks store compressed air for use in high-pressure applications.

What is the air pressure rating of an air compressor?from compressorworld.com

Tanks are either horizontal or vertical in alignment, and offer pressure ratings of 137 PSI, 150 PSI, 165 PSI, and 200 PSI.

When do sprinkler compressors turn on?from mcmaster.com

These compressors turn on when the tank falls to the activation pressure and they turn off when the tank reaches the maximum pressure.

Can you have enough storage for an air compressor?from compressorworld.com

However, there can never be enough storage for an air system. Installation - While there are many theories surrounding installation of air tanks, Compressor World experts recommend going by the textbook which states that air tanks should be installed after the compressor so as to reduce energy consumption, and help with the controls.

What Are Air Compressor Fittings?

Air compressor fittings are accessories that keep the compressor’s pressure and air flowing smoothly. Every fitting serves a distinct purpose; however, they are all necessary for maintaining the condition and functionality of your system.

What Are the Different Sizes of Air Compressor Fittings?

Metric fittings resemble NPT fittings in appearance, and a 1/4′′ NPT fitting has a similar diameter to a 1/4′′ Metric fitting; however, they are not interchangeable. The thread tip-to-tip distance differs significantly between metric and imperial fittings. As a result, metric thread diameters are incompatible with NPT equivalents of the same size.

What Are the Different Types of Air Compressor Fittings?

Couplers and compressed air plugs are two types of air compressor fittings that are required for connecting pneumatic tools to an air hose. We mentioned these above but let’s look at them in further detail.

Consider Pressure Ratings

Pressure ratings are commonly included with air fittings to help prevent leaks and pressure decreases. Couplings and clamps can be subjected to pressures that exceed their ratings if the system is not thoroughly assessed. If there are unusual pressure spikes inside the unit, this might go undetected.

The Bottom Line

It’s just as vital to pick the correct fittings as it is to choose the right air compressor. This simple guide to steel and brass pressure or air compressor fittings should help you start your journey; however, if you need more help, our team is here to assist you.