Copper Foil Stained Glass Technique

- Step 1: Pre-Assemble the Pattern ...

- Step 2: Wash the Glass Pieces ...

- Step 3: Apply the Foil to the Glass and Burnish It ...

- Step 4: Assemble the Glass Pieces ...

- Step 5: Solder the Copper Foiled Stained Glass ...

- Step 6: Clean, Apply Patina, and Polish Foiled Stained Glass ...

How to clean copper pipe before soldering?

Most Effective Ways to Clean a Copper Pipe

- Homemade Vinegar and Salt Copper Cleaner. With all the ways to use vinegar, it’s not surprising that you can make your own copper cleaner with this hefty ingredient.

- Soaking Copper Tubes in Vinegar. ...

- Homemade Copper Scrubber. ...

- Cleaning Copper Pipes with Calcium, Lime, and Rust Remover. ...

- Adding Extra Shine to Your Copper Pipes. ...

Is soldering copper pipe difficult?

Soldering copper water supply lines is not a difficult skill. Even a rookie can learn to solder leak-proof joints in 30 minutes. The process is simple—if you follow a few basic guidelines. In this story we'll show you how to solder copper quickly and easily.

How do you solder steel and copper?

- Look for a flux that is specifically designed for stainless steel use. This is usually printed on the product label.

- Use gloves and eye protection when handling acids.

- Other rosin-based fluxes are not effective for soldering stainless steel. Use a stronger, acid-based flux.

- If you’re soldering 2 pieces of stainless steel, wipe them both with the flux. ...

How to solder copper pipes properly?

To prep the solder, follow these steps:

- Unwind the solder.

- Snip off as much as you need.

- Bend the amount of solder you want to use to a 90-degree angle.

What is the best solder for copper foil stained glass?

60/40 solder60/40 solder (paid link) is better for soldering copper foil as it runs well, so it could be that you're using 50/50 which makes a smooth line a little more tricky – although certainly not impossible.

What size copper foil should I use for stained glass?

3/16” – 1/4” foil works well for most standard copper foil stained glass pieces. If you have a wider overlap you may find that the width of the solder is too wide when you start assembling the piece together.

How do you solder stained glass foil?

9:5418:08Soldering Your First Stained Glass Project - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou can drag your iron all along it like this and it deposits solder on there. So if you find thatMoreYou can drag your iron all along it like this and it deposits solder on there. So if you find that your foil is being resistant. And it's not accepting the solder just add some more flux.

How do you solder stained glass for beginners?

0:583:45How to Solder Stained Glass Panels - Part 1 - YouTubeYouTubeStart of suggested clipEnd of suggested clipOff so it'll be upright. Also you want to be across the solder line so you don't want to be right onMoreOff so it'll be upright. Also you want to be across the solder line so you don't want to be right on the edge of it you want to be across it and try to stay 90 degrees to your solder. Line.

What solder is best for stained glass?

There are 3 basic types of solder used in stained glass. 50/50: 50% Tin/50% Lead - This is most commonly used in box and lamp assembly. 60/40: 60% Tin/40% Lead - This is most commonly used in lead and copper foil assembly. 63/37: 63% Tin/40% Lead - This is most commonly used for decorative soldering.

What is the average thickness of stained glass?

A leaded stained glass window or other object is made of pieces of glass, held together by lead. The pieces of glass are about 1/8-inch (3.2 mm) thick and bound together by strips, called "cames" of grooved lead, soldered at the joints.

Do you need flux to solder stained glass?

2. Solder will not stick to glass alone, so each piece of glass must be wrapped in copper foil. 3. Solder needs a flux to flow smoothly and bond to other metals (i.e., copper foil or lead came).

How do you get smooth solder on stained glass?

4:536:56Making Smooth Solder Seams and Touch-Up Soldering - YouTubeYouTubeStart of suggested clipEnd of suggested clipI'm going to sink my iron into the surface. I hold it there until it gives way. And I just dab it.MoreI'm going to sink my iron into the surface. I hold it there until it gives way. And I just dab it.

What do you need for soldering stained glass?

Things You'll NeedPieces of stained glass.Glass cutter.Scissors.Copper foil.Liquid flux.Coil of non-lead solder.Soldering iron.Metal Soldering Iron stand.

What flux should I use for stained glass?

The best flux for stained glass is a gel flux that has a thick enough liquid to wet and shine the solder seams when you hand-solder copper sheet metal or copper foil between the stained glass pieces. You also want to choose a flux that won't stain the copper before you have a chance to wipe it clean when soldering.

Why is my solder not smooth?

The connection was not hot enough. Hold the tip of the solder gun on longer. If you have concerns about heating up the wire too much, put a clip on it, or even just hold it with a pair of needle nose plyers to disipate the heat off of the wire. And do not blow on the molten solder to make it cool faster.

Do I need a mask when soldering?

Once you breath glass dust in, like asbestos, it's there forever. Protect your lungs – wear a dust mask. A soldering iron hot enough to melt lead is more then hot enough to burn through flesh. Always be careful when handling a hot iron.

Does stained glass need copper foil?

10:5712:23How to Connect Stained Glass using Copper Foil - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd then you want to use your flux and just lightly brush the copper foil. With it and that's goingMoreAnd then you want to use your flux and just lightly brush the copper foil. With it and that's going to allow the solder to stick to the copper foil better.

What is copper foil used for in stained glass?

Applying Copper Foil: Copper foiling is the process by which the fine edge of piece of glass is wrapped with a continuous strip of copper foil. Because solder will not stick to glass, foiling each piece establishes a surface on which the solder will adhere.

How do you foil textured glass?

2:238:16Copper Foiling Glass Pieces for Stained Glass - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo I hold it in front of me like this I pull a little bit of backing away so I've got this exposed.MoreSo I hold it in front of me like this I pull a little bit of backing away so I've got this exposed. And then I just tug this a little toward me and then.

How do you clean copper foil?

mix a quarter cup of white vinegar and a quarter teaspoon of table salt until the salt dissolves. dip the pieces of foiled glass into the mixture and swirl it around for about 30 seconds. rinse the pieces with water and dry them. that's it!

How to stop soldering on glass?from everythingstainedglass.com

Stop soldering by either moving the iron tip sideways on to the glass quickly (don’t stay on the glass with the tip) or lift vertically off the seam. When you reach a join, don’t stop! Follow the solder through in all directions about 1/2″, keeping each ‘tail’ hot. Return to each ‘tail’ and pick up the seam from there.

How many watts to solder stained glass?from everythingstainedglass.com

Use a stained glass soldering iron that is at LEAST 80 Watts (I use a Hakko FX-601* ) and tack your panel together with soldering to hold it in place.

How to move soldering iron and soldering iron?from everythingstainedglass.com

With the hot soldering iron in one hand and the solder in the other, move them both slowly along the seam together

What is used to wrap around the edges of stained glass?from happyglassartsupply.com

Stained glass copper foil is used to wrap around the edges of glass and solder using an acid flux and solder for stained glass.

How does a foiling machine work?from craftandleisure.com

The machine will simultaneously pull the backing off of the foil, center the glass onto the foil, and fold the sides down the edges as you slide the glass edges along the roller.

How to foil glass?from craftandleisure.com

Apply foil to each piece by pressing the edge of the glass onto the roller and roll all sides of the glass until all sides have been foiled.

What knife to cut copper foil?from happyglassartsupply.com

Copper foil sheet can be cut with Xacto knife for filigree looking overlays.

How to make a glass holder with copper foil?

Start by peeling back a section of the paper to expose the adhesive on the copper foil. Hold the foil strip in your dominant hand and the glass piece in the other. Now you can start by attaching the copper foil making sure the glass is centered onto the foil.

When to foil stained glass?

The process of foiling stained glass usually begins after you have made all of your cuts. If you are wondering, making all of your cuts first before foiling or one at a time is certainly a preference but in the end, I think it ultimately saves time and allows you to work through your project in steps. Working through the steps will minimize any errors and having to go back to correct mistakes.

How to burnish glass with foil?

After you have wrapped the entire perimeter of the piece, press the foil down firmly onto the glass edges using the fid tool. Next fold the foil down the sides of the glass taking care on curves as they can cause the foil to split. Repeat the burnishing process on the sides.

What is the difference between copper foil and lead came?

The major difference between the two methods is found in the assembly. The copper foil technique is perfect for beginners as it is easier to get started with and will work with most stained glass projects. Lead came requires fitting the glass pieces into lead channels called cames, which is then soldered at the joints and cemented.

Why is it important to cut glass pieces?

It is important to note that the glass pieces must be cut accurately so they fit together very tightly to ensure a strong solder joint. Let’s get to the technique.

How to clean glassware?

To wash the pieces, fill a small basin with water with a couple tablespoons of ammonia then dip the pieces in the solution. After a quick dunk, dry them thoroughly with a clean lint-free towel. Be sure to clean all edges and surfaces of each piece. Be sure to dry the glass completely before moving on.

How to clean glass pieces after cutting?

After you have pre-assembled the pieces to check for fit, you may want to wash the individual glass pieces of your design after they have been cut as well as any irregularities have been ground smooth. You can always skip this step if you feel the pieces aren’t dirty with dust and oil. Another tip is to just wipe the edges with a cloth and rubbing alcohol.

What is the best way to crimp glass?

Use a cork for crimping textured glass as it is softer and provides pressure while reducing tearing.

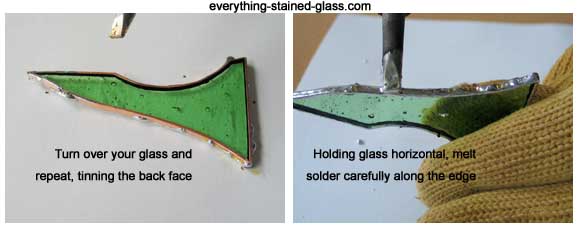

What does tining a stained glass edge mean?

If you tin the edges rather than creating a beaded edge. “Tinning” means covering them with a thin coating of solder. “Beading” is a rounded edge of solder that ‘clings’ to the edge of the stained glass and is much stronger. I have a video on how to do a beaded edge on this page.

What happens if you solder too slowly?

If you solder too slowly or go over the solder repeatedly the foil glue melts and becomes unstuck. It’s worth remembering that the glue is there to hold the foil in place until it’s soldered. It doesn’t serve to keep it on once it’s been heated.

Can you use rippled glass grinder bit?

Better still, you can use a rippled glass grinder bit like the one below to remove the heavy texture on the glass before foiling. This really helps with foil adhesion. Before you buy a rippled bit make sure it will fit your grinder.

Does copper foil deteriorate?

Stained glass copper foil can start to deteriorate if left out in the elements. You can lengthen the life of your foil by:

Can you use copper foil on stained glass?

When you copper foil stained glass by hand it can be hard to centre the foil. A simple trick was sent by one of my students to help with this. Use lined paper as a guide!

Can you cut foil off of shiny glass?

Hopefully that will prove to you that foil sticks to shiny glass. Your shiny cut edges are fine without grinding. Just be careful of your fingers. You can just deaden the sharp edges off with a wet scythe stone to avoid cutting yourself and to prevent sharp edges cutting the foil.

How to solder glass?from wikihow.com

Position your glass pieces for soldering. Assemble your glass pieces into their final design position. Leave a very thin gap (about 1⁄16 inch (1.6 mm)) between the pieces so the solder will be able to flow into the seam. You can assemble the glass on any hard, heat-resistant surface, but metal work tables are best.

How to make a metal hanger with copper foil?from wikihow.com

Use a piece of wire and form a loop or circle (depending on the look desired). Attach copper foil to the hanger. Apply solder to the foil, as the metal part of the hanger will absorb a lot of heat. Attempting to solder straight to the piece after adding foil will not form a strong joint.

How to prevent solder from melting?from wikihow.com

If the foil you're using is too wide, then the iron will need to provide more heat to get the foil to the solder melting temperature. Contamination on the foil will also prevent the solder from melting. Scrub the foil with a nail file and wipe it down with alcohol before trying again.

How to move soldering iron and soldering iron?from everythingstainedglass.com

With the hot soldering iron in one hand and the solder in the other, move them both slowly along the seam together

How to get copper foil to stick together?from wikihow.com

Brush a coat of liquid flux onto the copper foil. The flux helps the metal in the solder and the foil to stick together permanently. Brush one coat of liquid flux onto all of the copper foil. It doesn't have to be applied perfectly, so long as all the foil is covered.

How to remove adhesive foil from paper?from wikihow.com

Remove the backing from the strip of adhesive foil. After you cut the foil pieces, you can gently peel the backing off. You should be able to easily strip away the paper backing from the foil , revealing the adhesive side.

How to solder copper foil?from wikihow.com

Turn on your soldering iron and set up your materials. Set out your copper foil, liquid flux, and coil of solder. Plug in your soldering iron, set it on its stand , and allow it to heat up. It's important to have everything set up before you begin the soldering process, because precise timing is very important in this project.

What do you want to do before soldering glass?

What you'll want to do it push all of the glass pieces together before soldering. They should be touching all along each side as best as possible. This is where getting a good fit while grinding is very important. 4.

How does soldering work?

The reality is that using more solder: 1 will make your work heavier than necessary, 2 will cost you more money (solder isn't exactly cheap) 3 won't make your project stronger, only reinforcing it will

Why do stained glass windows have dark lines?

When we look at stained glass windows, they're normally back lit. The glass lets light through while the solder doesn't ( obviously!) So this creates dark lines in our designs. Well, that big hole you want to fill with solder will be visible because it's going to be a large dark space among all of your beautiful solder lines!

How to tell if a foiled project is right?

1. There are Uneven Spaces Across the Whole Project. Often, hobbyists will notice that foiled projects fit differently than they did before they were foiled, and they're right. It will always fit slightly differently as the foil takes up a hair width of space.

Why does glass fit differently after foiling?

For the average glass crafter, the problem with glass fitting differently after foiling isn't usually due to the copper foil. It normally stems from not realizing that things weren't quite lined up when they were grinding the glass.

How to prevent uneven glass?

There are a couple of things you can do to try and avoid the problem of uneven spaces between your glass pieces. Use push pins or jigs to hold your glass in place while testing the fit. This will prevent other pieces from slipping out of place without you noticing.

Can glass be flipped upside down?

Sometimes a piece of glass may have been accidentally flipped over or upside down. A square for example, may not be perfectly square and if turned 90 degrees, could fit very differently. Avoid this by labelling your pieces clearly so you always have them in the correct orientation.

What is used to wrap around the edges of stained glass?

Stained glass copper foil is used to wrap around the edges of glass and solder using an acid flux and solder for stained glass.

How to store copper foil?

To store your copper foil to keep it from tarnishing or having the glue go bad simply put it in a good zip lock type of bag.

What is black foil?

Black backed foil is used when we have clear or see through glass and are going to black patina our metals. The black backing does reflect into the glass and then looks like it belongs with the works very nicely.

What color glass do you use for roses?

While making a rose using a red / white wispy semi-translucent glass many years ago I decided to use black backed foil on a few of the flower petals. What happened was neat, the black resonated a burnt red color in the petal and so it looked as though I used different glass in a few petals and it was pretty. I began adding a black back to orange and yellow hued glass too and the same wonderful effect showed through. Over the years I have made many and that has been very unique and enjoyable.

Who came up with the copper foil technique?

Louis Comfort Tiffany was the one that came up with the copper foil technique. What he was trying to do is create the look of lead came without using lead came. The lead came had a top, a bottom and a heart. The heart was integral due to that is what holds the art together. The top and bottom can be flat or rounded depending on the look the artist wanted to have. With the copper foil technique Tiffany began doing overlays of glass on glass to achieve wonderful looks plus he used filigrees that were added and quite astonishing.

Can you use foil and foil on the same project?

With this in mind now you can imagine using wider foil and narrower foil within the same project in order to have a wider and narrower solder line. I have used this technique often and it does make a huge difference in the visual effect on a project.

Can you cut copper foil sheets?

Copper foil sheet can be cut out with scrap booking scissors then applied to our art edge.

How to solder glass with copper foil?

Place the tip of the unrolled solder above the copper foil. It might be tempting to lie the solder down on the seams between two pieces of glass and use the iron directly on them, but don't do it. Keep the solder at least 1⁄2 inch (13 mm) above the foil.The best results are achieved by letting the melted solder drop into the seam between the pieces of glass.

How to solder glass?

Position your glass pieces for soldering. Assemble your glass pieces into their final design position. Leave a very thin gap (about 1⁄16 inch (1.6 mm)) between the pieces so the solder will be able to flow into the seam. You can assemble the glass on any hard, heat-resistant surface, but metal work tables are best.

How to solder glass with a soldering iron?

Move both hands along the seam. Keep your hands in the same position--one holding the solder, the other holding the soldering iron up to it. Move your hands along the seams of the glass while the solder drips down onto it.

How to wrap copper foil around glass?

Place the adhesive side of the copper foil on the edge of the glass. Try to position the edge of the glass directly on the center of the copper foil. Then, press the foil down gently around the edges of the glass. Be careful when wrapping the foil around sharp edges!

How to make sure solder is firmly on glass?

Use a roller to make sure the foil is firmly on the glass. Use a roller or a pencil to roll out any creases, wrinkles, or bubbles in the foil. This is very important because the solder may not bond with wrinkled foil. ...

How to tack glass?

Many people prefer to "tack" the corners of each piece together before working on the seams. To tack glass, simply put a dot of solder on each connecting corner.

How to stabilize glass?

Adding a "wire frame" around critical areas can stabilize the glass. Be sure to position and solder the wire in the middle of the foil. Use a wooden shim at the level of the wire for keeping a constant height when soldering the wire. This should keep the piece level. Thanks!