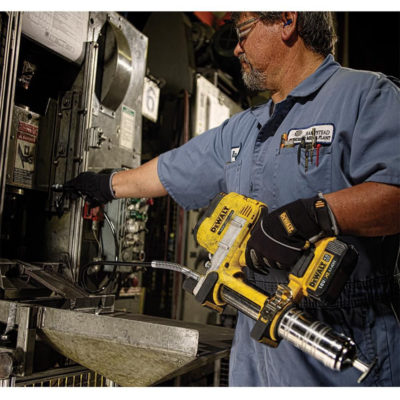

How to store a grease gun correctly

- Keep it in a horizontal position Storing your grease gun horizontally will help you prevent time damage which can happen easily if you store it vertically. Plus, if you place your gun in a horizontal position, it will not leak or get unwanted contaminants inside of it either. ...

- Hang the grease gun ...

- Store your grease gun in proper conditions ...

- Organize your lubricants and other accessories ...

Full Answer

How to keep grease gun clean?

Why should grease guns be labeled?

How to calibrate a grease gun?

How long does lithium grease last?

Why is it important to store grease guns?

How often should grease guns be calibrated?

What are the two factors that affect the life of lubricant?

See 2 more

How do you store a grease gun when not in use?

The best practice to maintain a clean grease gun is to hang it horizontally inside a clean, fireproof cabinet with the plunger disengaged from the tube. Grease guns should be stored horizontally to avoid two potential problems.

Should a grease gun be stored upside down?

New grease cartridges or tubes should be stored upright (vertically) with the plastic cap up at all times. This will help to prevent oil from leaking out of the tube. If the cartridge is left in a grease gun, the gun should be depressurized and stored in a horizontal position inside a clean, cool and dry area.

Can I leave grease in grease gun?

It is acceptable to leave unused grease in a grease gun. It is recommended to release the pressure from the grease by drawing the handle back and locking the spring in the retracted/compressed position.

Should you clean a grease gun?

Clean the plunger and exterior of the grease gun before refilling. This is especially important if you purchase your lubricant in kegs. If your grease gun or plunger is dirty when you refill from the keg, you run the risk of adding contaminants to your lubricant.

Should guns be stored vertically or horizontally?

Store guns horizontally, or with the muzzle pointing down. When guns are stored upright, gravity pulls gun oil downward into the action, which forms a sticky film. Oil also can drain onto the stock, softening the wood. Displaying guns in glass cabinets or wall racks is an invitation to thieves and curious children.

How often should I oil my stored guns?

twice a yearStored Guns: – Even with proper storage, moisture and dust can find their way to your firearms and lead to rust formation. – Clean and lubricate your stored firearms twice a year.

What do I do with my grease after cooking?

Throw it in the trash The overarching rule of thumb when it comes to grease and oil disposal is don't pour it down a drain. Toilets, sinks, and floor drains are all off-limits as gluey oils and animal fats will destroy your plumbing. Instead, turn to your garbage can.

How long can grease be left out?

What is this? If you store the fat at room temperature or below, it should retain its quality for about 6 months. If it sits in the fridge, it should easily last a year. Of course, the fat will probably stay perfectly fine for much longer, as these are super-safe estimates.

Is Vaseline a good gun grease?

Vaseline Gun grease lubricates and protects all metal parts as well as locks and mechanisms. Perfect to be applied with any kind of airgun and for the lubrication of compression pistons. Please use a lint-free piece of cloth or cotton bud - depending on the application.

Are you supposed to push in the plunger on grease gun?

Push the plunger-rod handle all the way into the grease gun. Now you can tighten the grease-gun body completely. Waiting until now to tighten it all the way helps remove entrapped air that can impede the gun's ability to pump grease. With a rag handy, pump the handle to prime the grease gun until grease begins to flow.

What happens if you don't oil your gun?

Failing to lubricate your gun means it will have a harder time operating properly, and metal parts can stress and even fail. Even if the gun isn't used, moisture from sweat and the storage environment can corrode the metal parts and form rust. These issues will impact your gun's reliability, accuracy and longevity.

How do I know if my grease gun is empty?

0:181:05How to Check the Level in a Grease Gun - YouTubeYouTubeStart of suggested clipEnd of suggested clipSimply pull the plunger out until it stops. The amount of grease on the raw which is exposed willMoreSimply pull the plunger out until it stops. The amount of grease on the raw which is exposed will show you how much grease is left in the cartridge.

What are the five rules for good grease lubrication?

Lubrication Rules to Help Your Equipment Run at its BestRight People.Right Time.Right Place.Right Quantity.Right Product.Right Method.The Right Track.

Are you supposed to push in the plunger on grease gun?

Push the plunger-rod handle all the way into the grease gun. Now you can tighten the grease-gun body completely. Waiting until now to tighten it all the way helps remove entrapped air that can impede the gun's ability to pump grease. With a rag handy, pump the handle to prime the grease gun until grease begins to flow.

Which way do you put a grease tube in?

0:062:15How to Properly Load a Grease Gun - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd sometimes you'll have grease on to the cap. And you want to make sure you get that into theMoreAnd sometimes you'll have grease on to the cap. And you want to make sure you get that into the barrel. Next you want to screw the barrel back onto the head of the grease gun.

Why do grease guns fail?

Grease guns can produce up to 15,000 psi, and when you overgrease a bearing housing, the lip seals can rupture, allowing contaminants such as water and dirt to gain access into the bearing housing. Keep in mind that lip seals usually fail around 500 psi. Read Lip Seals - A Practical Guide for more about this topic.

How to keep grease gun clean?

The best practice to maintain a clean grease gun is to hang it horizontally inside a clean, fireproof cabinet with the plunger disengaged from the tube. Grease guns should be stored horizontally to avoid two potential problems.

Why should grease guns be labeled?

Regardless of the model you purchase, each grease gun should be labeled to indicate the lubricant to which it is dedicated. If possible, it also is recommended that the grease gun’s barrel be clear.

How to calibrate a grease gun?

The best way to calibrate a grease gun is to slowly pump 10 strokes of grease onto a postal scale and then divide the total volume by 10. This will yield the average volume per pump of the grease gun. Each grease gun should also be dedicated to a single grease. This will significantly reduce the amount of cross-contamination.

How long does lithium grease last?

The expiration date will vary depending on the thickener. For example, lithium grease is often identified as having a 12-month shelf life, while calcium-complex greases may have a shelf life of just six months - and this is under good storage conditions.

Why is it important to store grease guns?

Properly storing your grease and grease guns is vital to achieving longevity from your lubricant. It is also essential to keep all your lubricants clean, cool and dry , with cleanliness often the most difficult to accomplish.

How often should grease guns be calibrated?

Grease guns should be calibrated before being placed into service and every 12 months after being put into service. There are many grease gun options on the market.

What are the two factors that affect the life of lubricant?

Two of the top oxidation accelerators are water and heat. By controlling these two factors, you can significantly extend the life of your lubricants. Just like my moving boxes, all greases are not created equal. It is important to mark the date when your greases were received and when they will expire.

Step 2: Layout

I marked the center of one end of the pipe. I drew layout lines for where the handle of the grease gun is going fit. I also drilled holes to start the bottom of the handle slots.

Step 3: Slots

Using a hacksaw, I cut slots in the pipe for the handle of the grease gun. I also filed the bottom of the slots square with a file.

Step 4: Mounting

I drilled holes in the pipe for mounting. On the opposite side of the pipe from the mounting holes, I drilled a larger hole so that a srewdriver and screw could pass through to access the mounting holes. I stood the pipe off from the mounting location using nuts. This was so that the end caps could be removed.

Step 6: Nozzle Storage

I drilled an angled hole near the bottom of the pipe as a place to store the nozzle. You can also see the bottom cap installed. Note that I did not use glue to attach the bottom cap. This is so that it can be removed to clean out any drippings.

Step 7: Caps

This picture shows the handle of the grease gun and the top cap installed as a dust cover. I hope you liked my first instructable. My Blog... http://www.shopngarage.com

Why does grease flow through a thickener?

When fresh grease is applied, the grease’s base oils are separated and flow through the built-up thickener due to hydrostatic extrusion, leaving the thickener system behind .

What affects the bleed rate of grease?

A grease’s oil bleed rate can be affected by a number of factors, including its composition, the type of manufacturing process used to produce the grease and distribute the thickener system within the base oil, and how the grease is stored once it reaches the customer.

Why does grease slip out of its original consistency?

Depending on the storage conditions, some greases can undergo age hardening, which results in the product becoming firmer and increasing in consistency or even softening. These changes in consistency can cause the grease to slip out of its original consistency grade. This behavior can be further aggravated by prolonged storage conditions. Because of this aspect, extended storage periods should be avoided.

What is grease made of?

This thickener system can be made up of either simple or complex metal soaps of lithium, calcium, aluminum, barium or sodium, or non-soap such as clay (bentone) or polyurea.

What is dynamic bleed?

Dynamic bleed is the actual controlled release of the base oils and additives during use due to temperature or mechanical stresses. It is important for the grease being used ...

What is a thickener system?

The thickener system can be thought of as a sponge that contains a matrix of fibers or platelets with a high surface area forming a dense network of micro-asperities (voids) or fibers. It is in these voids or fiber structure where the base oil and additives are stored until they are needed for lubrication.

When a machine is shut off or when the conditions of mechanical or thermal stress are relaxed, the grease must answer?

When a machine is shut off or when the conditions of mechanical or thermal stress are relaxed, the grease must have the ability to recapture its base oils to return to its original consistency. A grease’s reversibility characteristics are dictated by the type and amount of thickener used.

How to keep grease gun clean?

The best practice to maintain a clean grease gun is to hang it horizontally inside a clean, fireproof cabinet with the plunger disengaged from the tube. Grease guns should be stored horizontally to avoid two potential problems.

Why should grease guns be labeled?

Regardless of the model you purchase, each grease gun should be labeled to indicate the lubricant to which it is dedicated. If possible, it also is recommended that the grease gun’s barrel be clear.

How to calibrate a grease gun?

The best way to calibrate a grease gun is to slowly pump 10 strokes of grease onto a postal scale and then divide the total volume by 10. This will yield the average volume per pump of the grease gun. Each grease gun should also be dedicated to a single grease. This will significantly reduce the amount of cross-contamination.

How long does lithium grease last?

The expiration date will vary depending on the thickener. For example, lithium grease is often identified as having a 12-month shelf life, while calcium-complex greases may have a shelf life of just six months - and this is under good storage conditions.

Why is it important to store grease guns?

Properly storing your grease and grease guns is vital to achieving longevity from your lubricant. It is also essential to keep all your lubricants clean, cool and dry , with cleanliness often the most difficult to accomplish.

How often should grease guns be calibrated?

Grease guns should be calibrated before being placed into service and every 12 months after being put into service. There are many grease gun options on the market.

What are the two factors that affect the life of lubricant?

Two of the top oxidation accelerators are water and heat. By controlling these two factors, you can significantly extend the life of your lubricants. Just like my moving boxes, all greases are not created equal. It is important to mark the date when your greases were received and when they will expire.