Use your red lead to find 208 volts if you have a 3-phase circuit. Lift up your black lead from the ground connector and touch it to another hot wire connector so both of your leads are touching 2 separate connectors. When both leads are connected, your multimeter should give you a reading of 208 volts if it’s a 3-phase.

How do you test a 3 phase motor with a multimeter?

Next, examine the inside of the motor and the wires involved in the three-phase current. Set and calibrate your multimeter for voltage and find the six wires of the three-phase motor. When looking at the box, you should see six wires, three on each side.

How do you test for 208 volts on a 3 phase circuit?

Use your red lead to find 208 volts if you have a 3-phase circuit. Lift up your black lead from the ground connector and touch it to another hot wire connector so both of your leads are touching 2 separate connectors. When both leads are connected, your multimeter should give you a reading of 208 volts if it’s a 3-phase. 5

How to test 3 phase motor windings?

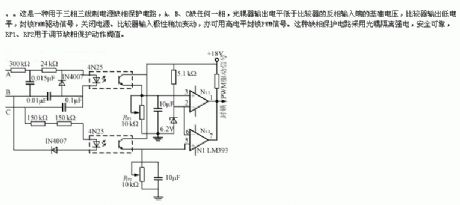

Often it is required to test the winding of the 3 phase windings with the aid of a multimeter or ohmmeter to determine whether the motor is still good or burnt or shorted. To determine whether a 3 phase motor is still good or has gone bad, a simple ohmmeter test across the windings of the motor will reveal its true state of health.

How do you wire a 3 phase a motor?

A three-phase motor must be wired based on the diagram on the faceplate. The first step is to figure out the voltage of your phases. In the United States, for low voltage motors (below 600v), you can expect either 230v or 460v.

How do you test a 3 phase cable?

0:305:253 PHASE INSULATION RESISTANCE TESTING SEQUENCE - YouTubeYouTubeStart of suggested clipEnd of suggested clipFor a three-phase circuit with a nominal voltage up to 500 volts ac. We would normally test at 500MoreFor a three-phase circuit with a nominal voltage up to 500 volts ac. We would normally test at 500 volts dc between the conductors. Under test the actual tests.

How do you know if a 3 phase is loaded?

3-Phase Calculations For 3-phase systems, we use the following equation: kW = (V × I × PF × 1.732) ÷ 1,000. Again, assuming unity PF and solving this equation for “I,” you get: I = 1,000kW ÷ 1.732V.

How do you test a 3 phase coil?

Check the motor winding resistance or ohms reading using a multimeter or ohmmeter for phase to phase terminal ( U to V,V to W ,W to U ). The ohms reading for each winding must be the same (or nearly the same). Remember that the three phases have identical windings or nearly so!

How do you check continuity in a 3 phase circuit?

1:124:11QR code 4 -- Three phase R1 and R2 test - YouTubeYouTubeStart of suggested clipEnd of suggested clipWhen we connect the leads together we need to make sure that we've got the solid part of theMoreWhen we connect the leads together we need to make sure that we've got the solid part of the crocodile. Lead touching the solid part of the other crocodile clip.

How do I test 3 phase power with a multimeter?

0:041:06Verifying Three Phase Voltage - A GalcoTV Tech Tip - YouTubeYouTubeStart of suggested clipEnd of suggested clipEach phase has to be checked. You can measure the first leg with the second one the first leg withMoreEach phase has to be checked. You can measure the first leg with the second one the first leg with the third one and then the second leg with the third one. Each reading should be the same if.

What is the voltage on each leg of 3 phase?

A 400 volt three-phase circuit means that each of the 3 lines is carrying 230 volts.

How do you test a phase sequence with a multimeter?

2:013:48QR code 14 -- Phase rotation/sequence test - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo if I put l1 on line 1 and L 2 on line 2 you can see there's a green light against the are on theMoreSo if I put l1 on line 1 and L 2 on line 2 you can see there's a green light against the are on the right-hand side of the indicator that tells me that the rotation is is correct.

How many ohms should a 3 phase motor read?

The reading should be between 0.3 to 2 ohms. If it is 0, there is a short. If it is over 2 ohms or infinite, there is an open. You can also dry the connector and retest to possibly get more accurate results.

How do you test field windings?

1:343:16How to test a motor field winding for continuity - YouTubeYouTubeStart of suggested clipEnd of suggested clipNow we're going to check for the continuity on one side first so i will test this side first i'llMoreNow we're going to check for the continuity on one side first so i will test this side first i'll put one probe on this end. And the other probe on the other end and the catalytic.

How do you test a wire for continuity?

0:592:52How to Test Continuity on Wires and Electrical Parts - YouTubeYouTubeStart of suggested clipEnd of suggested clipDisconnect. Both ends of the wire. Set your multimeter to check continuity with a tone. Put oneMoreDisconnect. Both ends of the wire. Set your multimeter to check continuity with a tone. Put one meter lead on one end of the wire. And the other meter lead on the opposite end of the wire.

What is a good continuity reading?

Know that a reading of 0 indicates perfect continuity. If your multimeter reads 0 ohms, it means that there is perfect continuity in the wire, fuse, battery, or device. Most multimeters will beep continuously when testing a connection with good or perfect continuity.

How do I test an electrical wire with a multimeter?

Set a multimeter to measure voltage. Insert a probe into each slot and read the line voltage measurement. A properly working outlet gives a reading of 110 to 120 volts. If there is no reading, check the wiring and the outlet.

How do you know if something is single-phase or three-phase?

The best way to tell if a property has a three phase supply is by looking at the electrical fuse (sometimes called electricity supply, service head, cut out). Typically a single phase will have one fuse and a three phase will have three 100amp fuses.

How do you check electrical phasing?

6:007:38Testing Phase Sequence - YouTubeYouTubeStart of suggested clipEnd of suggested clipBut general you're going to be using the three wire connection method there one onto all of theMoreBut general you're going to be using the three wire connection method there one onto all of the three phases and then it's clockwise or anti-clockwise. And a final note here on the testing.

How do you know if voltage is single-phase?

Measure Single Phase Voltage (208-230 Volt Systems)Using the set of test leads, Insert the black probe of the test lead into the meter's Common (COM) port and the red probe of the test lead into the port marked for voltage and ohms.Set your true RMS electrical multi-meter to read “Ohms” or “Continuity”.More items...•

What is the voltage on 3 phase?

In a single-phase power supply system, the voltage may reach up to 230 Volts. But on a three-phase connection, it can carry a voltage of up to 415 Volts.

What are 3-Phase Systems?

Phase systems are alternating current power supplies that are defined by the number of phases in the power supply. Single-phase power supplies one phase at 120 volts, while dual-phase or split-phase power consists of two alternating currents supplied by two wires. Three-phase power is a type of power circuit that is characterized by three single-phase AC supplies. The system shares a return path by separating each phase by 120 degrees, resulting in constant power over each cycle and more power overall. Compared to single-phase power, three-phase power arrangements supply 1.732 times more power on the same current, resulting in a more economical system overall.

How to do an earth continuity test?

To complete the earth continuity test, set the multimeter to continuity mode. Once this is done, place one point on the frame of the motor and the other point on a known connection to the earth, preferably an area close to the motor installation. A good motor should result in a reading that is less than 0.5 ohms. If the value is greater than 0.5 ohms, however, this indicates that the motor’s insulation is failing and has the potential to cause an electric shock. Determining the causes of this failure may require further testing.

How to disconnect a transformer motor?

Disconnecting the motor from power: When you are ready, move the transformer’s motor disconnect switch to take it off of power. Be careful to make sure that the power is actually turned off — on some motors, the disconnect switch is the same as the on/off switch, so switching the disconnect switch to the on position will power the motor. Also, be sure to disconnect all equipment and wiring that is not going to be included in the testing process.

What is the purpose of checking the nameplate?

This information can be used to assess the health of the motor compared to its intended design.

What to do if you find a problem with your motor?

If you complete your tests and find one or more problems with your motor, there are a few things that you can do depending on the problem at hand. Some issues, like faulty wiring or a damaged shaft, may require replacing the problematic parts. However, more serious problems like insulation issues may require a new motor entirely. If you’re not quite sure what to do or where the problem is coming from, however, it may be worthwhile to call in an electronics repair service to help assess the motor. Global Electronic Services can help.

How to tell if a motor is damaged?

This may appear in the form of burn marks or indentations. Check all over the motor for any indications of heat or environmental damage.

How to check a 3 phase motor?

1. General Inspections. The most basic inspection is a visual inspection. Once the motor is removed from power and you are prepared to begin inspection, remove the cover of the motor.

What is 3PH RCD?

The 3ph RCD has the same mechanical RCD parts over all 3 phases to close off all 3 phases at the same time. #N#You can test any phase and log them on your cert.

How many probes are there on an outgoing terminal?

It's only one probe to hold on the outgoing terminal, the n and e can be croc clips on the respective bars.

Where should RCD test be carried out?

Considering that an RCD test should always be carried out at the terminals of the device itself with the outgoing conductors disconnected i'd suggest you need to brush up on your testing methods!

Why do motor windings have different offsets?

In simple terms, the current is being alternated during a different time. As the motor windings receive current, they create a magnetic field which propels them toward the next stator winding.

How many volts should a motor be?

The first step is to figure out the voltage of your phases. In the United States, for low voltage motors (below 600v), you can expect either 230v or 460v. That being said, there is a wide range of different motors and what you have on hand can be completely different. Make sure that the voltage you will be supplying to your motor matches the specifications on the faceplate.

Where to find wiring diagram for motor?

The type of connectors will depend on the manufacturer and size of the motor. Locate the wiring diagram for your motor on the faceplate or inside of the cover you have removed. Typically, you will have two distinct diagrams. One will be for low voltage and another for high voltage connections.

What are the parameters of an appliance?

Any appliance will have a number of parameters related to its electrical properties. These parameters are Voltage, Current and Power. Voltage can be taught of as the available pressure of electricity. A typical home will provide 110 or 220 volts depending on where you live.

What is 3 phase wiring?

Three phase systems are extremely common in industrial and commercial settings. They can also be found in large residential complexes and appliances requiring a large amount of power. Although these systems may seem intimidating at first, a walkthrough on 3 phase wiring for dummies will help clarify the whole situation.

What is the purpose of 3 phase power?

The most common use of three-phase power is for motors. It provides a unique feature which is a rotating field in order to rotate the motor without the need of a starter circuit. This is accomplished due to the fact that each one of the three phases has a different offset.

What is a three phase system?

A three-phase system is simply a system which will have three conductors which will carry current and have a certain voltage. Depending on the source, this system may also have a neutral wire for returning current back to the transformer.

How to check voltage on a 3 wire submersible pump?

Set an ohmmeter to match the voltage on your 3-wire submersible well pump. Turn off the power to your well pump, hook one wire from your ohmmeter to the ground and the other wire to the colored ground cable. Make sure that the ohmmeter reads OL (Open Lead) so that you know that your well pump is powered correctly.

What does an ohmmeter read?

Before beginning any testing, be sure that your well motor is not on any power supply. An ohmmeter reads the resistance of items which do not have any power to them. If you test your engine with the electricity on, your ohmmeter may malfunction. At the very least, you won’t be getting any good readings.

Why are three wire pumps more prone to failure?

As a result, three-wire well pumps are more prone to potential faults because more can go wrong. But those parts are easier to access because everything is segmented . The final difference comes from the horsepower behind the motors.

Why is there a loud noise near my well pump?

If you are experiencing abnormal water pressure in your house or hearing strange noises near your well pump, there is a good chance that you may be having issues. Because of the high costs of getting plumbing technicians to your house, it is essential to understand how to test a three-wire submersible well pump.

How to determine the voltage of a well motor?

Remove your motor so that there is no power to it. Hook up one cord to the ground and the other to the other colored wire. Take measurements with an awareness of the resistance of cable types and lengths.

How to test a pressure switch?

The pressure switch has a connection to a tube that goes into the pressure tank. You can test it by tapping a screwdriver handle against the line. If there is a spark and you see the pump starting, that means it is likely time to make a replacement.

How to check if a pump is on?

Your first step is checking to see if the power is on. Much like any electronic component, it does have an off switch. If it is in the off position, switch it back on. Keep an eye on it for a couple of minutes to see if it is turning itself back off. If it is, that means that there is an issue with your pump.

What to do before testing windings of motor?

The first thing to do before testing the windings of the motor is to remove the links linking terminals W2U2V2 and the disconnect the motor from supply (L1, L2, L3) . A multimeter terminals placed across this matrix of terminals will indicate the following readings for a good 3 phase motor:

How many terminals are there in a 3 phase motor?

Every 3 phase motor has six (6) terminals with the supply voltage connected to three (3) of those terminals. The most common configuration of a three-phase motor is the Delta (∆) – Star (Wye) configuration with the Delta side connected to supply voltage. The terminal configuration of a 3 phase motor is shown below:

What is the most common failure mode of a 3 phase AC motor?

The most common failure mode of a 3 phase AC motor is burnt winding or shorted winding leading to the damage of the motor. Often it is required to test the winding of the 3 phase windings with the aid of a multimeter or ohmmeter to determine whether the motor is still good or burnt or shorted.

How to test a 3 phase motor?

How to Test the Winding of a 3 phase Motor. To determine whether a 3 phase motor is still good or has gone bad, a simple ohmmeter test across the windings of the motor will reveal its true state of health. As shown below, the indicated terminal matrix ( blue lines) shows the way the windings of a 3 phase motor should be tested with an Ohmmeter:

Why does a 3 phase motor fail?

The 3 phase motor is a rugged piece of equipment but as with everything man made, there comes a time when this beautiful piece of machinery fails either due to old age, misapplication, mal-operation or any other adverse cause.

What Are 3-Phase Systems?

- Read your electrical meter to see if it says single or 3-phase. Look near your fuse box to see if your meter is mounted next to it. Sometimes, the face of your meter includes information such as the wattage and the identification number. Look for a description such as "Single Phase," "Mono-Phase," or "1-Phase" to identify a single-phase or "3-Phase," "Tri-Phase," or "Polypha…

- Identify a single-phase power supply by a single pole. Find the main switchboard in your fus…

Types of Testing For 3-Phase Motors

What to Do Next

Contact Global Electronic Services Repair For 3-Phase Testing