How to Test a Crankshaft Position Sensor with a Multimeter

- Unplug the CKPS’s electrical connector and set your DMM to low-range DC voltage settings.

- Stop your engine from starting, then turn the ignition key to its “On” position.

- Connect your DMM’s black lead to the ground and connect the red lead to each sensor wire.

- Set your DMM to a low-range AC voltage scale and connect the sensor pins to your meter leads.

How to know if a crankshaft position sensor is bad?

$0.00

- Vehicle does not drive like it used to If your vehicle idles roughly, stalls frequently, has a drop in engine power, stumbles frequently, has reduced gas mileage, or accelerates ...

- Check Engine Light comes on The Check Engine Light will come on once the camshaft position sensor starts to go bad. ...

- Vehicle will not start

What are the symptoms of a bad crankshaft position sensor?

What Are The Symptoms Of A Bad Crankshaft Position Sensor

- Lighting Up Of The Check Engine Light. The symptom of a bad crankshaft position sensor is the lighting up of the check engine light on the car dashboard.

- A Problem In Starting The Car. One of the biggest symptoms related to the bad or faulty crankshaft position sensor is the difficulty in starting the car.

- Rough Idle. ...

- Misfiring Of The Engine. ...

How to test a crankshaft position sensor using a multimeter?

- Unplug the CKP sensor electrical connector.

- Set your digital multimeter to DC voltage scale using a low range.

- Turn the ignition key to the On position, but don't start the engine.

- Touch the DMM black lead to ground. ...

- Touch the DMM red lead to each of the sensor wires on the harness connector you just unplugged. ...

How do I access the crankshaft positioning sensor?

How do I access the crankshaft positioning sensor? Ensure the engine is cool and the ignition switch is off ; Detach the negative terminal from the battery. to able to gain access to the ; Unplug the crankshaft position sensor electrical connector. Lose the mounting bolt (s).

How many ohms should a crank sensor have?

If the internal resistance value is 200 to 1,000 ohms (depending on the reference value), the sensor is OK. If the value is 0 ohms, there is a short circuit, and in the case of M Ohm there is an interruption.

How do you know if a crank sensor is faulty?

5 Signs of a Failing Crank SensorCrank Sensor Problems Could Make it Hard to Start Car. One sign that your crankshaft sensor might be failing is if you find it hard to start your vehicle. ... Engine Vibration Issues. ... Fuel Economy Slippage. ... Uneven Acceleration. ... Check Engine Light On.

How much voltage should a crank sensor have?

If you use a voltmeter to measure the crankshaft sensor signal, it'd measure about 2.5 volts.

What happens when a crank sensor goes out?

Acceleration Problems As the engine speeds up, there needs to be adjustments to spark timing and fuel injection. Without accurate input from the crankshaft sensor, the engine control unit (ECU) can't make these adjustments as well as it should. This can result in slow or uneven acceleration.

How do you test a crankshaft sensor with a multimeter?

Connect one DMM lead to one of the sensor pins and the other DMM lead to the other sensor pin. It doesn't matter which. Turn on your DMM. The readout should indicate a resistance value, usually between 200 and 2000 ohms, depending on your particular vehicle model.

How do you reset a crankshaft position sensor?

Resetting Crank Sensor Without A ScannerSwitch off the accessories. ... Now, let the engine be idle in Neutral or Park position for 2 minutes.At part throttle, accelerate your car to 55 mph. ... Even after that, cruise at the same speed for another 5/6 minutes.More items...

Does the crankshaft position sensor have a fuse?

2:294:16CRANKSHAFT POSITION SENSOR FUSE LOCATION REPLACEMENT ...YouTubeStart of suggested clipEnd of suggested clipIts fuse number three starting okay from this side here the opposite side of the tooth. We have oneMoreIts fuse number three starting okay from this side here the opposite side of the tooth. We have one two three it's a 20 amp fuse.

What can cause a crank sensor not to get power?

There are a few things that can cause the crankshaft position sensor to fail, including damage, debris and faulty circuitry. Even for modern electronics, the engine is a violent and destructive environment. Though built for this, most sensors eventually succumb to the ever-present heat and vibrations of the engine.

Can a car run without a crankshaft position sensor?

The crankshaft position sensor is the most important of all engine management sensors, and the engine will absolutely not run without it.

Can you clean a crankshaft position sensor?

Simply unscrew 1 bolt holding it in. Remove the sensor and clean any metal or grease off of it. It is magnetic so it will attract metal. When I cleaned mine, it made a world of difference for idle.

How do you reset a crank sensor without a scanner?

Turn off all of the accessories. ... Accelerate the vehicle to 55 mph at part throttle. ... Cruise at 55 mph for another 5-6 minutes.Decelerate to 45 mph without using the brakes, and maintain 45 mph for 1 minute.Perform 4 deceleration cycles, without using the brakes, of 25 seconds each where no specific speed is necessary.More items...•

Does crank sensor affect fuel pump?

I can understand that the absence of a crank position sensor signal can prevent the engine from starting (the ECU won't allow the car to run without it). The lack of signal could also prevent the fuel pump relay from activating and priming the fuel lines.

Can you start a car with a bad crankshaft position sensor?

Can I Start the Vehicle with a Bad Crank? If you wonder if it is safe to start your car when the crankshaft goes, the answer is yes if it is the very beginning of the issue. Once the position sensor becomes compromised or if you have symptoms of a problematic crankshaft that you can't ignore, do not drive your vehicle.

What sensor would stop a car from starting?

The most common sensors that will stop your car from starting include the camshaft sensor, the crankshaft sensor, the mass air flow (MAF) sensor, the manifold absolute pressure (MAP) sensor and the throttle position sensor.

Can a car run without a crankshaft position sensor?

The crankshaft position sensor is the most important of all engine management sensors, and the engine will absolutely not run without it.

Can a crankshaft sensor be cleaned?

Simply unscrew 1 bolt holding it in. Remove the sensor and clean any metal or grease off of it. It is magnetic so it will attract metal. When I cleaned mine, it made a world of difference for idle.

How To Test Crankshaft Position Sensor

There are two most common types of crankshaft position sensors, inductive and hall-effect. The inductive or pick-up crank sensors have two wires while the hall-effect crank sensors have three wires. Below is the step-by-step procedure of testing inductive and hall-effect type crank sensors.

How To Test Crankshaft Position Sensor With Multimeter

Below is the procedure for two and three-wire crank position sensor testing with a multimeter.

How To Test 2 Wire Crank Sensor With Multimeter

The inductive or magnetic pick-up crank sensors have two wires. Here is the method of testing a two-wire crankshaft position sensor is as given below:

How To Test 3 Wire Crank Sensor With Multimeter

The hall-effect type crank sensors have three wires. Here is the method to test a three-wire crankshaft position sensor is as given below:

How to tell if crankshaft position sensor is working?

To test if it your crankshaft position sensor is working properly, you have to test the voltage output. Once that is done, you can compare the readings with manufacturer specifications.

What causes a crankshaft position sensor to trouble code?

The trigger wheel located on the crankshaft or damper could have damaged or missing teeth. Any of these components could trigger a crankshaft position sensor to trouble code. Completing the above tests thoroughly will let you know if the crankshaft position sensor is working or not.

Do voltmeters need to be probed?

If the voltmeter is equipped with needle probes, the wires at the sensor connector need to be back probed .

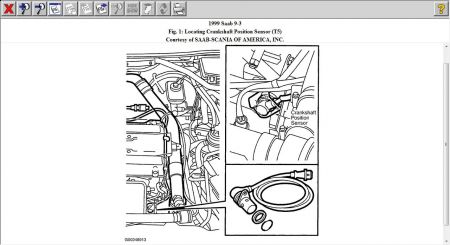

Where is the CKP sensor located?

Depending on your particular vehicle make and model, you can find the CKP sensor: mounted on an engine front cover or timing cover, near the crankshaft pulley or behind the harmonic balancer. somewhere around the middle of the engine block. under the starter motor.

What is CKP sensor?

In general, the CKP monitors piston movement and crankshaft position. It also helps the computer monitor engine misfires and engine speed. The computer uses this information to adjust ignition timing and fuel injection. However, a CKP sensor endures heat and vibration during engine operation.

What causes a sensor to fail?

Many times, a failing or inoperative sensor comes from a bad wire or connector. Make a visual inspection of the harness and connectors between the sensor and the PCM or ignition module.

How many volts should a fuel sensor produce?

One of the wires should produce around 1.5 volts; otherwise, the sensor is not receiving a reference voltage, and needs to be fixed. To prevent the engine from starting: Disable the fuel system by removing the fuel pump fuse or relay. Or disconnect the ignition cable between the ignition coil and distributor.

Why is it important to test CKP?

So, it is important to test the CKP to better diagnose the problem.

What to do if your car uses a distributor?

If your vehicle uses a distributor, disable the ignition system to crank the engine.

What is the shield on a sensor?

Keep in mind that some manufacturers provide a protective shield along the sensor's wiring, under the insulation. This prevents electrical interference. And there could be a third wire on the harness connector.

What is a crankshaft position sensor?

The crankshaft position sensor evaluates the rotation speed (RPMs) and the exact position of the engine crankshaft. It controls the situation and the rotational speed of the crankshaft and sends the notice to the engine control unit to make proper modifications based on running conditions.

How do crankshaft sensors work?

And the way these sensors produce their voltage, the teeth on your gear will stimulate the magnetic field at the end of these sensors. So then, your sensor will make an AC voltage that’s sent to your electronic control module through this wiring harness connector. So now I will do these testing procedures right here on this bench, but you don’t have to remove your sensor; you can do this on the car.

How many volts does a car sensor need?

When ignition ON or in the Cranking position, you always have a constant supply of 12 volts to these sensors; you always have a continuous ground. And if you want to test these sensors, you want to make sure your ground is your black test lead, and then you want to put the setting on your multimeter to DC volts. So our constant supply is 12 volts. Other times it is 5 volts depending on your car make and model, but all of those will be less than 20 volts, so we will go with 20 volts in this setting.

Why is there a check engine light on my crankshaft?

Another issue with the crankshaft position sensor could be illuminated Check Engine Light. If the multimeter detects a problem with the crankshaft position sensor’s signal, it would activate the Engine Light to alert the driver, ensuring the problem. A wide variety of other issues can also set off a Check Engine Light.

How many ohms does a 3 wire crankshaft sensor have?

The three-wire crankshaft position sensor is supposed to have about 2000 to 2500 ohms of resistance. So we will choose 20,000 ohms on the selector dial with the help of a multimeter and will take our measurement.

Why does my crankshaft break?

Another common symptom is related to a faulty crankshaft position sensor. When the problem is with the crankshaft position sensor or any damage in its wiring, it could cause the crankshaft signal to break while running the engine; it can also cause the stalled engine; this is generally a sign of a problem with the wiring. Similarly, a bad crankshaft position sensor can also produce this symptom.

What happens when a crankshaft sensor fails?

when the crankshaft sensor fails and lacks accurate timing information, the fuel injectors would not efficiently pump gas into the engine. The engine uses more gas than it usually needs on a short or a long drive, reducing the overall fuel economy.

What does it mean when a crank sensor is bad?

The most common symptom of a bad crank sensor is a ‘cranks but does not start’ problem. In other words, your GM vehicle will crank over when you turn the key to the Start position but will not start. Below is a simple list of more specific symptoms that accompany a bad crank sensor:

Can a multimeter test a crankshaft position sensor?

Since the 3-wire crankshaft position (CKP) sensor can not be tested by a multimeter resistance test (Ohms), I've written this article to show you how to do it with just a multimeter in Volts DC mode. This is a very accurate and effective test and will help you to know if it's good or bad.