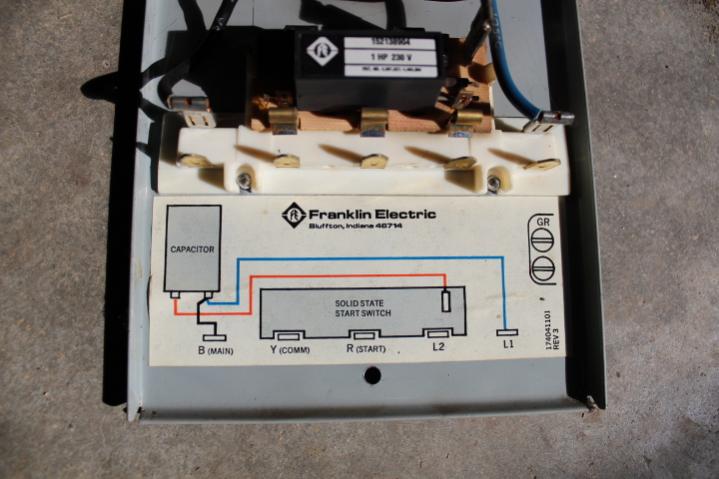

How to Test a Well Pump Control Box Step 1. Turn off the well's circuit breaker. The correct circuit breaker has a "Well" label. Step 2. Open the control box's lid. The control box mounts to a wall next to the well's water storage tank. A wire set... Step 3. Inspect the control box's wiring diagram ...

How do you test a well pump control box?

How to Test a Well Pump Control Box. Technicians should test a well pump's control box before pulling a nonworking pump from the well. When the water tank's pressure switch detects low water pressure, its switch closes, which turns on the electricity to the control box.

How to choose the right pump for your control box?

The control box voltage must match the pump voltage. It’s best to decide which kind of pump you will use, and then compare the voltage and amperage to the ratings of the control box. There are several kinds of control types that are used to control pumps: Float switch – Rises and lowers with the liquid level.

How do you test a pressure switch on a well?

Replace the wire connectors after testing the control box's capacitor. Turn on the circuit breaker. Turn a multimeter to its "VAC" setting. Open a faucet. This lowers the water pressure in the well's storage tank, which causes the well's pressure switch to turn on. Place the multimeter's probes on the control panel's "L1" and "L2" terminal.

How do you test a control box capacitor with a multimeter?

Turn a multimeter to the "Ohm" setting. Touch the multimeter's probes on the capacitor's terminals and watch the meter's reading. The meter should reach infinite, fall back slightly, then reach infinite again. If it does not, then replace the capacitor. Replace the wire connectors after testing the control box's capacitor.

What is a control box in a well pump?

Where to place multimeter probes?

How to change a capacitor in a control box?

What are the wires on a well pump motor?

How to fix a leaking control panel?

How to read a multimeter?

See 3 more

About this website

How do you test a well pump control box?

8:0910:52How to Troubleshoot a QD Control Box - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd the pressure switch would close thus allowing the the electricity to travel up to this panelMoreAnd the pressure switch would close thus allowing the the electricity to travel up to this panel here so I put my meter on l1 and l2. And we can see over there that the voltage is reading about 247.

How do I know if my pump controller is bad?

How to Tell If Your Well Pump Pressure Switch Is BadYour water pressure is at or above the cut-out pressure, yet the pump doesn't turn off.Your pump doesn't turn on at the proper cut-in pressure.You have low water pressure even though the pump is running.Your pump runs, but it cycles on and off repeatedly.

Can you run a well pump without a control box?

The short answer is yes. Most pumps will work without a control box. But here's the rub – if you want your pump to run better, for more hours in the day, if you want to use a float switch, and if you want to protect your pump from voltage and current spikes, then a control box is an excellent addition to your system.

What does a pump control box do?

(3) Pump Control Box – protects submersible pumps from low or high voltage, a drop in water level, low yield wells, clogged well screens, malfunctioning pumps and motors, and rapid cycling. Pump control boxes usually have microprocessors that monitor power-line voltage and pump motor power draw.

How do I reset my well pump control box?

Hold the reset lever in the start position until the pressure builds up and the gauge reads over 40 PSI; then let it return to the AUTO position. The pump should now run on its own and continue until the pressure reaches the cut out setting, (usually between 50 - 60 PSI), and then shut off.

Can pumping machine work without capacitor?

The motor will run fine without the capacitor. However, the problem comes if the motor stops and tries to restart. Say for instance you have a power blip for a second or two. The pump will shut down and not be able to restart, therefore ruining the motor.

Does a 2 wire well pump need a control box?

Two wire well pumps do not use a control box. All the elements already come built within the motor or pump house itself. This allows for easier installation. However, if any of the starting components fail, the pump will have to be pulled up and the whole motor will have to be replaced.

Are pump control boxes interchangeable?

The pumps are bolted onto the motors (with matching splined shaft). However, one major manufacturer makes its own motor and control box, which are not interchangeable. As for the others, motors and control boxes may be interchanged as long as horsepower, phase, and voltage are a match.

Does a 3 wire well pump need a control box?

While two-wire well pumps do not require a pump control box, three-wire submersible well pumps do. Control boxes contain the starting circuits for well pumps.

Can you run a well without a pressure switch?

You can run a well pump with a pressure tank. The purpose of a pressure tank is to keep the water pressure at a constant level. Without the pressure tank, your well pump needs to work harder and can go into a cycling state where it turns on and off quickly and constantly.

How do you test a water pump capacitor?

2:446:10How To Test A Pool Pump Motor Capacitor - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd um so you want to check your multimeter. And make sure it has the ability to to test capacitanceMoreAnd um so you want to check your multimeter. And make sure it has the ability to to test capacitance it'll have a symbol.

How do you test a well pump relay?

0:302:52How to Test the Relay in Franklin Electric Control Boxes - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd it is the R times 1,000. If you're following along with your meter so we're going to first startMoreAnd it is the R times 1,000. If you're following along with your meter so we're going to first start by testing this one here. And so we're going to test between number five and number two.

What causes automatic pump control failure?

The single most common reason a pump controller fails is due to a build-up of 'muck' in the internals of the controller. Typically, tank water collected off a roof catchment contains bacteria which with the addition of summer heat can develop bacterial growth.

How do you adjust a water pump controller?

If you want the water pump to turn OFF (cut out or cut-off) at a higher water pressure, turn this nut clockwise or "tighter". Adjusting the pressure on this spring shifts just the pump cut-out pressure up (clockwise) or down (counter-clockwise).

Why pressure pump keeps turning on and off?

A blockage in the water supply piping. For example, a clogged or nearly clogged water filter can cause the pump control to cycle on and off rapidly. This is because the blockage causes water pressure (between the pump and the filter) to rise very rapidly when the pump turns on.

How do you reset an automatic pressure switch?

0:552:05Well Pump Restart. (This is how you turn the water back on) - YouTubeYouTubeStart of suggested clipEnd of suggested clipUntil you hear the pump start and continue to hold until the pressure climbs above 20 pounds in yourMoreUntil you hear the pump start and continue to hold until the pressure climbs above 20 pounds in your system.

How to check if a pump is on?

Your first step is checking to see if the power is on. Much like any electronic component, it does have an off switch. If it is in the off position, switch it back on. Keep an eye on it for a couple of minutes to see if it is turning itself back off. If it is, that means that there is an issue with your pump.

How to test a pressure switch?

The pressure switch has a connection to a tube that goes into the pressure tank. You can test it by tapping a screwdriver handle against the line. If there is a spark and you see the pump starting, that means it is likely time to make a replacement.

How to check voltage on a 3 wire submersible pump?

Set an ohmmeter to match the voltage on your 3-wire submersible well pump. Turn off the power to your well pump, hook one wire from your ohmmeter to the ground and the other wire to the colored ground cable. Make sure that the ohmmeter reads OL (Open Lead) so that you know that your well pump is powered correctly.

What does an ohmmeter read?

Before beginning any testing, be sure that your well motor is not on any power supply. An ohmmeter reads the resistance of items which do not have any power to them. If you test your engine with the electricity on, your ohmmeter may malfunction. At the very least, you won’t be getting any good readings.

Why are three wire pumps more prone to failure?

As a result, three-wire well pumps are more prone to potential faults because more can go wrong. But those parts are easier to access because everything is segmented . The final difference comes from the horsepower behind the motors.

Why is there a loud noise near my well pump?

If you are experiencing abnormal water pressure in your house or hearing strange noises near your well pump, there is a good chance that you may be having issues. Because of the high costs of getting plumbing technicians to your house, it is essential to understand how to test a three-wire submersible well pump.

How to determine the voltage of a well motor?

Remove your motor so that there is no power to it. Hook up one cord to the ground and the other to the other colored wire. Take measurements with an awareness of the resistance of cable types and lengths.

What Does a Well Pump Control Box Do?

A well pump control box is basically the brain of a water system because it handles many tasks to keep the system functioning properly.

How to control a well pump?

Here are some specific things that control box can do: 1 Alternate the operation of pumps. 2 Change the speed of motors to avoid low water pressure. 3 Protect motors from an incorrect amount of voltage and waterlogged tanks. 4 Start motors that are high voltage. 5 Sense water flow and levels, and signal equipment to turn off/on. 6 Control pumps such as those that feed chemicals. 7 Activate well pump generator when needed. 8 Turn off well pumps when water is too low. 9 Open and closes valves. 10 Display the duration that a pump has been on.

What is pump control?

They are also responsible for protecting pumps against low and high voltage that can result from things such as short circuits and overloads.

How to contact well pump maintenance in Arizona?

If you live in Arizona and would like to receive reliable and affordable maintenance on your well pump control box at your home, contact us at (623) 582-5069. For commercial: (602) 254-6154. Find well pump replacement near me!

Why is price important when choosing a control box?

Price is an important factor when choosing a control box because there are many that are cheap but are also faulty. It’s common for manufacturers to use poor quality components in cheap control boxes, which can result in an unwanted well water pump repair.

Do well control boxes need to be carried?

It’s common for well control box installers to carry multi-purpose control boxes with them so they can install one at any job site. This sometimes results in the consumer paying more for something they don’t need.

Can you buy control boxes?

There are many affordable control boxes you can purchase that will suit your needs, just be wary of the things that you don’t need because the price will be higher.

Where is the control box on a well?from hunker.com

Open the control box's lid. The control box mounts to a wall next to the well's water storage tank . A wire set from the storage tank's pressure switch and a wire set that leads to the pump motor enters the control box.

How to check capacitors?from rcworst.com

Check the capacitor (s). Using an ohmmeter set to R X 1,000, place your leads on either of the contactor terminals. The meter should swing toward zero, then back to infinity. One unfortunate and important note for this test is that a capacitor that has lost some capacitance may test okay, however, it may no longer function properly.

How to check QD relay?from rcworst.com

Check the QD relay. Using an ohmmeter set to R X 1,000 you will perform what is know as the triac test. Connect meter leads to the capacitor and B terminals and you should get an infinity reading.

What are the wires on a well pump motor?from hunker.com

The wires heading to the well's pump motor connect to terminals with a start, run and neutral function. These are usually labeled "S," "R" and "N.". The wires connected to the green screw ground the well system.

How to read a multimeter?from hunker.com

Place one multimeter probe on the control box's neutral terminal. Touch the other probe against the start terminal and take the multimeter reading. Once the control box's relay switches to the run phase, move the probe from the start terminal to the run terminal and take a reading. The voltage between the start and neutral terminals will drop ...

What is a QD box?from rcworst.com

QD Boxes are designed for use with 3-wire, single phase submersible motors from ? to 1 hp. Troubleshooting inside the box is made simple by the control components automatically disconnecting from the system when the lid is removed.

Can you touch live parts on a hot wire?from rcworst.com

Warning: The power must be on for these tests. Do not touch any live parts. If you are not comfortable or are inexperienced working with hot wires contact a professional.

How to check capacitors?

Check the capacitor (s). Using an ohmmeter set to R X 1,000, place your leads on either of the contactor terminals. The meter should swing toward zero, then back to infinity. One unfortunate and important note for this test is that a capacitor that has lost some capacitance may test okay, however, it may no longer function properly.

How to check QD relay?

Check the QD relay. Using an ohmmeter set to R X 1,000 you will perform what is know as the triac test. Connect meter leads to the capacitor and B terminals and you should get an infinity reading.

What is a QD box?

QD Boxes are designed for use with 3-wire, single phase submersible motors from ? to 1 hp. Troubleshooting inside the box is made simple by the control components automatically disconnecting from the system when the lid is removed.

Can you touch live parts on a hot wire?

Warning: The power must be on for these tests. Do not touch any live parts. If you are not comfortable or are inexperienced working with hot wires contact a professional.

How to check if a well pump is tripped?from familyhandyman.com

Then check the well's double-pole circuit breaker to see that it hasn't tripped. If it has, reset it. A breaker that keeps tripping likely means a problem with the well pump, and you'll need to call a pro for that. Step 2.

What does it mean when a pressure switch kicks on a well pump?from familyhandyman.com

If banging on the tube under the pressure switch kicked on the well pump, it means the contact surfaces of the electrical contacts are pitted or burned, causing a poor connection. You can temporarily restore the surfaces to keep it going until you can buy a replacement switch.

How to replace a pressure switch?from familyhandyman.com

To replace the switch, start by removing the wires to the old switch and unscrew the switch. Pro tip: Be sure to label the wires!

What happens if a well pump switch is bad?from familyhandyman.com

The switch then powers up the well pump. If the switch is bad, it won't start the well pump and you won't have water, so testing the switch is your first step. Remove the cover and bang a screwdriver handle sharply against the tube below the switch to jar the electrical contacts.

What does it mean when a pump sparks?from familyhandyman.com

If you see a spark and the pump starts, the pressure switch is the problem.

How do you know if you have a well?from familyhandyman.com

The most common symptoms of well trouble are no water at all, pulsing water pressure and a well pump that runs constantly. If you experience any of these, there's a good chance you can solve the problem yourself.

What does the switch on a well pump do?from familyhandyman.com

It's what senses when water pressure has dropped to the point where the pressure tank requires more water. The switch then powers up the well pump.

How to test coils?from rcworst.com

Coil test. Using an ohmmeter, set your meter to R x 1. Connect meter leads to L1 and B and the correct reading is Zero ohms for all models.

How to measure voltage on a pressure switch?from rcworst.com

Measure Voltage at Pressure Switch. Ensure that the motor is off and measure voltage at L1 and L2 of pressure switch. The reading should be +/- 10% of motor rating. With the motor running, measure voltage at the load side of pressure switch. The voltage reading should remain the same except for a slight dip on starting. Excessive voltage drop can be caused by loose connections, bad contacts, ground faults, or inadequate power supply. Relay chatter is caused by low voltage or ground faults.

How to check if a solder overload is tripped?from rcworst.com

Check Overloads. Set Ohmmeter to lowest ohm setting and test each of the overloads by touching the solder points inside the box. You are looking for a reading less than 0.5 A zero reading will indicate that the overloads are tripped. Reset the overloads and retest.

What is a QD box?from rcworst.com

QD Boxes are designed for use with 3-wire, single phase submersible motors from ? to 1 hp. Troubleshooting inside the box is made simple by the control components automatically disconnecting from the system when the lid is removed.

Can you touch live parts on a hot wire?from rcworst.com

Warning: The power must be on for these tests. Do not touch any live parts. If you are not comfortable or are inexperienced working with hot wires contact a professional.

Do wells have control boxes?

A lot of wells don't have control boxes. The pressure switch is the only control (although there is usually a power switch for turning off the power to the pressure switch). So no worries!

Is there a box in the well house?

My well head. There is no box anywhere in the well house.

Is it normal to have two wires on a pump?

I have a two wire pump and no control box so for me it's a pretty normal setup. Yes, it is a bit confusing when they say two wire when they don't count the ground as a third.

What is a control box in a well pump?

Well pumps with control boxes have start and run circuits. During start-up, the control box sends electricity to the pump motor through the start circuit. Once the pump motor reaches operational speed, the control box switches the electrical feed to the run circuit. Advertisement.

Where to place multimeter probes?

Place the multimeter's probes on the control panel's "L1" and "L2" terminal. The voltage should read within 10 percent of the control panel's stated operating voltage. If not, then check the circuit breaker and the pressure switch.

How to change a capacitor in a control box?

Pull the wire connectors off of the capacitor with needle-nose pliers. Lay a screwdriver across the capacitor's terminal. This discharges the capacitor. Turn a multimeter to the "Ohm" setting. Touch the multimeter's probes on the capacitor's terminals and watch the meter's reading. The meter should reach infinite, fall back slightly, then reach infinite again. If it does not, then replace the capacitor. Replace the wire connectors after testing the control box's capacitor.

What are the wires on a well pump motor?

The wires heading to the well's pump motor connect to terminals with a start, run and neutral function. These are usually labeled "S," "R" and "N.". The wires connected to the green screw ground the well system.

How to fix a leaking control panel?

Visually inspect the control panel's wires, wire connections, relay and capacitor. Replace all burnt or broken wires or parts . Tighten all wire connections with the correct screwdriver, often a flat-head screwdriver. Replace the capacitor if it has a leaking or swollen case.

How to read a multimeter?

Place one multimeter probe on the control box's neutral terminal. Touch the other probe against the start terminal and take the multimeter reading. Once the control box's relay switches to the run phase, move the probe from the start terminal to the run terminal and take a reading. The voltage between the start and neutral terminals will drop ...