Silane/Siloxane sealers are commonly used as water repellents and waterproofers especially on extremely porous cement based substrates like cinderblocks, stucco, brick and concrete. Excellent sealers for protection from freeze-thaw damage and salt degradation and commonly used on municipality jobs, highways and bridges.

What is siloxane sealer used for?

Silane/Siloxane sealers are commonly used as water repellents and waterproofers especially on extremely porous cement based substrates like cinderblocks, stucco, brick and concrete. Excellent sealers for protection from freeze-thaw damage and salt degradation and commonly used on municipality jobs, highways and bridges.

How do silane and siloxane work together?

While the silane particles penetrate within the concrete, they do not react chemically to densify the concrete. Instead, the silane and siloxane particles will work in concert to create a hydrophobic barrier that will block out water and moisture.

How do you apply silane siloxane sealer?

Silane siloxane sealers are very easy to apply. They can be applied with a roller or sprayer, but a sprayer will provide more constant coverage, and the material with stretch further. Clean the surface to make sure it is clean and free of anything that could prevent proper penetration.

Why are siloxanes used in landfills and waste water?

The use of these compounds is increasing rapidly - and so is their presence in landfills and waste water. As the material in a landfill or digester decomposes and generates biogas, the siloxane molecules enter the biogas stream as a vapor. During combustion these siloxanes undergo a phase change from a vapor to a solid silicon dioxide powder.

How long does siloxane sealer last?

6 months to 10 yearsSilane Siloxane Water Repellent Sealers: Silane-Siloxane water repellent sealers will last anywhere from 6 months to 10 years depending on the quality of Silane-Siloxane sealer used, and the percent solids.

How long does siloxane sealer take to dry?

Silane-Siloxane concrete sealers will appear to have dried in as little as 30 minutes, but they will continue to react below the surface for up to 72 hours.

Is siloxane a good concrete sealer?

Siloxa-Tek 8500: Silane/siloxane designed for extremely porous concrete and masonry substrates. We have found this sealer to be extremely effective against salt degradation, spalling, cracking, freeze-thaw damage and water.

How does siloxane sealer work?

Silane-siloxane bonds chemically to the pores inside and below the surface of brick and masonry substrates, keeping water from entering the brick. The penetration allows the substrate to maintain its natural texture, and the sealer will be almost undetectable on most concrete or brick surfaces.

What happens if you put too much sealer on concrete?

Heavy coats of sealer, or a buildup of sealer applied numerous times over the years, will cause moisture to become entrapped under the sealer and, in time, the sealer loses adhesion from the concrete.

Is siloxane a sealant?

About Penetrating Silane Siloxane Sealers Lock out water and its damaging effects on dense concrete and masonry with Rust-Oleum® OKON® S-20 Water-Repellent Sealer. This silane/siloxane formula penetrates deeply to create a tough hydrophobic barrier against water invasions. Ready to use and paintable.

How do you apply siloxane concrete sealer?

This sealer is ready to use; do not dilute. Apply to porous, bare, uncoated concrete and masonry surfaces only. Do not apply to non-porous substrates or smooth troweled concrete where penetration of the product will not be sufficient. Apply until saturated using a roller or low-pressure garden sprayer.

What do professionals use to seal concrete?

Epoxy. Also known as polyurethane sealers, epoxy sealants cost more than acrylic ones. However, rather than providing a soft finish that lasts one to three years, a quality epoxy sealer can protect your concrete for five to 10 years.

What is the strongest concrete sealer?

Epoxy concrete sealers are the most durable, making them good for sealing garage floors and high-traffic retail environments. Softer acrylic sealers, which require a sacrificial floor wax, are more affordable and popular for residential concrete floors, including basements.

What is the difference between silicone and siloxane?

The key difference between silicone and siloxane is that silicone is a polymer material whereas siloxane is a functional group. Furthermore, silicone has a number of siloxane groups repeating throughout the structure while the structure of siloxane is Si—O-Si bond.

What is the best product to seal concrete with?

BEST OVERALL: Foundation Armor AR350 Wet Look Concrete Sealer.BEST BANG FOR THE BUCK: MasonryDefender Penetrating Concrete Sealer.BEST PENETRATING: Ghostshield Siloxa-Tek 8500 Penetrating Sealer.BEST ACRYLIC: Eagle Armor Seal Urethane Acrylic Concrete Sealer.BEST EPOXY: TotalBoat Table Top Epoxy Resin 1 Gallon Kit.More items...•

Is siloxane and silicone the same thing?

Siloxanes are commonly known as silicones. They belong to the organosilicon compounds and are exclusively obtained by synthesis. Their chemical structure determines a range of physicochemical properties which were recognized as unique.

How long should sealant be left to dry?

It might seem that certain shower sealants or caulks are dry to the touch quickly after application, but they actually take around 24 hours to properly cure fully.

What happens if concrete sealer gets wet before it dries?

Second, the concrete surface must be dry at the time of sealer application. If a polyurethane sealer comes in contact with moisture, a chemical reaction takes place, causing bubbles and foam.

How quickly does silicone sealant dry?

Silicone sealant dries fairly quickly, usually taking around 30 minutes to an hour. However, silicone sealant is waterproof only after it cures completely, which takes significantly longer. Curing involves a series of chemical changes that take place once the silicone is exposed to oxygen.

How long does silicone sealant need to dry?

Silicone sealant generally cures within 24 hours. If it has been over 24 hours, check the silicone sealant “Use By” date on the package. If the product is older than the “Use by” date printed on the product, safely dispose of the product.

BIOGAS SOURCES AND TYPES

The energy sector is one of the most important and most developed today. Since the 20th century, the world has come to understand that it must renew and expand its energy sources to meet the growing needs of society, while taking care of the environment.

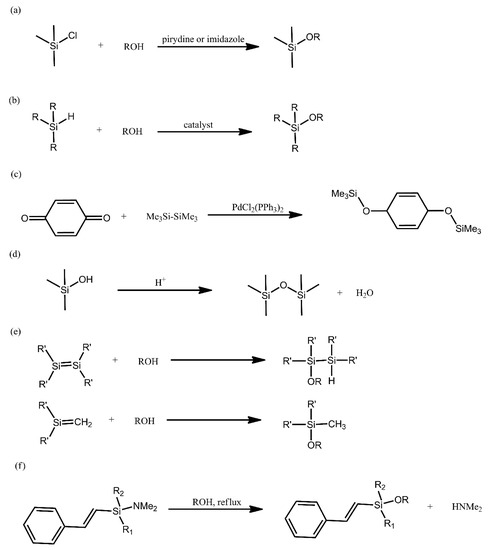

ORIGIN OF SILOXANES

Among the components with the greatest impact on the energy use of the biogas generated in sewage treatment plants and landfill are siloxanes. These wear down the internal parts of the machines used, damaging them and reducing their useful life, as well as increasing operation costs due to repeated oil changes and internal parts replacement.

EFFECT OF SILOXANES

Unlike sulphides, silicones do not react with water to form acids. However, during combustion, the siloxane molecules are broken down and release oxygen and silicon.

SILOXANES TREATMENT

Current systems to remove these compounds use techniques that generally have one or two stages involved. Among these are subcooling, adsorption on activated carbon/silica gel, graphite filters, certain types of resins and washing with certain reagents (e.g. methanol, sulfuric acid and hydrocarbon mixtures).

Silane Sealers for Concrete

Silane belongs to the group of penetrating sealing agents wherein a chemical reaction happens between silane and concrete components to create a protective barrier against moisture and soluble salt penetration.

What are sealing agents?

Sealing agents are chemicals designed to increase the durability of the concrete structures. These chemicals are applied on the surface of concrete to avoid any penetration for damage-causing substances such as water and soluble salts.

What makes a good sealing agent?

The primary characteristic that defines a good sealing agent is its ability to provide protection to concrete structures.

Types of Sealing Agents

The two classifications of concrete sealers are surface or topical sealers and penetrating sealers which significantly differ on their mode of surface protection.

Silanes for Old and New Concrete

Because the reaction between concrete components and silane sealing agents are affected by pH (specifically favored basic conditions), the application of silane sealers on fresh alkaline concrete requires a shorter period of time to reach completion.

Advantage and Disadvantages of Using Silane

As mentioned, silane is one of the most popular penetrating sealers for concrete in the market because it can offer higher depth of penetration compared to siloxane. Its effectiveness also increases when the solid content is high. Furthermore, penetrating sealers have low initial cost compared to other sealing agents.

Conclusion

This blog post discussed the topic “Silane Sealers for Concrete”. It was clearly explained that concretes require sealing agents to increase its durability by having protection against water and soluble salt penetration.

Sections

Biogas Sources and Types

- The energy sector is one of the most important and most developed today. Since the 20th century, the world has come to understand that it must renew and expand its energy sources to meet the growing needs of society, while taking care of the environment. Biogas from landfill, methanation plants and wastewater treatment plants (WWTP) is a valuable material for energy p…

Origin of Siloxanes

- Among the components with the greatest impact on the energy use of the biogas generated in sewage treatment plants and landfill are siloxanes. These wear down the internal parts of the machines used, damaging them and reducing their useful life, as well as increasing operation costs due to repeated oil changes and internal parts replacement. Siloxanes are a family of orga…

Effect of Siloxanes

- Unlike sulphides, silicones do not react with water to form acids. However, during combustion, the siloxane molecules are broken down and release oxygen and silicon. The latter combines with other elements forming silicates, silica and other crystalline compounds which are deposited in the combustion chamber (mainly in the upper part of the jacket)...

Clean-Bgas® Mp Dry

- CLEAN-BGAS® MP DRY is a multipurpose cleaning and conditioning technologybased on combining operations, such as cooling, condensing, washing, drying and adsorption in activated carbon, which minimizes both energy and active carbon consumption. The technology has two basic stages: one for the gross elimination of contaminants, including type D siloxanes, hydrocar…