How long does it take to wire a horn?

Wiring a horn the right way, whether to replace a non-working horn, or to install a new one to a custom vehicle is a job that a competent do-it-your self type should be able to complete in an hour or two.

What gauge wire is used for pin 87A?

Connect Pin 87a and Pin 86 with a short piece of 14-gauge wire, having a female solderless spade connector on each end.

HOW TO FIND THE CAR HORN?

As you’ll see once you begin the repair, on most of today’s cars locating the car horn can be a serious task.

Why is a car horn important?

Car horn is one of the most important parts of the car in terms of signalizing. Sound signals are equally important as visual ones in everyday traffic. So having a faulty car horn is both dangerous and annoying. When a traffic situation comes up and you need the car horn, it will be like you turned mute on the TV.

HOW TO MAKE A CAR HORN REPLACEMENT?

If you’ve concluded that the car horn has totally malfunctioned, then you have to replace it.

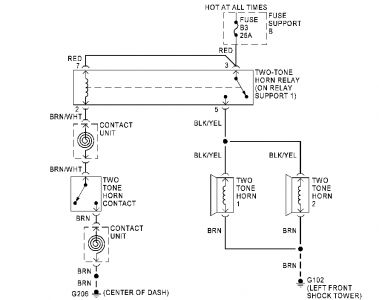

What is the purpose of horn relay?

The main task of a horn relay is to take off the burden of high electric current from the horn switch and the rest of the electric installation. If you want to see how a relay actually works, click here for a great explanation on Wikipedia. This fault is pretty rare.

What causes a car horn to blow?

Listed below are the common problems regarding car horns. BLOWN FUSE. This usually happens if there is a short-circuit in the electric system (wiring, perhaps a faulty relay or the car horn itself). Also, a blown fuse can happen if the car horn is used extensively (like long,uninterrupted continuous usage).

How many volts does a car horn need?

Make sure that the power supply voltage is adjusted to the horn. On a car it will probably be 12 volts, for bigger pick-ups and trucks it can be 24 volts. Take a look before you start so you don’t damage the horn (higher voltage supply will damage or burn out the horn). Make a good connection to the car horn.

Why do horn switches break?

Horn switches are held back by springs which may lose strength overtime or break due to material fatigue. Loose parts or weak springs that can’t hold the switch in place can cause an accidental connection and activate the car horn. This is solved by removing the horn switch and replacing the springs or broken parts.