How does a screed work?

In the United States, screeding is the process a person called a concrete finisher performs by cutting off excess wet concrete to bring the top surface of a slab to the proper grade and smoothness. A power concrete screed has a gasoline motor attached, which helps smooth and vibrate concrete as it is flattened.

How does a power concrete screed work?

Concrete is poured from a wet mix of cement, sand, aggregate and water. Prior to the mix drying, the concrete should be smoothed out on the desired surface. A power screed assists in the smoothing out process by leveling out and/or vibrating the wet mixture.

Is screed stronger than concrete?

Concrete is much coarser than screed and has bigger aggregates, making it much stronger and longer-lasting. These qualities make it ideal for many structural projects.

Can I screed straight onto concrete?

These screeds can be applied both bonded directly onto a concrete base or un-bonded (applied on to a polythene sheet damp proof membrane). Both screed and concrete are referred to as being green during the period from application through to the time it gains strength and reaches dimensional stability.

What is the best way to screed concrete?

4:299:15How The Pro's Screed Concrete (Learn How Here) - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo you want to just be skimming over the surface of that pad. Whether it's on the outside edge or inMoreSo you want to just be skimming over the surface of that pad. Whether it's on the outside edge or in the middle.

How do you screed concrete without forms?

0:332:08How to level concrete without using a form board - YouTubeYouTubeStart of suggested clipEnd of suggested clipI simply cut a notch in it on one end and that notch happens to be the height difference that I needMoreI simply cut a notch in it on one end and that notch happens to be the height difference that I need between the existing concrete pad in the new concrete pad.

Why does screed crack?

Cracks typically form in new screeds because the excess water evaporates from the surface at a faster pace than it is replaced by the residual water, trapped in the concrete slab. Or at stress points such as doorways and corners.

How thick should a concrete screed be?

Traditional screeds, when floating, must be a minimum of 75mm thick for commercial projects and may be reduced to 65mm for domestic only situations. A floating Cemfloor screed would need to be minimum 35mm thick for a domestic application and 40mm thick for a commercial application.

Is screed waterproof?

Making a cement screed has lots of advantages. For instance, you could lay a screed for a floor with heating. By using Cementmix instead of water, you'll create a screed that's permanently waterproof, through and through.

What is the minimum thickness of screed?

The optimum thickness of a sand and cement bonded screed is 25–40mm, an unbonded screed should have a minimum thickness of 50mm, whilst a floating screed should have a thickness greater than 65mm for lightly loaded floors and 75mm for more heavily loaded floors.

What goes under a floor screed?

How to prepare to lay unbonded screedFirst, clean the concrete floor to get rid of any dust or grease. ... Once the flooring area is clean and free from dirt or dust, lay down polythene sheets, or another form of membrane, to keep the concrete flooring separate from the screed.More items...

What is the maximum thickness of screed?

Recommendations for pumpable self-smoothing screeds are given in BS 8204 Part 7, which recommends the minimum thickness of a bonded screed should be 25mm. Manufacturers quote maximum thicknesses of up to 80mm and therefore there are less restrictions on the overall thickness.

How does a laser screed work?

Laser Screed technology produces slab-on-grade concrete floors that are flatter and stronger than any comparative floors produced by using conventional methods. They establish grade by laser, utilizing a 3D Profiler System, disperse concrete by auger, and then vibrate and consolidate the concrete.

Are vibrating screeds good?

It does a slightly better job of leveling, but a considerably better job of consolidating. Vibration is the key to dispersing aggregate and filling air pockets, thus the end result is a stronger, more uniform slab.

How does a power float work?

Power floats have an electric motor or petrol engine fixed over a circular pan or skimmer which smooths concrete before hardened steel reversible metal blades rotate at up to 150 rpm over the surface to create a hardened finish.

Can you power float a screed?

There are many advantages to having a power float concrete finish, starting with the fact that the process eliminates the need for more time and materials when applying a power float screed.

Concrete Screed Specifications

A minimum thickness of 25 mm is required for a fully bonded screed, 50 mm for an unbonded screed and 65 mm for a floating screed (i.e. on top of in...

Composition of Concrete Screed

A floor screed is usually a cementitious material made from a 1:3 or 1:4.5 ratio of cement to sharp sand. It may be applied onto either a solid in-...

Advantages of Concrete Screed

Liquid cement screed creates a smooth and even surface that could easily accommodate different floor coverings such as carpet or tiles. Because it...

Application of Concrete Screed

Screed is usually applied on top of the concrete slab and is most commonly used as a finishing layer on internal floors or to level the floor prior...

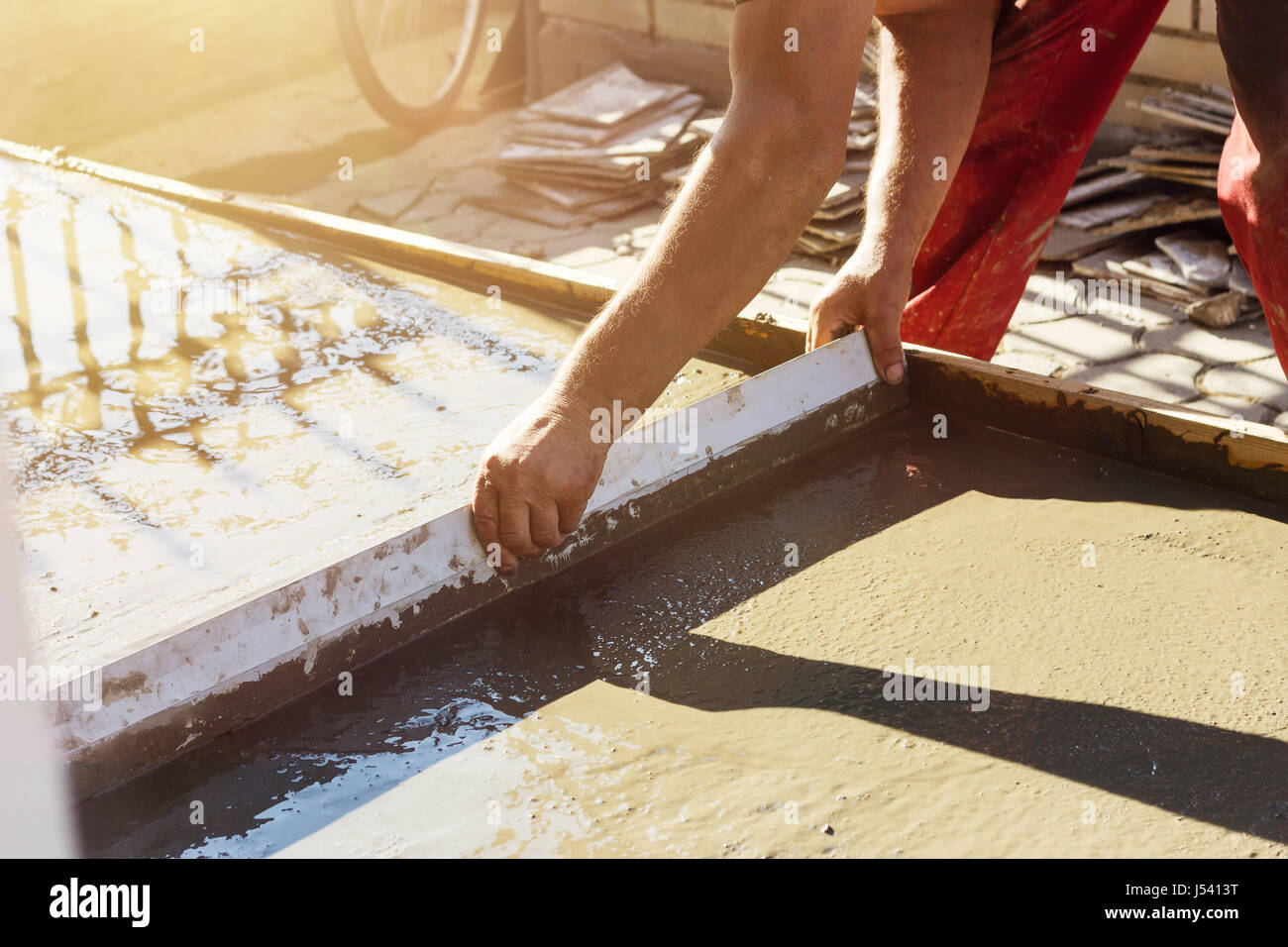

What is screeding concrete?

Screeding concrete is one of the first steps in placing and finishing concrete. Screeding is the art of skimming or striking off the surface of the concrete after rough raking it. Screeding when done properly will leave you with a good even flat surface free of humps, bumps holes and low spots.

How do laser screeds work?

A laser screed is operated usually by one guy, a couple of rakers and a laser set up for heights. This specialty screed is not usually something anyone can use, it requires special training to be able to operate it. Alot of times companies who own a laser will rent them out with the operator.

What is power screeding?

Power Screeds – Power screeding makes the smoothing out process alot easier by leveling out and/or vibrating the wet concrete mixture. They are usually used for larger pours. If quality is important I definitely would not recommend using one unless you have been trained. They do save time and effort but are not always the most accurate screed with experienced operators.

What is the hardest way to screed concrete?

Picking the right tool for the job will of course depend on the job your performing. Hand Screeds – Hand screeding is physically the hardest way to screed the concrete, but in the right hands it is the most accurate way to screed. Hand screeds can be a straight wood 2X4.

How long is a roller screed?

The rollers are available up to 24 feet long with many different attachments available for perfect gutters, curbs and more. The roller screed is a must if you are using pervious concrete. The best thing is the roller screed is so simple to use, even a beginner can turn out decent quality.

What is truss screed?

Truss screeds can have many sections bolted on for reaching across large spans. They are built to ride on forms or rails that are set out prior to pouring. Laser Screeds – Laser screeds are usually used on larger pours where accuracy is important. This is probably the easiest most accurate form of screeding.

What Is Concrete Screed?

Screed is a thinner layer of concrete which is typically poured over a base floor to help form a smooth floor coating to provide a strong foundation for the top floor.

What is screeding on concrete?

A floor screed is usually a cementitious material made from a 1:3 or 1:4.5 ratio of cement to sharp sand. It may be applied onto either a solid in-situ concrete ground floor slab or onto a precast concrete floor unit.

What is screed cement?

Screed is usually a cementitious material made from a 1:3 to 1:4.5 ratio of cement to sand. A simple cement and sand mix will be fine for a simple application but more sophisticated mixes are suitable for a wider range of applications. Some of these new compounds can be laid on substrates other than concrete.

What is sufficient thickness for screed?

Sufficient Thickness: Screed thickness is according to the kind of screed planned to put in, the thickness of the floor & its type, and additionally the intensity of estimated traffic.

What is screed flooring?

Screed is usually applied on top of the concrete slab and is most commonly used as a finishing layer on internal floors or to level the floor prior to final floor coverings carpet, tiles, natural stone, linoleum, wood flooring, resin coatings, etc.

Why is concrete screed shrinking?

This is due to a part of evaporation of the blending water or the drying process. This shrinkage will lead to curling or cracking of screed& may result in floor detachment.

How to resist hairline cracks on screed?

To resist hairline cracks on screed surfaces, an anti-fracture membrane ought to be utilized. Clean: The screed surface must be made tidy. Dust, dirt on the screed surface must be removed before the installation of flooring. Unclean surfaces will end in the prevention of adhesion between the ground & screed.

How To Use Concrete Power Screed?

The term ‘screed’ may be quite confusing to many. Sometimes it is referred to as the flashy layer over the concrete while some may get demented with the tool that flattens the screed.

How long is a power screed?

It saves a lot of muscle power as the operator has only to control the speed and direction of the power screed. A screed length can vary from 2 feet to 16 feet. The screed can be easily detached and replaced when needed. For a 4 inch or higher flop, vibrator handheld screed is appropriate.

What is laser screeding?

Concrete laser screed is used for large and tough surfaces. Talking about its speed, a 240 square feet surface can be leveled in a minute. A surface containing steel fibers can also be leveled with ease.

What is a screed bar?

The most common type of screed available in the market is the vibrating handheld screeds. A metal screed bar is to a frame. The frame is equipped with a vibrating motor that is controlled by the operator. Push-Pull operation is controlled by the handle that leaped to change the directions too.

How to stream concrete?

Always stream the concrete in smaller blocks. By moving the chute back and forth, try to even the spread of concrete as it is easy to roll over the concrete power screed on a smaller surface for a robust surface.

Is concrete power screed effective?

Not only it enhances speed but also it is proven to be more effective. From a 2 *4 hand-driven power screed to a gigantic vibrating s creed, concrete power screed comes in many forms as per the requirements.

Is concrete screed good for a large area?

This could result in inefficiency as well as exorbitance. For a larger area, concrete power screed is always recommended for the sheer finishing. Not only it guards the surface against cracks and stains, but also it makes it look vibrant.

What is screeding in concrete?

In the process of pouring concrete, a screed is usually a long length of straight 2 x 4 board or an aluminum bar manufactured for the purpose. Whatever object is used, screeding is done by drawing the tool across the wet surface of the concrete. The screed is generally long enough so that the ends can rest on opposite sides of the concrete form.

What is screeding in engineering?

elenaleonova / Getty Images. In its broadest definition, the term screeding refers to any action of smoothing out a pliable material into a flat layer. The term can be used both as a verb ("to screed") or as a noun referring to the tool that is used to do the flattening. There are tools manufactured expressly for screeding, ...

How to keep screeding consistent?

One trick to keep screeding consistent is to lay out 1-inch PVC pipes before dumping the sand. As you screed the sand across the pipes, the pipes act as guards to prevent you from screeding any deeper.

How many people do you need to use a screeding tool?

But when the screeding tool is a full-length two-by-four (8 feet or even longer), it is very difficult for one person to effectively handle the tool. You'll need two people—one at each end—to control this heavier, larger tool.

Why use aluminum screeding tool?

Aluminum screeds are often used where precision is needed, as they provide a straighter edge.

Can you kneel in the sand before using a screed tool?

Working with an assistant is critical for perfect screeding. If not, you're kneeling in the sand layer ahead of the screed tool. The screed tool will help to smooth out your knee and shoe depressions. But it's best not to kneel in the sand in the first place. When you work with an assistant, both of you can remain outside of the project area.

What is a screed in concrete?

A concrete screed (or straight edge) is used to strike-off or level concrete.

How wide is a screed?

Since it's 2" wide, the screed pulls the concrete and kind of smoothens it at the same time, making it easier to bull float.

Why is 2x4 screed used?

The 2x4 screed for it's simplicity and easy learning curve.

What is EZ screed?

EZ Screed makes a type of concrete screed you can use in the upright position.

How many rakers do you need for a vibra-screed?

Although the vibra-screed is quite easy to operate, you need at least 1 , preferably 2, good rakers behind you pulling and pushing the concrete in order to get a really flat floor.

Do we straight edge slabs?

We straight edge a lot of slabs this way, it's how we were taught.

Does Day's Concrete Floors screed concrete?

My company, Day's Concrete Floors, Inc. pours concrete just about every day. So we screed a lot of concrete. We've got a good system for screeding that's easy for us.

What Is a Vibrating Concrete Screed

A vibrating concrete screed is a piece of equipment made to screeding the concrete to make it smooth and level.

How Does a Vibrating Screed Work

A vibrating screed is essentially a beam with a vibrating unit. The vibrating unit is generally mounted in the center of the beam along with the pair of end roller assemblies. The vibrations are transmitted to the concrete through the beam directly. There is no transverse movement in the beam.

How to Use Vibrating Concrete Screed

Following steps should be followed for the smooth operation of vibrating concrete screed:

Types Of Vibrating Screed

There are various types of the vibrating screed. The most common are the following

Power Source

As the name suggests it is a portable model of vibrating screed usually powered with a battery. It is more suitable for jobs which require less concrete to be screeded or jobs locate in a remote area with limited access to gasoline or electricity supply.

DIY Concrete Power Screed (Homemade)

You can have a homemade vibrating screed. It is simple. You just need to follow these steps:

Conclusions

You can have a homemade vibrating screed. It is simple. You just need to follow these steps:

What is a Concrete Screed?

In a nutshell, a concrete screed is a straightedge tool that levels and smoothens the surface of freshly poured concrete. They can be powered by gas, electricity, hydraulics or operated by hand. Screeds are typically made of aluminum, magnesium, steel or wood – though there are exceptions. As a screed passes over wet concrete, it pushes large aggregate down and brings “creme” to the surface. They leave concrete surfaces smooth, flat, and free from any deformities.

What is screeding for concrete?

Screeding is a highly important process when pouring flatwork projects like driveways, floors or parking lots. A contractor that doesn’t cut any corners can pour strong, beautiful slabs that will last for decades to come. As a screed passes over of concrete, it levels the surface of the concrete. Most screed either vibrate or spin – working larger aggregate down, just below the surface. This leaves smaller sand and cream (a thin slurry of cement) on the surface that finishers can work with to build a smooth, professional-looking finish.

What are the Different Types of Concrete Screeds?

Concrete contractors are responsible for deciding what is the best concrete screed type for their company or for a particular pour. There are many different types of concrete screeds available on the market and each one has its place. Let’s take a closer look at each.

What do the Best Concrete Screeds Have in Common?

All good screeds have one thing in common: they do their job well if they are kept in good condition. Any screed that is bent, dented, has dried concrete left on it, or doesn’t run well, is not going to perform well and the finished concrete will show that. It is important that screeds are kept well-maintained and in good working order. If your beat-up old screed isn’t fast, easy to use, and leaves a beautiful, professional finish, then it may be time to consider upgrading your equipment. After all, a high-quality finished product is the most important thing for your customers.

How does dragon screed work?

Dragon Screed works in forward or reverse and off of either side of the machine. It can also be configured to work directly in front of the machine. Dragon Screed eliminates the need for draggers in front of the screed, drastically reducing much of the manual labor associated with pouring and screeding concrete (see concrete project profitability analysis ). Your crew can focus their energy and attention on finishing concrete behind the screed.

How to screed concrete fast?

One of the fastest ways to screed concrete is the Dragon Screed system. Dragon Screed is easy to set up and extremely easy to use. Its versatility allows crews to screed gravel and concrete in many different configurations – up to 32 feet wide. Dragon Screed levels gravel or sand subgrade quickly and accurately. Crews no longer have to drag gravel in order to have a quality subgrade. Once the gravel is level, simply remove the subgrade panels and switch to the vibrating floats. You then use the same equipment to screed the conc rete.

Why do roller screeds throw concrete?

Roller Screeds are powered to spin, but leveling the concrete comes down to brute manpower. When concrete is left too high or is poured at a low slump, roller screeds have a tendency to throw concrete over the top of the screed. In this case, in order to avoid a wavy slab, the two pullers have to carry the screed back.