Crosscut saw

A crosscut saw (thwart saw) is any saw designed for cutting wood perpendicular to (across) the wood grain. Crosscut saws may be small or large, with small teeth close together for fine work like woodworking or large for coarse work like log bucking, and can be a hand tool or power tool.

What is a cross cut saw used for?

A crosscut saw (thwart saw) is any saw designed for cutting wood perpendicular to (across) the wood grain. Crosscut saws may be small or large, with small teeth close together for fine work like woodworking or large for coarse work like log bucking, and can be a hand tool or power tool .

How does a crosscut saw tooth work?

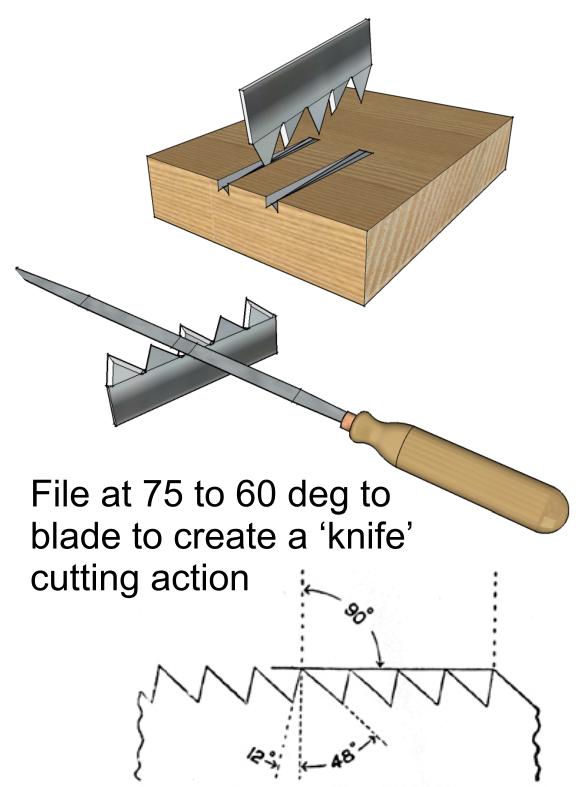

The cutting mechanics of the crosscut saw tooth has been described as a ‘knife like’ cutting action. [citation needed] The sharp bevelled cutting edges sever the wood fibers perpendicular to the grain, reducing the amount of bending within the work-piece.

How does a crosscut saw cut the dust?

The numerous cutting teeth between the heel and toe have alternating cutting edges. Each cutting tooth cuts with one edge and pushes the sawdust out with the other. Crosscut saws have 8 to 15 pointed teeth per inch.

What is a fully conditioned crosscut saw?

No crosscut saw ever made was “fully conditioned,” if you mean working at it’s optimum performance. Basically, trial cuts are required in the wood you’ll be cutting and the amount of “set” needs to be adjusted accordingly. (due to the moisture content of the particular wood you’re cutting)

What is the difference between a rip saw and a cross cut saw?

Both crosscut saws and rip saws teeth are 'set' (bent away from the blade) but crosscut teeth are angled on their inside edge, whereas rip teeth aren't. This sharp angled edge means that crosscut teeth can slice through material like a series of little knives.

How does cross cut saw work?

Crosscut saws include a blade and a handle. The blade edge below the handle is the heel and the opposite end is the toe. The numerous cutting teeth between the heel and toe have alternating cutting edges. Each cutting tooth cuts with one edge and pushes the sawdust out with the other.

What is a 2 person saw called?

A two-man saw (known colloquially as a "misery whip") is a saw designed for use by two sawyers. While some modern chainsaws are so large that they require two persons to control, two-man crosscut saws were primarily important when human power was used.

What is a cross cutting blade used for?

A crosscut blade, on the other hand, is designed to produce a smooth cut across the grain of the wood, without splintering or tearing. This type of blade will usually have 60 to 80 teeth, and the higher tooth count means that each tooth has to remove less material.

Why are crosscut saws used?

Crosscut saws have been in use around the world since historic times, with the design of the saws (the cutting surfaces, the bow and shape of the saw, and the handles) changing over time to accommodate differences in the types of trees being cut, changes in metallurgy technology, and the application of experience.

What is a cross cut saw?

The cutting edge of each tooth is angled in an alternating pattern. This design allows each tooth to act like a knife edge and slice through the wood in contrast to a rip saw, which tears along the grain, acting like a miniature chisel. Some crosscut saws use special teeth called "rakers" designed to clean out the cut strips of wood from the kerf . Crosscut saws generally have smaller teeth than rip saws.

What is the difference between a cross cut saw and a rip saw?

Crosscut saws generally have smaller teeth than rip saws. Some saws, such as Japanese saws and those used by the ancient Egyptians, are designed to cut only on the pull stroke. Western saws, on the other hand, are designed to cut on the push stroke.

How does a raker work?

The raker follows the cutters, paring the bottom of the kerf like a chisel or plane. As the raker pares the bottom of the kerf, a strip of wood is lifted upward, and curled forward into the gullet. As the saw is drawn out of the kerf, the wood that has accumulated in the gullets is allowed to fall out onto the ground.

How old are vintage crosscut saws?

There are two types of crosscut saw classification, vintage and modern. Vintage saws are saws that can be anywhere from 30 to as much as 250 years old and are much sought after by professionals, and as such are typically very much more expensive than modern crosscut saws.

What is a crosscut saw handle?

Many crosscut saws have a wooden handle with the return edge at right angles to the un-toothed edge of the saw blade, allowing the saw to serve as a square for marking material to be cut at a right angle .

What is a 5 foot crosscut saw?

A five-foot lance-tooth crosscut saw. A crosscut saw (thwart saw) is any saw designed for cutting wood perpendicular to (across) the wood grain. Crosscut saws may be small or large, with small teeth close together for fine work like woodworking or large for coarse work like log bucking, and can be a hand tool or power tool .

What is a crosscut saw?

The Crosscut Saws are the oldest hand tools that are used to make perpendicular cuts through the woods. These were the most treasured tools in the olden days for the users who were into wood cutting work. These tools are used back then when history ruled the world. Crosscuts are of the major use to make cuts through the grain of the wood.

How long is a crosscut saw?

The one-man saw is of a single handle with 3-6 ft of the length. While on the other side, the two-man crosscut saw is of the two handles and is of about 4-16 ft in the length. Additionally, the two-man crosscut saw has two patterns; one is of tree felling pattern and the other is of Bucking pattern.

What is the difference between rip saw and crosscut saw?

The crosscut teeth are built with the interior edged angles, whereas the rip saw teeth are not. Generally making the cuts over the grains of the wood is a challenging and strenuous task. Therefore, crosscut saws are specially made for this purpose.

What is a hand saw used for?

Obliged by the carpenters, the hand saws type of crosscuts saws are majorly utilized to make the cuts through the long grains resulting in an accurate outcome. The two-person crosscut saw is also a prominent among the house users. This is mainly used to cut the trees to fall them.

What is a backsaw?

A Backsaw is a handy tool specially built to make intricate cuts through the trees. With the additional capability of trimming and cutting firewoods, this can be a good fit for the carpenters too for small projects.

Do crosscut saws need batteries?

Used for the variety of the wood cutting purposes, the crosscuts saws are one of the most preferred saws since they are pollution-free and this does not require any battery or the extension cord to let the saw run on electricity.

Do chainsaws replace crosscut saws?

Yet the chainsaws have replaced these crosscut saws, but still, there are a lot of users who seek to opt for this small hand tool. Here we move on with further detailing. This article presents you with all the description with regards to the crosscut saws. What is a crosscut saw used for ?? What are the types of crosscut saws ?? What are the best crosscut saws ?? and many more questions.

How does a crosscut saw work?

In general, crosscut saws work by pairing one or more sets of cutting teeth with a set of rakers; the cutting teeth, sharpened on opposite sides, sever the fibers on each side of the kerf, the raker comes behind them and planes out the chip. Crosscut saws come in a variety of designs, depending on the intended use.

What is a crosscut saw?

Crosscut saws come in a variety of designs, depending on the intended use. Felling saws are used to make a backcut on standing trees, often in concert with an axe for cutting the front notch. A felling crosscut is made with relatively little steel and has a curved back, both of which provide for better balance and less sag when holding ...

How deep should a crosscut saw be?

Use a straight edge set on top of the closest cutting teeth and a feeler gauge to measure the depth. Optimum depths are 0.008 inches for hard or dry wood or 0.030 for soft springy wood; saws used for a variety of woods are often set around 0.012.

What type of saw cuts on pull and push strokes?

Virtually all crosscut saws cut on both the pull and push strokes, regardless of whether they’re one- or two-person saws. Tooth pattern is another variable in crosscut saws. Among antique saws, the lance tooth and perforated lance tooth patterns are the most common and can be very effective at cutting.

What was used before chainsaws?

Not that long ago, in the days before chainsaws, work in the woods was done with an axe and a crosscut saw. While this era is only 50 years behind us, crosscut saws are now viewed by most as a relic from our past, suitable for hanging on a wall or occupying a dusty corner of the shed.

How deep should a saw be for hard wood?

Optimum depths are 0.008 inches for hard or dry wood or 0.030 for soft springy wood; saws used for a variety of woods are often set around 0.012. Now give it a try. If you are sawing with a partner, remember to let the saw float in your hands on the “push” stroke, and pull steady and straight on the “pull” stroke.

How to clean rust off a saw?

For removing rust, use a green scrubby cut to fit a palm sander. Apply a mixture of 1 part each of diesel, kerosene, and bar oil to the saw to help with cleaning (this mixture also works well as a lubricant/pitch-cutter while sawing pitchy softwoods).

Where do trail crews find vintage saws?

U.S. Forest Service volunteer David Roe instructs trail crews on crosscut use in Oregon and Washington. For him, finding quality vintage saws is part of the fun. “Sometimes I take road trips just to look for saws,” said Roe, who lives in western Oregon.

What is the difference between a vintage saw and a modern saw?

The differences between a vintage saw and a modern saw, she said, are legion. Vintage saws were made from top-quality steel, while modern saws are made of thin, soft sheet metal. Yesterday’s saw teeth were set in an arc, giving each tooth an equal cut, while new ones are set in a straight line.

What saws were taken down by the Westward expansion?

Following westward expansion, the humble, no-gasoline, human-powered crosscut took down some of North America’s most massive Douglas firs, redwoods, and sequoias. Even after the chainsaw displaced it in the 1950s, the saw retains a small but devoted following. For trail crews working in designated wilderness areas, where motors are prohibited, ...

Is a crosscut saw good for forestry?

The Crosscut Saw: Still the Best Tool for Some Wild Jobs. The crosscut saw is a workhorse of backcountry forestry and trail maintenance. But due to its tiny niche in the cutting market, finding a quality crosscut is harder than ever. For better or worse, the crosscut saw is a legend of American forestry.

Do vintage saw teeth come out?

Vintage saw teeth were stamped out evenly, and modern ones aren’t. Old saws were taper-ground, creating less friction with the wood and therefore less work for the sawyer. New saws are flat-ground.

Do crosscuts work in wilderness?

For trail crews working in designated wilderness areas, where motors are prohibited, crosscuts are still essential. And yet, to find a quality saw-maker nowadays, you have to go all the way to the other end of the world (more on this later).

Is crosscut sawing exercise?

Crosscut saws are exercise,” Chapman said, quoting a friend. “With a chainsaw, there’s no relaxation. You’ve got the noise and pull of the engine, and fast action. With crosscut sawing, there’s a relaxation and using your large muscles and making the tool do the work.”. Diehards aside, it’s still a niche market.

Evolution of the Antique Crosscut Saw

History recanted by word of mouth has many faces. Some say the antique crosscut saw is from the Neolithic age, whereas others insist it’s older than that. The Ancient Egyptians used it for woodwork.

How to Identify an Antique Crosscut Saw

Every hand saw has a special purpose. It looks like all hand saws do the same thing on the surface, but that’s wrong. The first step in identification is differentiating an antique crosscut saw from other hand saws.

Valuing Your Antique Crosscut Saw

You can sell, restore, resharpen, recycle, or donate your antique Crosscut saw to a museum. Whichever route you take, you must understand the value of your tool to make the best decision. There’s no fixed price for all antique Crosscut saws because they’re not the same.

Concluding Thoughts

The market for antique Crosscut Saws is smaller than the demand. Many collectors favor this design because of its durability, efficiency, and history.

When did crosscut saws come into use?

The crosscut saw did not come into use until the 15th

Which saw has a concave back?

Felling saws have a concave back and are narrower than

Why don't felling saws make a saw?

Because felling saws are fl exible, they do not make a

How many handle holes does a bucking saw have?

bucking saws can have two handle holes per side.

What is a bucking saw used for?

Bucking Saws—Bucking saws can be used for felling.

How long is a vintage saw?

stroke. Vintage saws were made from 4 to 7 feet long in

Where were vintage saw teeth?

vintage saws had teeth all the way to the ends of the

How does a crosscut saw work?

A one-person saw has a fixed D-shaped handle with additional holes on the top of the saw to attach a supplemental handle. Many two-person crosscut saws (usually bucking saws) have two holes on each end for handles. Moving the handle from the lower hole has the same effect as moving the hands several inches up the saw handle. With the handle in the upper hole, a push stroke applies more downward force on the saw, causing the teeth to sink deeper into the wood. The deeper cut requires more force on the pull stroke. A slight upward force is applied to the saw, making it easier to pull.

When did crosscut saws come into use?

The crosscut saw did not come into use until the 15th century. Early saws had a plain peg-tooth design. Saws were used in Colonial America and were being manufactured in this country by the mid-1800’s. Saws were not used for felling timber until around 1880. The machinery to make these vintage saws is no longer available. Crosscut saws manufactured today are lower quality.

What is a bucking saw?

Bucking saws (figure 4-3) can be used for felling. Some saws were manufactured to try to incorporate the best characteristics of both types of saws. Bucking saws have a straight back; they are much thicker than felling saws, so they are heavier and stiffer. Because the bucking saw is usually operated by one person, it cuts on both the push and pull strokes. The saw’s additional stiffness helps prevent the saw from buckling on the push stroke.

What is a 2 person crosscut saw?

Two-person crosscut saws are symmetrical. They cut in either direction on the pull stroke. Vintage saws were made from 4 to 7 feet long in 6-inch increments. Two-person crosscut saws (figure 4-2) manufactured today are flat ground. Most vintage saws were either straight taper, crescent taper, or flat ground. The saws have one or two holes, or a groove, on the blade ends to attach removable handles. Most vintage saws had teeth all the way to the ends of the blade. Saws manufactured today do not.

What are the two types of crosscut saws?

Crosscut saws can generally be divided into two types: one- and two-person saws.

What is the best vintage saw?

The best vintage saws were crescent taper ground (figure 4-5). Early saw manufacturing companies used different trade names for crescent taper-ground saws. The names included: crescent ground (Simonds), improved ground (Disston), and segment ground (Atkins). Crescent taper-ground saws offer the saw the most clearance in the kerf of any of the grinds. These saws require the least amount of set, allowing the narrowest kerf. The thinnest part of a crescent taper-ground saw is at the back center.

Why are taper ground saws better than flat ground saws?

Straight taper-ground saws have an advantage over a flat- ground saw because the saw is thinner at the back than at the center (figure 4-4). The back of the saw has more clearance, reducing binding. Straight taper-ground saws require less set. Set is the cutter tooth’s offset from the plane of the saw.

What type of saw should I use for green wood?

It sounds to me like you are using a crosscut saw with a relatively fine tooth pattern (think Pax or Disston). These saws typically have a wood handle and a 2-3' steel blade that tapers from about 4-5" at the handle to 2-3" at the tip. These saws are suitable for DRY woods. You mentioned that it's difficult to see any progress even in green woods. For green woods, you would really benefit from a saw with fewer teeth per inch, as saws with many TPI will quickly clog. For green wood, a buck saw is your best bet if a chainsaw is not available. Also, a bandsaw with a blade specifically designed for green wood is a good choice. It has a wider kerf.

Is a tuttle saw a log saw?

I googled up a "tuttle" pattern saw and it is certainly a saw for log work. The site I found it on showed a picture of the blade and it looked like the teeth were not well shaped and set, it looked rather crude in fact, just punched out. Proper tooth shape and setting is critical for the saw to work well.John White

Overview

A crosscut saw (thwart saw) is any saw designed for cutting wood perpendicular to (across) the wood grain. Crosscut saws may be small or large, with small teeth close together for fine work like woodworking or large for coarse work like log bucking, and can be a hand tool or power tool.

The cutting edge of each tooth is angled in an alternating pattern. This design …

Common features

Many crosscut saws have a wooden handle with the return edge at right angles to the un-toothed edge of the saw blade, allowing the saw to serve as a square for marking material to be cut at a right angle.

Larger saws used for forestry and logging work include both one-man and two-man saws, and both bucking and felling saws. A bucking saw generally has a straighter back and less of a prono…

How crosscut saws cut

All saws have cutting teeth, some may also have rakers and gullets.

As the saw is pulled toward the operator, the cutters score the wood to the left and right of the width of the blade, cutting a channel downward into the wood. Many sawtooth patterns have four cutters; each cutter that cuts to the left of the blade is paired with another that cuts to the right of the blade.

Crosscut saws vs. chainsaws

Felling or bucking is an inherently dangerous job. On top of that, both chainsaw and crosscut saws are dangerous in their own rights.

A kit for crosscut saw work weighs much less than a kit for chainsaw work. A chainsaw kit includes fuel, oil, a few tools, and more personal protective equipment.

The primary maintenance carried out on crosscut saws is sharpening, which requires a shop an…

History

Crosscut saws have been in use around the world since historic times, with the design of the saws (the cutting surfaces, the bow and shape of the saw, and the handles) changing over time to accommodate differences in the types of trees being cut, changes in metallurgy technology, and the application of experience. Records exist of crosscut saws in use during the Roman Empire although not widely. They came into wide usage in Europe in the middle of the 15th century. Earl…

Vintage saws versus modern saws

There are two types of crosscut saw classification, vintage and modern. Vintage saws are saws that can be anywhere from 30 to as much as 250 years old and are much sought after by professionals, and as such are typically very much more expensive than modern crosscut saws. Modern saws are typically stamped out of sheet metal and are manufactured from contemporary alloys; they behave very differently from vintage saws, which have historically been made by craf…

Crosscut saw training

Many areas of the National Forests of the United States are designated as Wilderness Areas and as such the use of mechanized and motorized equipment is prohibited except by special circumstance. Because of this, the United States Forest Service (USFS) organizes the crosscut saw training of USFS employees and forest working volunteers in an effort to maintain skills and proficiency a…

See also

• Bucksaw

• Hand saw

• Saw pit

• Two-man saw

• Underbucking