What diesel injection pump is usually driven by?

Fuel injection pumps in diesel engines operate under high pressure. A device that pumps fuel into gasoline or diesel engine cylinders is known as a fuel injection pump. The pump is usually driven by a chain or toothed timing belt that is motivated by the gears in a crankshaft.

How to set diesel injection pump timing?

- Rotate the engine until the #1 piston rises to its highest point.

- Connect the new pump to all fuel lines, except for the top hard lines that connect to each injector. Do not connect the pump yet.

- Press the primer pump to build pressure, open the bleeder valve to release air, then close the bleeder valve. ...

- Slowly rotate the fuel injection pump shaft. ...

How does diesel fuel injector pump work?

How does injection pump work on a diesel By pressurising and injecting the fuel, the system forces it into air that has been compressed to high pressure in the combustion chamber. Some types of fuel tanks also have a fuel sedimentor at the bottom of the filter to separate water content from the fuel.

How to rebuild an injector pump?

How to Rebuild an Injector

- Obtain Rebuild Kit. The first step in the repair process is to obtain an injector rebuild kit. ...

- Take Injector Apart. Remove the O-rings at either end of the injector and soak it in carburetor cleaner overnight. ...

- Clean Injector While Applying Power. The injector is controlled by a solenoid which opens a valve. ...

- Rebuild Injector. ...

How does an injection pump work in a diesel fuel system?

The pump camshaft is connected to the engine crankshaft, so that when the engine cranks automatically the pump camshaft rotates. This rotation will move the plunger, so that the plunger is pressed upwards and as a result the fuel that is already in the fuel barrel is pressed with high pressure and enters the injector.

What are the symptoms of a faulty diesel injector pump?

Dirty Fuel Injector SymptomsThe Engine Misfires. Dirty fuel injectors may cause your vehicle's engine to misfire. ... Idling Gets Rough. Does your vehicle sputter and shake when you're at a stop sign or sitting in traffic? ... Your Gas Mileage Tanks. ... The RPM Needle Starts to Dance. ... Your Car Won't Start.

How do you test a diesel injector pump?

1:453:48Diesel Fuel Injector Test (Mechanical) - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd what we want to do is lean on the handle. And check for a single pop check the spray patternMoreAnd what we want to do is lean on the handle. And check for a single pop check the spray pattern crank. On it really hard and see the spray pattern I make sure that it you get a nice steady.

At what speed does the diesel injection pump turn?

A diesel engine needs to rotate between 150 and 250 rpm to start.

How do you diagnose a bad injector pump?

Symptoms of a Bad or Failing Diesel Injection PumpEngine may run roughly, or not at all.Hard starting.Engine misfires.Lack of power.Excessive smoke from the exhaust.

How do I know if my injection pump is out of time?

You can check the injection timing by measuring the injector pump's stroke at TDC using a dial indicator.

What causes diesel injector pump failure?

A major cause for fuel injection pump problems is the use of dirty fuel. Over time, residue builds up throughout your system. Using poor-quality fuel exacerbates this issue. Bring your vehicle in for auto repair if you notice sputtering or your vehicle hesitates when accelerating.

How do I know if my diesel pump is working?

0:006:05How to Properly Test and Diagnose a Bad Fuel Pump - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd what you're listening for is a low-pitched humming sound that goes on for a few seconds. That'sMoreAnd what you're listening for is a low-pitched humming sound that goes on for a few seconds. That's basically the sound of your fuel pump priming.

Can a diesel pump be repaired?

With the high costs of these units, it is economical to know if they are faulty or if there are other underlying issues on your vehicle. Your diesel pumps will be professionally repaired/reconditioned as follows: Disassembled. All parts completely cleaned.

How many PSI does a diesel injector pump put out?

30,000 psi*In today's diesel engines, fuel leaves the injector at 30,000 psi. For comparison, this number fits in the range of pressures in hich waterjets operate.

What pressure do diesel injectors work at?

10,000-30,000-psiIn many cases, the injector is mounted just like a spark plug would be in a gas engine. But unlike fuel-injected gas engines that inject fuel at 10-60 psi, diesel fuel-injection systems run in the 10,000-30,000-psi range.

How much PSI does an injection pump have?

Because of the need for positive injection into a very high-pressure environment, the pump develops great pressure—typically 15,000 psi (100 MPa) or more on newer systems.

What causes diesel injector pump failure?

A major cause for fuel injection pump problems is the use of dirty fuel. Over time, residue builds up throughout your system. Using poor-quality fuel exacerbates this issue. Bring your vehicle in for auto repair if you notice sputtering or your vehicle hesitates when accelerating.

Why is my diesel not accelerating?

If your filter isn't letting enough fuel pass through, your engine isn't going to accelerate the way you need. Trouble starting your engine is another indicator that your fuel filter is clogged. If you've got a full tank of diesel and your engine won't start, there's a good chance your filter may need changing.

What causes a diesel engine to sputter?

One of the most common causes of a sputtering engine is an issue with the vehicle's fuel system—the filter, pump, and injectors. These three critical components work together to ensure fuel flows smoothly from the fuel tank to your engine's fuel injectors, and then pumps into the engine evenly.

What happen if injection pump would not time properly to the engine?

One of the most noticeable problems caused by faulty fuel injection pumps is that your engine is not running smoothly. When the fuel is not entering your engine properly, then it affects the performance of your car. This may not be noticeable at times.

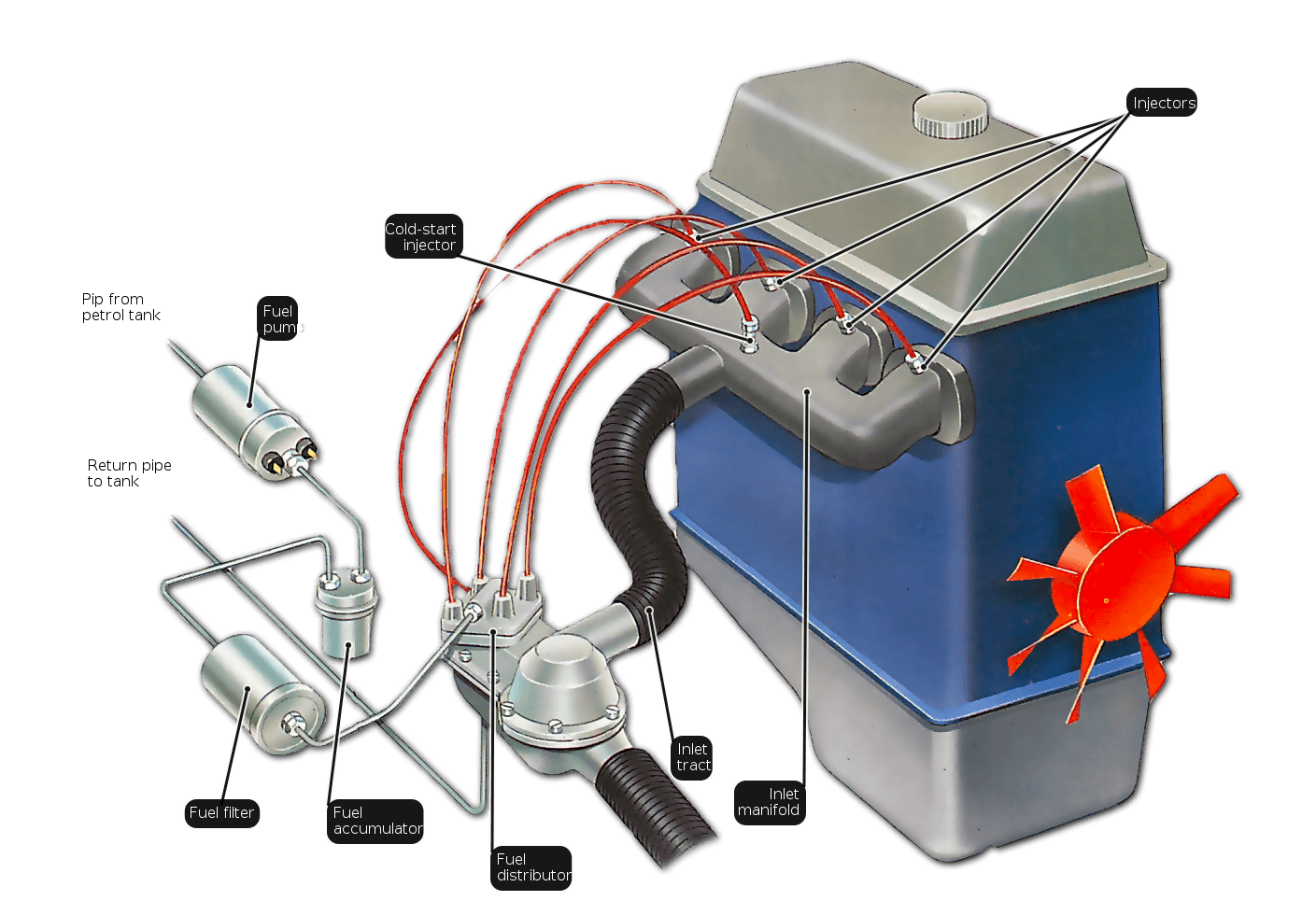

What is an injection pump?

Inline injection pump is a high pressure pump on a diesel engine that is used to increase diesel fuel pressure up to 18,000 PSI individually. That is, each injector will be served by a plunger unit. It can be said, in a 4 cylinder diesel engine there are 4 injectors and 4 plungers.

How does a pump camshaft work?

The pump camshaft is connected to the engine crankshaft, so that when the engine cranks automatically the pump camshaft rotates. This rotation will move the plunger, so that the plunger is pressed upwards and as a result the fuel that is already in the fuel barrel is pressed with high pressure and enters the injector.

How does a mini pump work?

Generally, there is a mini pump that is used to transfer fuel from the tank into the injection pump. This pump works mechanically, meaning it is driven by the crankshaft engine. So, to run the fuel flow we need to crank the engine.

What are the two types of injection pumps?

There are two types of injection pumps on conventional diesel engines, inline pump and distributor pump.

What happens when you press the plunger on a cam?

When the cam has finished pressing the plunger, the plunger returns to the bottom position. This will reopen the fuel barrel chamber, so that the fuel from the inlet feed filling the fuel barrel directly.

How many injectors are in a 4 cylinder engine?

It can be said, in a 4 cylinder diesel engine there are 4 injectors and 4 plungers. The main characteristic of the inline injection pump, lies in the configuration of each plunger. Each plunger is placed in line above a camshaft pump. That's where the name inline pump is taken.

How to adjust RPM on a diesel engine?

To adjust engine RPM on conventional diesel, it is done by adjusting the amount of fuel injected by the injector. In this case, the control is located in the fuel barrel. How much the amount of fuel in the fuel barrel when it is pressed will affect the engine RPM. it is the task of rack and pinion.

How does a fuel injection system work?

A fuel injection system must increase the pressure of the fuel to overcome compression pressure and to ensure proper dispersion of the fuel injected into the combustion space. Proper dispersion is essential if the fuel is to mix thoroughly with the air and burn efficiently.

What is diesel fuel injection?

The diesel fuel injection system is a major component of a properly operating engine. An engine out of adjustment can cause excessive exhaust smoke, poor fuel economy, heavy carbon buildup within the combustion chambers, and short engine life. The diesel engine is known as a CI (compression ignition) engine, while the gasoline engine is known as ...

Why is fuel injection delayed?

When the fuel is injected too early in the cycle, ignition may be delayed because the temperature of the air at this point is not high enough. An excessive delay, on the other hand, gives rough and noisy operation of the engine. It also permits some fuel to be lost due to the wetting of the cylinder walls and piston head.

How is diesel engine speed controlled?

Another difference is, the speed of a diesel engine is controlled by the amount of fuel injected into the cylinders. In a gasoline engine, the speed of the engine is primarily controlled by the amount of air admitted into the carburetor or fuel injection system. Diesel fuel is injected into the cylinder by a fuel injection system, ...

What is the compression ratio of a diesel engine?

Compression ratios in diesel engines can be up to 24:1. This high compression ratio causes increased cylinder pressures of 400 to 600 psi, this in turn increases the air temperature inside the cylinder to such a high degree that it ignites the atomized diesel fuel that is injected.

Why does high velocity occur when fuel enters combustion?

As the fuel enters the combustion space, high velocity is developed because the pressure in the cylinder is lower than the fuel pressure. The created friction, resulting from the fuel passing through the air at high velocity, causes the fuel to break up into small particles. 5. Creating pressure.

What is the high injection pressure needed in diesel fuel?

The high injection pressures needed in the diesel fuel system are attained with close tolerances in the pumps and injectors. These tolerances make it necessary for the diesel fuel to have sufficient lubrication qualities to prevent rapid wear or damage.

What is a good injector?

A good injector can withstand the pressure and temperature in the cylinder while delivering fuel efficiently. The diesel delivers as a fine mist that circulates in the engine cylinder for even distribution. Some engines use a pre-combustion chamber, special induction valves, and other devices to improve the ignition and combustion process.

What is the solenoid in a diesel engine?

An integral part of diesel fuel injectors is the solenoid, which opens to pass the vaporized fuel. The process is called pulse width, and each cylinder receives a different fuel amount as calculated by the ECU. The ECU also ensures the combustion process reaches an appropriate stoichiometric ratio, which is the proportion between air ...

What is the difference between a diesel engine and a gas engine?

Diesel engines use a fuel injector to deliver fuel to the cylinders. The injection process is different from gas engines, which uses a carburetor or a port injection system. While a carburetor mixes air and fuel before the former makes it to the cylinder, a port injection system mixes fuel before the intake stroke.

What is the most complicated component in a diesel engine?

Diesel engines use a direct injection system that inserts fuel directly into the motor cylinders. A diesel engine injector is the most complicated component and can be in different areas.

Why do engines use pre combustion chambers?

Some engines use a pre-combustion chamber, special induction valves, and other devices to improve the ignition and combustion process . The compression process is compromised when the diesel engine becomes cold since the air cannot reach a high enough temperature for the fuel ignition to occur.

How does a computer chip work?

The computers chips work with an elaborate number of sensors to measure ambient air temperature and delay engine timing in cold weather. This process allows the injector to dispense fuel when the weather is warmer, for more efficient compression.

What is the pump part of the ecosystem?

Part of this ecosystem is a small pump that forces air into the injector. The air ends up mingling with diesel, so the pump should be able to withstand increased amounts of pressure and high temperatures.