How does a dowel joint work?

- It requires lot more time to create Tenon and mortise joints.

- It involves the use of dowelling so for novices the arrangement could be hard.

- Face to face grain contact is absent, so joints tend to be weak.

- In the situation of no rights to use the drill press, it is tough to get right align.

What are the advantages and dissadvantages of a dowel joint?

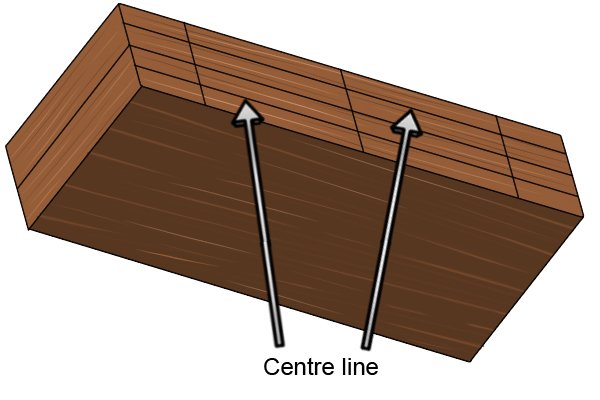

Mar 08, 2022 · A dowel joint, also known as doweling, is a form of connection used to link two pieces of wood together by drilling dowel holes in each component and attaching the pieces together with a wooden peg (the dowel).

What types of joint can you make with dowels?

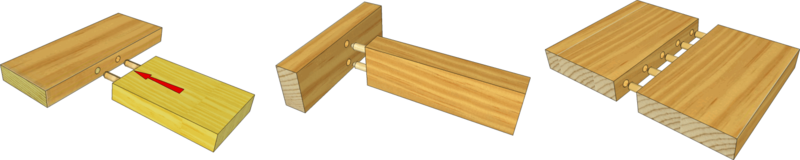

Oct 13, 2019 · T he principle behind doweling is simple: small round but evenly cut sticks of wood, called dowels, are inserted into perfectly matched holes in corresponding boards that, when glued in place, provide a strong, durable woodworking joint. Why are dowels fluted? Flutes. Most pre-cut dowels come with grooves cut along their length, known as flutes.

How to drill dowel holes without a jig?

Mar 29, 2020 · How do dowel joints work? Dowels are round wooden pins of small diameter used to strengthen (reinforce) a joint. They can be bought ready made and can be used instead of nails or screws, or instead of mortising, dovetailing, etc. They should be dipped in glue and driven at a tight fit into holes made for their reception. Click to see full answer.

How to thread a dowel?

How does a dowel joint work? It requires lot more time to create Tenon and mortise joints. It involves the use of dowelling so for novices the arrangement could be hard. Face to face grain contact is absent, so joints tend to be weak. In the situation of no …

How does a wood dowel work?

The principle behind doweling is simple: small round but evenly cut sticks of wood, called dowels, are inserted into perfectly matched holes in corresponding boards that, when glued in place, provide a strong, durable woodworking joint.Dec 10, 2019

How is a dowel joint assembled?

The dowel joint is assembled in the same way that you would screw a regular joint together only pieces of dowel are glued and inserted into holes instead of screws. By using pieces of dowel over screws the joint becomes much stronger and can be turned into an appealing feature.

What are the pros and cons of a dowel joint?

Dowel Joint Pros & ConsDowling is a quick process.It helps to ensure a neat finish.There is no need for screws, nails or other equipment.Dowel joints are the strongest type of joints when it comes to woodworking, especially when using multiple rows of dowels.More items...•Nov 28, 2018

How does a dowel joint make a wood joint stronger?

Because a dowel jig assists in machining evenly spaced holes that are square to the surface, and doesn't allow the drill bit to wander during drilling, they provide a snug fitting joint with a surprising amount of strength.

How do you separate dowel joints?

A dowel that's broken near the surface is tough to grip with pliers. So drive a small screw into the dowel, then pull it with a claw hammer. 5) Clean up the holes. After removing the dowel, take a twist drill the same diameter as the hole and turn it by hand to clean out any remaining glue or chips.Nov 2, 2016

How do you do dowel miter joints?

1:2810:47Dowel Key Miter Joints - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd what it is is basically you put your corner. Your your corner of your joint in like so and thenMoreAnd what it is is basically you put your corner. Your your corner of your joint in like so and then it gives you a bushing at a perfect 45 degree angle to drill a very precise.

Are dowel joints stronger than screws?

Dowel Strength Dowel joinery is stronger than screw joinery. The increased glue surface caused by the glue deeply penetrating the wood gives the dowel more holding power. The clamp and dry method used in dowel construction ensures that the joint is sufficiently set before the next step in building the item is taken.

How far in should a dowel go?

We recommend placing the first dowel at least 27 mm from the front and back. The distance between the pins is arbitrary. Remember that long distance between the pins usually means your joint won't be strong enough. We recommend creating a distance of 65-100 mm.

Which is stronger pocket screws or dowels?

The dowel joints were 1.5x stronger than the pocket hole joints. I could have made the dowel joints stronger by using four dowels instead of two....More videos on YouTube.Joint typeBreaking forcesAveragePocket hole95, 120, 75, 10599 poundsDowel160, 160, 149153 pounds3 more rows

How strong is dowel joint?

Test results show that dowels are the strongest method for cre ating this type of joint. The dowel joint in solid oak failed at an average of 650 pounds pressure, mortise and tenon joints failed at 500 pounds and biscuits failed at 325 pounds. Variations in the pressure at failure was less than 5 percent.Oct 28, 2021

Do dowel joints add strength?

Adding a dowel to this strong joint provides only a little (1 or 5 percent) extra tensile strength to the joint. Shortening the dowel's length in half would reduce the tensile strength provided by the dowel by about one-half.Jan 22, 2013

Should you glue dowels?

0:021:01Using Titebond with dowels for joinery - YouTubeYouTubeStart of suggested clipEnd of suggested clipDowels are an easy and convenient way to join wood. Together but there's a technique to adding theMoreDowels are an easy and convenient way to join wood. Together but there's a technique to adding the glue the first thing we want to do is add a little glue to the face of our joint.

What are dowels used for?

Dowels are tiny cylindrical bits that you can use to join two boards together. To make sure that dowel joints are sturdy and efficient, woodworkers use dowel jigs. The doweling jigs are designed to guide the drill bits to bore precise and accurate holes for the dowels’ insertion. At the start, it will be helpful to differentiate between ...

Why do you use a dowel jig?

The dowel jig allows you to make a strong joint in your woodworking projects. Of course, its use should be your primary option when joining blocks of wood because the result manifests a clean joint. Moreover, dowel joints formed using dowel jig are strong and sturdy.

How to drill holes in a dowel jig?

You should beforehand determine the size of the bits and the dowel jig. Once you got the right drill bit size , insert the drill bit into the guide bushing and drill the first hole. Then, repeat this process to drill the other spots. Afterward, repeat the drilling process on the other plank.

Doweling jigs help?

Using a doweling jig will help if you take the necessary precautions to ensure that you do your work safely. At the onset, ensure that you have carefully read the manual if it is your first time using the dowel jig. You can also follow the simple safety precautions:

What is a doweling jig?

The doweling jig, on the other hand, is the tool that guides the drill bits in drilling holes for the insertion of the dowels. The doweling jig feature a steel block that bears holes where you can fit the drill bits. Some dowel jig models come with holes designed for threading, which further expand the drill bit’s range.

What do you use for a 3/4" panel?

If you are going to use a 1/2-5/8″ board, you can use a 1/4″ dowel. For a 5/8″ to 3/4″ panel, you need to use a 5/16″ dowel, and for 3/4″ to 1 1/2″, you need to use a 3/8″ dowel.

What are side bolts on a dowel jig?

A cursory look at the dowel jig would reveal that it features side bolts. The side bolts are there to secure the jig in place and to make accurate measurements of the wood pieces. The side bolts consist of two screws that go through each side of the jig for accuracy and tightening purposes.

What is a dowel bar?

The dowel bars are small steel bars that are used to produce a mechanical connection between slabs without restricting horizontal joint movement and these bars are mainly used in the jointed plain concrete pavement to carry the additional stress and load included.

Why do we need dowel bars?

Dowel bars are used to transfer the load from one slab to its adjacent slab and two consecutive slabs move together which reduces the impact loading developed by the slab. These bars are used to reduce corner cracking and joint faulting. These bars are used to improve the performance of pavement joints.

How long is a dowel bar?

On the thickness of the pavement the size of dowel bar depends and mostly dowel bars are 18 inches long, 1.25 to 1.5 inch in diameter, and spaced 12 inches. The dowel bars are either stainless steel or epoxy coated to protect the bars from corrosion.