What does a water transfer pump do?

Water transfer pumps create a difference in pressure, which moves fluid from one location to another. They are used for emptying waterbeds, draining water he... Water transfer pumps create a difference in pressure, which moves fluid from one location to another. They are used for emptying waterbeds, draining water he...

How do pumps work?

Pumps are all around us, let us take a look at how they work! A pump is a device for moving fluids from one place to another, or for pressurizing gases. Fluids tend to flow from an an area of higher pressure to an area of lower pressure. Most simple pumps make use of a moving piston and one way valves.

What is the difference between a transfer pump and hose?

Despite their differences, most transfer pumps operate in a broadly similar way, by creating a difference in pressure that pushes the water from the inlet to the outlet. Typically, a standard garden hose can be hooked up to either side (if not, use lengths of plastic tubing of the type you can find at any home center).

How does a pressure washer pump work?

As the contact lines pass the inlet port, liquid is pulled into the cavities between the disc and plates. The fluid, then, is swept through the pump to the discharge port (much as a squeegee wipes water from a window) where it is released under pressure. A so-called bridge separates inlet flow from outlet flow.

What is a fluid transfer pump?

Fluid transfer pump systems are used in processing, water purification and desalination, or liquid handling applications. Some products are used in heat transfer applications or fluid flow and heat transfer applications. Others are designed to transport a heat transfer fluid or coolant.

What are the three requirements of a pump to transfer fluid?

The first step in selecting a centrifugal pump is to determine application requirements: quantity of flow, pressure rise (or change in head) in ft of fluid, and other conditions such as high fluid viscosity or temperature.

What is the difference between a transfer pump and a pressure pump?

A transfer pump is only used when moving water from one place to another; for instance, from a water tank to a garden pond. It has high flow and low pressure. Firefighting pumps are used mostly in rural areas with farms and large open bush land. They are either petrol or diesel motors, depending on the application.

What are 3 types of fluid pumps?

There are three basic types of pumps: positive-displacement, centrifugal and axial-flow pumps. In centrifugal pumps the direction of flow of the fluid changes by ninety degrees as it flows over an impeller, while in axial flow pumps the direction of flow is unchanged.

What are the 2 types of pumps?

Pumps are divided into 2 major categories: Dynamic and Positive Displacement (aka Displacement).

How does a pump increase pressure?

Centrifugal pumps increase the pressure of the liquid by using rotating blades to increase the velocity of a liquid and then reduce the velocity of the liquid in the volute. A good analogy to this procedure is a football (soccer) game.

How long can you run a transfer pump?

Milwaukee M18 Transfer Pump Features It moves up to an astonishing 480 gallons per hour. The 18v REDLITHIUM battery delivers up to 240 gallons on one charge. Doing the math, that means it can run for 30 minutes straight. You can now see why a professional might carry 2 or 3 batteries on his/her person.

How do you prime a transfer pump?

0:001:15How-To: Prime Your Water Pump - YouTubeYouTubeStart of suggested clipEnd of suggested clipPossible. First remove the priming plug and fill the pump body with water until it's completely fullMorePossible. First remove the priming plug and fill the pump body with water until it's completely full and water spills out of the outlet. Flange.

Can transfer pumps be used for dirty water?

Transfer pumps or Fire Fighting Pumps are fine for clear water. If it contains debris or solids, you'll need a trash pump; these are quite common on construction sites. For sewage water or thick sludge you may need a diaphragm pump.

What is difference between pump and centrifugal pump?

Positive displacement pumps draw fluid into a cavity, or displace the fluid, and then force the fluid out of the cavity through suction. Centrifugal, or aerodynamic, pumps have a spinning impeller that draws the fluid into the pump and forces it out of the outlet point at an increased velocity.

Which pump is more efficient?

Where different pump designs could be used, the centrifugal pump is generally the most economical followed by rotary and reciprocating pumps. Although, positive displacement pumps are generally more efficient than centrifugal pumps, the benefit of higher efficiency tends to be offset by increased maintenance costs.

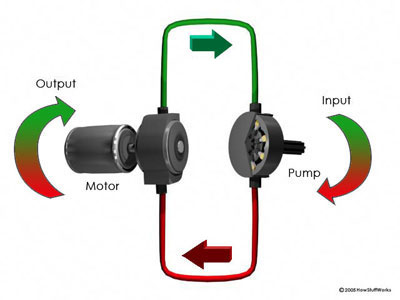

What is the difference between hydraulic motor and pump?

A hydraulic motor is a machine that uses hydraulic pressure to generate mechanical power. A hydraulic pump is a device that extracts energy from the hydraulic pressure to generate mechanical work.

What is the difference between a transfer pump and a water pump?

0:001:22What are Transfer Pumps? - YouTubeYouTubeStart of suggested clipEnd of suggested clipPut simply transfer pumps work by creating pressure that pushes water from the inlet to the outlet.MorePut simply transfer pumps work by creating pressure that pushes water from the inlet to the outlet. In most cases a standard garden hose can be attached to either side of the pump.

How do I choose a liquid transfer pump for my needs?

Factors To Consider When Choosing A Liquid Transfer PumpFactors To Consider When Choosing A Liquid Transfer Pump.Flow Rate.Operating Temperature.Vapor Pressure.Fluid.Maximum Head.Size Of The Inlet Valve.Conclusion.

Can you use a transfer pump as a pressure washer?

0:092:01Boost pressure to clean with a PC4 Transfer pump - YouTubeYouTubeStart of suggested clipEnd of suggested clipKevon another opportunity to use your transfer pump is to actually boost pressure to clean the toolsMoreKevon another opportunity to use your transfer pump is to actually boost pressure to clean the tools that you use every day such as your bikes or your farm equipment.

What does a drill pump do?

0:151:26Need to Know How a Drill Pump Works? Watch this Video - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe drill so that turns impeller. And pumps that water through this is ideal to be decanting waterMoreThe drill so that turns impeller. And pumps that water through this is ideal to be decanting water out of one container or catchment area through to another area.

what is a fuel transfer pump?

The purpose of a fuel transfer pump is to move fuel from one position to another or from a fuel container to an automobile. Fuel transfer pumps are...

How does a diesel lift pump work?

In short, a lift pump is a fuel supply pump that can deliver fuel from the fuel tank to the injection system of the engine. Like General Motors' Du...

What is the use of a Transfer Pump?

Transfer pumps can transfer all types of fluids from one position to another, e.g., from pipelines to large tanks. When you want to transfer the li...

Can we use a diesel transfer pump for the petrol engine?

The answer is yes; diesel is most likely much safer than gasoline because of its flash point and volatility.

What is the use of a Transfer Pump?

Transfer pumps can transfer all types of fluids from one position to another, e.g., from pipelines to large tanks. When you want to transfer the liquid, a transfer pump comes into use.

What is the flow rate of a fuel transfer pump?

Mostly these pumps have a 1″ or 3/4″ release hose. Most of these supply pumps have a flow rate of 10 to 30 GPM. They are ideal for transferring fuel from one location to another.

How to choose a Diesel Transfer pump?

The fuel transfer pump has several types in the marketplace. Most of them are flexible and have different functions for different applications. There are many factors to consider when selecting a transfer pump. These factors are given below:

How does a diesel lift pump work?

In short, a lift pump is a fuel supply pump that can deliver fuel from the fuel tank to the injection system of the engine. Like General Motors’ Duramax, Smooth engines use a factory lift pump assembled into the engine’s high-pressure CP3 pump to pump fuel from the fuel container.

What is a gear pump?

It is also known as a positive displacement pump . Gear pumps use a gear grid to pump fluid through displacement. This is one of the most famous type of pump used in hydraulic applications. These pumps can move fuel from fuel tanks to generators, boiler feedwater pumps, and filter polishing systems. Common brands are Tuthill, Blackmer, and Viking. Gear pump has exceptional suction features of up to 20 vertical feet. These have high-pressure output capacities of up to hundreds of PSI and very low to high flow rates of 0.25 to hundreds of GPM. The characteristics of the suction channel can make it difficult to maintain starting and priming problems.

What is centrifugal pump?

The centrifugal pump directs the fuel flow between the automobiles in the suction state to the bulk material container. Gorman Rupp and Gould are Common brands of these pumps. These pumps offer high flow rates at a relatively low price.

What is a siphon pump?

Siphon pump: It can transfer or diesel from tall containers into short containers by gravity. The user can first manually inject a small amount of fuel to fill it with oil. The best type of pump depends on many factors, such as the type of fuel to be pumped and the container to be pumped back and forth.

How does a transfer pump work?

Despite their differences, most transfer pumps operate in a broadly similar way, by creating a difference in pressure that pushes the water from the inlet to the outlet. Typically, a standard garden hose can be hooked up to either side (if not, use lengths of plastic tubing of the type you can find at any home center).

How to choose a transfer pump?

When choosing among the many transfer pumps on the market, base your selection on how you plan to use the equipment. If you need to shift volumes of water only between locations that are for the most part dry, then opt for a standard, non-submersible model. If your needs are more demanding—if, for example, your goal is to pump water out of a pond or hot tub—then go for a submersible model, one whose motor sits within a special watertight housing. Also, be sure to consider the fact that transfer pumps range widely in terms of overall capacity. The pumping power of any given model is influenced by two key measurements—the horsepower generated by its motor and the amount of water the pump can move (measured in gallons per hour). Generally, you need to pay more for more power.

Why use a transfer pump for a water heater?

If, for instance, you wanted to empty out your water heater for maintenance or repair purposes, a transfer pump would enable you to get the job done effectively and with minimal mess. Likewise, if your swimming pool cover had begun to sag under the weight of an oversize puddle, you could use a transfer pump to relocate the water to ...

What is a sump pump?

Sump pumps go a long way toward preventing basement floods, but for a versatile, all-purpose weapon in the war against moisture, you may want to consider arming yourself with a transfer pump. Also sometimes known as utility pumps, transfer pumps perform one simple but critical function: They move water from one place to another.

How does a fuel pump work?

A mechanical fuel pump drives through a camshaft or a special shaft that drives by a crankshaft. When the shaft rotates, the cam goes under the pivot level and pushes the shaft up at one end.

How does a pump pull fuel?

As the lever forces the diaphragm downward, a suction force is created that pulls fuel inside the pump by a check valve along the fuel pipeline. When the rotating cam continues to rotate and no longer pushes the lever, the return spring moves the lever back and releases its tension on the diaphragm.

How Much Does Fuel Pump Replacement Cost?

The average cost for the replacement of a fuel pump is from $200 to $1160. The cost of the parts varies from $95 to $854. If you are not replacing your vehicle pump yourself and hire labor for it, the labor cost varies from $120 to $260.

What is the difference between a carburetor and an injector?

Carbureted engine generally use s a low-pressure mechanical pump located outside of the fuel tank, while a fuel injector engine generally uses an electric fuel pump. Electric fuel pumps use in engines that are equipped with a fuel injector to transfer fuel from the fuel tank to the fuel injector. According to the use, these pumps must supply fuel ...

What is a fuel pump?

A fuel pump is a part of an automobile that supplies fuel from a fuel container to the carburetor of an IC engine. A fuel pump is an important part of the IC (Internal Combustion) engine. This is because the fuel supply is important to keep the engine running. Whether you’re trying to breathe new life into a large piece ...

Why do you put an electric fuel pump in a fuel chamber?

One more advantage of placing the electric fuel transfer pumps inside the fuel chamber is that it is less prone to fire. Electric parts (like fuel pumps) generate sparks and ignite fuel vapors, but liquid fuel does not detonate. For that reason, immersing the pump in a fuel chamber is one of the most important places.

Why is it important to change the pump in the fuel chamber?

Changing the mechanical pump with an electric fuel pump can reduce the stress on the engine parts and reduce the fuel consumption of the engine.

How does a pump work?

When drive air is initially introduced to the pump, the pump will cycle at maximum speed, providing maximum flow and also functioning as a transfer pump by filling the test piece or actuator with liquid . The pump will then begin to cycle at a slower rate as the outlet pressure rises and offers more resistance to the reciprocating differential piston assembly. The piston assembly then stalls when the forces balance, i.e. when air drive pressure x air drive piston area = outlet (stall) pressure x driven hydraulic plunger area.

How does an air driven pump work?

Air driven liquid pumps work on a standard reciprocating differential area principle utilizing a large air drive piston connected to a smaller hydraulic piston/plunger to convert compressed air power into hydraulic power. The nominal ratio between the area of the hydraulic plunger and the air drive piston is shown by the dash number in the model description and estimates the maximum pressure the pump is able to generate. The actual ratio can be higher than the nominal so the pump will still cycle when the ratio of the output hydraulic pressure to the air drive pressure equals the nominal ratio. Consult technical information chart in the catalog for actual pressure ratios. Example: an S35 has an actual ratio of 1:39.

What is the purpose of a hydraulic piston?

Its purpose is to pull liquid into the hydraulic body through the inlet check valve and push it out through the outlet check valve at an elevated pressure.

Why is the hydraulic pressure drop on an air pump low?

The hydraulic pressure drop (hysteresis) needed to cause the air driven pump to restart is very low due to little frictional resistance from the large diameter air drive piston seal and hydraulic seal. This can be as low as two times the pump’s ratio under certain conditions.

What is the purpose of a check valve in a pump?

These check valves are spring loaded and direct the passage of liquid through the pump. During the suction stroke of the hydraulic piston/plunger, the inlet check valve opens to its maximum. The liquid is pulled into the pump while the outlet check valve is held shut by a spring and differential pressure. On the pressure stroke, the inlet check valve is closed as the hydraulic piston/plunger moves the liquid out through the outlet check valve.

How does an air piston work?

This section is comprised of an unbalanced, pilot operated, lightweight spool which moves the compressed air to either side of the air piston, depending on position. The air piston moves pilot valves at the end of each stroke, alternately pressurizing and venting the large area of the spool, allowing it to control the air flow to the air piston, providing automatic cycling. The main drive air is vented through an exhaust muffler. On the larger pumps, an unregulated pilot air port is used to overcome friction and differential pressures which enables excellent pressure control. This is also an ideal place to use any pump control devices.

How high should a pump be above the fluid level?

The maximum recommended height of a pump above the fluid level is 10 ft. for LO and L pumps, 7 ft. for S pumps and 3 ft. for PPO and PP pumps.

How does a mechanical pump work?

In mechanical pumps such as the one above, heat builds up from internal friction, which warms the air as it is drawn into the pump. Warm air increases in volume and is not compressed as easily.

Why do pumps move liquids around?

Because gases are compressible, pumps can actually force more and more of a gas into a closed space, increasing the pressure of the gas. Lesson. Quiz.

How to operate a pump?

To efficiently operate this simple pump, it is imperative to pull the piston all of the way to the top of the cylinder on the upward stroke, and press the piston completely to the bottom of the cylinder on the downward stroke. Failure to do so will result in inefficient movement of air by the pump. Failure to compress the piston completely against the bottom of the cylinder will result in some air remaining in the bottom portion of the cylinder. During the following upward stroke less pressure difference between the top and the bottom of the cylinder will limit the quantity of air transferred to the bottom of the cylinder. This will leave some pressurized air in the top of the cylinder, and will draw less air in through the top one way valve during the next downward stroke. So, an incomplete upward or downward stroke will limit the quantity of air moved by the pump.

How does a bicycle pump work?

It is composed of a piston which is a one way valve sealed inside a cylinder equipped with two, one way valves. The one way valve on top allows air to enter the cylinder when the piston is moved down by the attached rod. The piston seals against the cylinder acting as a one way valve and and presses down on the air below it. This downward movement causes two things to happen: the piston is forced down by the attached rod, and air is forced out of the bottom of the pump under pressure. At the same time, air rushes into the top part of the pump to fill the area of lower pressure created by increased volume. When this happens, both one way valves are open allowing air to move.

What is a pump?

Pump Basics. A pump is a device for moving fluids from one place to another, or for pressurizing gases. Fluids tend to flow from an an area of higher pressure to an area of lower pressure. Most simple pumps make use of a moving piston and one way valves. One way valves allow the fluid —which is anything that can flow be it gas or liquid— ...

How does pressure change affect pump efficiency?

In piston pumps, incomplete up or down strokes of the piston will decrease the air movement. The intake of cool air increases pump efficiency.

What happens when a piston is pulled up?

As the piston is pulled up, the portion of air in the cylinder above the piston is squeezed into a smaller volume and is pressurized. At the same time, the portion of the cylinder below the piston increases in volume effectively decreasing the pressure.