How does a governor work on Air Brakes

Air brake

An air brake or, more formally, a compressed air brake system, is a type of friction brake for vehicles in which compressed air pressing on a piston is used to apply the pressure to the brake pad needed to stop the vehicle.

How does a 120 psi air brake Governor work?

Apr 03, 2022 · On an air brake equipped vehicle, the compressor pumps air the entire time the motor is running. The governor controls the compressor. The governor puts the compressor into the load (cut-in) and unload (cut-out) phase. It’s like a thermostat on a furnace. The governor controls when the air compressor will pump air into the air storage tanks.

What does the Governor do on an air compressor?

How does a governor work on Air Brakes? On an air brake equipped vehicle, the compressor pumps air the entire time the motor is running. The governor controls the compressor. The governor puts the compressor into the load (cut-in) and unload (cut-out) phase. It's like a thermostat on a furnace.

What is an air pressure Governor on a car?

The governor controls when the air compressor will pump air into the air storage tanks. When air tank pressure rises to the "cut-out" level (around 125 pounds per-square-inch or "psi"), the governor stops the compressor from pumping air.

How does an air brake system work on a tractor?

Jun 01, 2010 · An explanation of how an air governor works in the truck air brake system. Created by the School of Motive Power Technology at Fanshawe College, and the LO S...

How do you test the air compressor governor?

3:147:20How to Test The Governor for Air Brakes Course - YouTubeYouTubeStart of suggested clipEnd of suggested clipThrottle up a little bit and watch the needles climb if the needles are climbing you know that theMoreThrottle up a little bit and watch the needles climb if the needles are climbing you know that the governor has put the compressor back into the load phase.

How do you adjust the governor on an air brake system?

0:251:31How To Adjust D2 Governer Valve - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe turns as you adjust it screw it out any clockwise to raise the cutout pressure screw. It inMoreThe turns as you adjust it screw it out any clockwise to raise the cutout pressure screw. It in clockwise to lower the cutout pressure be sure to tighten the locknut pump.

What is a brake governor?

The governor controls the compressor. It puts it into the load phase the unload phase or cut-in cut-out, as it's called in Ontario and other jurisdictions.

When should the air governor cut-out the air compressor?

Cut-out Pressures. compressor should start at about 100 psi and stop at about 125 psi. (Check manufacturer's specifications.) Run the engine at a fast idle. The air governor should cut-out the air compressor at about the manufacturer's specified pressure.

How do you plumb an air Governor?

0:442:54D-2 Governor Installation - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd then mount your gasket. And then bolt it to your air compressor. And what that does is it doesn'MoreAnd then mount your gasket. And then bolt it to your air compressor. And what that does is it doesn't allow the air to flow through your governor. And unload your compressor.

Where is the air Governor located?

The governor is usually attached directly to the compressor. The inlet port connects the governor to the air reservoir it regulates. As the air pressure in the reservoir increases, the piston and inlet/exhaust valve shifts up against the resistance of the pressure setting spring.

What does an air governor do?

Explanation In an air brake system, the air compressor governor controls when the air compressor pumps air into the storage tanks. It stops pumping if the pressure in the tanks becomes too high, and begins pumping if the pressure becomes too low.

How should you check if your service brakes are working properly?

To test service brakes, you should brake firmly while moving slowly forward. The brakes are O.K. if you notice: a. The vehicle pulls to one side b.

How can you manually check the slack adjusters?

With service brakes in the released position, mark the push rod even with the brake chamber. Make a full brake application and mark the push rod again. Measure between the two marks to determine the length of push-rod travel (stroke).

At what psi do air brakes lock up?

If the pressure in the air system pulls below 60 psi, the parking brake knob will pop out and set the parking brakes. This is a safety feature so the truck will stop, because if the pressure falls too low, the service brakes will not work. The other system component stops the vehicle when you push on the brake pedal.

What are the maximum leakage rates for air brakes?

What are the maximum leakage rates? Less than four psi in one minute for single vehicles and less than eight psi in one minute for combination vehicles. Less than two psi in one minute for single vehicles and less than three psi in one minute for combination vehicles.

What activates the stop switch?

The stop light switch (Fig. 22) is an air-signaled electrical switch which is turned on any time a brake application is made. The switch is usually connected to a double check valve and can be plumbed anywhere in the application side of the circuit.

What does the governor do on an air compressor?

The governor controls when the air compressor will pump air into the air storage tanks. When air tank pressure rises to the "cut-out" level (around 125 pounds per-square-inch or "psi"), the governor stops the compressor from pumping air. When the tank pressure falls to the "cut-in" pressure (around 100psi), the governor allows the compressor to start pumping again.

Why do air brakes have an evaporator?

This helps to reduce the risk of ice in air brake valves and other parts during cold weather. Ice inside the system can make the brakes stop working.

What does increased brake pressure mean?

This gauge shows how much air pressure you are applying to the brakes. (This gauge is not on all vehicles.) Increasing application pressure to hold the same speed means the brakes are fading. You should slow down and use a lower gear. The need for increased pressure can also be caused by brakes out of adjustment, air leaks, or mechanical problems.

What gauge do you use for air brakes?

All vehicles with air brakes have a pressure gauge connected to the air tank. If the vehicle has a dual air brake system, there will be a gauge for each half of the system. (Or a single gauge with two needles.) Dual systems will be discussed later. These gauges tell you how much pressure is in the air tanks.

How to put on brakes?

You put on the brakes by pushing down the brake pedal. (It is also called the foot valve or treadle valve.) Pushing the pedal down harder applies more air pressure. Letting up on the brake pedal reduces the air pressure and releases the brakes. Releasing the brakes lets some compressed air go out of the system, so the air pressure in the tanks is reduced. It must be made up by the air compressor. Pressing and releasing the pedal unnecessarily can let air out faster than the compressor can replace it. If the pressure gets too low, the brakes won't work.

What to do if your air pressure is low?

If the low air pressure warning comes on, stop and safely park your vehicle as soon as possible. There might be an air leak in the system. Controlled braking is possible only while enough air remains in the air tanks. The spring brakes will come on when the air pressure drops into the range of 20 to 45 psi. A heavily loaded vehicle will take a long distance to stop because the spring brakes do not work on all axles. Lightly loaded vehicles or vehicles on slippery roads may skid out of control when the spring brakes come on. It is much safer to stop while there is enough air in the tanks to use the foot brakes.

How do brakes work?

Applying: As the brakes are applied, air pressure decreases. As the amount of air decreases, the valve allows air back into the reservoir tanks, while the brakes move to the applied position.

How does a triple valve brake system work?

Instead of using force or directed air to apply the brakes much like hydraulic fluid in our cars, the triple-valve system fills a supply tank and uses air pressure to release the brakes. In other words, the brakes in a triple-valve system remain fully engaged until air is pumped throughout the system.

What happens when you depress the brake pedal?

As soon as you depress the brake pedal, the air pressure decreases, turning the s-cam and spreading the brake shoes against the drum.

How does fluid get into a brake rotor?

When you push the brake pedal, fluid is pumped through brake hoses or lines into pistons mounted on each wheel. These brake pistons either push against two brake shoes, which expand and cause friction inside a brake drum, or against a brake pad, which clamps down on a brake rotor.

What would happen if a locomotive's brake system suddenly busted?

A speeding locomotive that relied on hydraulic brakes would turn into a deadly steel bullet if the brake system suddenly busted a leak. Before air brakes, trains used a primitive brake system that required an operator, or brakeman, in each car to apply a hand brake at the signal of the train director or engineer.

What happened to the Mack truck?

On April 25, 1996, a 1988 Mack cement truck collided with a small Subaru sedan in Plymouth Meeting, Pa. As the driver of the cement truck approached an intersection at the end of a downhill off ramp, his brakes failed and the truck barreled into the intersection, striking the Subaru and killing its driver. The National Transportation Safety Board investigated the incident and found several problems with the truck, notably reversed brake lines and a secondary system failure. Those two issues left the truck with only an estimated 17 percent to 21 percent of its total braking capability. Unfortunately, the driver had no idea he had a brake failure. Poor maintenance resulted in a senseless death that could have been avoided. [source: NTSB]

How do you activate emergency brakes?

Emergency air brakes complement standard air-brake systems and can be activated by pulling a button on the dash (near the one with the light that we saw in the introduction). Before you can drive a vehicle with air brakes, you must push in the emergency brake button to fill the system with air.

What does the governor do in an air compressor?

The governor controls when the air compressor will pump air into the air storage tanks. When air tank pressure rises to the "cut-out" level (around 125 pounds per-square-inch or "psi"), the governor stops the compressor from pumping air. Click to see full answer.

What is governor cut out?

Governor cut-out occurs when the needle stops rising. The air compressor should cut-out not higher than 140 psi (max). For testing purposes, you must identify the pressure at which governor cut-out occurred and verbalize the maximum pressure (cut-out) at which this can occur.

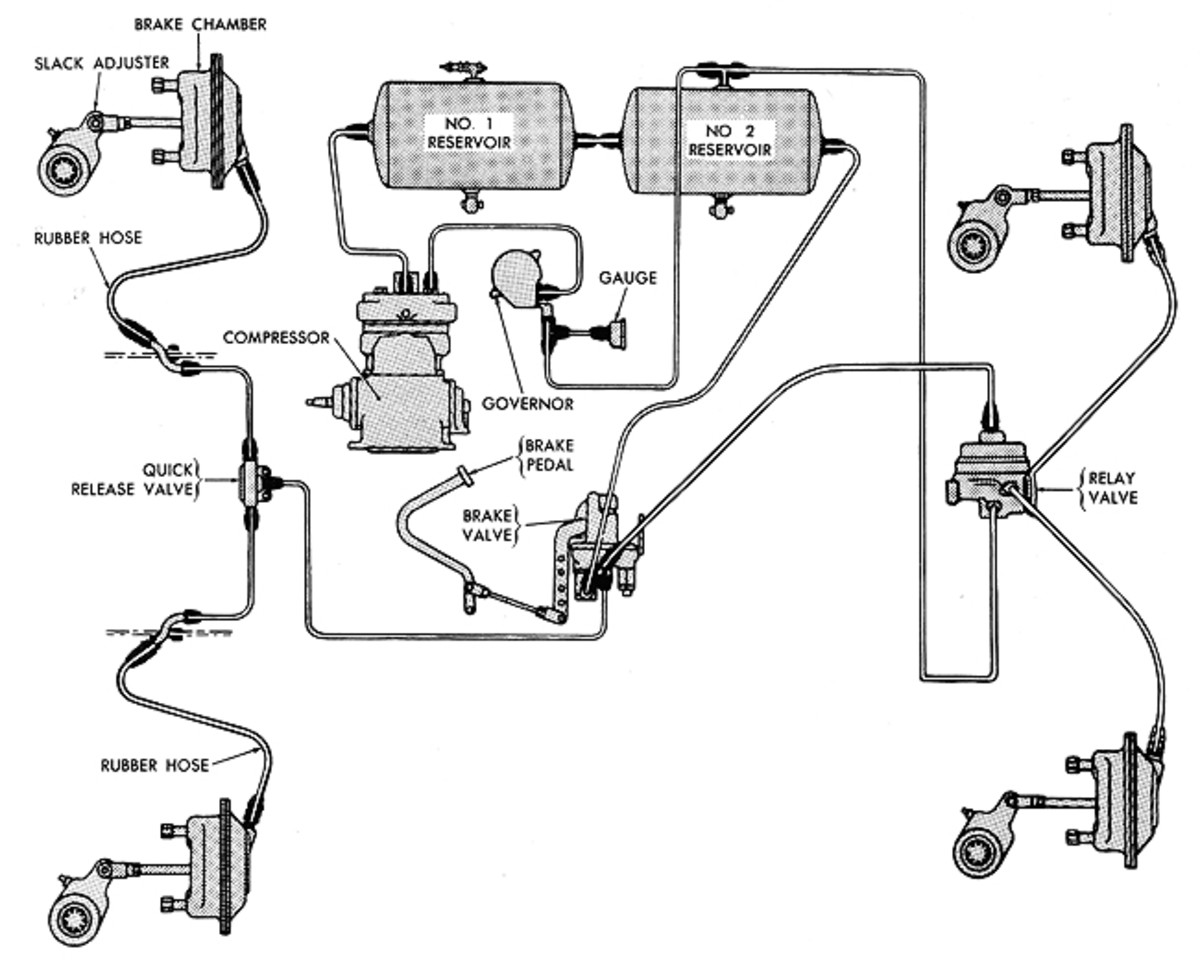

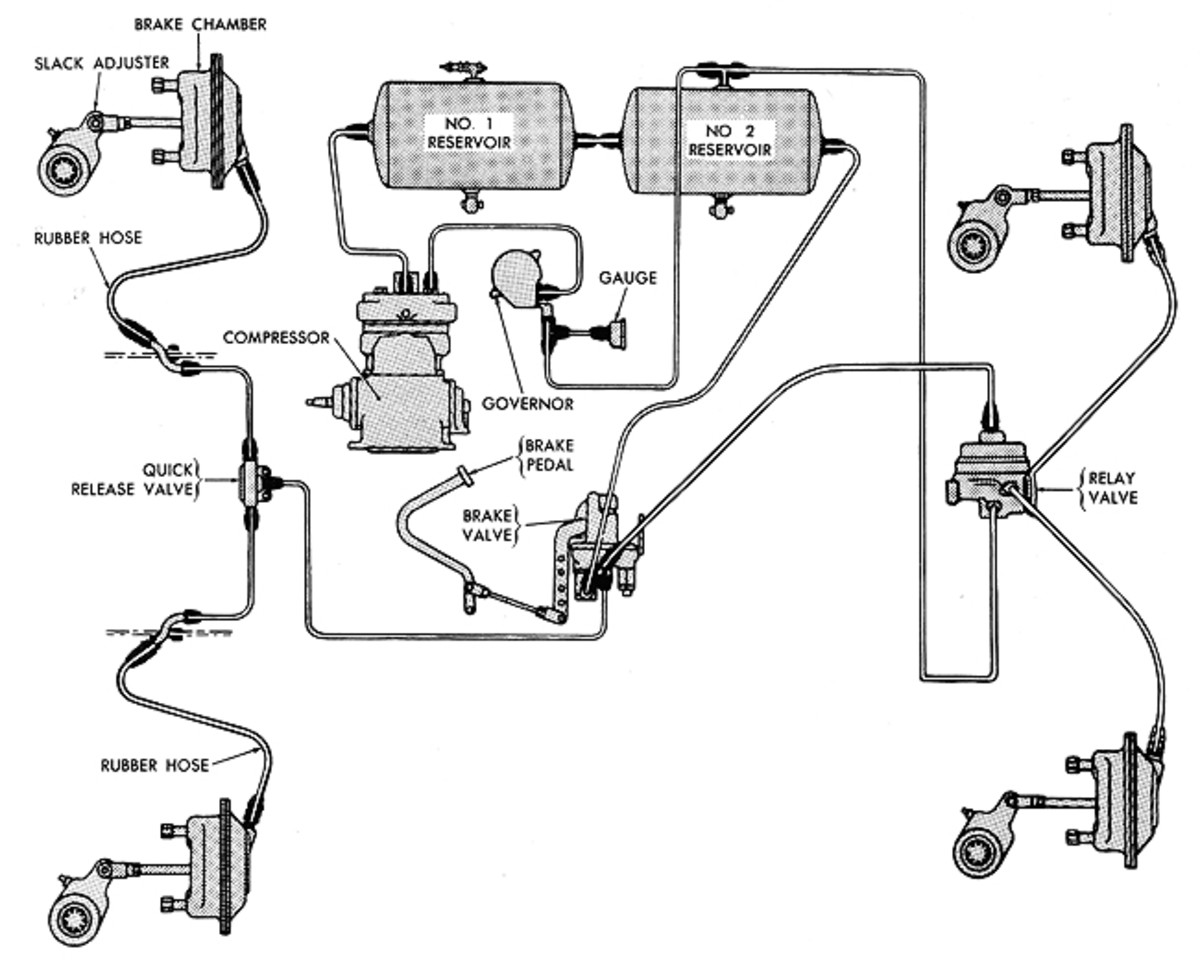

How is air pressure sent to the brakes?

Air pressure is sent from the air tanks to the brakes by relay valves. The pressure in the service line tells how much pressure the relay valves should send to the trailer brakes. The pressure in the service line is controlled by the brake pedal and the trailer hand brake.

What are air brakes?

AIR BRAKES:#N#Air brakes are used in trucks, buses, trailers and semi-trailers. This is the preferred type of braking system for these vehicles for several reasons. First, the use of air allows multiple vehicle units to be coupled so that all units have braking capability and so that all of those units' brakes may be controlled from the cab. Coupling would be infeasible if a liquid were used as the mode of transmission of force, as it is in hydraulic brakes. In addition, the use of an air brake system allows for the incorporation of an emergency braking system that utilizes parts of the service brake and parking brake systems. Emergency braking systems are required on all semi-trailers by CFR 49 393.43, as it states "Every motor vehicle, if used to tow a trailer equipped with brakes, shall be equipped with a means for providing that in the case of a breakaway of the trailer, the service brakes on the towing vehicle will be capable of stopping the towing vehicle."#N#Air brake systems are three braking systems combined: 1 The service brake system applies and releases the brakes when one uses the brake pedal during normal driving. 2 The parking brake system applies and releases the parking brakes when one uses the parking brake control. 3 The emergency brake system uses parts of the service and parking brake systems to stop the vehicle in the event of a brake system failure.

Why is the hand valve on a trailer not used?

The trailer hand valve is used only to test the trailer brakes. It is not used in driving because of the danger of making the trailer skid. The foot brake sends air to all of the brakes on the vehicle including the trailers. There is much less danger of causing a skid or jackknife when using just the foot brake.

What is the power screw on a disc brake?

But instead of the S-cam, a "power screw" is used. The pressure of the brake chamber on the slack adjuster turns the power screw.

What is the purpose of a parking brake system?

The parking brake system applies and releases the parking brakes when one uses the parking brake control. The emergency brake system uses parts of the service and parking brake systems to stop the vehicle in the event of a brake system failure. The air brake system:

Why do air brakes need a dryer?

An air dryer is used to take the moisture out of the air, so that water condensation will not build up in the air storage tanks and cause the brakes to fail, such as when the water freezes in the winter. Air Storage and Drain Tanks:

Why do air brakes have an evaporator?

Some air brake systems have an alcohol evaporator to put alcohol into the air system. This helps to reduce the risk of ice in air brake storage tanks, valves, and other parts during cold weather. Ice inside the system can cause brake failure.