What is hydrostatic testing?

Why is hydrostatic testing important?

How do I avoid disasters with hydrostatic testing?

What is the weight of a vehicle that is required for hydrostatic testing?

What is the name of the fluid that is used to make hydraulic fluid?

How does a leaky faucet work?

See 1 more

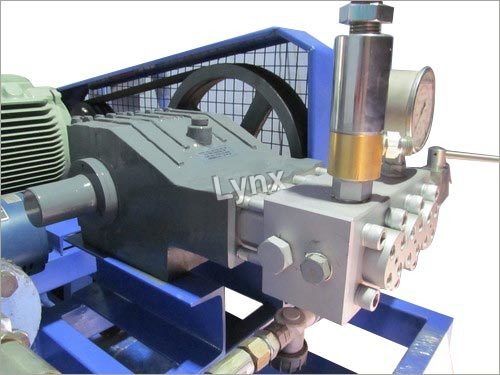

What is hydrotest pump?

Hydro test pumps are common procedure used to check fluid pressure vessel, such as, cylinders, boiler, tubes pipe, valves, castings, components etc.. Hydro testing is also a common testing procedure to verify pressure vessels do not leak or have manufacturing flaws.

What is the procedure of hydro test?

A vessel is completely filled with water and is then loaded it into a sealed chamber called a test jacket, also filled with water. The vessel is then pressurized inside the test jacket for a certain amount of time. Once the vessel expands, water gets forced out into a glass tube used to measure the total expansion.

How much pressure should a hydro test have?

The hydrotest pressure is set by code, namely, ASME III and ASME B31. 1. For ASME III piping and tubing systems the hydrostatic test pressure is often 1.25 × Pdesign to which are typically added a 6% code margin and a 75 psi test margin.

Which type of pump should be used for hydrostatic testing?

High-pressure positive displacement pumps are the best choice for hydrostatic testing. With positive-displacement pumps, flow is constant regardless of system pressure, which means high-pressure can be achieved and maintained in a system. This pump characteristic is important for hydrostatic testing.

Which water is used for Hydrotest?

potable waterHydrostatic pressure tests of equipment having components of Type 300 series stainless steel should be conducted with potable water or steam condensate having a chloride concentration of less than 50 ppm.

How long does a Hydrotest last?

Duration of the test is two hours. Special consideration must also be given when multiple piping products are used."

Why is hydro test pressure 1.5 times?

Safety. To ensure that that the boiler components can withhold more pressure than the working pressure. To ensure that even if there is an accidental increase in pressure, the boiler and its components are safe. Even after some years of service, after repair, the hydro test is repeated to ensure safety.

What is the most serious hazard about a hydro test?

The main risk associated with the hydro test, is the rupture of a high-pressure hose, due to deterioration or failure to inspect and connect properly them. There may be a loss of integrity of fittings resulting in damage to people or equipment this is due to flying of accessories used in the test.

What is the difference between hydrotest and pressure test?

A hydrostatic test is performed by using water as the test medium, whereas a pneumatic test uses air, nitrogen, or any non-flammable and non- toxic gas. At SLAC pressure tests must be hydrostatic unless pneumatic tests can be justified.

What is the difference between Hydrotest and hydrostatic test?

Hydrotesting is another pressure testing option where a liquid (usually water) is injected into a pipe system to check for structural flaws permitting leakage. Hydrostatic testing allows the detection of leaks that only become obvious at elevated operating pressures.

What kind of oil goes in a hydrostatic?

The fluid recommended for Hydro-Gear transmissions and pumps is a 20W-50 motor oil or 15W-50 synthetic motor oil.

Can a hydrostatic pressure test damage pipes?

However, hydrostatic testing has been used by the underslab plumbing industry since the 1970s. So how, if the tests themselves cause damage, are they still being used to test anyone's sewer pipes? The short answer. Because these tests do not cause damage.

How much does Hydro testing cost?

The cost of hydrostatic testing usually depends on the extent of the plumbing system being inspected. Most hydrostatic tests cost between $250 to $500. Bigger plumbing systems can cost thousands of dollars to be inspected.

What is hydro test and why it is required?

A hydrostatic test is a pressure test in which the pipe or other component is pressurized to evaluate its integrity. This test is used to evaluate the structural integrity of pipeline or other pressure containing infrastructure.

Is hydro test compulsory?

As per the Indian Standards 8451: 200 & Gas Cylinder Rules, 2004, it is mandatory for all CNG vehicles to get their CNG Hydro tested every three years.

How do you perform a pressure test?

The test involves filling the vessel or pipe system with a liquid, usually water, which may be dyed to aid in visual leak detection, and pressurization of the vessel to the specified test pressure. Pressure tightness can be tested by shutting off the supply valve and observing whether there is a pressure loss.

What is hydrostatic testing?

Hydrostatic testing is an integral part of quality control. Hydrostatic tests are performed to determine the structural integrity and fitness for use of a variety of objects including gas cylinders, storage tanks, and chemical pipelines. The test works by filling the object with water until it’s completely full and then pressurized–ensuring that it can hold up under pressure without bursting open at any seams nor allowing leaks to escape from within its structure.

Why is hydrostatic testing important?

This is important because if you have a DOT-required container and it’s not been properly tested, what is inside the canister could be contaminated.

How do I avoid disasters with hydrostatic testing?

The best way to avoid disaster is to have an experienced technician perform your hydrostatic testing. There are two main types of tests:

What is the weight of a vehicle that is required for hydrostatic testing?

Meeting DOT Specifications for hydrostatic testing. Sometimes, hydrostatic testing is required for vehicles with a gross vehicle weight of more than 26000 pounds. Hydrostatic testing is also mandated by the Department of Transportation (DOT) as part of the certification process to show that a cargo tank and its fittings are able to maintain an ...

What is the name of the fluid that is used to make hydraulic fluid?

The name comes from when engineers used compressed air as their hydraulic fluid instead of water; the term “hydro” meaning water in Greek) and “statikos,” which means solid (as in static).

How does a leaky faucet work?

The process works because water will breach any gap between two pieces of imperfectly sealed pipe if there’s enough pressure applied to force its way through ; this means every time we turn on our faucet and allow water into the pipes below ground, those leaks are being detected without us ever knowing about them.

What is hydrostatic testing?

Hydrostatic testing is an integral part of quality control. Hydrostatic tests are performed to determine the structural integrity and fitness for use of a variety of objects including gas cylinders, storage tanks, and chemical pipelines. The test works by filling the object with water until it’s completely full and then pressurized–ensuring that it can hold up under pressure without bursting open at any seams nor allowing leaks to escape from within its structure.

Why is hydrostatic testing important?

This is important because if you have a DOT-required container and it’s not been properly tested, what is inside the canister could be contaminated.

How do I avoid disasters with hydrostatic testing?

The best way to avoid disaster is to have an experienced technician perform your hydrostatic testing. There are two main types of tests:

What is the weight of a vehicle that is required for hydrostatic testing?

Meeting DOT Specifications for hydrostatic testing. Sometimes, hydrostatic testing is required for vehicles with a gross vehicle weight of more than 26000 pounds. Hydrostatic testing is also mandated by the Department of Transportation (DOT) as part of the certification process to show that a cargo tank and its fittings are able to maintain an ...

What is the name of the fluid that is used to make hydraulic fluid?

The name comes from when engineers used compressed air as their hydraulic fluid instead of water; the term “hydro” meaning water in Greek) and “statikos,” which means solid (as in static).

How does a leaky faucet work?

The process works because water will breach any gap between two pieces of imperfectly sealed pipe if there’s enough pressure applied to force its way through ; this means every time we turn on our faucet and allow water into the pipes below ground, those leaks are being detected without us ever knowing about them.