How do pressure switches work?

A pressure switch is a simple electromechanical device that is triggered by pressure to turn an electrical circuit on or off. The pressure point that activates the switch is called its set point, and the pressure threshold that deactivates the switch is called the cut out point.

Do you need pressure switch for air compressor?

The pressure switch is an important part on your air compressor. The pressure switch tells your compressor when to stop and when to start. But in my experience, it is also a part that will break down quite often. The air compressor pressure switch on small and older compressor is a completely mechanical device.

Can you bypass pressure switch on air compressor?

Simply put a jumper wire across the contacts of the pressure switch. It will then run without stopping. Be sure that the safety valve on the pressure vessle is operating, and large enough to vent the entire capacity of the compressor.

How do you adjust a compressor pressure switch?

0:573:56How To Adjust A Pressure Switch - Mastertoolrepair.com - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt's always clockwise to increase counter clockwise to decrease.MoreIt's always clockwise to increase counter clockwise to decrease.

How do I know if my compressor pressure switch is bad?

If the AC is cutting on and off rapidly, unable to cool the cabin, or failing to turn on the compressor, you should replace your AC pressure switch.

How do you test a pressure switch?

Test the Switch for Resistance Disconnect the wires connected to the pressure switch by pulling the wire connectors off of the switch terminals. Set a multimeter to test for resistance (ohms). Touch each tester probe to one of the switch terminals. The tester should read 0 or close to 0 (indicating no resistance).

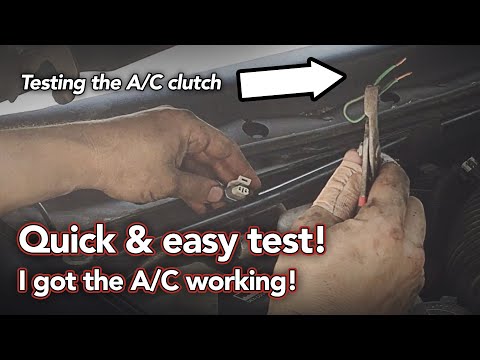

How do you trick an AC pressure switch?

3:187:59AC Pressure Switch P0530 P0531 P0532 P0533 P0534 P0745 P0746 ...YouTubeStart of suggested clipEnd of suggested clipThe easiest way to test a pressure switch is by performing a test which bypasses the pressure switchMoreThe easiest way to test a pressure switch is by performing a test which bypasses the pressure switch. This is a lot easier than trying to test the pressure switch by.

What causes an air compressor to not shut off?

A faulty pressure switch, a check valve that has malfunctioned, and leaks are the most common causes of an air compressor failing to shut off. Other things worth checking include the gauge and the intake valve. Also, remember that even the motor could be having problems so check it as well.

What is the lever on a pressure switch for?

The lever (or knob, in a few cases) is used to manually separate the contacts. It should always be turned to the 'off' position before plugging in or unplugging the air compressor.

Do I need a 30 50 or 40 60 pressure switch?

For a single level home or a two story home without water fixtures on the 2nd floor a 30/50 PSI setting may be sufficient. For two or more levels with water fixtures on more than one level you may want to use 40/60 PSI setting. It's easier for a pump to supply the lower pressures and it's less strain on old plumbing.

What PSI should I set my air compressor?

Air tools made for general use with portable air compressors typically require 0 to 5 cubic feet per minute (cfm) at 70 to 90 pounds per square inch (psi), whereas with larger tools connected to stationary systems, the requirements usually exceed 10 cfm at 100 to 120 psi.

What pressure should a compressor cut-out?

Most pressure switches are factory-set at a cut-in pressure of 6 bar with a pressure differential of 1 bar (which makes the cut-out pressure 7 bar).

What are 3 common issues problems with a pneumatic air compressor?

Most Common Air Compressor ProblemsAir compressor won't operate.Leaking air.Excessive noise.Compressor humming.Oil doesn't last long enough.Excessive oil in the air compressor discharge air.Constant vibration.Compressor won't build pressure.More items...•

What PSI should I set my air compressor?

Air tools made for general use with portable air compressors typically require 0 to 5 cubic feet per minute (cfm) at 70 to 90 pounds per square inch (psi), whereas with larger tools connected to stationary systems, the requirements usually exceed 10 cfm at 100 to 120 psi.

What is an air pressure switch?

The air compressor pressure switch measures the pressure inside your air tank and shuts off your compressor when it reaches the air pressure you need. The air compressor pressure switch will also help your machinery maintain the proper pressure level as you go about your work.

How do I release pressure from my air compressor?

To release pressure, pull the ring on the ASME safety valve. For safety, it is recommended that you wear safety glasses when doing this step. You can deflect the air by shielding the valve with one hand as you pull the ring with the other hand. Continue pulling until the tank is empty.

What is an Air Compressor Pressure Switch?

Air compressors pressure switch is the thing that helps to identify what is the pressure inside the tank as well as the compressor. When you want to fill a tank or anything else, you need to use the switch for turning the compressor on. Again for shutting down the compressor, you will need to switch.

What does a pressure switch on an air compressor tell you?

Rather, this is the thing that can tell you when the air pressure is enough in a tank and if the air is going down. You can measure the PSI with the switch.

How to tell if a compressor is working properly?

When the switch’s diaphragm is deformed to a particular level, the pressure switch will stop passing air. However, when the pressure level is in the right condition, the switch will continue passing air and the dance of diaphragm will be continued. From there, you can know that the compressor is working properly and you can use it.

What is the diaphragm on an air compressor?

Usually, a standard air compressor switch comes with a diaphragm that compresses when exposed to air. When you are using the compressor, it also builds up backward pressure. The tank of the compressor does this which is called cut-out pressure. This changes the shape of the diaphragm of the switch. When the switch’s diaphragm is deformed ...

How does a pressure switch work?

It is usually mounted to the reservoir of the compressor with which the compressor can flow air. It will then monitor the air coming from the compressor tank. Pressure Switch Work. The switches are designed with an air line that actually monitors the pressure of air. It moves to and from the air tank and tells the reading.

How to control air compressor pressure?

Pressure Switch. This also helps to maintain the proper pressure for the compressors. You will control it by moving the switch clockwise and anticlockwise. This is the most used part of an air compressor and it needs to be maintained properly for ensuring the performance of the air compressor. This is the main protection for your compressor.

What is an air compressor?

An air compressor is a Handy Tool for a wide range of projects. Whenever you need air for something, you can simply turn on the compressor and complete your work. An air compressor is built with different parts and the most important part of an air compressor is its pressure switch. A pressure switch in the air compressor is not like ...

What is the line running from the pressure switch to the compressor?

One of these is the “hot” or power line, the other is the “return”. The “hot” line runs to the switch and then runs from the switch to the compressor motor.

How many wires are in an external pressure switch?

The external pressure switch typically often has 3 wir es from the power cord, and two wires running from it to the motor circuit. On the supply side, the side from the plug, one wire is the “hot” or power wire (often black), another is the return (often white) and another is the ground or earth wire (often green).

What does a switch trip do?

The “tripping” of the switch will either allow power to flow to the motor circuit from the supply line, and the compressor motor starts, or when the rising tank or line pressure on a particular switch reaches the high-pressure setting for that switch, the switch “trips” again, this time cutting the power flow to the motor and the compressor stops running.

Do tank pressure switches work the same?

Whether an in tank or on tank pressure switch, both do the same job.

Do air compressors have a pressure switch?

Every air compressor with a tank has a pressure switch. Most really small air compressors with no tank have a pressure switch. If you aren’t sure what a compressor switch is or how a compressor pressure switch works, this is the page for you.

Why is the pressure switch important in an air compressor?

It is because the compressor function does not touch the height you expect if the pressure switch does not work well.

What Is an Air Pressure Switch and How Does It Work?

An air pressure switch is a mechanical device that depends on pressure for controlling the electric air compressor’s operation process. The air pressure circuit mechanism of the device sends power to the motor to function. The air compressors’ pressure switch has a pressure switch relief valve.

What is a switch disconnector?

What is a switch disconnector? How does it work? A disconnector disconnects an electrical network for safety reasons. Disconnector is a technical term that is used

Why use air pressure switch?

Air pressure switch is widely used in manufacturing sectors. The air pressure switch helps industries and manufacturing sectors achieving goals without any gap. The efficiency of production in any manufacturing sector is achieved by the pressure switch. Yes, the switches ensure a constant gas and fluid supply for the continuous working of the systems in the industries.

What happens when an air compressor is plugged in?

Once the air compressor is plugged in, the person in charge can move the level to auto position. Due to this action, the motor starts, and at the same time, the compressor is pressurized. As a result, a pressure system is reached in the device.

How does a diaphragm stop a motor?

Due to this pressure set, a diaphragm inside stops the motor by breaking the circuit. Simultaneously, back pressure escapes out through the pressure relief valve. Because of the air used for the process, the pressure drops to a specified level. Again, the motor starts once the contacts close. This process continues until the air compressor is in use.

What is the prime adjustment instruction?

Clockwise or counterclockwise turning of primary spring for increasing or decreasing cut in or cut out settings is the prime adjustment instruction. The differential in the air compressor can be increased or decreased.

Why is the pressure switch on an air compressor important?

It helps maintain a proper level of pressure inside a compressor by turning it on and off . The pressure switch turns off the compressor when the pressure inside the air tank rises to a certain level and no more air is needed to be compressed.

How does a pressure switch work?

A pressure switch maintains the air pressure inside the tank of an air compressor by setting the cut-in and cut-out pressures. You can use the different adjustment screws available on your pressure switch to adjust the cut-in and cut-out pressures.

Why is the pressure switch important?

One important thing to note is that the pressure switch is a part which is used quite often while your air compressor is operational and hence it wears down quite quickly as compared to other air compressor parts. You need to check it from time to time and in case it is damaged, you need to fix or replace it as soon as possible. The pressure switch is your best line of defense against any possible ruptures as it prevents the tank from getting over-pressurized.

What is the purpose of a pressure switch?

As discussed throughout the article, the purpose of the pressure switch is to start and stop the air compressor motor based on the pressure in the compressor tank. The pressure switch can also be used to adjust the cut-in and cut-out pressures.

How do you know if a pressure switch is bad?

You know that your pressure switch is bad if it shows any of the following signs. the pressure switch leaks. the air compressor doesn’t start, in which case pressure switch can be the reason. the compressor stops before reaching the cut-out pressure. the compressor doesn’t start at the cut-in pressure. the compressor doesn’t stop ...

What does the diaphragm do in an air compressor?

Which, in turn, shuts off the air compressor.

What is the pressure at which the shape of the diaphragm changes enough to stop the power flow to motor?

The pressure at which the shape of the diaphragm changes enough to stop the power flow to motor resulting in the motor shutdown is called cut-out pressure . When the pressure inside the tank decreases and drops down to a certain level, the diaphragm gets back into its original shape making the circuit close. As a result, the power flows back ...

How does an air compressor work?

With the air compressor plugged in, the user moves the lever to the ‘auto’ position, forcing electrical contacts inside the switch together to complete the circuit. Simultaneously, the motor starts and the air compressor begins to pressurize. When the specified system pressure is reached, a diaphragm inside the pressure switch pushes against a mechanism which forces the electrical contacts apart, breaking the circuit and stopping the motor. At the same time, the pressure relief valve opens and relieves back-pressure caught between the pump and check valve. As air is used and tank pressure drops to a specified ‘cut-in’ setting (approximately 30 PSI below the ‘cut-out’ setting) the contacts close and the motor starts again. The cycle continues as long is the air compressor is in use.

What is a terminal in a pressure switch?

The terminals are the points where the incoming and outgoing power leads are connected to the pressure switch.

What is the diaphragm in a motor?

Diaphragm. The diaphragm is made of a flexible material that pushes against the block as air pressure increases. When the specified ‘cut-out’ pressure is reached, it forces the contacts apart and shuts down the motor.

Where is the pressure switch relief valve located?

The pressure switch relief valve, which is located on the base of the pressure switch, is plumbed into the top of the check valve with a copper or nylon tube. When the pressure switch contacts separate, a lever actuates this valve to relieve pressure that was trapped between the pump and check valve.

What is an adjustment spring?

The adjustment spring is used to increase and decrease the cut-in and cut-out pressure settings. Some pressure switches have a secondary spring (usually smaller than the primary spring) that will adjust the cut-out pressure without affecting the cut-in setting.