How does an impact driver work?

In this demonstration Youtuber Nick Moore opened up a impact driver and then put to use driving a bolt, all while filming it at 1200 frames per second. You can see how each 1/2 turn of the drill rotates an internal hammer that compresses a spring. When that spring is released, the energy drives the hammer down while simultaneously twisting it.

What separates an impact driver from a drill?

This concussive force is what separates an impact driver from a standard drill/driver which requires a user to apply downward force. The recently released Stealth Force impact driver from RIDGID has done away with the loud tapping sound by combining the hammer mechanism with an oil chamber.

Can you use an impact driver to drill concrete?

Furthermore, impact drivers are not suitable for drilling into hard materials like brick or concrete. For that, choose a hammer drill. As the name suggests, these tools are built for driving but can be used to drill in a pinch.

Do you need a special bit for an impact driver?

But if you want a hole greater than ¼” in a more substantial or denser material, you’ll need a bit designed for an impact driver. Otherwise, the added torque of the driver will snap the bit.

Is an impact driver good for screws?

Impact drivers handle large screws and bolts more efficiently than the average compact drill. Because they automatically add extra rotational force when they encounter resistance—two to three times more torque than a drill—you'll find using an impact driver is easier on your hand and wrist.

Can you use an impact driver as a screwdriver?

Can Impact Drivers Be Used as Screwdrivers? Good news! The primary purpose of an impact driver is to drive screws. While an adapter (such as this one by Makita) can be used to in order for impact drivers to be used as drills, impact drivers are generally designed to drive screws.

How do you screw with an impact driver?

2:306:44Using An Impact Driver To Drive Screws Into Wood - YouTubeYouTubeStart of suggested clipEnd of suggested clipBit on the impact driver I have the inch of the quarter screw. Now check this out I'm gonna put theMoreBit on the impact driver I have the inch of the quarter screw. Now check this out I'm gonna put the bit in the screw. Place it down with the impact driver. You want it to be placed nice.

When should you not use an impact driver?

When Not to Use an Impact Driver? 5 SituationsNon-Hex Shank Bits. Impact drivers are very useful tools indeed, but something that does need to be said about them is that the special mechanism they use for their bits only accepts hex-shaped bits. ... Short Screws. ... Soft Materials. ... Precision Work. ... Drilling Holes.

Can I use an impact driver to remove lug nuts?

Can an Impact Driver Remove Lug Nuts? Yes, technically. You would need to use a hex shaft to square drive adapter in order to attach a lug nut socket to the tool. However, an impact driver may not have enough torque to break loose a lug nut that's rusted/frozen or over tightened.

Do you need to pre drill with an impact driver?

A regular drill is all you need. Impact drivers are for driving screws very quickly, not drilling holes.

Can an impact driver replace a drill?

A cordless impact driver or drill on its own cannot replace a power drill. Impact drivers are not designed to drill holes and they can't take all of the accessories that a cordless drill can.

Is it worth getting an impact driver?

Do You Need an Impact Driver? If you need to drill holes and drive the occasional medium-sized screw, a regular drill will suit you fine. If you've got a deck to build, a plywood subfloor to install, a tree house to screw together or any other job involving lots of wood screws, consider investing in an impact driver.

What are the benefits of an impact driver?

The main advantage of impact drivers is their ability to drive in numerous fasteners quickly. The added force offered by the tool saves your hands and wrists as you work. This can help extend the time you can comfortably work on your project. Also, the impact driver is much less likely to strip your screws when in use.

What is impact driver?

Impact drivers are an essential tool for any Pro. They let you apply more force (or torque) than a drill. Used in tandem, a cordless drill handles hole-making while an impact driver sets or sinks the fasteners. For basic screwdriving, an impact driver might be the only tool you need.

How long is an impact driver?

The icing on the cake is that impact drivers are typically smaller, lighter, and able to get into tighter spaces. The best impact drivers measure less than 5-inches in length! They also won’t wrench violently in a bind-up like a high-torque drill. If that all sounds, well, impactful, you’re not alone.

How often do impact drivers hit?

This action happens rapidly. In fact, most impact drivers hit more than 50 times every second. This creates much more force than a drill can typically muster at a similar size tool.

How do impact drivers work?

Impact drivers essentially work by combining the rotational motion with a hammering action to generate high torque. If you have no idea what that means, picture it this way. Imagine while you are turning a screw, you started tapping it with a hammer in the direction of rotation. The screw would go in faster.

Why use impact driver?

When used properly, it helps you stop your drill from damaging screws and the surface you are drilling into. Since they do not have torque control, you will have to be extra careful when using an impact driver; otherwise, you will have a lot of stripped screws and damaged surfaces on your hands.

How much torque does an impact driver give?

An impact driver gives a blow to the screw around 50 times a second, which produces upwards of 5 times more torque than your average cordless drill.

What is the difference between impact drill and drill driver?

The major difference, when compared to a standard drill/driver, is that it has a special impact driving mechanism that kicks-in, when the force exerted by the motor is not enough. Another key difference is that the impact drivers have hexagonal-shaped collets instead of a traditional 3 jaw chuck. You can also use the impact drill/driver ...

What is the drive source of an impact driver?

The drive source of the electric impact driver is the electric motor. If you can afford it, get an impact driver with a brushless motor. They are more energy-efficient, do not heat-up like regular motors and draw less battery power.

Why do people buy impact drivers?

One of the reasons people buy an impact driver is that it is easy on your wrists. You will likely be holding an impact driver for long periods of time, so make sure it is comfortable to use.

Is an impact driver better than a cordless drill?

Higher Torque: As discussed before, impact drivers are much more powerful (about 5 times as powerful) when compared to cordless drill/driver. So, when you need drive screws in tough material, you will be able to do them faster and better with an impact driver.

How does an impact driver work?

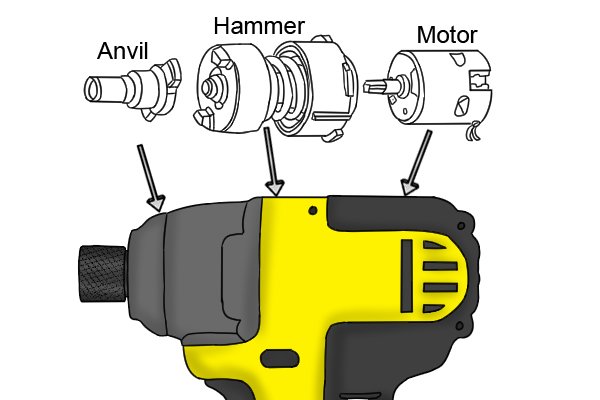

You’ve probably used a cordless electric impact driver before. They’re handy tools with an exterior comprised of housing, a trigger, a battery and a collet, which holds a hex bit (usually one-quarter inch). Internally, these drivers’ rechargeable battery provides power to a motor that applies rotational force to twist a spring-enabled hammer. After compression, the spring tension is quickly released, allowing the hammer to strike an anvil while still carrying a rotational force. The applies a force of impact and torque to the component attached to the collet. This means your socket or bit not only turns a fastener, but drives it in at the same time.

What is the advantage of impact drivers over drills?

One major advantage over drills is higher torque that doesn’t get transferred to the user. Any frequent user of a drill has experienced the kickback to your wrists when a drill bit gets stuck, but impact drivers send that force to the component on the collet instead.

What are the advantages and disadvantages of impact drivers?

Like all tools, impact drivers have their benefits and disadvantages. One major advantage over drills is higher torque that doesn’t get transferred to the user. Any frequent user of a drill has experienced the kickback to your wrists when a drill bit gets stuck, but impact drivers send that force to the component on the collet instead. Compared to drills, drivers are smaller and lighter for something that delivers as much torque as they do. Lastly, its concussive punching action in conjunction with the torque makes for more efficient driving.

Why use impact driver?

Because they automatically add extra rotational force when they encounter resistance—two to three times more torque than a drill —you’ll find using an impact driver is easier on your hand and wrist. So, if your project involves a lot ...

What is the difference between a hammer drill and an impact driver?

There are a few differences between impact drivers and hammer drills. The main difference between a hammer drill and an impact driver is the type of force used. Hammer drills use a hammering action to exert extra force when needed, as though a hammer was hitting the back of the drill.

What is the purpose of a hammer drill?

You can use hammer drills to drive bolts into concrete, brick, masonry, or heavy metal. Like the cordless drill, an impact driver uses rotational force to drive a screw and saves its bursts of quick power when it feels resistance. You would use an impact driver for long screws or large fasteners when working with wood.

What are some similar looking items to a screwdriver?

If you think you may need something more in the toolbox than a standard screwdriver, you’ll probably see similar looking items with very different names, such as a cordless drill, hammer drill, or impact driver. Knowing what makes them different from each other will help you in your selection.

Why are drills so versatile?

Drills are versatile. Some have more settings for both speed and torque, and some even have an impact setting. They also can tackle many kinds of small projects because they can use a wide variety of bit types. Experts agree that when building your tool collection, begin with a drill.

Can impact drivers be used to drill holes?

Impact drivers are for driving fasteners, not drilling holes. However, in a pinch, if you have the proper bit, you can drill a hole in light-gauge steel or softwood with a standard hex-shank drill bit.

Do impact drivers run on cordless batteries?

Impact drivers run on cordless battery packs. The higher the voltage, the longer the battery life and the more power your driver will have. Finally, consider the weight of the driver. If you plan to use it to install fasteners overhead, you’ll want something that won’t fatigue your arm or wrist. Advertisement.

Get serious

To start your path to success, skip the BS. The worst thing you can do with an impact screwdriver is to graduate from a partially stripped fastener to a fully stripped fastener. If that Phillips-head screw on your brake rotors looks like it’s going to be a pain to remove, go straight for the big guns and bring out the impact.

Invest in good bits

One hit and these flathead bit both twisted and chipped. Now it stays around just to remind me why I buy nice tools. Kyle Smith

Prep the fastener

Test-fit the bit you think is the right size. You’re looking for a good, tight engagement to the fastener. Kyle Smith

Now, swing it

Slide the impact driver onto the set bit and get everything lined up and level. Kyle Smith