The procedure of the Proctor Compaction Test consists of the following steps:

- Obtain about 3 kg of soil.

- Pass the soil through the No. 4 sieve.

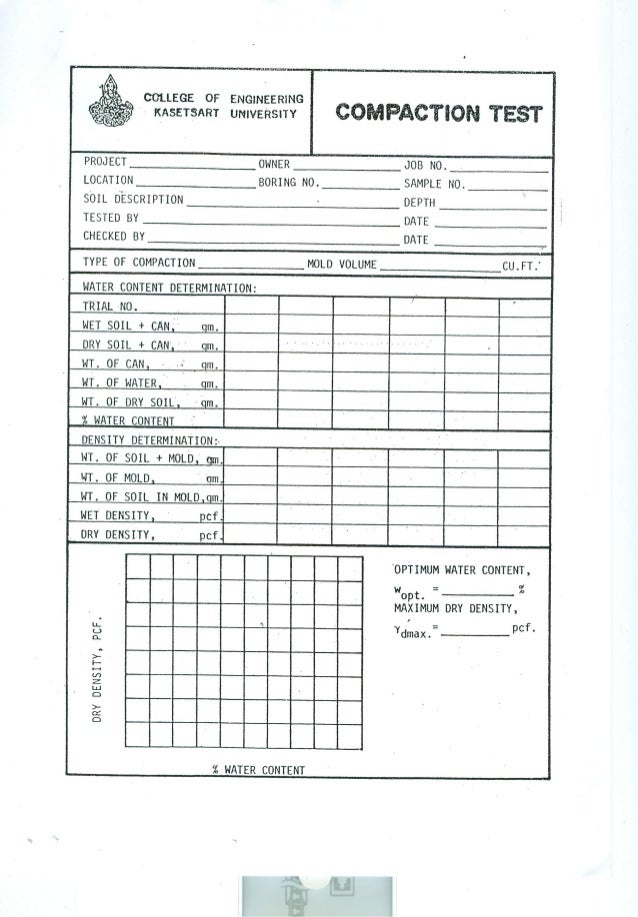

- Weight the soil mass and the mold without the collar (W m ).

- Place the soil in the mixer and gradually add water to reach the desired moisture content (w).

- Apply lubricant to the collar.

- Remove the soil from the mixer and place it...

How to do compaction testing?

You will need to know:

- What type (s) of soil that is being compacted

- The proctor densities for each type of soil

- The percent compaction required by the design engineer for each soil type

- Maximum lift size for each soil type

- Who to report to when arriving

How much is a compaction test?

Soil compaction tests cost $75 to $150 each plus $200 to $500 for an onsite technician if it’s required by local regulations. This investigates the density after compaction. You’ll find it used most often under foundations and for roads. Perc tests cost $150 to $3,000.

How to test compaction of ABC stone?

f) Take the test on the material where you will be performing the density tests. g) The material under the standard block should be at least 100pcf (no tailgates). h) Turn the gauge on and let it warm up for 10 minutes. Put the gauge in the standard count mode and take the test. If the test passes, record the results.

What is the best gravel for compaction?

- Subgrade—this is the native soil (or improved soil), usually compacted

- Subbase—this is a layer of gravel on top of the subgrade

- Base (or base course)—this is the layer of material on top of the subbase and directly under the slab

What is the purpose of a modified Proctor compaction test?

What is the purpose of soil compaction?

How to measure water content?

How accurate is a nuclear test?

How long does a compaction test take?

Compact the soil with 25 well-distributed blows of the hammer. Carefully detach the collar extension and base without distributing the soil. Determine the weight of the Proctor mold and the soil. Oven dry the soil for 12 hours to determine the moisture content.

How do you measure soil compaction?

Dry density is calculated by dividing the weight of the wet soil by its water content in percent. The percent compaction for the field density test is calculated by dividing the dry density of the soil by the maximum dry density from the proctor test.

What are the method of compaction?

The method of compaction is primarily of four types such as kneading, static, dynamic or impact and vibratory compaction. Different type of action is effective in different type of soils such as for cohesive soils; sheepsfoot rollers or pneumatic rollers provide the kneading action.

What is a compaction test and why is it required?

In a nutshell, compaction testing is the comparison of the moisture and density of a specific soil being placed during construction to an optimum moisture and density for that soil, which was determined in a geotechnical lab.

How is soil testing done for construction?

Various methods like Calcium Carbide Method, Oven Drying Method, Sand bath Method, Radiation Method, and Alcohol Method. Of all the methods, Oven Drying method results are most accurate in which the moisture content is defined as the mass of water that can be removed from the soil by heating at 105 – 110°C.

How many compaction tests are required?

3.02 TESTING REQUIREMENTS A. Frequency of Compaction Tests: Make a minimum of ten (10) field compaction tests for each of the fill parameters specified in Table 3-2.

How do you do compaction in concrete?

0:112:26Compaction of Concrete - YouTubeYouTubeStart of suggested clipEnd of suggested clipWell to make concrete dense. And impervious compaction can either be done manually or mechanicallyMoreWell to make concrete dense. And impervious compaction can either be done manually or mechanically manual compaction is done either by rodding with steel rods or tamping using wooden cross beams.

How many types of compaction tests are there?

Two types of compaction tests are routinely performed: (1) the standard Proctor test, and (2) the modified Proctor test.

What are the four common types of compaction equipment?

The main types of compaction equipment within our coverage are:Vibrating Plates. Hand-guided equipment, including one-way and reversible types.Pedestrian Rollers. ... Trench Compactors. ... Tandem Rollers. ... Self-Propelled Rollers. ... Pneumatic-Tyred Rollers (PTRS) ... Combination Rollers. ... Towed Rollers.More items...

What is compaction test of concrete?

Compaction factor test is the workability test for concrete conducted in laboratory. The compaction factor is the ratio of weights of partially compacted to fully compacted concrete. It was developed by Road Research Laboratory in United Kingdom and is used to determine the workability of concrete.

How do you compact soil for building construction?

How to Select Your Soil Compaction EquipmentSmooth Rollers are very effective on granular soils including gravel and sand. ... Padfoot and Tamping foot rollers can compact soils with more cohesive content. ... Pneumatic rollers work well on small to medium soil compaction jobs.More items...•

What types of equipment are used for soil compaction?

There are three basic types of compaction machines: rammers, vibratory plates, and rollers.Rammers. Rammers apply high-impact compaction forces generated by a small gasoline or diesel engine that powers a piston with two sets of springs. ... Vibratory Plates. ... Rollers.

1. Place the metal tray

The technician can now place the metal tray as per the Consultant or Quality Engineer’s preferred location. As a Quality Engineer, you should make sure that the area to be tested is compacted and within the area submitted in the Inspection Request.

2. Marking the sample container

As QC Engineer, you should see to it that the sample container is marked by a technician of its location and other related markings, just make sure all the marks are correct.

3. Digging the soil

A helper will start to dig the soil by a using pointed steel rod (250mm long 16 – 20 mm dia.) and a hammer. The head of the rod shall be stricken at slow speed and at conditional pressure. Use gloves for hand protection to prevent hand injury.

4. Putting the loose soil in the sample container

The dug loose soil shall be placed in the sample container, make sure there are no any pieces of soil shall be wasted otherwise, it will affect the results of compaction.

5. Measuring the depth of the hole

While the digging progresses, monitor the depth of the hole by measuring a ruler, make sure that the depth is 200 mm or 150 mm depending on the requirement of the specification. If the depth is not yet achieved continue digging until it reaches the desired or required depth.

7. Taking the silica from the hole

The hole, once filled with silica and when the hole has fully filled, remove the silica and place it to an extra container it may use again for the next set of compaction.

How to do a compaction test?

The procedure of the Proctor Compaction Test consists of the following steps: 1 Obtain about 3 kg of soil. 2 Pass the soil through the No. 4 sieve. 3 Weight the soil mass and the mold without the collar (W m ). 4 Place the soil in the mixer and gradually add water to reach the desired moisture content (w). 5 Apply lubricant to the collar. 6 Remove the soil from the mixer and place it in the mold in 3 layers or 5 layers depending on the method utilized (Standard Proctor or Modified Proctor). For each layer, initiate the compaction process with 25 blows per layer. The drops are applied manually or mechanically at a steady rate. The soil mass should fill the mold and extend into the collar but not more than ~1 centimeter. 7 Carefully remove the collar and trim the soil that extends above the mold with a sharpened straight edge. 8 Weight the mold and the containing soil (W). 9 Extrude the soil from the mold using a metallic extruder, making sure that the extruder and the mold are in-line. 10 Measure the water content from the top, middle and bottom of the sample. 11 Place the soil again in the mixer and add water to achieve higher water content, w.

What is the most common test for soil compaction?

The most common laboratory test for soil compaction is the Proctor compaction test. The Proctor test was invented in the 1930s by R. R. Proctor, a field engineer for the Bureau of Waterworks and Supply, in Los Angeles, California. The process, which simulates the in-situ compaction processes typically performed during construction ...

What determines the degree of compaction of soil?

The degree of the compaction depends on the soil properties, the type and amount of energy provided by the compaction process and the soil’s water content. For every soil, there is an optimum amount of moisture for which it can experience its maximum compression.

What is the process of compaction of soils?

Compaction of soils is a procedure in which a soil sustains mechanical stress and is densified. Soil consists of solid particles and voids filled with water or/and air. A more detailed explanation of the three-phase nature of soils is provided in Soil as a three-phase System. When subjected to stress, soil particles are redistributed within ...

What is soil compaction testing?

Soil Compaction Testing is a crucial step in the construction process. Ground that has not been properly compacted can be detrimental to the structural integrity of buildings, retaining structures, roads and pavements, just to name a few. Essentially, proper soil integrity could make or break your structure. Since soils are so critical to a structures reliability you will find that soil compaction testing is required most cases. For instance, most regulatory agencies such as, the Department of Transportation and American Society for Testing and Materials all require laboratory testing. Additionally, you will find that the California and Uniform Building Codes, the geotechnical engineer, and structural engineers will also require soil compaction testing.

Why is compaction testing important?

Why Compaction Testing is Important. There is a very good reason for all the necessity. Basically, if soil tests are not conducted you risk shifting, cracking, and even the collapse of your building . Roadways could also result in disaster by cracking, sagging, potholes, or even sinkholes. In the end, it’s vital for the success ...

Which agencies require soil compaction testing?

Additionally, you will find that the California and Uniform Building Codes, the geotechnical engineer, and structural engineers will also require soil compaction testing.

Why do you take a sample from a stockpile?

This is usually done if the technician notices that the stockpile soil has different properties than the other site soil, or because several soil types are being blended together.

What is the purpose of the compaction test?

Compaction test of soil is carried out using Proctor's test to understand compaction characteristics of different soils with change in moisture content. Compaction of soil is the optimal moisture content at which a given soil type becomes most dense and achieve its maximum dry density by removal of air voids.

How many blows of rammer should be used to compact a layer?

The top surface of the first layer be scratched with spatula before placing the second layer. The second layer should also be compacted by 25 blows of rammer. Likewise, place the third layer and compact it.

What is the process of densification of soil by reducing air voids?

Compaction is the process of densification of soil by reducing air voids. The degree of compaction of a given soil is measured in terms of its dry density. The dry density is maximum at the optimum water content. A curve is drawn between the water content and the dry density to obtain the maximum dry density and the optimum water content.

How to determine the water content of soil?

Remove the soil from the mould. The soil may also be ejected out. Take the soil samples for the water content determination from the top, middle and bottom portions. Determine the water content. Add about 3% of the water to a fresh portion of the processed soil, and repeat the steps 10 to 14. (a)

How to make a rammer out of soil?

Mix the soil thoroughly. Divide the processed soil into 6 to 8 parts. Attach the collar to the mould. Place the mould on a solid base. Take about 2.5kg of the processed soil, and hence place it in the mould in 3 equal layers. Take about one-third the quantity first, and compact it by giving 25 blows of the rammer.

What Is a Proctor Compaction Test?

The Proctor test measures soil compaction to determine the point at which soils can most efficiently be compacted using construction equipment, based on their optimal moisture content and maximum dry weight.

Benefits of the Proctor Test

Soil compaction helps create a more stable surface upon which to lay roads, airstrips, and other projects designed to increase load-bearing capabilities.

Required Equipment for Conducting a Soil Compaction Test

You can perform a Proctor soil compaction test with the following equipment:

Steps for Conducting a Proctor Test

In addition to having the right equipment, it’s important to follow the proper test procedure in measuring soil density. You can see the test in action in this video from the University of Missouri.

Standard and Modified Proctor Compaction Test

There are two versions of the Proctor test: the standard Proctor test ( ASTM D698 / AASHTO T99), and what’s known as the modified Proctor test ( ASTM D1557 / AASHTO T180), which was introduced in the 1950s.

Reasons for Conducting a Proctor Test

The Proctor test can be used to find the maximum level of compaction, by weight, that soil can achieve at optimum water content. This information can be used in compactive efforts for geotechnical engineering in projects such as roadbeds and airstrips.

Test Results

Repeating the Proctor test several times will enable you to plot a compaction curve based on the results. Such a curve plots the dry unit weight on one axis and the water content on another, enabling you to determine the maximum dry unit weight, and optimum water content for this weight.

Why is compaction factor test done?

Why compaction factor test is done? Simply it is done to calculate the work-ability of concrete. It means that It checks weather the quantity of water that should be maintain for the required strength of structure. The compaction factor test is designed for use in the laboratory but it is also used in the field.

How to fill a concrete trap?

Procedure. Place the concrete in the upper hopper. Then, the hopper door is opened. The sample of concrete drops to lower hopper filling it to overflowing. Now, open the lower hopper of the trap door and fill the sample of concrete up to overflowing.

What are the disadvantages of a concrete cylinder test?

Disadvantages. Due to the large and bulky nature of the device, its use reduces in the field. This method requires a balance to measure the mass of the concrete in the cylinder. In this method, there is no use of vibration and it is used rarely. Although the test is commercially available and but used rarely.

How thick is a concrete cylinder?

The cylinder is again filled with concrete in layers of thickness, not more than 50 mm. Each layer of concrete is fully compacted with the help of a tamping rod.

What is the purpose of a modified Proctor compaction test?

For soil with higher densities, a Modified Proctor Compaction Test which uses higher values will be necessary.

What is the purpose of soil compaction?

In the construction of high load structures such as dams, paved roadways, and construction projects that rely on the stability of embankments; soil compaction is used to increase soil strength.

How to measure water content?

Water content can also be measured with the nuclear test by emitting neutron radiation into the soil. Neutrons lose energy when they collide with hydrogen atoms, so based on the amount of moderated neutrons the detector reads the moisture content can be determined.

How accurate is a nuclear test?

A Nuclear Test is a quick and fairly accurate way to measure the density and moisture content of the compacted soil. This test utilizes a radioactive isotope source at either the surface of the soil or from a probe placed in the soil (called direct transmission).